Metalware Interlok User manual

Metal

that works

Industrial shelving solutions since 1954

2020 Installation Guide – Interlok

Strength • Support • Integrity

*A minimum of two persons is recommended to carry out the assembly

2020-07

MELWARE

NOTICE

Use caution when handling and assembling metal parts. The metal may have sharp edges or corners. The use of

protective gloves is recommended. Do not use this unit for anything that is outside the designed function of

storage. Do not store loose or heavy items on the top shelves or on the top of the unit, for they create a falling

hazard that can injure yourself or others. Always remember to use proper lifting techniques when moving either

the boxed or assembled unit. Shelving should be periodically inspected for loose bolts, for damaged “T” uprights or

shelves, for proper seating of shelf and clip. Check loading to assure it is not being overloaded. If any damage

is detected, units should be unloaded immediately and repaired or replaced before returning to service.

2020-07

Table of Contents

Recommended Tools for Assembly............................................................................... 4

How to assemble a standard Interlok shelving unit .................................................... 5

Sub-assembly Component Reference Guide ............................................................... 7

a. Footplates............................................................................................................... 7

b. Splice bracket........................................................................................................ 7

c. Cross aisle bracket ............................................................................................... 8

d. Down aisle bracket................................................................................................ 8

e. Shelves ................................................................................................................... 9

i. 1in Clip.............................................................................................................. 9

ii. 2in Clip.............................................................................................................. 9

f. Back panels.......................................................................................................... 10

g. Floor channel....................................................................................................... 11

h. Cross channel ......................................................................................................11

i. Guardrail............................................................................................................... 12

j. Back-to-back tie clip ........................................................................................... 12

k. Side brace............................................................................................................. 13

l. Back brace............................................................................................................ 13

m. Divider................................................................................................................... 14

n. Sliding divider...................................................................................................... 14

o. Half divider ........................................................................................................... 15

Annex A ........................................................................................................................... 16

Annex B ........................................................................................................................... 17

Annex C ........................................................................................................................... 18

Tools for Assembly

Below is a list of recommended tools to assemble a standard Interlok Shelving Unit

Pliers to position the brackets on the end of the back

braces

716

$

”"

key and socket wrench to secure the metal shelves

together

Hammer drill with

38

$

”"

cement drill bit for anchoring the

shelving unit to the floor

Rubber mallet

A level, 36” wide minimum

Work gloves

Safety glasses

Mask for protection

1

2

3

4

5

6

7

8

7

(514) 937-9533 / (833) 937-9533 / [email protected] 4/20

2020-07

www.metalware.ca

STEP 1

*If you are not using footplates, please go directly to STEP 2.

Bolt the footplate at the bottom of each upright, and add a

short shelf clip, also called the "H" clip, (refer to Image C)

on the first level. This clip is intended to sup-port the

lower shelf when using a footplate.

STEP 2

While holding the 4 uprights, insert 4 shelf clips

and install the bottom shelf. Either 1" clips (refer

to Image A) or 2" clips (refer to Image B) are

provided. If you are also installing footplates

directly insert the bottom shelf on the short shelf

clips. Then, insert the required shelf clips in the

top holes and install the top shelf.

Make sure the shelf clips are positioned

as shown on the right

STEP 3

Determine the shelves elevations and then place the shelf

clips onto the posts at the desired height. Install sides brace

with the supply bolts without tightening them to permit nal

adjustments.

Do not use braces and end panels as they both serve the

same purpose

STEP 4

Using a screwdriver, angle the tips of the back brace in the proper position. Then, bolt the back braces on the

post. If you are using back panels, bolt them as shown.

A.

B.

Interlok Installation Guide

(514) 937-9533 / (833) 937-9533 / [email protected]

5/20

C.

Only one short shelf clip is needed per each post, even if

side by side units are used.

2020-07

www.metalware.ca

STEP 5

Install the shelves at the desired height.

Ensure the section is square and tighten

the nuts and braces

CORNER GUSSETS

Use gussets to ensure rigidity of the sec-

tion when you are not using back braces and

back pannels. Second gusset hole must be

drill on location after levelling the unit, do not

use tek screw.

4 pairs of gussets every 2nd section

Use two hooks per hole to place

units side by side. Below are example of ways

to position the braces:

BASEPLATE

Slide the base plate, use base snap to lock

into place.

TIE CLIP

Install tie clips at the top and bottom of every sec-

tion with side braces.

DIVIDERS

4 dividers clips are needed per dividers.

SLIDING DIVIDERS

2 dividers clips are needed per dividers.

(514) 937-9533 / (833) 937-9533 / [email protected]

6/20

2020-07

2020-07

www.metalware.ca

Sub-Assembly Component Reference Guide

a. Footplates

● (1x) Footplate per post

● Footplates can be 2-½” x 3” x 1”

galvanized, 2-½”x 3” x 3/16” painted

or 4” x 5” x 1/4”

● They are bolted to the base of the

post using ¼”-20UNC x ⅝” bolt with

¼” lock nut

● (1x) ⅜” x 3” anchors are required per

footplate

● One “H” shelf clip is needed to

support the first shelf clip. Only one

shelf clip per post is needed to

support the shelf on either side

b. Splice bracket

● Splice brackets are used to connect two posts or panels

vertically

● They are made up of a pair of L-shaped ⅛” thick x 7-½”

long galvanized plates

● Splice brackets are bolted using (4x) ¼”-20UNC x ⅝”

bolts and nuts

7/20(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

c. Cross aisle bracket

● Cross aisle brackets are used to connect custom

floor channels, top ties or lighting support

components

● They are made up of a pair of 12ga brackets

● Cross aisle brackets are bolted using (2x)

5/16”-18UNC x 5/8” bolts and nuts on each bracket

d. Down aisle bracket

● Down aisle brackets are used to connect custom

floor channels, top ties or lighting support

components

● They are made up of a pair of 12ga brackets

● Down aisle brackets are bolted using (2x)

5/16”-18UNC X 5/8” bolts and nuts on each

bracket

8/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

e. Shelves

i. 1in Clip

● 1” clips are used to support the

shelf with a 1” vertical

adjustability

● They are made of 16ga

galvanized steel

ii. 2in Clip

● 2” clips are used to support the shelf

with a 2” vertical adjustability

● They are made of 12ga galvanized

steel

9/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

f. Back panels

● Back panels are used to close the back of a

unit, and simultaneously acting as a brace

● They are made of 24ga steel

● Back panels are connected to the post using

specific clips and (2x) 1/4”-20UNC x 5/8”

bolts and nuts per clip

● Back panels clips are used to connect the

back panel with the post

● They are made of 12ga steel

● Maximum vertical spacing should be 28”

10/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

g. Floor channel

● Floor channels are used to support

flooring by connecting the post on both

ends, with a 2” vertical adjustability

● They are made of 14ga steel

● Floor channels are connected to the

post with a pin and 1/4”-20UNC x 5/8”

bolt, and lock nuts on both ends

h. Cross channel

● Cross channels are used to

support a floor and add

rigidity to the floor channel

● They are made of 14ga

steel

● Cross channels are bolted

to the floor channel with a

(2x) 12ga lug, using (6x)

1/4”-20UNC x 5/8” bolts

and nuts

11/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

i. Guardrail

● Guardrails are made of 1.5” x 1.5” x 1”

HSS

● They are connected to the post using

(2x) guardrail clips, (1x) 1/4”-20UNC x

5/8” and (1x) 5/16”-18UNC x 2.5” bolts

and nuts

j. Back-to-back tie clip

● Back-to-back brackets connect back-to-back posts

● They cannot be used in row with a closed back

panel, except on either end of the row

● They are made of 12ga steel

● Back-to-back brackets are bolted to the post of each

unit with (1x) 1/4”-20UNC x 5/8” bolt and nut

● Please refer to annex A for accurate pattern

12/20(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

k. Side brace

● Side braces are used to reduce longitudinal

deflection

● They are made of 11ga steel

● Side braces come in pairs and are bolted to the post

using (4x) 1/4”-20UNC x 5/8” bolts and nuts

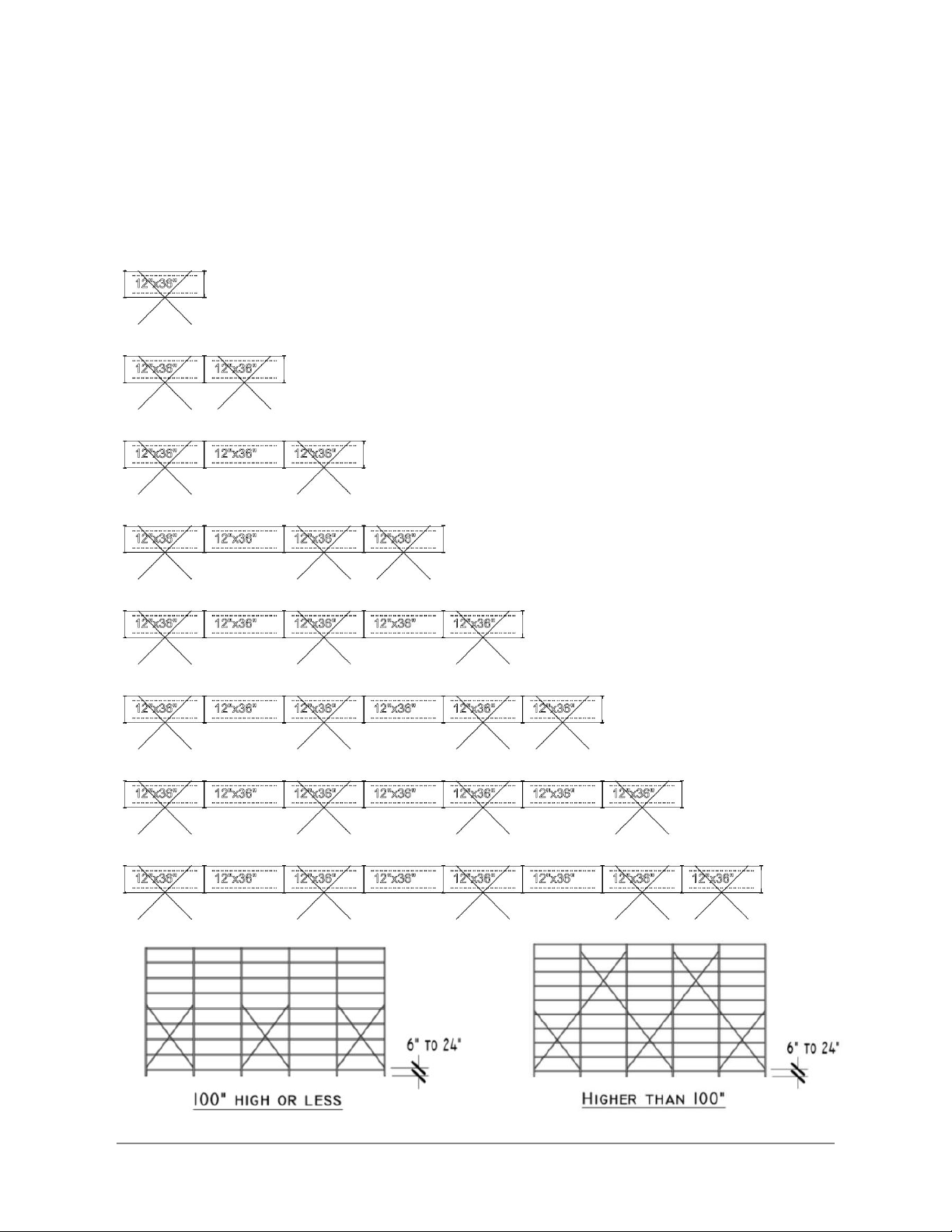

● Please refer to annex B for installation pattern unless

a specific drawing is provided

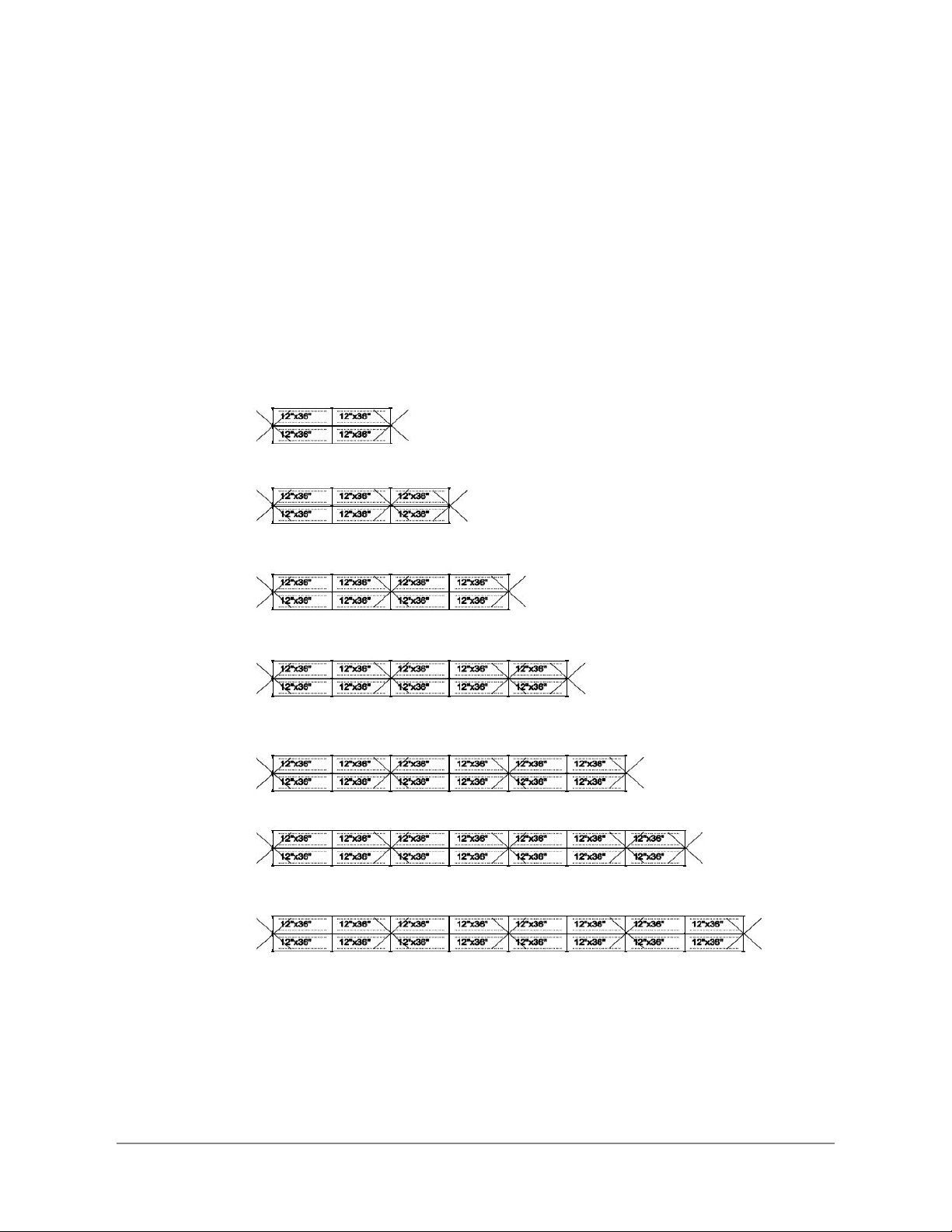

l. Back brace

● Back braces are used to reduce lateral

deflection

● They are made of 11ga steel

● Back braces come in pairs and are

bolted to the post using (4x) 1/4”-20UNC

x 5/8” bolts and nuts

● Please refer to annex C for installation

pattern unless a specific drawing is

provided

13/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

m. Divider

● Dividers are made of 22ga steel

● They are locked in place using (4x)

dividers clips, clipped into the shelf

● Dividers on top of each other share

the same dividers clips

n. Sliding divider

● Sliding dividers are made of 22ga steel

● They are locked in place using (2x) divider

clips, clipped into the shelf

14/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

o. Half divider

● Half dividers are made of 18ga steel

● They are bolted to the shelf using (2x)

1/4”-20UNC x 5/8”

15/20

(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

Annex A

Back to back bracket position in aisle.

16/20(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

Annex B

Side brace position in the aisle.

17/20(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

2020-07

www.metalware.ca

Annex C

Back brace position in aisle.

18/20(514) 937-9533 / (833) 937-9533 / [email protected]

2020-07

www.metalware.ca

MELWARE

2020-07

Table of contents

Other Metalware Storage manuals

Popular Storage manuals by other brands

Supero

Supero 5028R-E1CR12L user manual

Tabernus

Tabernus Enterprise Erase E2400 user guide

Quantum

Quantum PX506 Unpacking and installation instructions

Tandberg Data

Tandberg Data SLRTAPEDRIVE - Installation and user guide

PANTRYCHIC

PANTRYCHIC Smart Storage System quick start guide

Medion

Medion LIFE S88400 instruction manual