ENGLISH

14

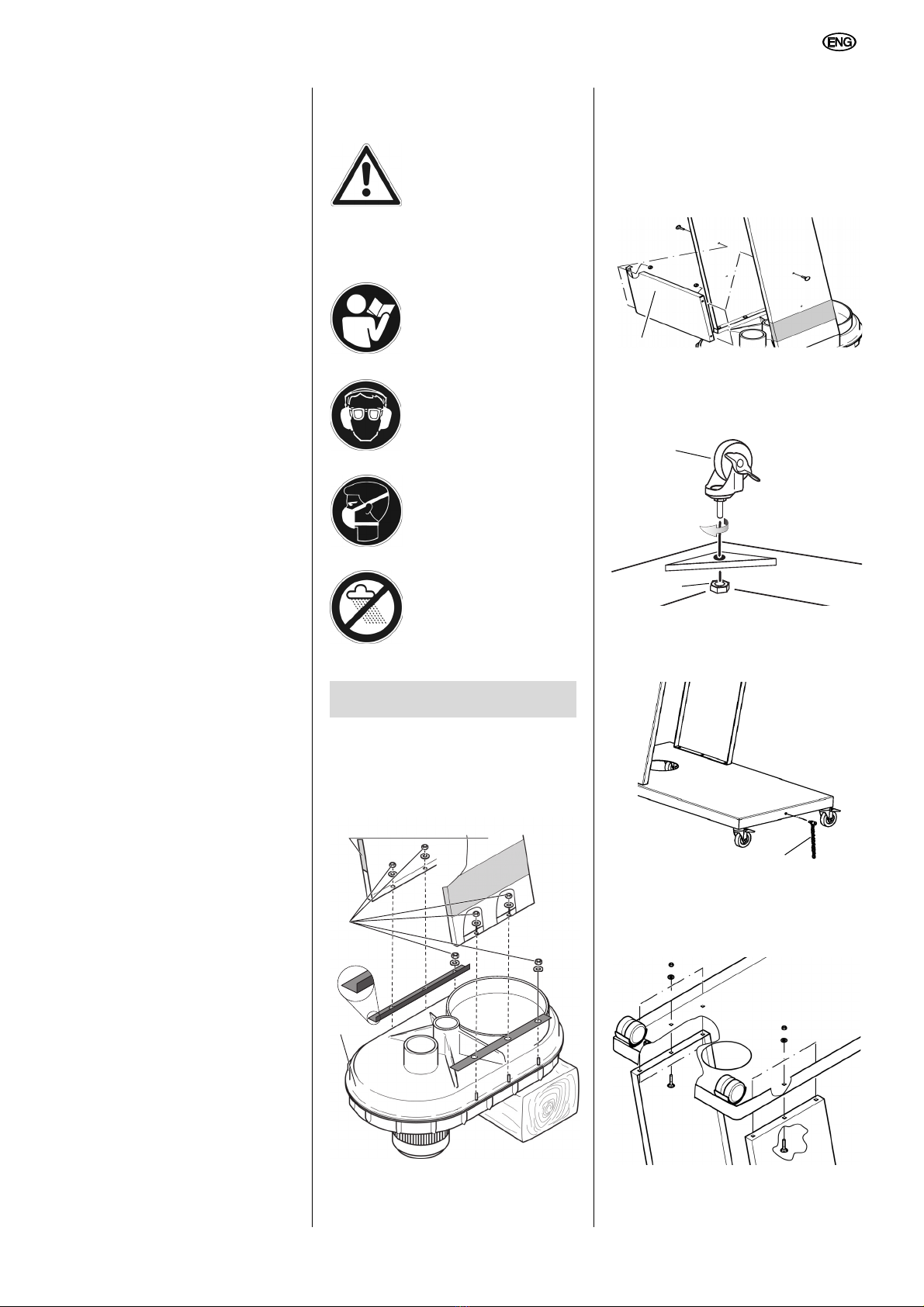

with carriage bolts and hex flange

nuts. Then check all screws and

nuts for tightness and place ma-

chine with the castors on the floor.

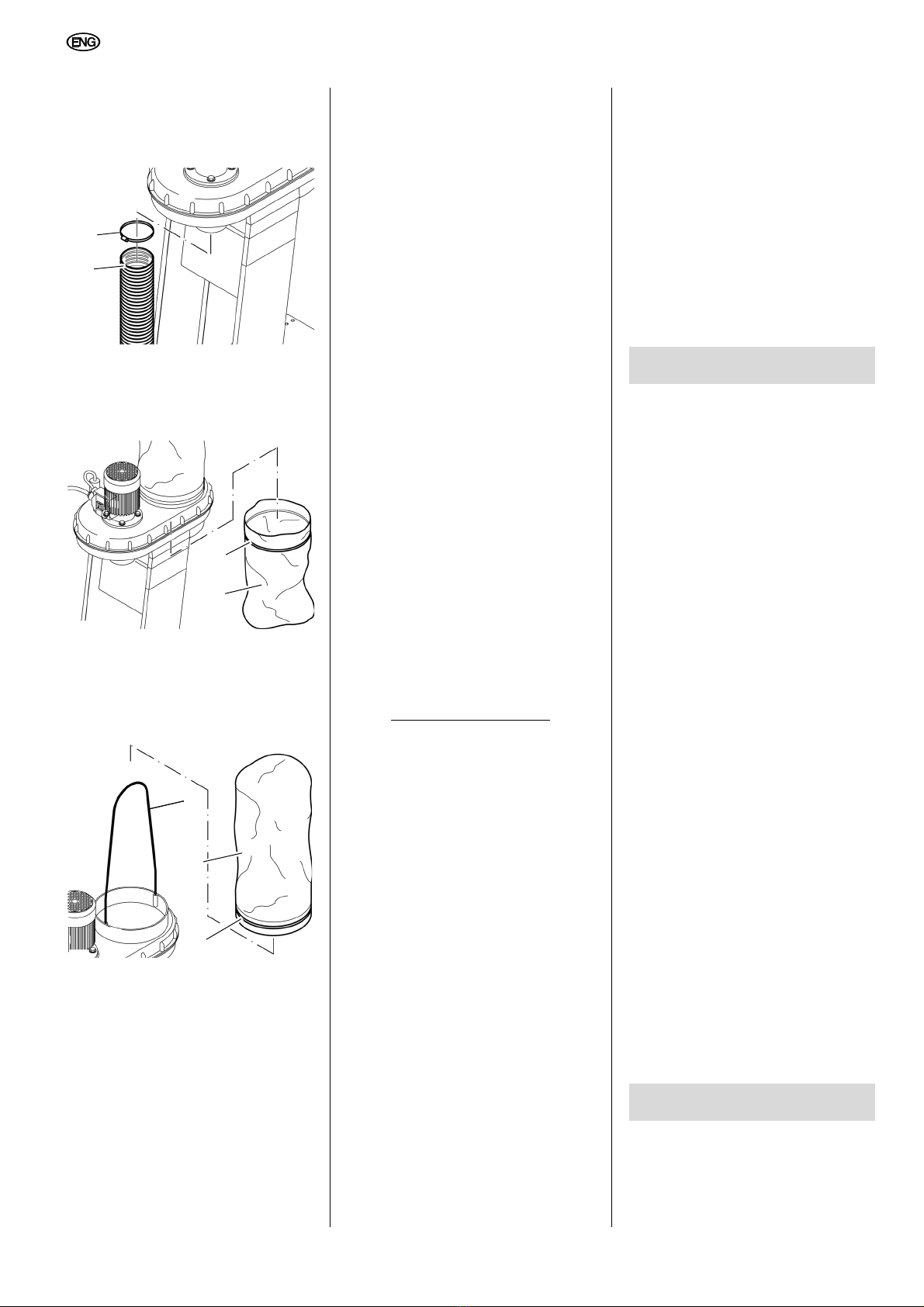

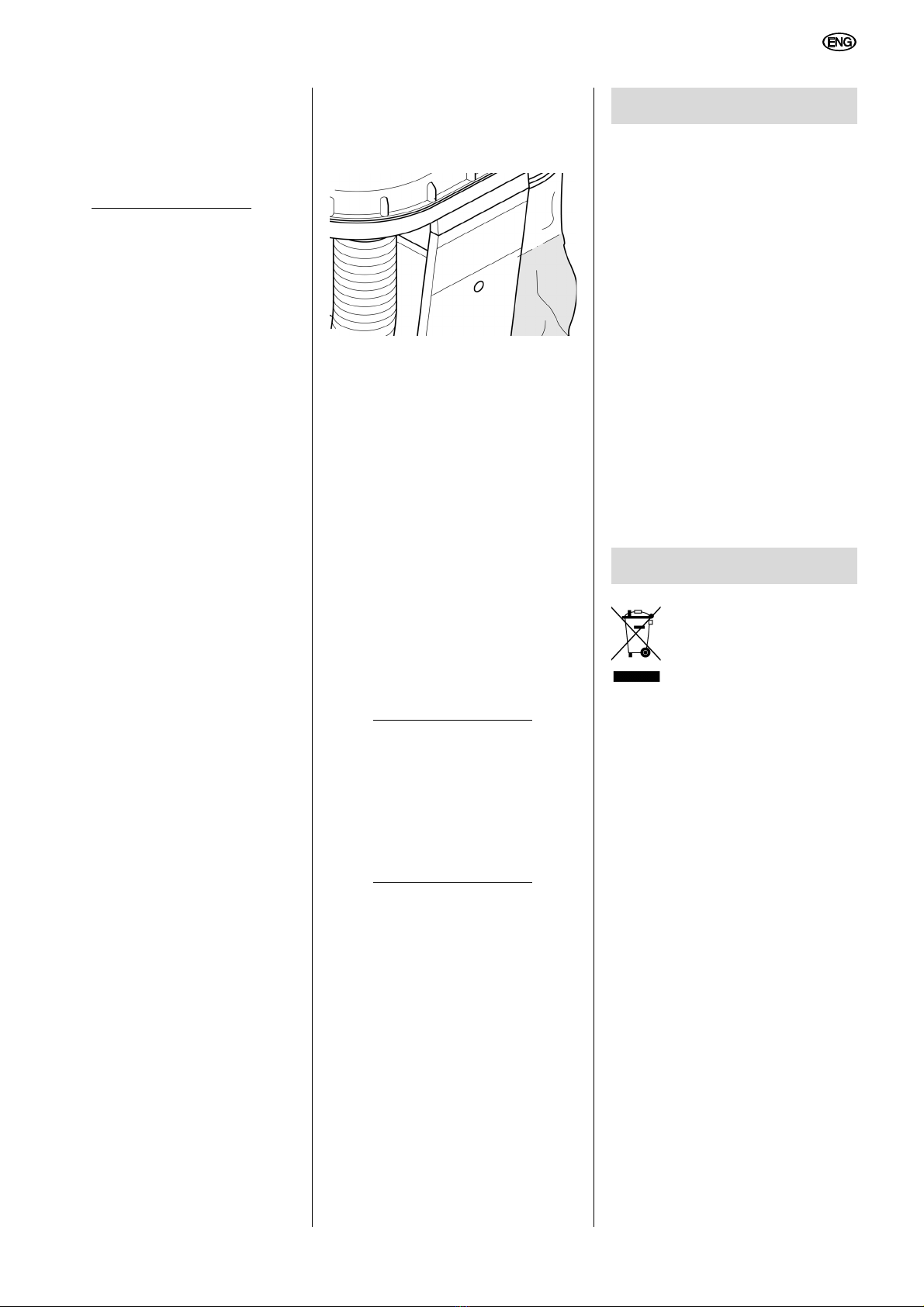

7. Put the hose clamp (14) on one end

of the suction hose (15), then push

the hose on the suction port below

the motor. Tighten the hose clamp.

8. Clamp dust collection bag under the

fan opening. Fit a sufficiently long

and wide dust collection bag (16)

(eg 600 × 900 mm) and tighten it

with the tightening strap (17).

9. Insert the rod (18) into the two holes

on the edge of the upper dust bag

opening. Thread the clamp ring (20)

through the guide sewn into the

dust bag (19). Fit the dust bag over

the dust bag opening. Tighten the

clamp ring.

4.1 Mains Connection

BDanger! High voltage

Operate this machine in dry sur-

roundings only.

Operate machine only on a power

source meeting the following re-

quirements (see also “Technical

Specifications”):

– outlets properly installed, earthed

and tested.

– outlet protected by a 10A fuse

(time-lag);

– mains voltage and system fre-

quency conform to the voltage

and frequency shown on the ma-

chine´s name plate;

– fuse protection by a residual cur-

rent device (RCD) of 30 mA sen-

sitivity.

Use only oil-resistant extensions

cords class H07 RN-F. Lead cross-

section should be at least 1.0 mm2.

Protect the power supply cable from

heat, aggressive liquids and sharp

edges.

Run the power supply cables in a

way that they do not interfere with

your work and will not get damaged.

Do not pull on power supply cable

to unplug.

4.2 Electrostatic Charging

The entire extraction system of the ma-

chine is constructed of electrically non-

conductive components. If the suction

hose is connected to electrically con-

ductive parts (eg metal dust chutes or

suctions pipes), they need to be

earthed to dissipate possible electro-

static energy.

On the machine no plastic parts may be

replaced by metal parts. The suction

hose in particular must not be retrofitted

with a metal spiral. In this context small

metal parts like screws and hose

clamps are harmless.

Use only genuine spare parts. These

spare parts are designed for the ma-

chine.

4.3 Overload Protection

To protect the electric motor against

overloads it has a motor protection built

in. If the motor is overheated or over-

loaded the machine will shut off.

In this case the motor can be restarted

after a few minutes of cooling down.

3Note:

If the machine is shut OFF repeatedly

by a tripped motor protection

(2–3 times) within a short time, the ma-

chine needs to be checked by a quali-

fied electrician, before attempting to

turn it ON again.

1. Place the dust extractor next to the

woodworking machine in a way that

it will not interfere with your work.

2. Connect the suction hose to the

dust extraction port of the wood-

working machine.

3. Place the power supply cable on the

floor and plug it into an outlet.

4. Turn the motor ON and wait a few

seconds, until the fan has reached

fuill speed.

– If the upper dust bag does not fill

with air after a few seconds, pull

it up.

5. Only now start the woodworking

machine and commence with your

work.

6. Let the dust extractor postrun for at

least 10 seconds after the wood-

working machine has been turned

OFF.

3Note:

For extended daily use of your wood-

working machine an automatic power

relay for the dust extractor would be of

advantage This relay turns the dust ex-

tractor time-delayed ON and OFF once

the woodworking machine is turned ON

or OFF respectively.

This automatic power relay is available

from the manufacturer in two versions

(see chapter "Available Accessories").

ADanger!

Prior to all servicing:

1. turn the machine OFF,

5. Operation

6. Care and Maintenance