Memak STELLA COMBINE User manual

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I1

2I memak.com

2I memak.com

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I3

STELLA COMBINE FIRIN KURULUM VE KULLANIM KILAVUZU I3

4I memak.com

INSTALLATION AND

USER MANUAL

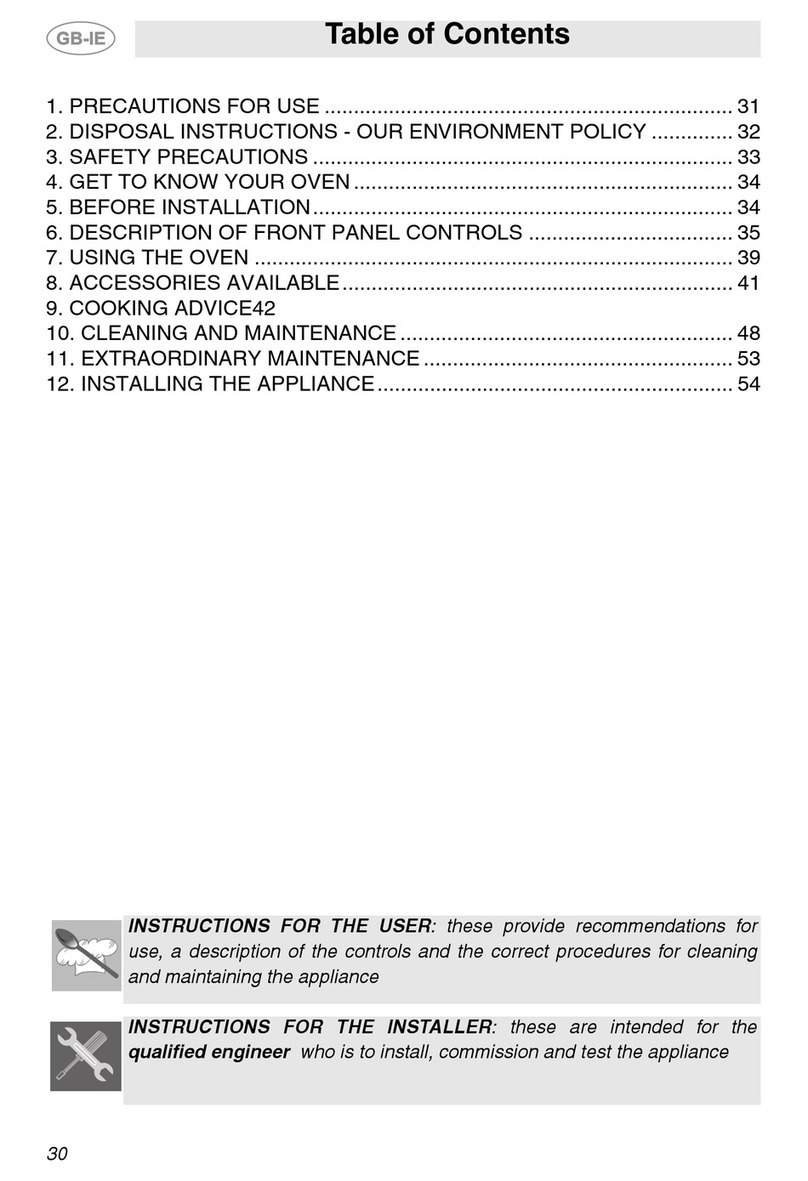

INTRODUCTION 6

Warning Signs Used 7

Warranty 8

Manufacturer Company 9

Product Information 9

About the Machine 10

Manufacturing Site Design 11

Product Dimensions 12

Product Technical Detail 13

PRODUCT COMMISSIONING 14

General Rules on Unpacking the Machine 14

Rules on Stockpiling the Machine 16

Load Structure 16

General Rules for Lifting and Transporting the Machine 17

PRODUCT INSTALLATION 20

Fresh Water Installation 21

Waste Water Installation 22

Electrical Connection Rules 23

OPERATING THE OVEN 24

Intended Use and Place of the Oven 24

Conditions Not to Use the Oven 24

Conditions Required for Correct Machine Operation 25

Pre-operation Control Areas 25

Initial Operation 26

TOUCH CONTROL PANEL SIGNALS 27

Device Definition 28

Manual Cooking 29

Stone Base 32

Yeast Chamber Interface Definition 34

Recipe Interface Definition 36

Recipe Creating Display 38

Language Option 40

Failure Reporting 41

Phase Sequence Failure 41

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I5

Phase Thermal Failure 42

Fuse Failure 43

Settings Window 44

Settings> User Window 44

Settings> Oven Window 45

Settings> Cooking Window 46

Settings> Power Window 47

Settings> Aspirator Window 48

Settings> Yeast Window 49

SAFETY 50

PERSONNEL PROTECTIVE EQUIPMENT 51

GENERAL CLEANING 52

Cleaning Rules 52

Hygienic Areas 52

Food Areas 52

Spray Areas 52

Out of Food Area 52

Water Installation Cleaning 53

Basket Removal and Cleaning 53

Periodic Cleaning Calendar 55

MAINTENANCE AND SETTING 56

Cooking Period and Temperature Setting 56

Steam Injection Setting 56

Periodic Maintenance 56

Routine Procedures 57

Supply Water Filter Cleaning 57

Steam Injection 57

Oven Glass Replacement 58

Itermediate Level (Stone Base) Glass Replacement 59

Yeast Chamber Glass Replacement 60

Door Seal Replacement 61

Door Mechanism Lubricating 62

Lamp Replacement 63

Door Lock Replacement 64

PERIODIC MAINTENANCE CALENDAR 65

POSSIBLE FAILURES AND CAUSES 65

6I memak.com

Introduction

Manual

• Installation instructions are part of the device and

contain information for the safe device use.

• Installation instructions must be fully read before

installation.

• Installation instructions must always be ready to be

accessed by the installer at the installation site.

• Installation instructions must be maintained along the

device service life.

• MEMAKMAKİNA shall not be held responsible for the

problems arising from unintended use of the oven.

• Installation instructions must be delivered device’s

subsequent operators.

Figures

• All figures given in this manual are exemplary.

• It may show dierences according to the current device.

The company reserves its rights for technical modifications for

development!

©2018 MEMAK TECHNICAL SERVICE. All Rights Reserved. Transfer of

product-specific information to third parties is prohibited.

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I7

Ths way up Move n a manner as the drecton looks upwards wth the

arrow sgn.

Fragle Handle the package wth care

Keep t dry Packed so as not to contact wth open ar.

CE Mark The machne meets the basc safety requrements.

Center of Weght Indcates the pont where the machne should be lfted.

Hanger Pont Indcates where to attach ropes or chans.

Warnng A hazardous stuaton, t may result n severe njury and

death.

Fre Fre hazard!

Hgh Voltage Attenton, Death Rsk

Hgh Temperature Door, glass and ts vcnty reach hgh temperatures when

the oven s operatng.

Operating

Mechanical Parts

Do not perform mantenance or repar work on movng

parts.

Warning Signs Used

8I memak.com

Warranty

MemakMakine provides opportunity for material or parts replacement

as a result of investigation for the problems arising from material or

workmanship.

Manufacturer provides 2 (two) year warranty from the date of installation

according to the contract of sale and the legal conditions in force except

the ones to be specified below.

Those not covered under warranty;

• Glass damage, bulbs and seals

• Violating the intended use of the device,

• Amendments or technical modifications to the device by persons and

persons not authorized by the manufacturer,

• Manufacturer’s original parts are not used,

• Damage caused by mechanical impacts that may occur from the

dispatch of the oven by the customer.

• Damage caused by insucient supply of all mains supplying the

oven.

• Faults that may occur due to users’ neglect of the oven.

• No one other than authorized personnel or authorized service

personnel should interfere with the repair and modification of the

device.

• Due to malfunctions in electric motors.

• Due to malfunctions in all electrical equipment.

• If the settings on the oven are tempered and broken.

• Failure to comply with the rules specified in the instructions for use.

• MemakMakine cannot be held responsible for failures or problems

caused by the use of the oven by a person who does not know how

to use the oven.

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I9

Manufacturer Company Information

Manufacturer: MEMAK PLASTİK GIDA MAKİNA SAN. TİC. A.Ş

Address: 4.Organize Sanayi Böl. Kayacık Mah. 103. Cad.

No: 10 Selçuklu/KONYA/TÜRKİYE

Telephone: +90 332 345 36 16

Fax: +90 332 345 36 26

Web: www.memak.com

E-Mail: [email protected]om

Product Information

LABEL INFORMATION

1. Manufacturer company information

2. Machine type

3. Machine weight

4. Machine model

5. Production date

6. Serial number

7. CE mark

8. Operating voltage

9. Operating frequency

10. Operating power

10 I memak.com

About the Machine

Our Combine series ovens manufactured by MEMAK MAKİNA are electric convection rotary type ovens

used in restaurants, hotels and patisseries.

Compact designed for narrow use areas, prescription recording and easy operation with touch control

panel. It provides easy cleaning with internal evenings.

It is also used for the baking of frozen products in the central production of baked goods chains and

tempered glass cover which prevents heat loss.

Because it is designed in dierent sizes and can meet the needs of small, medium and large enterprises.

The specially designed air recirculation system provides stable distribution of hot air to every point of

the cooking chamber and provides stable leavening, volume and cooking.

PLEASE DO NOT INTEND TO OPERATE THE MACHINE WITHOUT READING USER MANUAL.

MEMAKMAKİNA shall not be held liable for damages to the human and the environment due to

the failure to fulfill the instructions in this manual or the incorrect use of the machine.

MEMAKMAKİNA reserves the right to make changes in the properties and dimensions of the

oven.

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I11

Production Area Design

1. In the entire area, there should be some room to allow for inspection and cleaning when

manufacturing equipment is installed.

2. When placing the machines, all connections must be closed so that there are no openings.

3. The floor on which the machines are placed should be accessible from the point of view of the

cleaning operation or should be completely closed.

4. In cases where equipment passes through sections such as ceiling, floor, wall, sucient floor

should be provided between equipment and wall for cleaning or machine should be mounted on

the wall not to permit any gap.

5. Auxiliary equipment must be removable and can be reassembled to facilitate cleaning.

6. Production base should be covered with hard, smooth, easy to clean and non-absorbent material.

7. For insulation, non-absorbent materials should be used. These surfaces should be accessible.

8. Stacking should be made on palettes to let minimum 100 mm distance with the floor when

storing the products.

9. Vessels used to collect waste products and waste water should be made of easy to clean materials

and should have sucient volume.

10. Doors and windows opening out of the plant should be isolated to prevent any outsourced

contamination.

11. Sucient ventilation should be ensured in the washing rooms.

12. Water and water vapor that come into direct contact with the products should be of drinkable

quality.

13. Pipes, valves and fittings used for liquid materials: Either “on-site cleaning” programs should be

implemented for these sections or systems allowing easy disassembly and assembly should be

used.

14. All fixed pipes should be isolated to prevent condensation.

15. Drainage systems for wastewater must be installed in areas where cleaning is required.

16. Floor slope should be such as to prevent water accumulation on the surface.

17. Illumination lamps should be protected as to prevent falling and breaking.

18. Power cables should be stabilized (their contact with the ground should be prevented)

19. Machine’s electrical components should be closed to prevent dust formation. Water should be

prevented from entering electrical panels.

20. Machine parts such as fan, motor should be accessibly mounted.

21. Motor and other auxiliary equipment should be placed not to touch the floor.

12 I memak.com

COMBİNE

DEPTH ( A ) mm / inc

(A1) mm / inc

1291

1560

WIDTH ( B ) mm / inc 995

( H ) mm / inc

HEIGHT (H1) mm / inc

(H2) mm / inc

715

384

1150

Machine’s dimensions are as follows (Figure 1)

(Figure1)

Product Dimensions

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I13

ROTARY CHAMBER

MODEL TYPE COMBİNE

Tray Sze cm 40*60

Number of Trays pcs 6

Dstances Between Trays cm 8,5

Cookng Area m21,44

Door Entry cm 48,5

Steam Shaft Ext Ø 120

Water Inlet nch ½’’

Power Sources Electrcal

Weght kg 350

Electrcal Connecton 380v/50-60hz/3 phase

Control System Computerzed touch panel

Connecton Power kw 15

FERMENTATION CHAMBER

MODEL TYPE COMBİNE

Tray capacty for 80*60 sze cm 6

Tray capacty for 60*40 sze cm 12

Electrcty Power kw 4

Weght kg 100

STONE BASE ROOM

MODEL TYPE COMBİNE

Celng capacty for 60*40 sze cm 2

Cookng area m20,5

Layer dmensons cm 60*80

Layer entry dmensons cm 60*21

External dmensons 100*130*33

Electrcal power kw 5,2

Weght kg 145

Product Technical Details

14 I memak.com

PRODUCT COMMISSIONING

• Installation is carried out by the manufacturer’s personnel or by the personnel authorized by the

manufacturer.

• Manufacturer is not responsible for any failure caused by unauthorized personnel. Manufacturer

is not responsible for any malfunctions caused by unauthorized personnel during the installation,

despite the labor guarantee.

• Manufacturer cannot be held responsible for the place and technical and legal suitability of the

machine.

• All operations must be carried out in accordance with the directives of a sole authorized person.

• Operators and people under their command must wear protective clothing in compliance with

the operation.

Manufacturer is not liable for accidents, damage and machine failures caused by the failure to comply

with the rules in this section.

General Rules on Unpacking the Machine

• Inspect the machine for damages during transportation before unpacking. Check that all parts

listed in the shipping documents are present. If there are missing parts, manufacturer must be

informed within 24 hours.

• Dispose of the packaging material in accordance with the applicable legal regulations when the

machine is fully installed.

• Store the materials used for lifting the machine in a suitable place for future use.

Unpacking procedure is illustrated in (Figure 2).

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I15

PLEASE CHECK THE CASE OF PACKAGING CAREFULLY BEFORE RECEIVING THE PRODUCT.

DO NOT EVER ACCEPT PRODUCTS WITH DAMAGED, CRUSHED, STRIPED PACKAGE.

ALSO IF SUCH EVENT OCCURS PLEASE TAKE A PHOTOGRAPH AND WRITE A BRIEF NOTE

BRIEFING THE SITUATION AND NOTIFY TO THE MANUFACTURER COMPANY.

(Figure2)

16 I memak.com

Rules on Machine Storage

• Store the machine in a confined space away from dust, moisture, and heat.

• The permissible ambient values for storage are as follows: Temperature: -5 C to 45 C

• Maximum humidity: 60%

• where the machine is stored; there is no risk of collision with the vehicle.

• Check the guarded parts regularly.

• Do not stack machines on top of each other.

• If the machine is stored unpacked, it should be raised from the ground with the help of wooden

pallets. Cover the product to protect from dust and dirt.

Load Structure

Machine can be shipped in form as stated below:

• Completely assembled;

• Partially assembled;

• Not completely assembled; parts are stacked on the pallet or optionally on top of any wooden

structure.

The vehicle to be transported must have the required lifting capacity. (Please see machine’s technical

information chart.). Furthermore, vehicle’s minimum loading areas should be as follows.

Lifting device used to raise the machine; should have sucient lifting capacity and fork length.

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I17

General Rules on Lifting and Transporting the Machine

• •Before starting the operation, designate and inspect the entire transport area, the parking area

of the vehicle carrying the transport and the area where the machine will be installed. Ensure

there is no hazardous situation.

• Make sure that the vehicle to carry out the machine’s lifting and transport procedure of the

machine has sucient lifting capacity. Weights are stamped on the packaging and / or are

available in this manual.

• Check that the hoisting ropes and chain types are approved and that the capacity instructed by

the manufacturer is clearly written on the ropes. Check whether there is a damage and corrosion

with the lifting ropes before use.

• Do not knot or twist the lifting ropes and follow the rules written in this manual by the

manufacturer. Same rules apply to chains and belts.

• Particular attention should be paid for lifting the machine centrally.

• Do not climb over and pass under when the machine is loaded and moving.

• Care must be paid that unauthorized personnel are not in the loading area.

• In order not to cause any accident and injuries; all operators must stand at a safe distance when

lifting the machine.

• Special care must be paid to keep the system stable when realizing machine lifting procedure.

Moving from Lifting Point;

• Take the necessary precautions during transport! Make sure the hooks are fully inserted and start

lifting.

• Pay particular attention to lifting the machine centered.

• Do not bend or twist the hoisting ropes and follow the rules specified in this book by the

manufacturer. The same rules apply to chains and belts.

• When the machine is loaded and moving, do not climb over or pass under.

• Make sure that the lifting capacity of the machine is sucient for the lifting and transport of the

machine.

Machine lifting operation is illustrated under (figure 3) and (figure 4).

18 I memak.com

WARNING: Take necessary cautions during transport! Start with the lifting procedures after ensuring

that hangers are fully installed.

(Figure3)

(Figure4)

INSTALLATION AND USER MANUAL FOR STELLA COMBINE OVEN I19

Transport on pallets;

• Use of a forklift;,

• Place the forklift forks on the bottom of the pallet and make sure that the fork is at least 20 cm

from the opposite side.

• Use a forklift with sucient lifting capacity and a fork.

• Slowly transport and transport safely.

• Check that the oven (material on the pallet) rests well on the forks.

Transport on the pallet (Figure 5) and (Figure 6) are also shown.

Lifting device used to lift the machine; should have sucient lifting capacity and fork length.

The packaging structure of the product is made according to the world and European norms. It is made

ready for the shipping procedure by placing into cases packed with nylon and design in compliance

with standards by compressing with nylon with bubble pack.

(Figure5) (Figure6)

20 I memak.com

PRODUCT ASSEMBLY

Ready assembled machine:

The machine comes pre-assembled and requires special installation settings.

Unassembled or semi-assembled machine:

If the machine has not been installed or has been semi-assembled; The assembly operation must be

performed by the personnel authorized by the manufacturer.

If there is no previous layout of the furnaces, the oven is placed properly.

IMPORTANT: Between the oven and the wall should be at least 500 mm (half meter). (figure 7)

NOTE: The machine is taken on the scale after its distances have been adjusted. (Figure 8)

(Figure7)

Table of contents