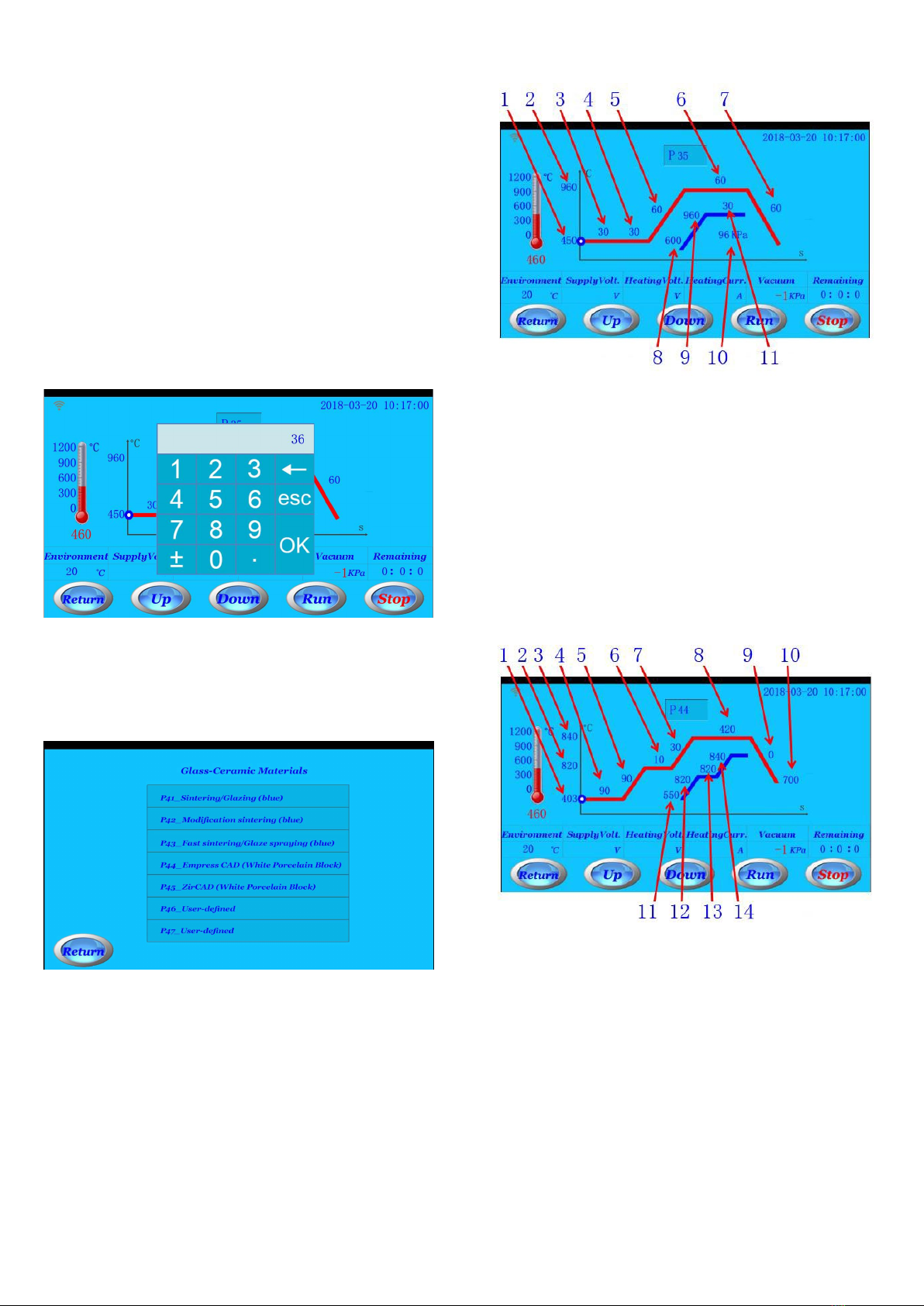

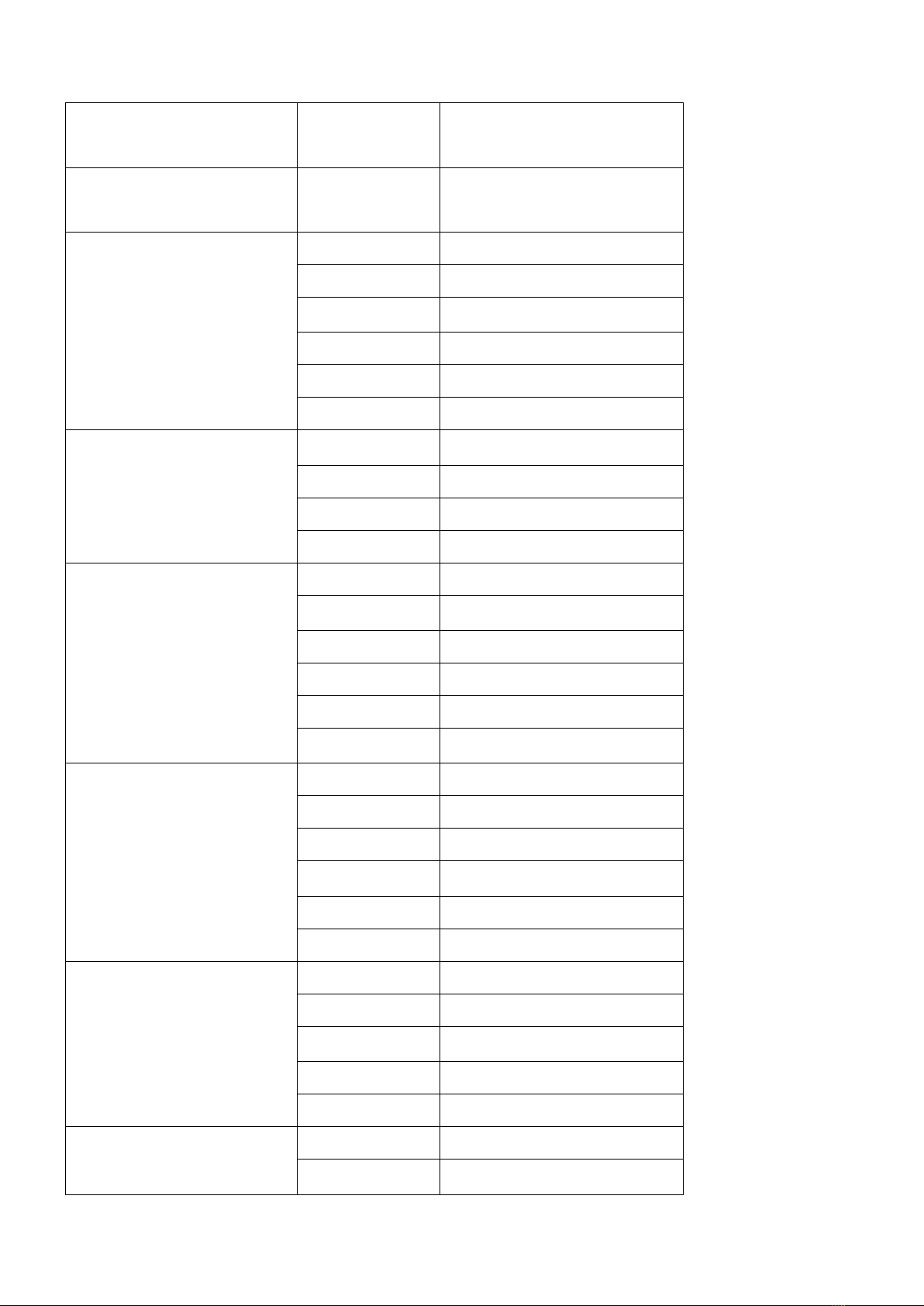

Parameters can be set within following values range:

Idle temperature: 350 ~ 750 ℃

Firing temperature: 500 ~ 1150 ℃

Times: 0 ~ 3600 seconds

Heat rate: 2 ~ 120 ℃/minute

Vacuum value: 0 ~ 99 kPa

Vacuum starting temperature: 400 ~ 960 ℃

Vacuum releasing temperature: 600 ~ 1200 ℃

When setting every firing parameter, please note

following important points:

Firing temperature should be greater than idle

temperature.

If cooling time is less than 60 seconds, the tray will

be opened after 60 seconds.

Vacuum releasing temperature should be greater than

Vacuum starting temperature.

Vacuum starting temperature should be greater than

Idle temperature.

Vacuum releasing temperature should be less than

Firing temperature.

Vacuum time should be less than firing time.

When you need to hold vacuum, please be sure to set

the vacuum value in parameter menu.

If vacuum time is set to 0:

-When temperature in the chamber is reached to

vacuum starting temperature, the vacuum pump

will be started.

-When temperature in the chamber is reached to

vacuum releasing temperature, the vacuum in the

chamber will be released.

If vacuum time is not set to 0, the vacuum pump will

be started only when temperature is rising and after

tray is closed; the vacuum in the chamber will be

released after vacuum time is completed.

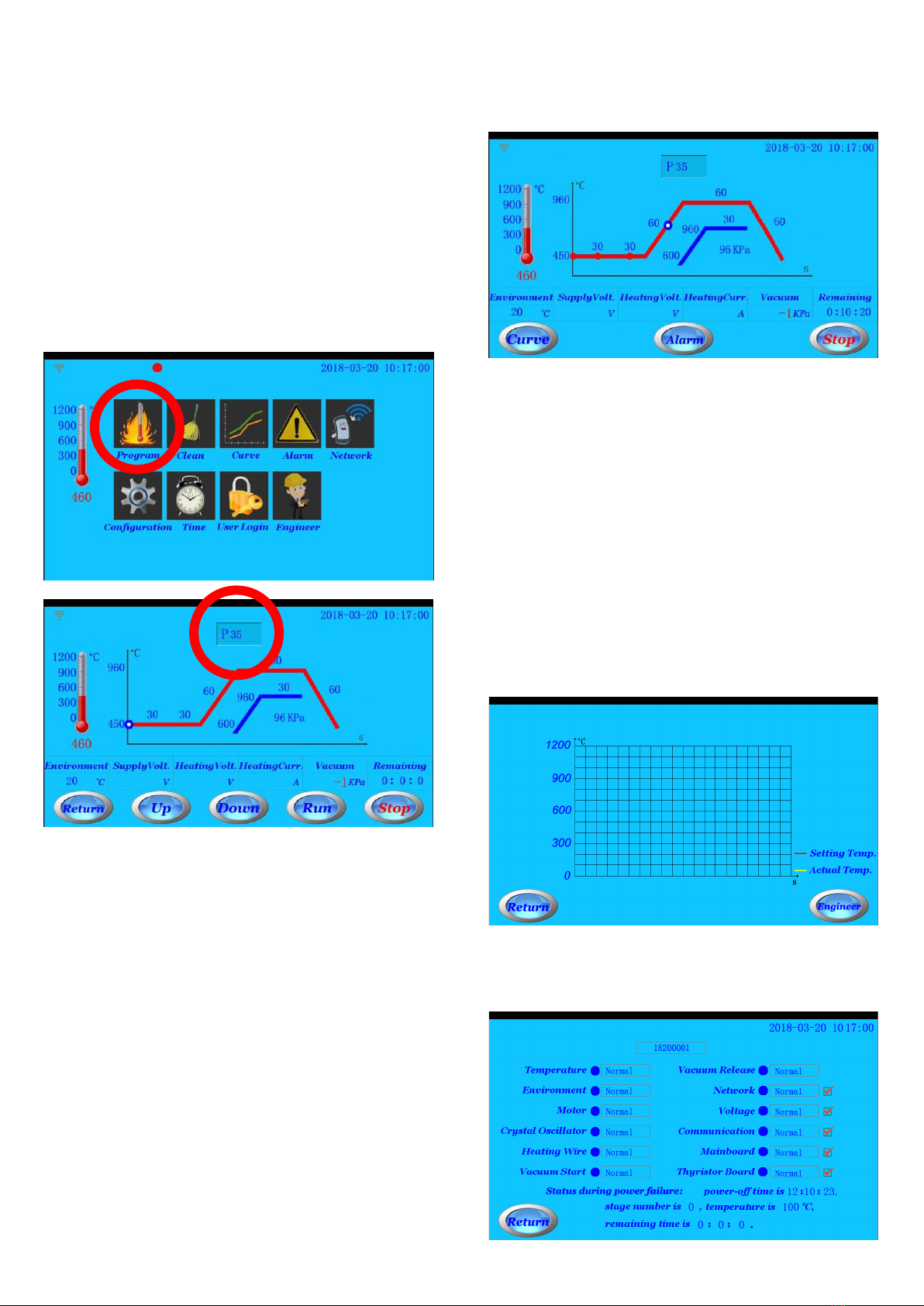

5.3.Purge

In standby menu, click Clean icon to enter clean menu.

If the muffle is moistened, contaminated or not used for

a long time, the clean function is recommended. This

clean function can also be used for testing vacuum

pump.

Click Run icon, the clean program will be started to

run. The temperature will reach to 960 ℃, and then

firing time will hold 300 seconds. During clean

program running, the vacuum pump will start to work

after tray is closed. The vacuum will be released in

the last 30 seconds of firing time.

NOTE:before vacuum is released, if vacuum in the

chamber is lowed to the limit, vacuum pump will

start to work again.

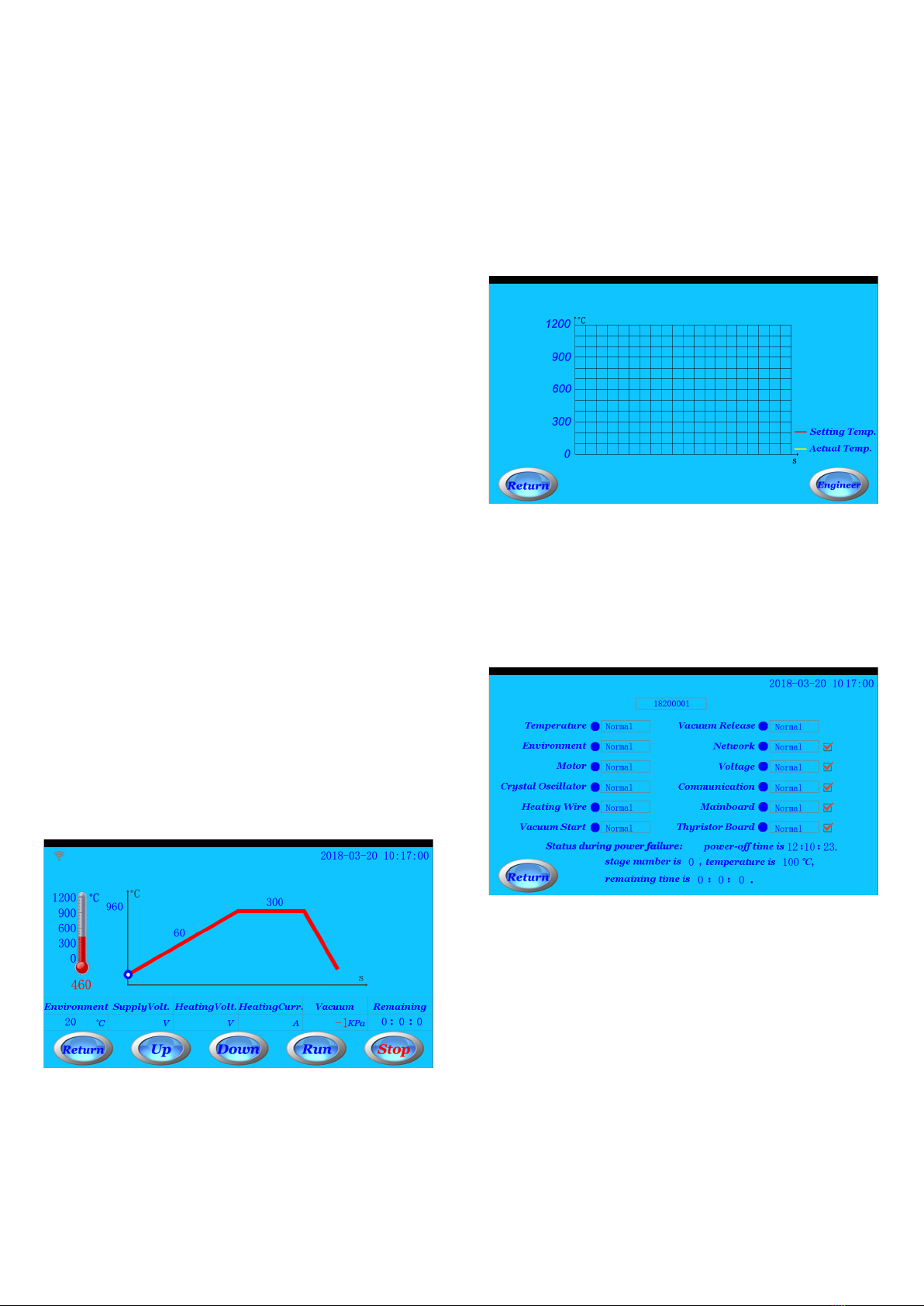

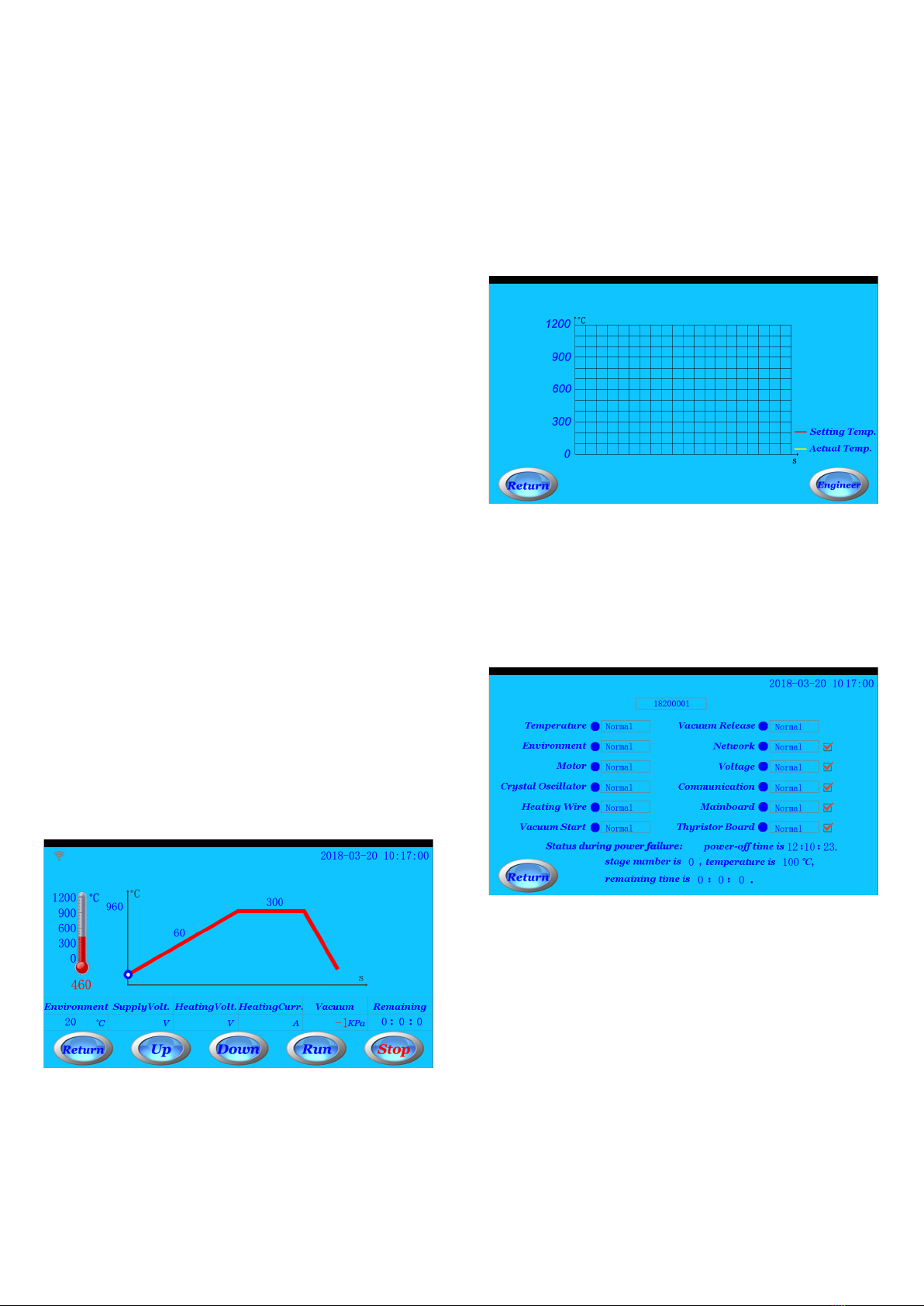

5.4.Program running curve

In standby menu, click Curve icon to enter program

running curve menu.

In program running curve, you may see the latest

temperature process curve.

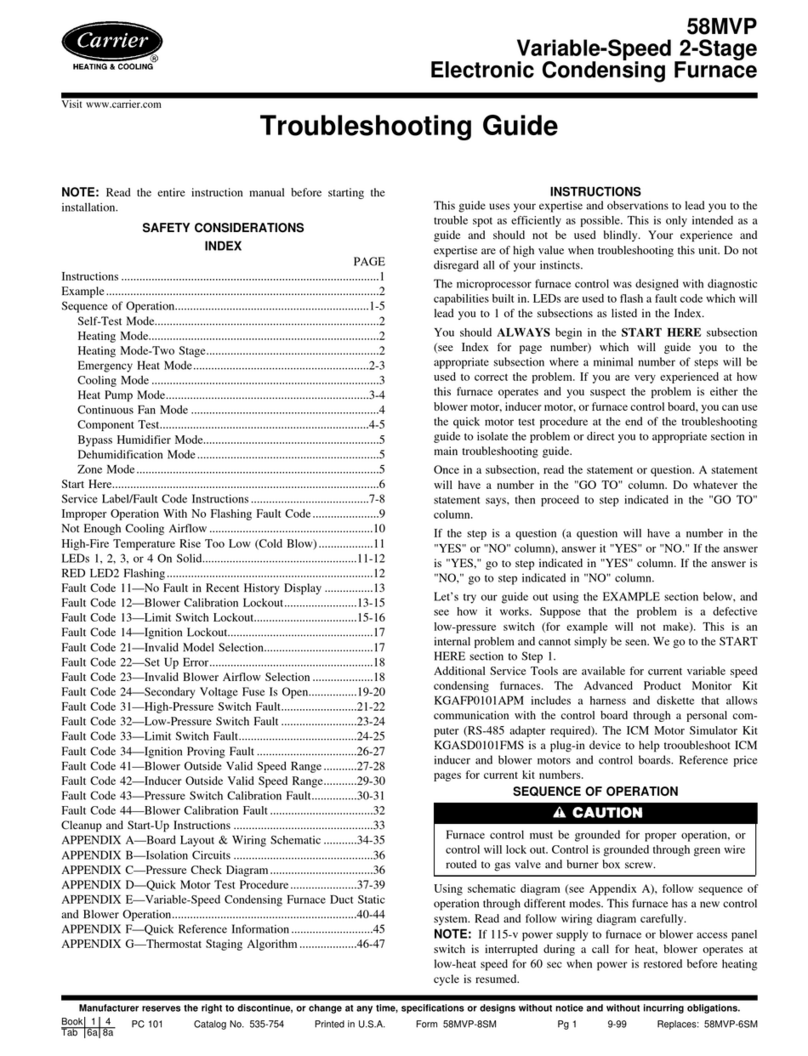

5.5.Alarm information

In standby menu, click Alarm icon to enter alarm

information menu.

When furnace has the trouble in standby status, a red

round icon will be flashed. The detailed alarm

information can be checked in alarm information

menu.

When the program is running, if power is failure, you

can see the status of program running in this alarm

menu when power is continued.

In alarm information menu, the upper part of screen

shows the serial number of this furnace; the bottom

parts show the furnace’s status in a recent of power

failure;

Five types of alarm information can set to cancel

reminder (including network alarm, voltage alarm,

communication alarm, mainboard alarm, thyristor

board alarm). When one or all of them are canceled

reminder, the relevant alarm information will not be

showed.