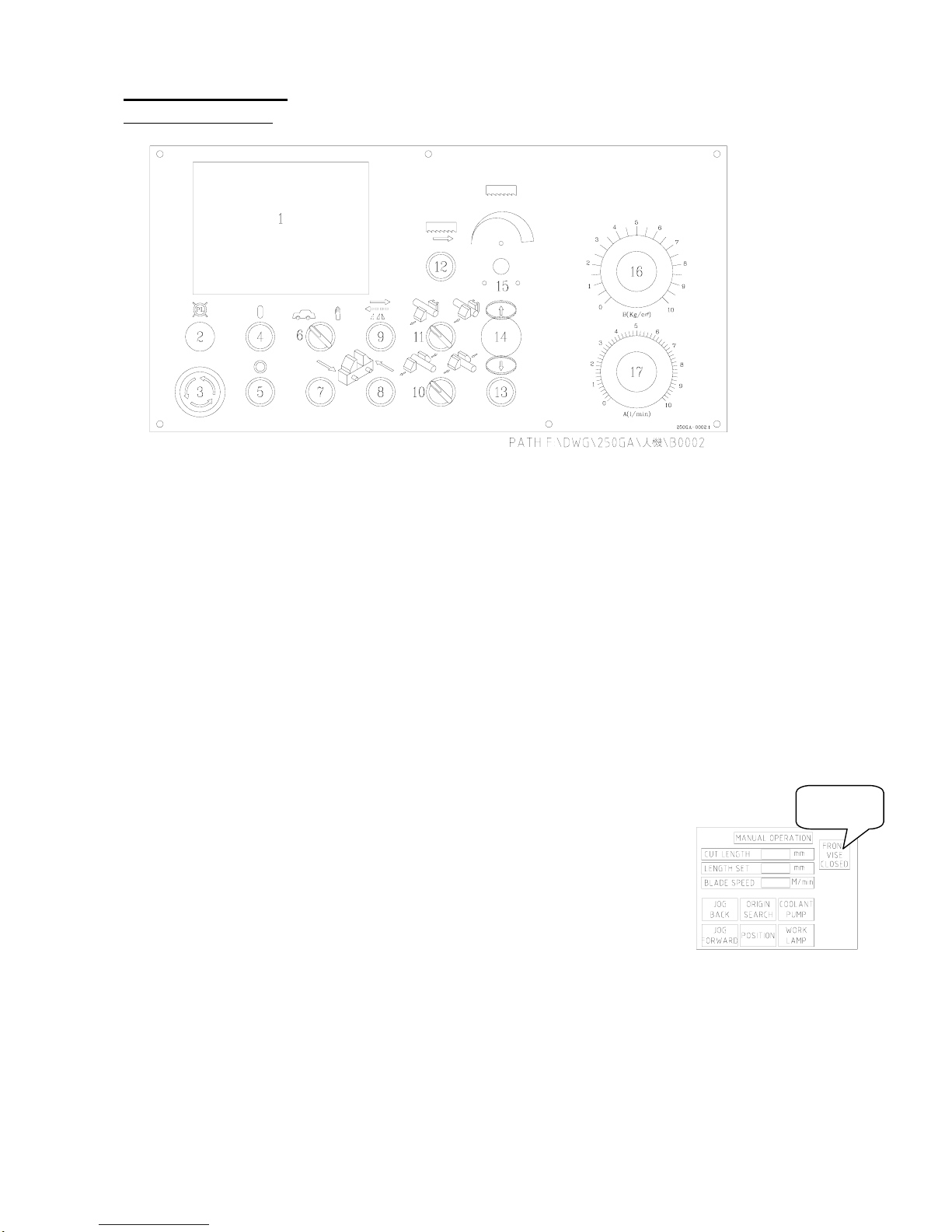

4. OPERATION

4.1. Control Panel

1. LCD Panel illustration

2. PILOT LAMP -- This light will comes on when the power supply is on.

3. EMERGENCY STOP -- This switch is used for emergency case to stop the machine only.

Turn this switch clockwise makes power source on. When this switch is pressed, all machine's operation

stop immediately.

4. POWER SWITCH ON -- This switch is used for turning on the power by depressing it.

5. POWER SWITCH OFF -- This switch is used for turning off the power by depressing it.

6. AUTO - MANUALSELECTOR -- For continuous cutting , turn this selector to left "AUTO".

To individually operate each function, turn this switch to right "manual".

7. MANUAL FEED FORWARD --When this button is pressed the workpiece moves forward.

The workpiece stops advancing when the button is released.

NOTE: Turn (10) VISE SWITCH right position before depress switch (12) BLADE DRIVE to cutting.

8. MANUAL FEED BACKWARD --When this button is pressed the workpiece moves backward.

The workpiece stops moving when the button is released.

NOTE: Don't depress (7) and (8) two switches, if the workpiece are clamped by

both front and rear vises in the meantime.

9. FRONT INCHING OPEN SWITCH -- The front vise clamp the

workpiece when turn switch NO.(11) right and press button NO.(9)

1.5sec in the same time. Then the front vise hold the workpiece

after the LCD “Front vise closed” light.

10. REAR VISE SWITCH -- This switch control the rear vise jaws in manual

mode, switched to the left makes the front vise open. and switched to the right

makes the front vise clamp.

11. FRONT VISE SWITCH -- The switch control the front vise jaws in manual mode, The front

vise clamp when turn the switch to right. Then if release the switch, the switch come back to

the middle position, the vise doesn’t hold the workpiece. If operator would like to hold the

workpiece, he would follow the (9) illustration.

The front vise open little by little if the guide arm is under the front vise when the switch turn to left.

And the front vise open continuously if the guide arm is above the front vise. At last, if release the

switch, the switch come back to the middle position.

7

Light