COMMISSIONING

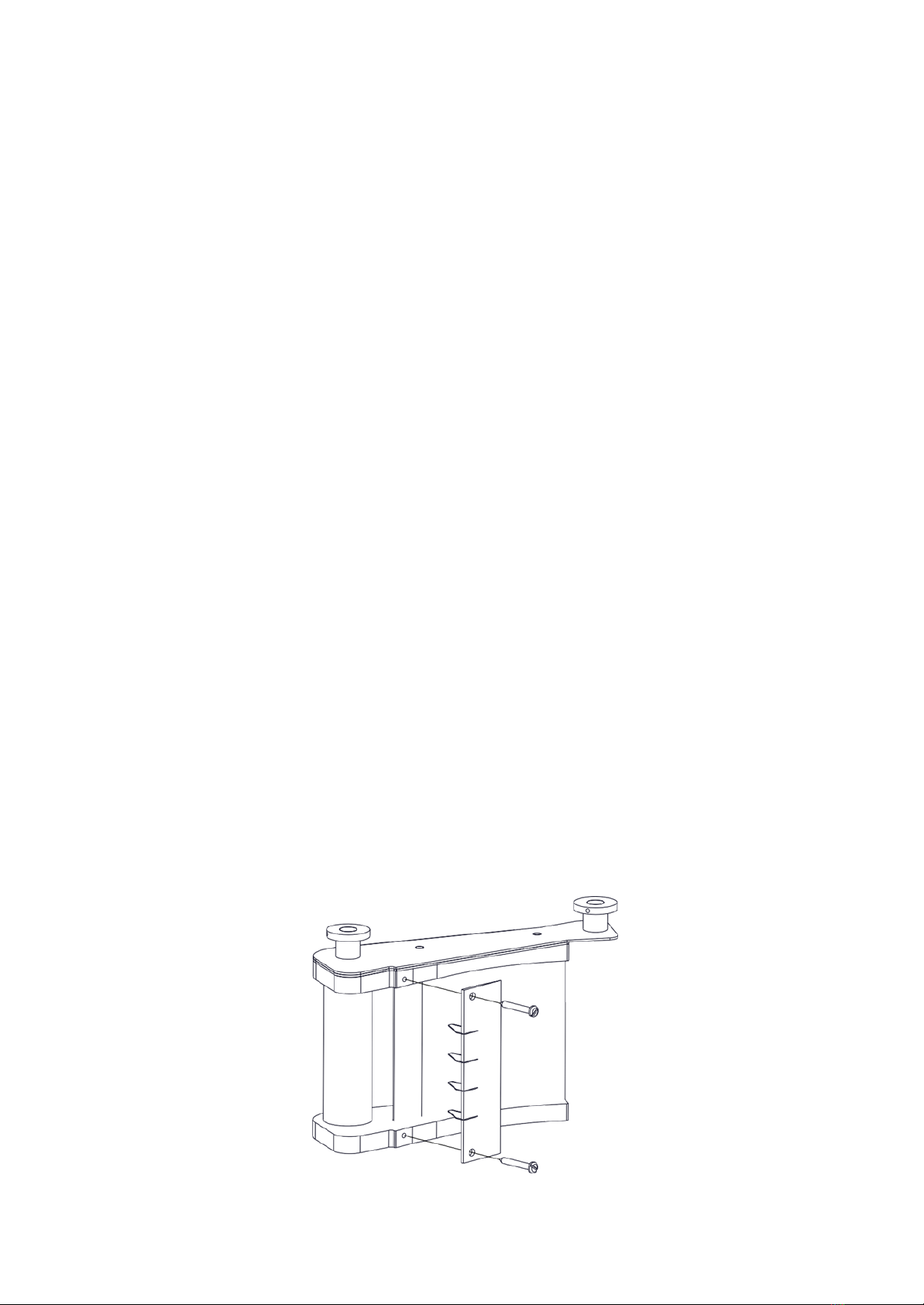

Open the hopper by fully unscrewing the interlock knob at the front and lifting up until the

hopper is fully resting back on its hinges. Turn the rotor by hand to ensure that it is completely

free to rotate and that the knife block assembly is properly in position. Replace the hopper and

screw down the interlock knob until it is tight.

It is now safe to switch on at the wall socket and to start the machine by pressing the start button

on the front of the machine (green button). To stop the machine, press the red button.

One of the safety features provided on the Metcalfe Chipper are the interlock devices that

ensures that the machine cannot run unless both the knife block and the hopper are properly

and fully in position. This makes it impossible for the operator to touch the spinning rotor whilst

it is running.

To confirm that the interlock is operating correctly press the start button to switch the machine

on. Then whilst it is still running, unscrew the hopper interlock knob. After two or three turns

the machine should switch off, but there are still two or three further turns of the knob necessary

before the hopper can be opened. The rotor should be stationary within 2 seconds of the hopper

being opened. If the knife block is not in place, another interlock will prevent the machine from

running.

OPERATION

With the machine running, feed peeled potatoes into the hopper. It will hold approximately 15kg

of potatoes, which self-feed into the mechanism of the machine and discharge as cut chips from

the chute.

Some care is necessary when loading, as the rotor will not accept abnormally large potatoes, so

these must be cut into two. The hopper is specially designed not to pass potatoes which are over

size and which could otherwise clog the mechanism. It is also essential that only potatoes be fed

in to this machine.

NOTE: take great care to ensure that there are no stones mixed in with the potatoes.

A stone or any other foreign object will damage the cutting knives and could cause the machine

to jam. In this event the machine has an inbuilt protection device, which will switch it off before

the electric motor burns out. This overload protection feature will automatically reset itself

when it cools down but it is necessary to wait a few minutes for this to happen. After clearing

the jam resume operation by pressing the start button. Should a stone damage the knife blades

they must be replaced as further use could break the blades.