Metek Apollo XF Octane User manual

Apollo XF/XLT/Octane

Basic User

Guide

Rev. 1.5

June 24, 2016

Contents

Octane Basic User Guide

Page 3 of 25

Table of Contents

1 Introduction .......................................................................................................................................... 5

1.1 Detector Types.............................................................................................................................. 5

2 Safety Precautions ................................................................................................................................ 7

2.1 High Voltages ................................................................................................................................ 7

2.2 Not Hot Swappable ....................................................................................................................... 7

2.3 Cooling .......................................................................................................................................... 7

2.4 Motorized Slide............................................................................................................................. 7

2.5 Radiation safety ............................................................................................................................ 8

2.6 Extending Detector Window Life .................................................................................................. 8

2.6.1 Do not allow the detector to come into close proximity or contact with high voltage

components .......................................................................................................................................... 8

2.6.2 Prevent particle contamination inside the sample chamber................................................ 9

2.6.3 Proper care when using a compressed gas to vent the sample chamber ............................ 9

2.6.4 Avoid hitting the detector or inducing mechanical vibrations in the detector or SUTW ..... 9

2.6.5 Avoid touching the window ................................................................................................ 10

2.6.6 When not in use leave the SEM in high vacuum mode ......................................................10

2.6.7 Do not expose the detector to extreme temperatures ...................................................... 10

2.6.8 Do not expose the SUTW to plasma ...................................................................................10

2.6.9 Windowless detectors.........................................................................................................10

3 Installation and Environment Requirements...................................................................................... 11

3.1 Power requirements ................................................................................................................... 11

3.2 Space and Weight specifications ................................................................................................ 11

3.3 Environment requirements.........................................................................................................11

4 Basic Detector Operation.................................................................................................................... 13

4.1 Startup ........................................................................................................................................ 13

4.2 Detector Cooling .........................................................................................................................13

4.2.1 Status LEDs.......................................................................................................................... 14

4.2.2 Using an Octane detector with TEAM software .................................................................15

4.2.3 Using an Octane detector with Genesis Software .............................................................. 16

4.3 Motorized Detector .................................................................................................................... 17

4.4 Adding to company network....................................................................................................... 17

4.5 Light Element Operation.............................................................................................................18

4.6 Frequently Asked Questions (FAQ)............................................................................................. 18

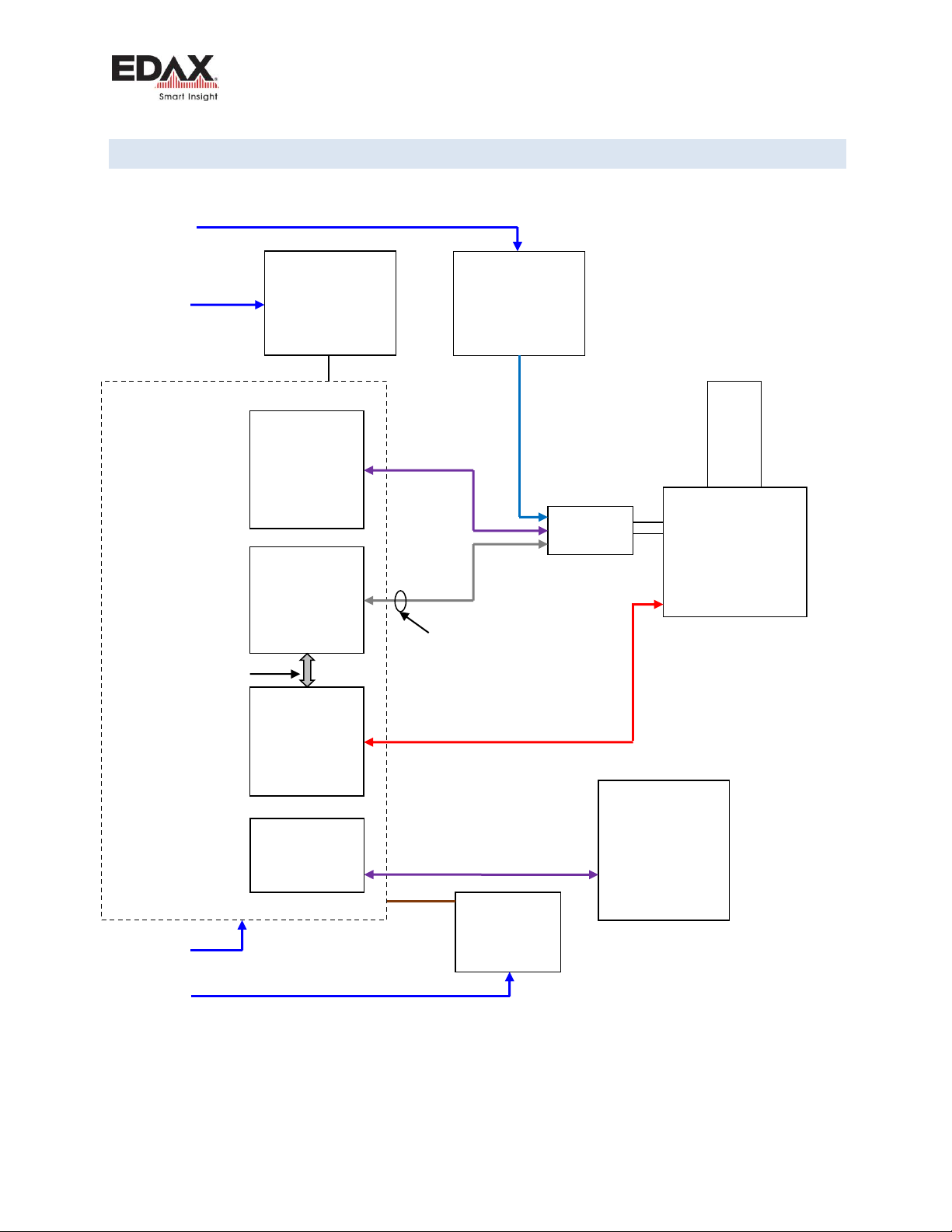

5 Basic System Cabling........................................................................................................................... 19

5.1 Typical Workstation configuration.............................................................................................. 19

5.2 Typical Microscope System configuration (SG-2) .......................................................................20

5.3 Typical Dual Detector Microscope System configuration...........................................................21

5.4 Typcial Microscope System Interconnect (SG-3) ........................................................................22

6 Troubleshooting..................................................................................................................................25

6.1 Remote Diagnostics ....................................................................................................................25

6.2 Detector Problems ......................................................................................................................25

Contents

Octane Basic User Guide

Page 4 of 25

This page is intentionally left blank

Introduction

Octane Basic User Guide

Page 5 of 25

1INTRODUCTION

The detector is a sophisticated precision instrument.

Removal of any system’s covers must be done by

qualified EDAX Factory trained engineers or

representatives.

All User / Operator adjustments and calibrations are done within the TEAM or Genesis software

environment. Users of the system should not attempt removing any covers or making any service

adjustments.

Proceed with caution where the following label is found.

Please send feedback regarding this manual to:

edax.suppo[email protected]

1.1 DETECTOR TYPES

The detectors listed in the table below are covered by this basic user guide. Note that a “W” in the

detector part number on the label, indicates the detector is a Window-less detector.

Name

Description

Octane Pro

10 mm2SUTW for SEM

Octane Plus

30 mm2 SUTW for SEM

Octane Super

60 mm2 SUTW for SEM

Octane Ultra

100 mm2SUTW for SEM

Apollo XF

60 mm2 SUTW for SEM

Octane Prime1

10 mm2SUTW for SEM

Apollo XLT

30 mm2 SUTW for TEM

Apollo XLT2

30 mm2 SUTW for TEM

Apollo XLT W

30 mm2Windowless for TEM

Apollo XLT Light Shield

30 mm2Windowless w/Light shield for TEM

Apollo XLT2 W

30 mm2 Windowless for TEM

Apollo XLT2 Light Shield

30 mm2Windowless w/Light shield for TEM

Octane T Ultra W

100 mm2Windowless for TEM (Racetrack)

Octane T Optima - 30

30 mm2 Windowless for TEM

Octane T Optima - 60

60 mm2 Windowless for TEM

Octane T Plus

30 mm2 SUTW for TEM

Table 1 - Detector models

1

See Technical specifications for differences from Octane Pro and limitations

Removing any of the instrument

covers, may pose a safety hazard as high

voltages may be exposed.

Do not attempt to use until fully

understanding its proper connections and

functions. Users should have a basic

understanding of the operation of the

system before operating.

Introduction

Octane Basic User Guide

Page 6 of 25

This page is intentionally blank

Safety Precautions

Octane Basic User Guide

Page 7 of 25

2SAFETY PRECAUTIONS

Use the following safety guidelines to help ensure personal safety and to help protect the detector

system from potential damage.

2.1 HIGH VOLTAGES

Exercise extreme caution where this label is found. High Voltage is present and can cause burn,

shock and/or cause serious injury.

There is circuitry in the detecting unit that generates high voltage (200 VDC) required to

bias the detector. Terminals carrying these voltages may be exposed when covers or panels are

removed.

2.2 NOT HOT SWAPPABLE

The electronics are NOT hot swappable unless otherwise specified. The power to the system must

be turned off before inserting or removing any of the modules, boards or any of the interconnecting

cables. If this precaution is not taken, component will be damaged nearest to the connecting pins.

2.3 COOLING

The detecting unit is cooled by the detecting unit body’s heat sink fins. No fans are used, just

ambient cooling via the heat sinks. Be sure these heat sinks are not blocked or covered. Keep away from

heat radiators or other heat sources. The detectors may fail if used in an enclosure with inadequate air

cooling.

2.4 MOTORIZED SLIDE

Warning! Pinch Hazard!

Fingers may be squeezed when operating the detector optional motorized slide.

□Do not place fingers or hands near the detector when operating the motorized slide.

Safety Precautions

Octane Basic User Guide

Page 8 of 25

2.5 RADIATION SAFETY

The electron microscope generates ionizing radiation when the electron beam is energized. The

detector is designed to have radiation leakage far less than the allowable level when properly mounted

with all covers and shielding in place.

EDAX warrants that its detectors and microscope interfaces when assembled and installed per EDAX

Engineers or Representatives, will provide Radiation Safety performance levels that will be in

compliance with the original Microscope design specifications.

Removal of any of the system's covers must be done by qualified EDAX Factory trained service engineers

or representatives. Opening covers or bypassing interlocks may expose users to radiation.

If the EDAX detector is removed from the microscope, it should be replaced by the original blanking port

cover provided by the microscope vendor.

Modification of covers or shielding or use of any other material than provided by EDAX or the

microscope vendor must be reviewed by a certified radiation expert and EDAX Inc. before use.

Caution: The radiation levels should be checked around the instrument after any service in which

covers or any radiation containment parts were removed.

2.6 EXTENDING DETECTOR WINDOW LIFE

Introduction

Super Ultra-Thin Windows (SUTW) for EDS detectors were introduced to the EDS market several years

ago to improve the transmission of low energy X-rays (e.g. B, C, N, O) through the window. The SUTW is

constructed of a 300 nm thick polymer foil with an additional 40 nm of coatings to reduce visible light

transmission and permeability. The polymer window is stretched over a silicon grid which provides

support over larger areas. The goal of the window is to allow signal X-rays to pass through to the

detector component while providing a hermetic seal on the atmosphere surrounding the detection

element. While the SUTW serves its intended purpose very well, it can be damaged if care is not taken

by users of the EDS system into which the window is installed.

Recall that the overall window thickness is approximately 340 nm, which is 150 times thinner than the

average human hair. When the window is damaged, this contaminates the atmosphere surrounding the

X-ray detector which in turn can degrade detector performance or cause failure. Damage to the SUTW

can be caused by physical contact, excess vibration, exceeding pressure or temperature specifications,

vapor condensation, electrical discharge to the detector or other factors.

2.6.1 DO NOT ALLOW THE DETECTOR TO COME INTO CLOSE PROXIMITY OR CONTACT

WITH HIGH VOLTAGE COMPONENTS

Do not allow the detector to come into close proximity or contact with high voltage components inside

the electron microscope, e.g. the extraction grid of a video detector. This can lead to an unsafe electrical

discharge to the detector which may damage the window.

Safety Precautions

Octane Basic User Guide

Page 9 of 25

2.6.2 PREVENT PARTICLE CONTAMINATION INSIDE THE SAMPLE CHAMBER

Particulates inside the sample chamber have a tendency to become entrained in the gas flow while

venting the sample chamber. The gas flow during a chamber vent or increase in chamber pressure is

generally turbulent meaning that entrained particles can fly in all directions, including toward the

detector window. Particulates which impact the window can cause micro cracks compromising the

vacuum seal of the window. In more extreme situations, particles can fully penetrate the window

causing what is known as a “bullet hole”, which causes a larger leak in the detector. It is also possible to

dislodge particles from the sample via the electron beam. If these particles are charged, they may be

accelerated toward the detector, which is at ground potential.

Recommendations:

• Always use particle free gloves when loading samples or working in the sample chamber.

• Be certain that there are no loose particles on the sample before placing the sample in the chamber.

Sample surfaces, fractures and powdered samples stuck to an adhesive should be cleaned with

compressed air to ensure the surfaces are clean and free of loose particles.

• Avoid venting the sample chamber too quickly. Specifically, do not exceed 10 cm/s gas velocity into

the chamber, as this can increase the risk of particle-induced detector window damage. This may

require a small aperture in the vent port or decrease in supply pressure if N2 purge is used to reduce the

gas velocity.

• If there is a high risk of particulates becoming dislodged during some operation in the microscope,

fully retract the detector to minimize the risk of damaging the detector window.

2.6.3 PROPER CARE WHEN USING A COMPRESSED GAS TO VENT THE SAMPLE CHAMBER

Ensure that the gas pressure does not exceed 2 atm.

Recommendations:

• Release any latching mechanism that is designed to keep the chamber door closed.

• Make certain that the chamber door will open normally when the chamber reaches atmospheric

pressure.

• Avoid venting the chamber too quickly as this can cause unsafe pressure-induced vibrations on the

window. See recommendations in section 2.6.2 above.

2.6.4 AVOID HITTING THE DETECTOR OR INDUCING MECHANICAL VIBRATIONS IN THE

DETECTOR OR SUTW

The SUTW can be ruptured by excessive physical vibration or shock.

Recommendations:

• Be careful not to run samples into the EDS detector.

• Close the sample chamber door gently.

• Do not pull the sample chamber door open while venting the sample chamber. This may lead to unsafe

pressure fluctuations inside the sample chamber which could damage the detector window.

Safety Precautions

Octane Basic User Guide

Page 10 of 25

2.6.5 AVOID TOUCHING THE WINDOW

Recommendations:

• Exercise extreme caution when working near the SUTW. The collimator provides a physical barrier to

protect the SUTW. Do not work with tools near the SUTW.

• If it is necessary to remove the collimator, the collimator should be removed and installed by a trained

technician so as not to touch the window or stress the end cap tip.

• Do not direct pressurized gas or liquid streams at the SUTW, for example in an attempt to clean the

SUTW.

• If necessary to clean the microscope chamber, retract or remove the detector using extreme caution

not to bump the detector tip or collimator.

2.6.6 WHEN NOT IN USE LEAVE THE SEM IN HIGH VACUUM MODE

If possible, leave the SEM in High Vacuum mode instead of in low vacuum or wet mode.

2.6.7 DO NOT EXPOSE THE DETECTOR TO EXTREME TEMPERATURES

Be mindful of conditions which may cause vapor condensation on the window or may cause the

temperature at the window to exceed manufacturer’s specifications. This may occur during a

microscope chamber bake or operation of a heat stage.

Recommendations:

• If there is a possibility that the sample may emit vapors while in the sample chamber, especially vapors

acidic or alkaline in nature, fully retract the EDS detector to minimize the risk of condensation on the

detector window.

• Take care when using a heating stage to follow manufacturer’s guidelines. Prior to using the heat

stage, confirm the EDS detector window type and temperature specifications as well as the heat load on

the EDS window during operation of the heating stage.

• The maximum temperature specification on Moxtek AP3 windows is not to exceed 40°C with 1 atm

differential or 70°C with zero pressure differential on the window.

2.6.8 DO NOT EXPOSE THE SUTW TO PLASMA

The window manufacturer of the SUTW does not recommend exposing the window to a plasma

generated by a plasma cleaner.

2.6.9 WINDOWLESS DETECTORS

Care should be taken to allow the detector to warm before venting the microscope to air. Failure

to do so may damage the detector module.

Installation Requirements

Octane Basic User Guide

Page 11 of 25

3INSTALLATION AND ENVIRONMENT REQUIREMENTS

Keywords: Room requirements, power needed, electrical requirements

3.1 POWER REQUIREMENTS

Component

XM2 Configuration

Workstation Power

400 watts (maximum); 100-240 Volts, 50/60 Hz, 3.5 to 7.0 Amps

Monitor

25 watts (typical) ; 100-240 Volts, 50/60 Hz

Detector

75 watts; 100-240 Volts, 47-63 Hz, 0.5 to 1.25 Amps

Table 2 - Power requirements

3.2 SPACE AND WEIGHT SPECIFICATIONS

Workstation dimensions: 17.5 (H) x 7.75 (W) x 19.5 in (44 x 20 x 49.5 cm)

Workstation weight: 33.0 lb. (14.97 kg)

Detector Body dimensions 4.375 (W) x 4.375 (H) x 6.75 in (L) (110 x 110 x 165 mm)

Detector Weight 8 lb. (3.63 kg)

3.3 ENVIRONMENT REQUIREMENTS

Parameters

Operating Conditions

Temperature

+5C to +30C

Humidity

0% to 85% RH, non-condensing

Barometric Pressure

525 to 800mm of Hg

Air Velocity

0 to 0.5m/sec

Table 3 - Environment requirements / Operating conditions

Installation Requirements

Octane Basic User Guide

Page 12 of 25

This page is intentionally blank

Basic Detector Operation

Octane Basic User Guide

Page 13 of 25

4BASIC DETECTOR OPERATION

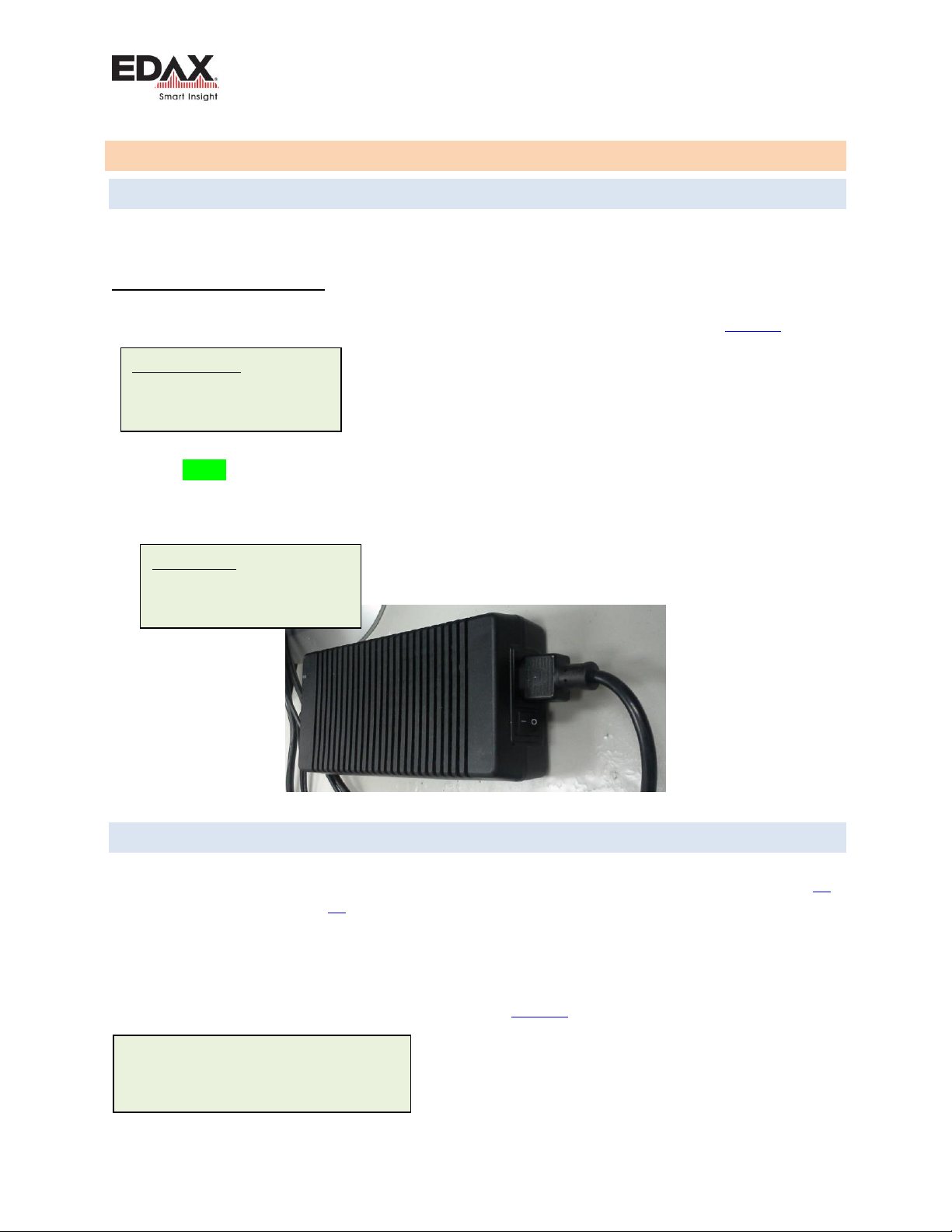

4.1 STARTUP

A minimum EDS configuration consists of a PC Workstation with a Ethernet connection for the detector,

and the Detector, with its external power supply.

Start up the system as follows:

1. Power on the PC Workstation. The default Windows Login from the EDAX Factory is:

2. Power on the detector using the switch on the small “brick” style power supply. Figure 1

The detector communication is normally established within a couple of minutes after the PC has started.

There is a Green LED that will flash at the Ethernet connection on the detector when connected to the

Network board in the PC. This should be flashing rapidly (i.e. 10 flashes) /sec and continuously.

Then launch the TEAM or Genesis software. By default, there is an Administrator login set up for TEAM.

Figure 1 - Detector Power Supply

4.2 DETECTOR COOLING

By default, detector cooling is “Off”until it is started by the user. When the cooling is started, either in

Genesis or in TEAM, the detector should cool down in about 2 minutes. See the status lights on Page 14

or software indicators on Page 15, to see the status of the cooling, and when the detector is ready to

use. Spectra can be collected after the detector reaches its operating temperature, but for optimal

performance and stable peak positions, it may be best to wait about 60 minutes.

Note that when using the detector, a few microscope conditions may need to be met, and may require

the user to manually acknowledging the status is OK. See Figure 3 for Safety Interlocks.

Windows Login:

User: Administrator

Password: apollo

TEAM Login:

User: Administrator

Password: apollo

A Windowless detector should only be

cooled when the microscope chamber

is in high vacuum!

Basic Detector Operation

Octane Basic User Guide

Page 14 of 25

4.2.1 STATUS LEDS

There are two status LEDs located on the back panel of the detector. They function as follows:

Status 1 LED

Indication

Status 2 LED

Indication

RED

Warm

RED

Not ramping

Blinks YELLOW

Cooling

Blinks YELLOW

Cooling

Blinks GREEN

Near Operating Temp

Blinks GREEN

Ramping

GREEN

At Operating Temp

Blinks RED

Warming

Table 4 - Status LEDs definitions

When the detector is first powered ON both Status lights on the detector back panel will light RED.

There is a Yellow LED that should be lit at the Ethernet connection when powered ON.

There is a Green LED that will flash at the Ethernet connection when connected to the

Network board in the PC. This should be flashing rapidly (i.e. 10 flashes /sec) and continuously

before starting the Genesis or TEAM software.

Figure 2 - Detector Status Lights

Status LEDs

Basic Detector Operation

Octane Basic User Guide

Page 15 of 25

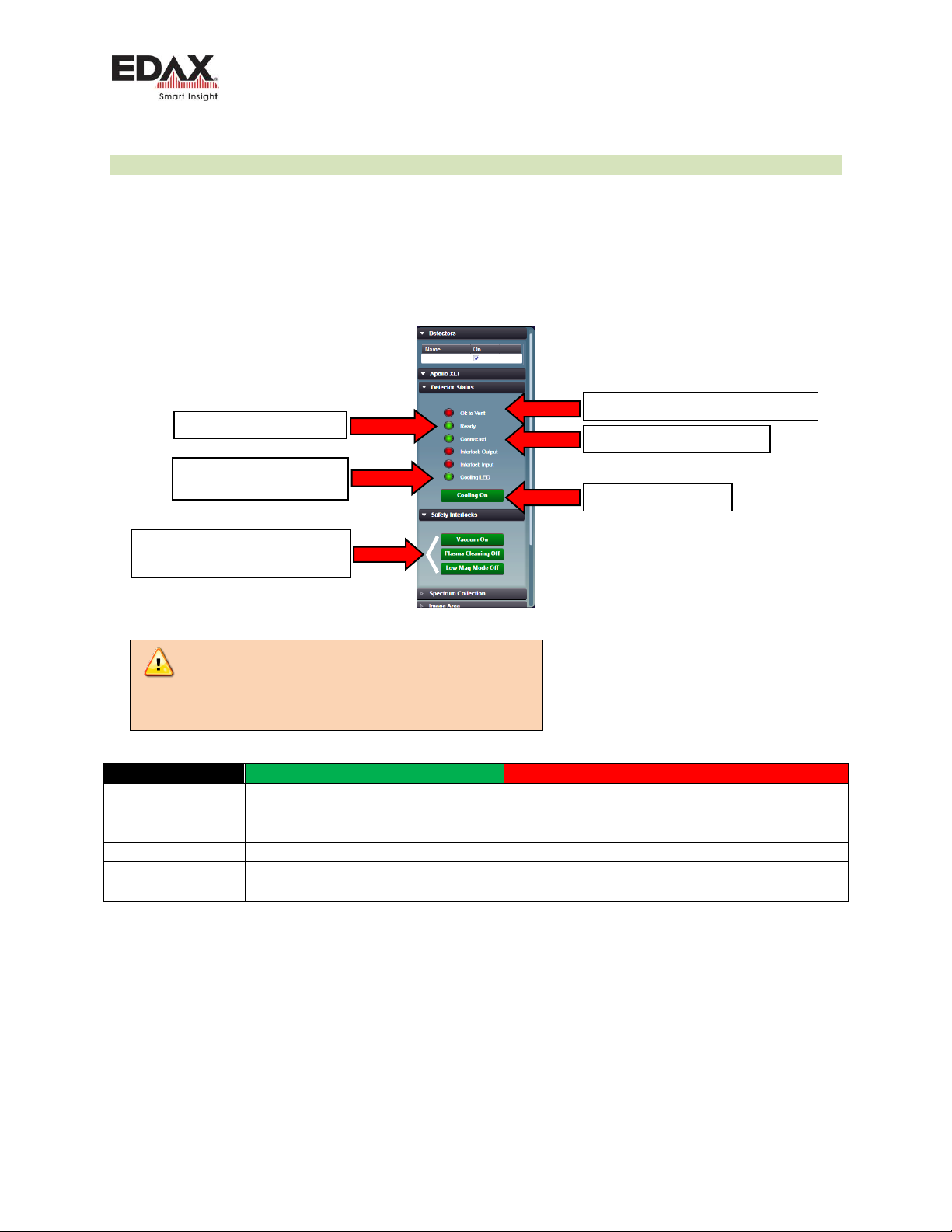

4.2.2 USING AN OCTANE DETECTOR WITH TEAM SOFTWARE

Check all detector functionality in the TEAM software. See the next section for Genesis software.

Turn the detector cooling on in the Detector Status area.

The detectors may be hardware or software interlocked with the microscope. Some or all may simply be software

buttons that the user must acknowledge that it is ok to cool the detector. Toggle each button so each Safety

Interlock is Green.

Figure 3 - Detector control and detector status in TEAM

Status Indicator

Green

Red

OK to Vent

DU is warm. OK to vent microscope

DU is cold. Not OK to vent microscope for Window-

less DU

Ready

DU is cold. OK to collect spectra.

DU is not ready to collect spectra

Connected

Communication with DU is OK

No communication with detector

Cooling LED

DU is cold, at Operating Temp

DU is Warm

Cooling On

Detector cooling is on

Detector cooling is off

Click on each to turn Green

All must be Green to turn cooling ON.

Click to turn on Cooling

This is the same as Status 1

LED on back of DU

Detector is communicating OK

DU ready to collect spectra

Detector is warm. OK to vent microscope

Care should be taken to warm a Windowless

detector before venting the microscope to air. Failure

to do so may damage the detector module!

Basic Detector Operation

Octane Basic User Guide

Page 16 of 25

4.2.3 USING AN OCTANE DETECTOR WITH GENESIS SOFTWARE

When a detector is used with the Genesis software, a small icon is placed in the Windows Task Tray that

provides control for the detector for cooling and driving the optional motorized slide.

The detectors may be hardware or software interlocked with the microscope. Some or all may simply be

software buttons that the user must acknowledge that it is ok to cool the detector. Toggle so each

Safety Interlock is Green.

Figure 4 - Detector control and detector status for Genesis

Click on each to turn Green

All must be Green to turn

cooling ON.

Click to turn on Cooling

This is the same as Status 1

LED on back of DU

Detector is communicating OK

DU ready to collect spectra

Detector is warm. OK to vent microscope

Care should be taken to warm a

Windowless detector before venting

the microscope to air. Failure to do

so may damage the detector

module!

Basic Detector Operation

Octane Basic User Guide

Page 17 of 25

4.3 MOTORIZED DETECTOR

If the detector is configured with a motorized slide, when a user wants to use the detector for analysis,

after cooling the detector, there will be a software control to insert the detector into the analyze

position. The control is in the TEAM software with the detector cooling controls, or in the Genesis

detector controls in the Task Tray.

Figure 5 - Motorized Slide Control

There are Slide controls in the TEAM Environment Panel as well as in the Advanced Properties Panel.

A detector with a motorized slide, will automatically retract from the Analyze position if it detects a high

count condition. This high count condition is normally set by the factory or installation service engineer.

The purpose is to protect the detector from high energy backscattered electrons in a TEM which can be

harmful to the detector. Under those conditions, the detector cooling may also be shut down.

4.4 ADDING TO COMPANY NETWORK

Care must be taken if the EDAX computer is added to a company network, the detector and its

Network Interface Card (NIC) IP information are NOT CHANGED. Changing any of the detector

networking configuration may cause the system to stop functioning.

EDAX service engineers will require Administrator login privileges to service the system.

The detector must be moved to the Analyze position to collect spectra and maps.

The detector should be moved to the Retract position when not in use.

Slide

Control

Retract the motorized slide detector before shutting down the system

Basic Detector Operation

Octane Basic User Guide

Page 18 of 25

4.5 LIGHT ELEMENT OPERATION

1. Check that the geometry is correct when collecting spectra. For example, an incorrect tilt used,

giving an incorrect Take Off Angle, will affect the Quant results. You can also correct this after

the data has been collected by editing the spectra file parameters.

2. Check that you are using a well-defined peak when quantifying. Avoid using peaks that are

“buried” in the background.

3. Use one of the longer amp times when specifically looking for light energy elements. They

typically provide better light element performance.

4. Use low accelerating voltage when specifically looking for light energy elements.

3. Make sure the samples are flat and homogeneous when possible.

4. Collect for sufficient time to improve the statics when the peaks are very small, for example

when looking at Boron.

4.6 FREQUENTLY ASKED QUESTIONS (FAQ)

Q1. Should I leave the detector powered on all of the time?

A1. In most laboratory conditions (stable power, temperature controlled), leaving the detector powered

on all of the time is fine.

Q2. Should I leave the detector cold all of the time?

A2.The detector will reach operating temperature in about two minutes, so it does not need to be left

cooled when not in use. Spectra can be collected after the detector reaches its operating temperature,

but for optimal performance and stable peak positions, it may be best to wait about 60 minutes. It is

okay to leave the detector cold when the microscope chamber is left under vacuum. There is a user

preference option in the software to automatically turn the cooling off after inactivity, in case the user

prefers to turn the cooling off automatically.

Q3. The software displays a message that the detector temperature is not changing, or a

communication problem with the detector. What should I do?

A3. In this case, power off the detector using the switch on the small black power “brick” for the

detector then reboot the PC. Then power the detector back on after Windows has started.

Q4. How often should I calibrate?

A4. Many labs only calibrate their systems during a regularly scheduled service preventative

maintenance visit. The detector will need to be calibrated in some cases when then spectrum peaks do

not match the blue line modeled peaks. For this case, a calibration will bring the peaks into alignment

with the modeled line. In other cases, labs may want to set a regular calibration schedule any time from

weekly to monthly.

Q5. What count rate should I use to calibrate?

A5. We recommend using a copper and aluminum sample with a primary beam at ≥ 20 kV. Adjust the

sample position so both Copper and Aluminum can be seen on the same screen. Set the position so the

Copper and Aluminum Kα peaks are similar in height, but with the Al peak larger than the CuK peak by

20 to 50%. Set the beam conditions so the Dead Time is ≤ 40% as you should use during normal use.

Basic System Cabling

Octane Basic User Guide

Page 19 of 25

5BASIC SYSTEM CABLING

5.1 TYPICAL WORKSTATION CONFIGURATION

Figure 6 - PC Workstation Connections

Power Supply

Air Flow

Hard drive

USB Restore

SG-3 Board

Fan

Air Flow

Internal Sync cable

Sync Panel

Network Board

Card bracket

Microscope

Beam Interface

cable

Ethernet cable

Sync cable

(RJ11)

Octane detector

Basic System Cabling

Octane Basic User Guide

Page 20 of 25

5.2 TYPICAL MICROSCOPE SYSTEM CONFIGURATION (SG-2)

Figure 7 - Typical System Connections (SG-2)

EDAX PC

Mains

Mains

Cable - 4035.008.07290

Monitor

NIC (PCIe)

2735.171.30939

IP. 192.168.0.101

SYNC (PCIe)

5335.007.28300

SG-2 (PCI)

5335.007.20000

Mains

24V

Power Supply

2735.171.31074

Microscope

Octane

IP. 192.168.0.100

NIC

IP ###.###.###.###

Microscope PC

IP ###.###.###.###

Ethernet cable

2435.072.44045R

Sync cable

4035.008.10900

Ferrite

For Column control and/or Network

Beam control cable -Microscope model dependent

4035.008.#####

24V

100-240V

100-240V

100-240V

J1

J5

Printer

(optional)

100-240V

Mains

This manual suits for next models

1

Table of contents

Other Metek UPS manuals