4

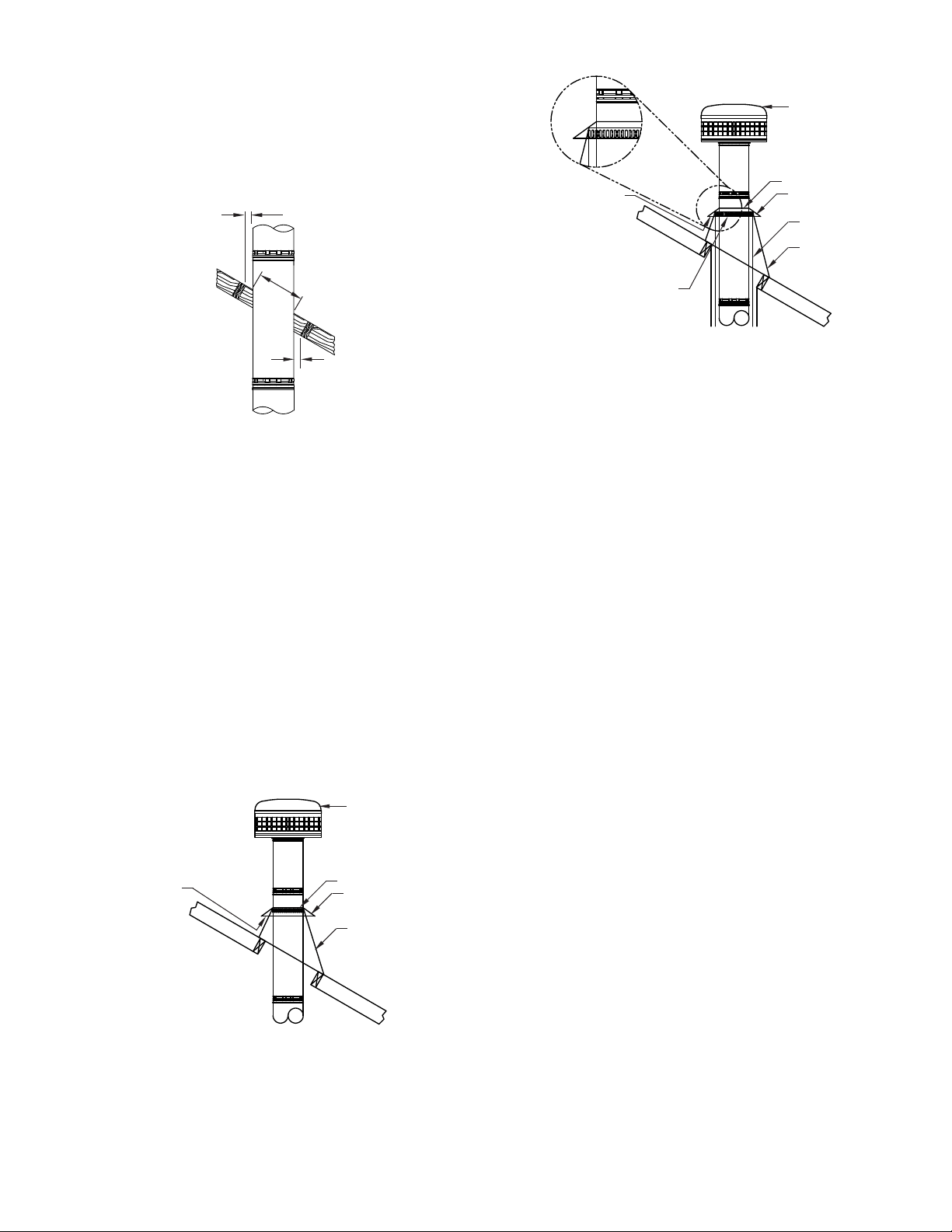

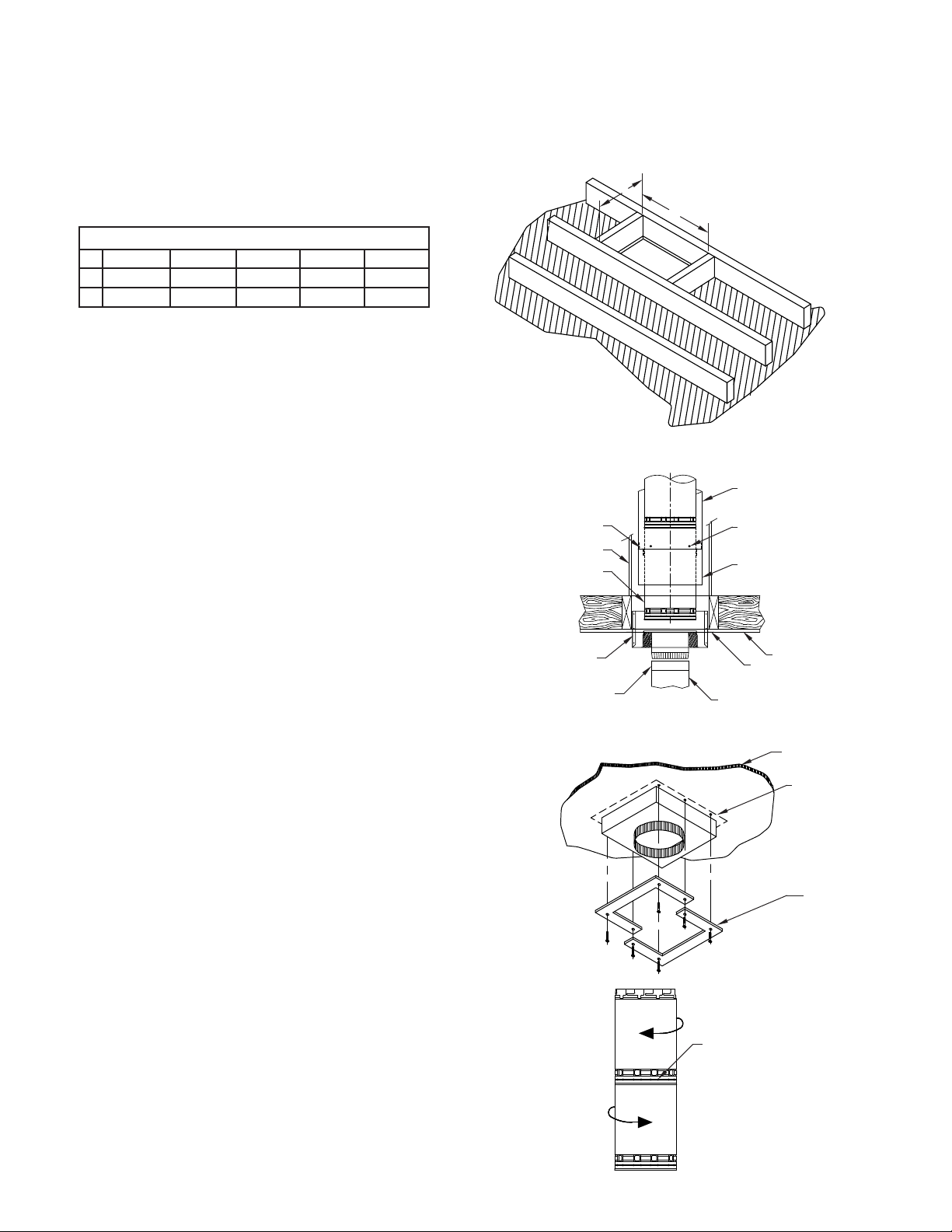

INSTALLATION THROUGH FLAT

CEILING(S)

1. From the appliance manufacturer’s instructions,

determine the correct ue diameter for the chimney,

and proper location of the chimney.

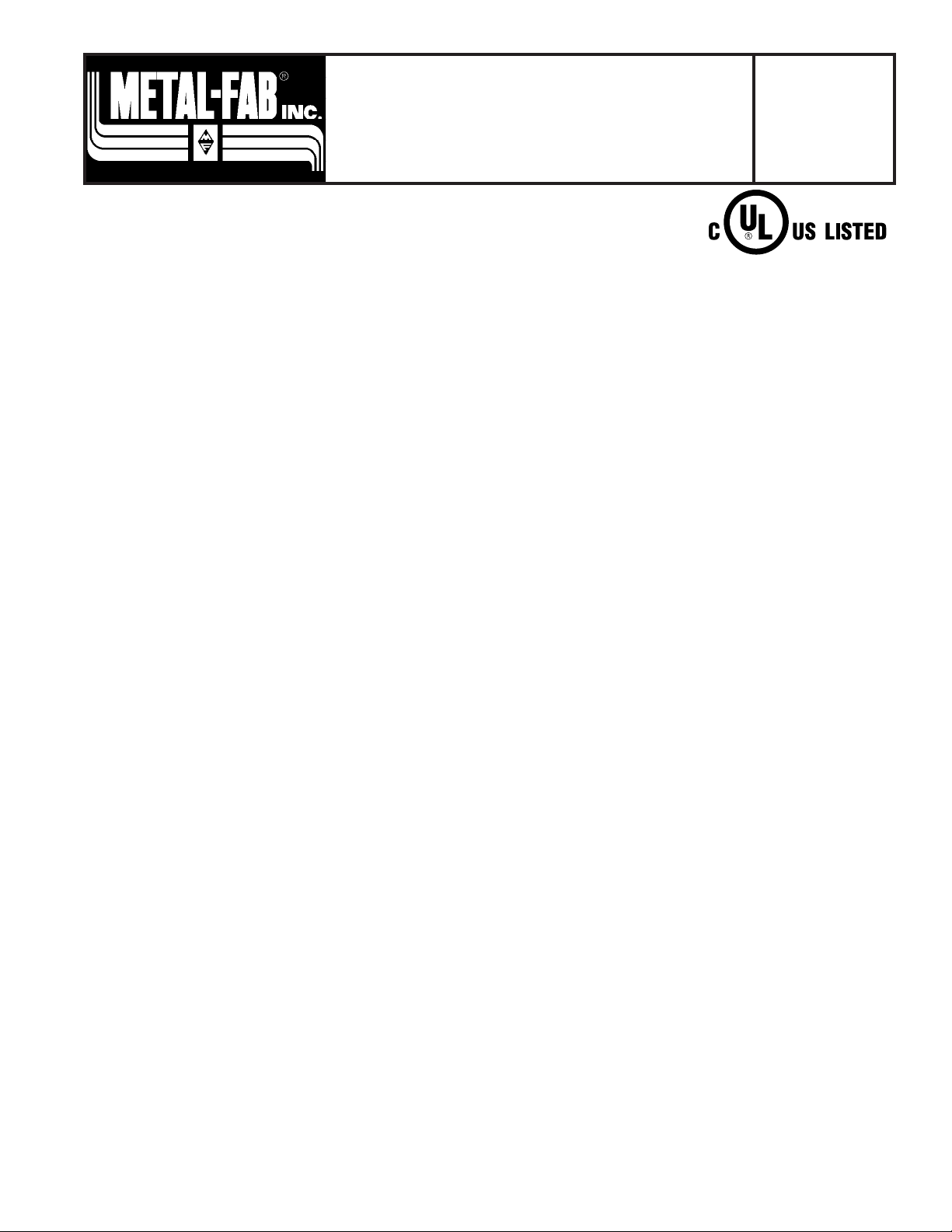

2. Using framing lumber equal to ceiling joist size, frame

ceiling opening as shown in FIG. 2 and TABLE 1.

TABLE 1

CHIMNEY FLUE DIAMETER

6” 7” 8” 10” 12”

A12-7/16” 13-7/16” 14-7/16” 17” 19”

B12-7/16” 13-7/16” 14-7/16” 17” 19”

NOTE: If possible, it is recommended that the chimney be located

in such a manner as to not cut the ceiling joist. The chimney can

be centered between joists on 16 inch centers in these areas.

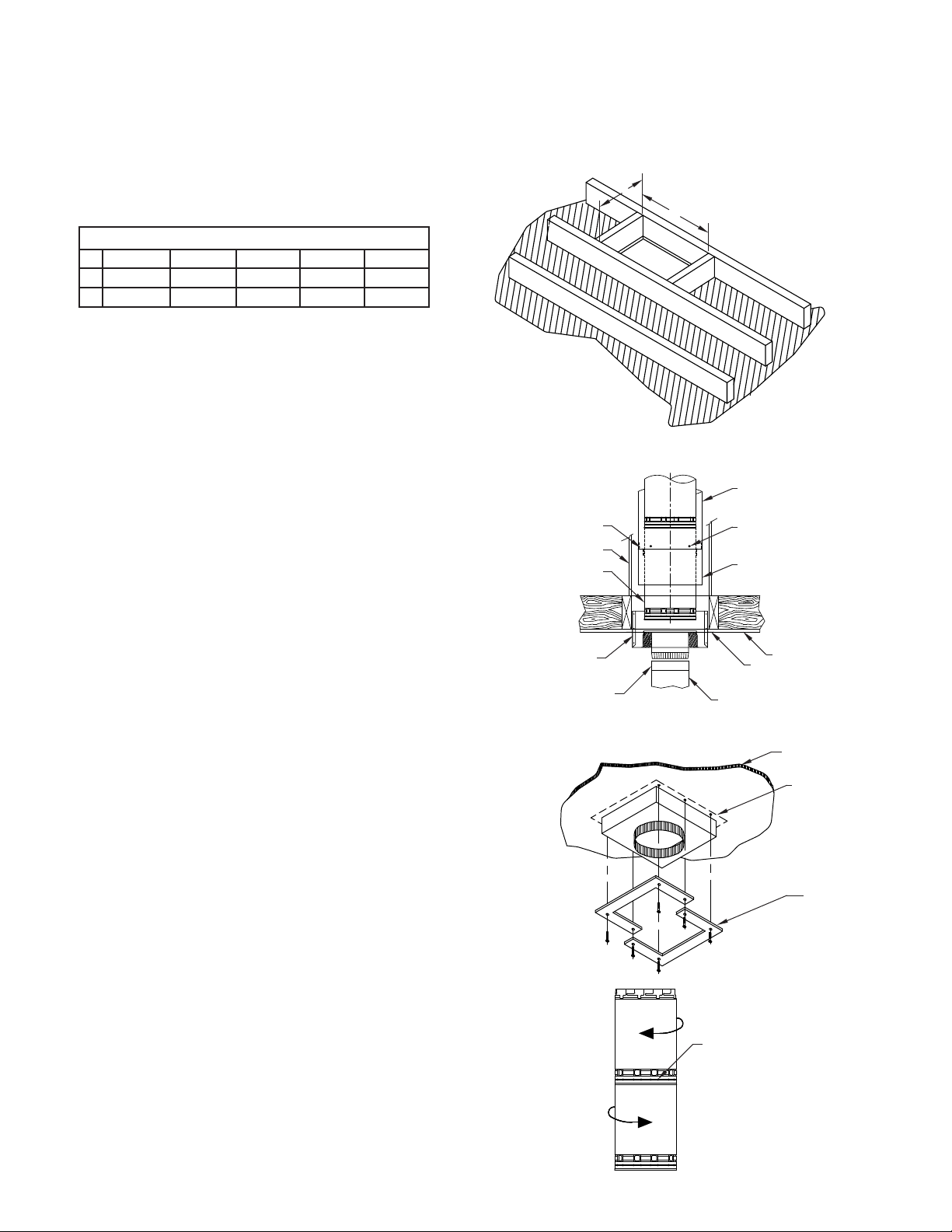

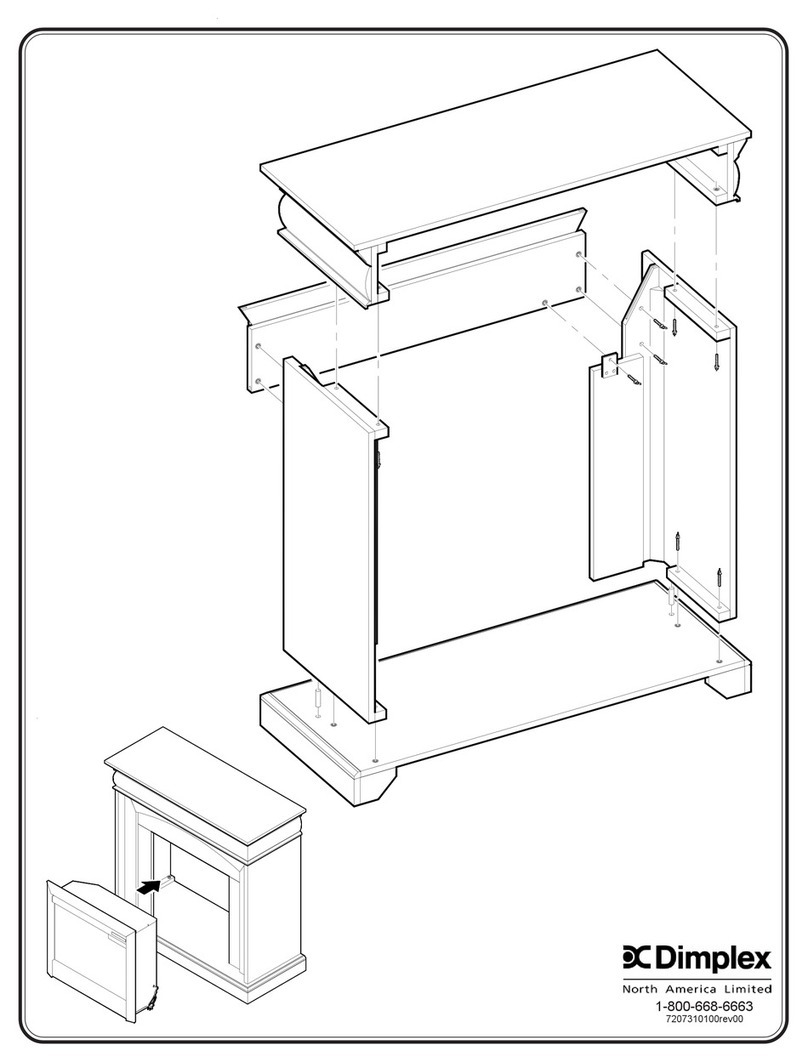

3. As shown in FIG. 3, insert the Ceiling Support

(TGCSP) from below until the anged edges are

rmly against the ceiling drywall. Secure into framing

with eight (8) 8-penny nails inserted through the sides

of the ceiling support. If the TGCSP was installed

during construction and drywall now covers the

anged edges, install Metal-Fab’s ceiling support trim

kit (TGCST), as shown in FIG. 4.

4. If the chimney is an enclosed installation for a wood stove or

coal burning appliance the clearance shields must be

installed (TGICS-C & TGOCS-C). Begin by installing a

TGICS-C around the Temp/Guard chimney and resting

on the Temp/Guard Ceiling Support (See FIG. 3).

The TGICS-C will center itself by the brackets attached

to the shields. Continue installing the shields around

the chimney for the full enclosed height. The

clearance shields are telescoping components and

will alternate between the inside clearance shield

(TGICS-C) and outside clearance shield (TGOCS-C).

The (TGICS-C and TGOCS-C) will be held together

by (3) self tapping screws supplied with the shields.

For offsets and tees use shields TGICS15L-C,

TGICS30L-C and TGICST-C.

5. Single wall or double wall connector pipe may now be

installed between the appliance and the ceiling support.

(See FIG 3.)

If the area above the ceiling is an attic, go to step 7.

6. Proceed to the next ceiling. If Metal-Fab Elbows are to

be used because the chimney is to be offset, refer to

“Installation of Elbows” section. Directly above the

Center of the ue in the ceiling support, mark the ceiling. A

plumb bob is normally used to nd the center. Cut an

opening in the ceiling using FIG. 2 and Table 1.

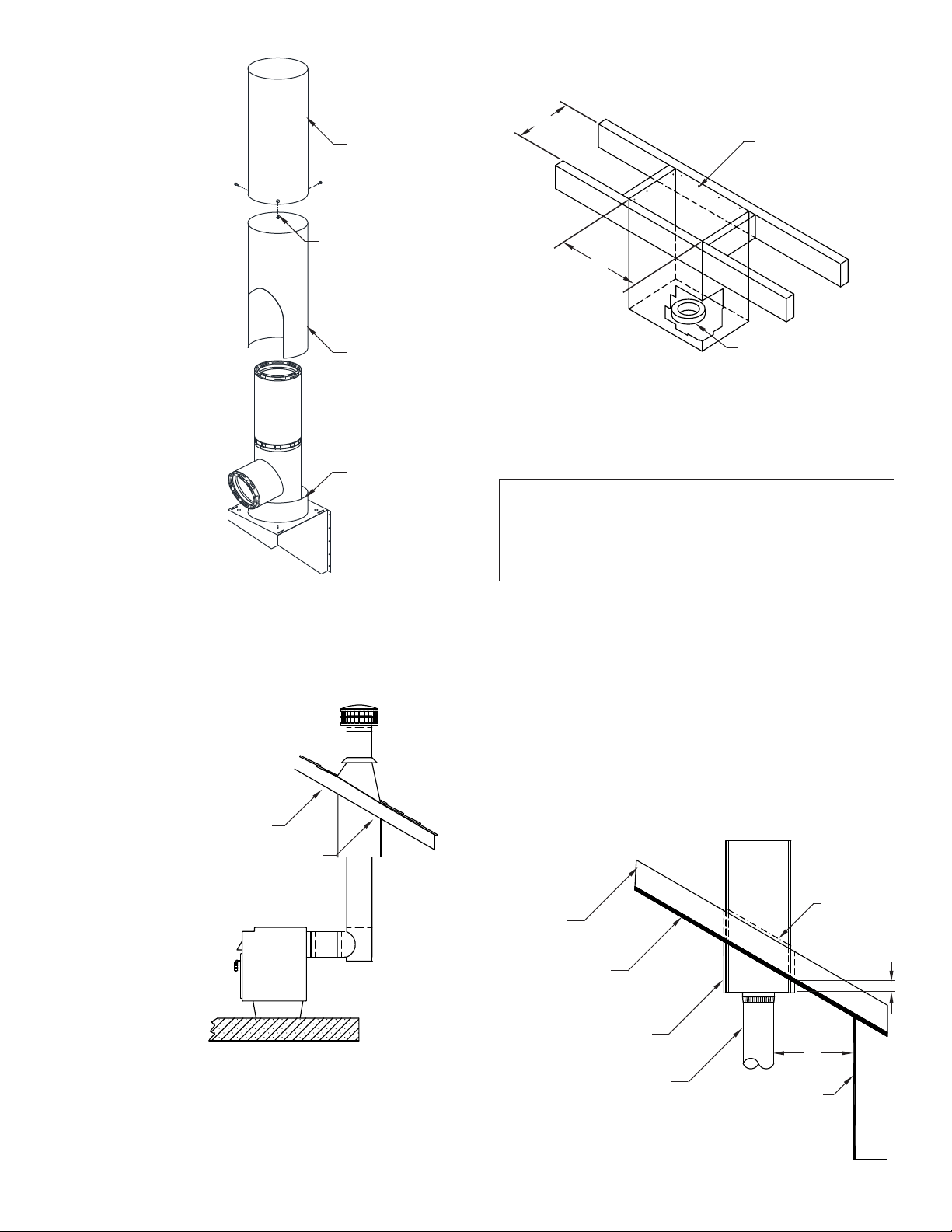

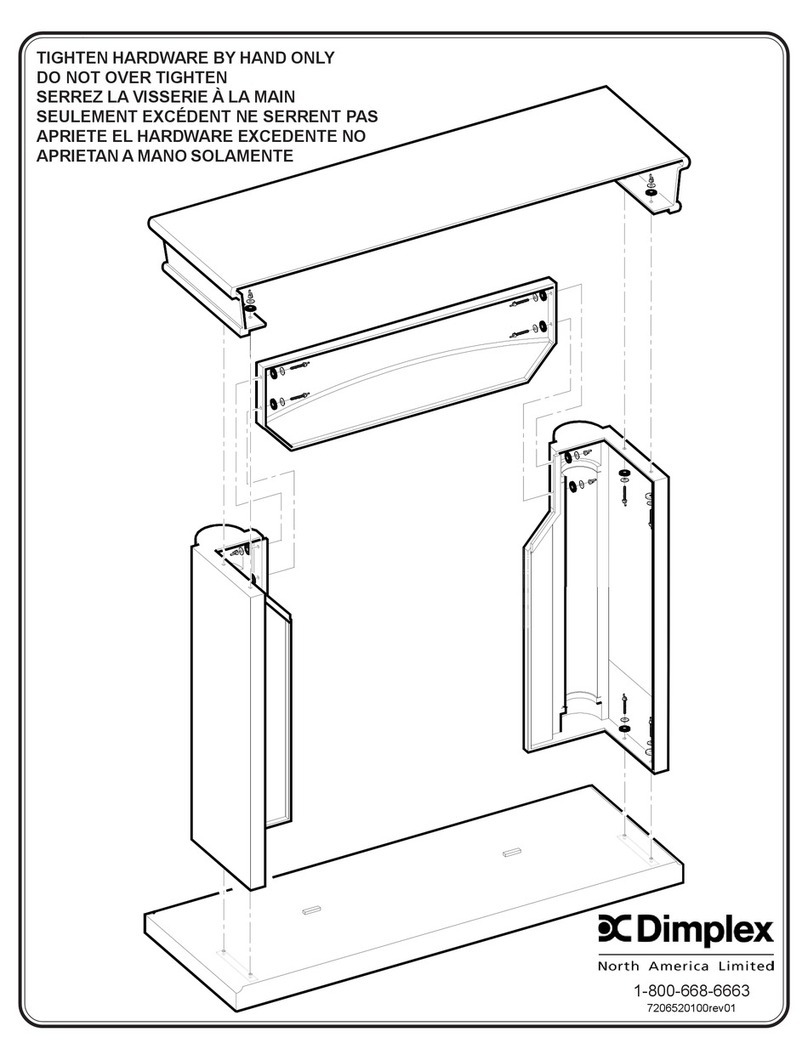

7. Install Temp/Guard chimney sections starting at the

TGCSP. Secure the sections by pushing together

and twisting until stop-locked (See FIG. 5).

Additional chimney sections may be added

to maximum height of 60 feet. At each additional

ceiling, a restop (TGFSA for Unenclosed

Installation) (TGFSA-C, For enclosed Installation

using Clearance Shields) is required. Insert the

TGFSA/TGFSA-C into the joist area prepared in step

5. Continue this process for each oor level until the

area above the attic.

B

A

FIG. 2

Framing lumber of

equal size to the joist should be used.

CEILING

DRYWALL

FLANGE

COVERED

BY DRYWALL

CEILING

SUPPORT TRIM

(TGCST)

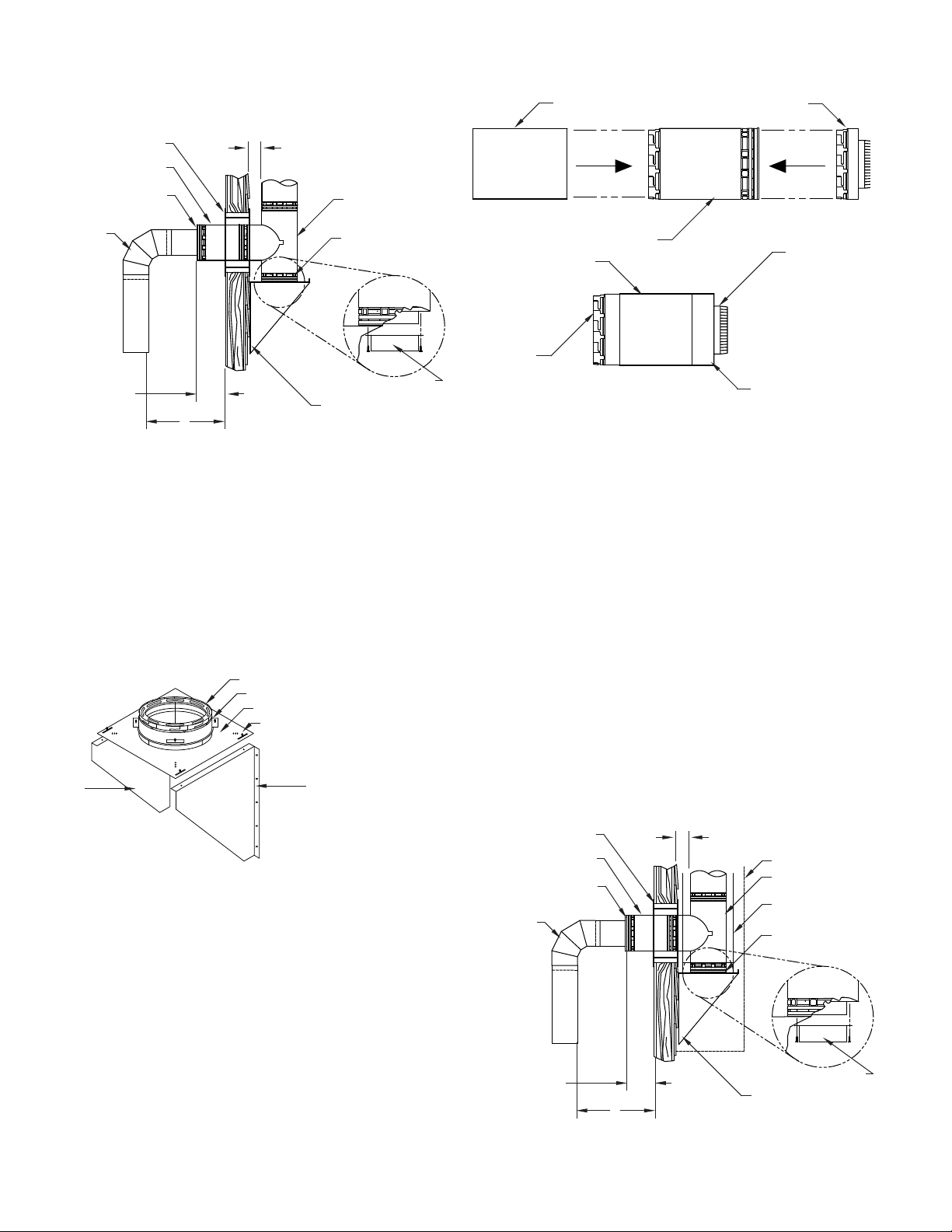

FIG. 4

TWIST LOCK JOINT

FIG. 5

FIG. 3

CLEARANCE SHIELD

(TGOS)

CEILING DRYWALL

FLANGED EDGE

SINGLE OR

DOUBLE WALL

CONNECTOR PIPE

ATTACH TO

TGCSP WITH

SCREWS

CEILING

SUPPORT

(TGCSP)

CLEARANCE SHIELD

(TGICS)

SECURED WITH SELF

TAPPING SCREWS

(PROVIDED)

SPACER CLIPS

ENCLOSURE

TEMP/GUARD

CHIMNEY

NOTE: When the chimney extends between oors, which

can be occupied, the chimney must be enclosed to prevent

contact. As previously noted, 2” clearance to combustibles

for 6” - 12” diameters is to be maintained, except within the

joist area controlled by the TGCSP.