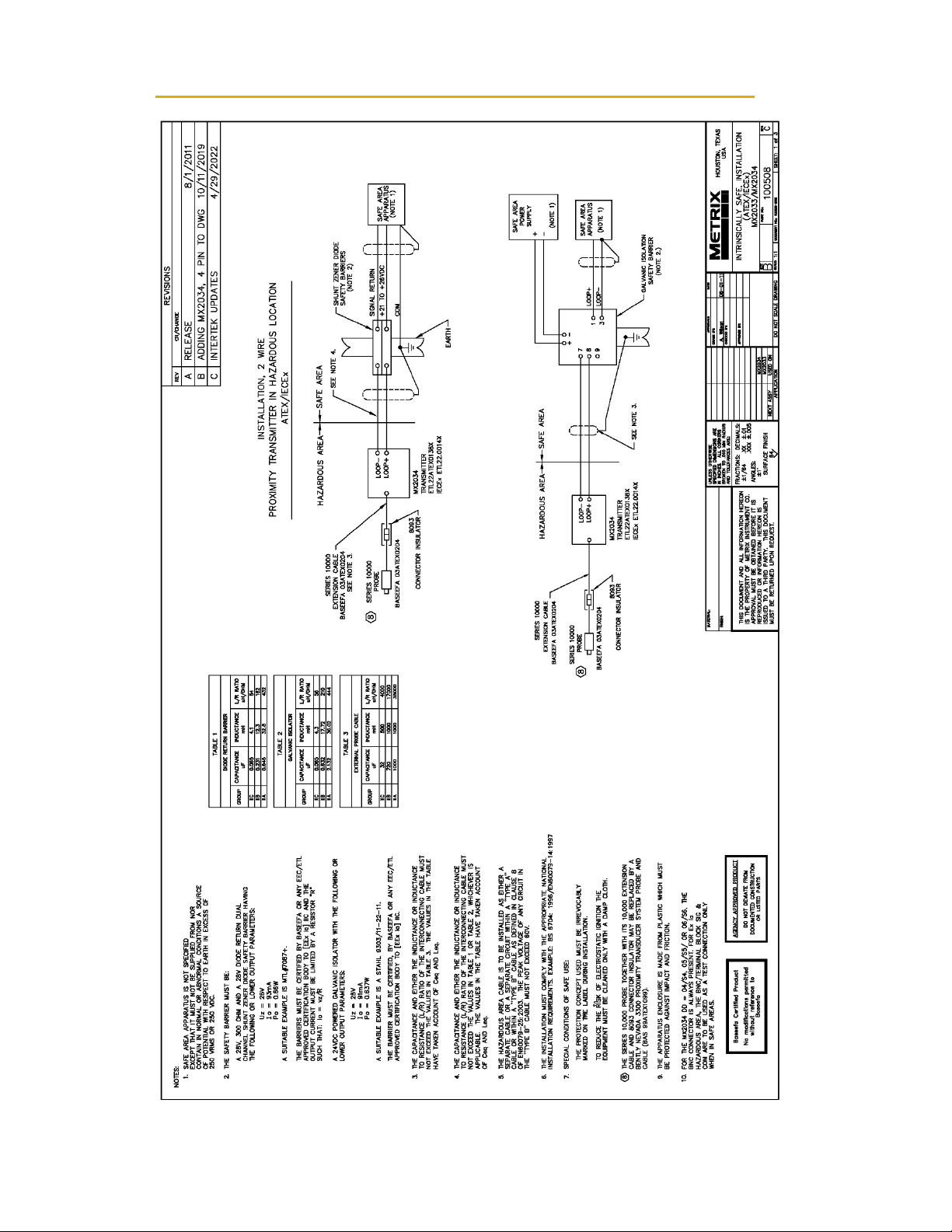

Hazardous Area Installation Manual

MX2033 and MX2034 Digital Proximity System

Document 1232961

Rev. E (April 2022)

1. Overview

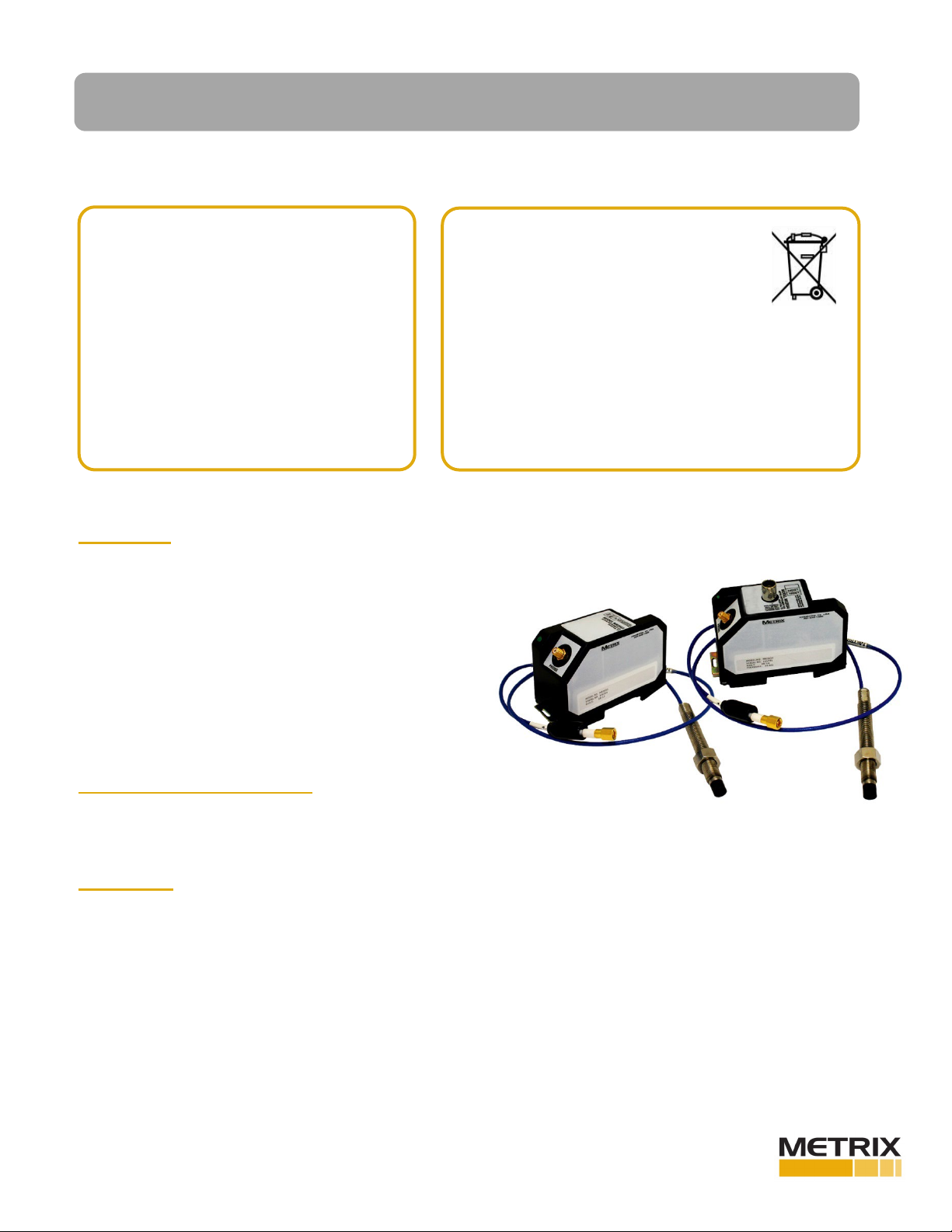

The Digital Proximity System (DPS) provides the performance of a

fully API 670-compliant eddy-current proximity measurement system

with the flexibility of digital programmability. For the first time, users

have the ability to easily select their transducer system in the field

from pre-programmed calibrations for a variety of probe tip

diameters, manufacturers, extension cable lengths, target materials,

and linear ranges.

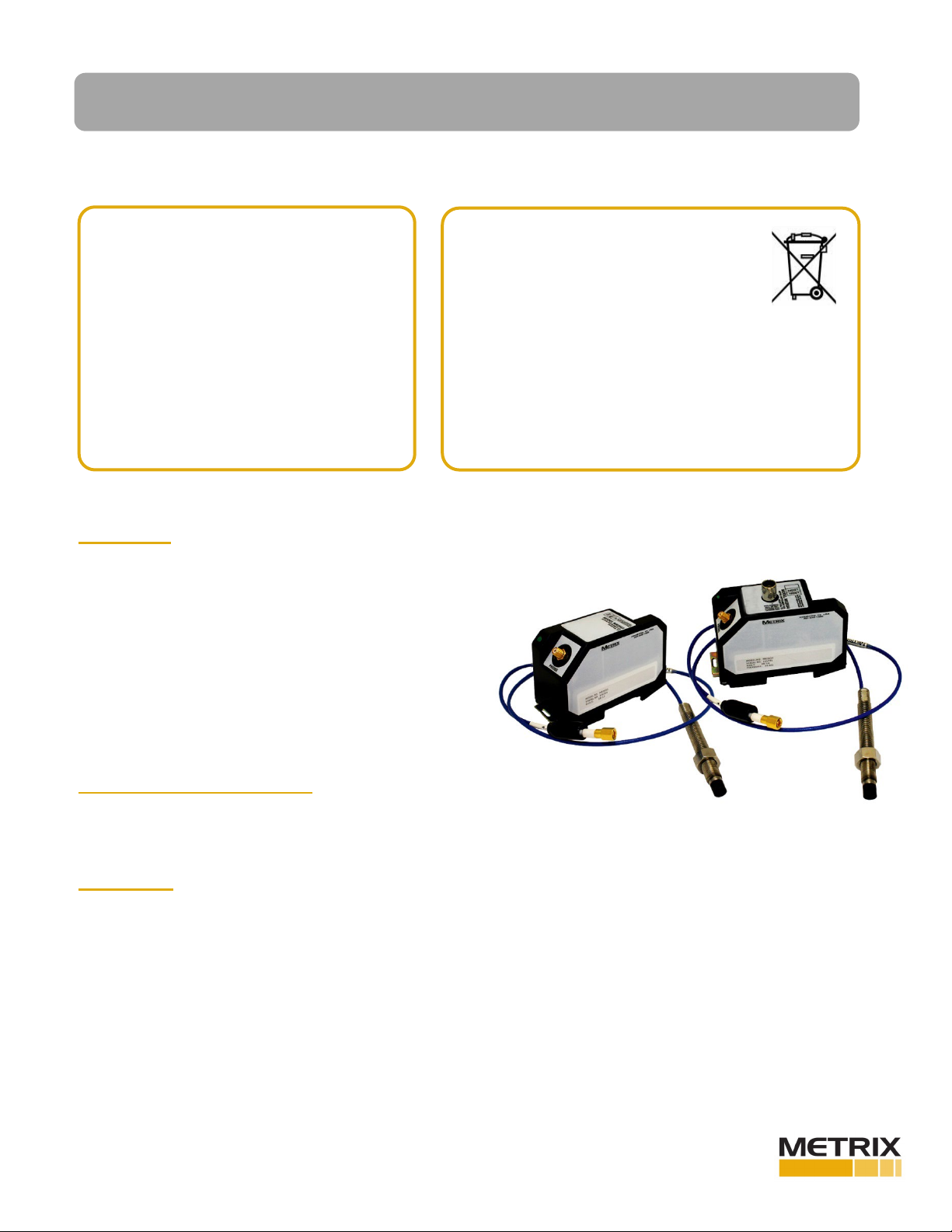

A Digital Proximity System consists of a probe, extension cable, and

MX2032, MX2033 or MX2034 DPS signal conditioner.

2. Supplementary Information

Refer to Product Datasheet 1087015, Installation Manual 100545, and Operation & Maintenance Manual 100576. These are available at

www.metrixvibration.com.

3. Mounting

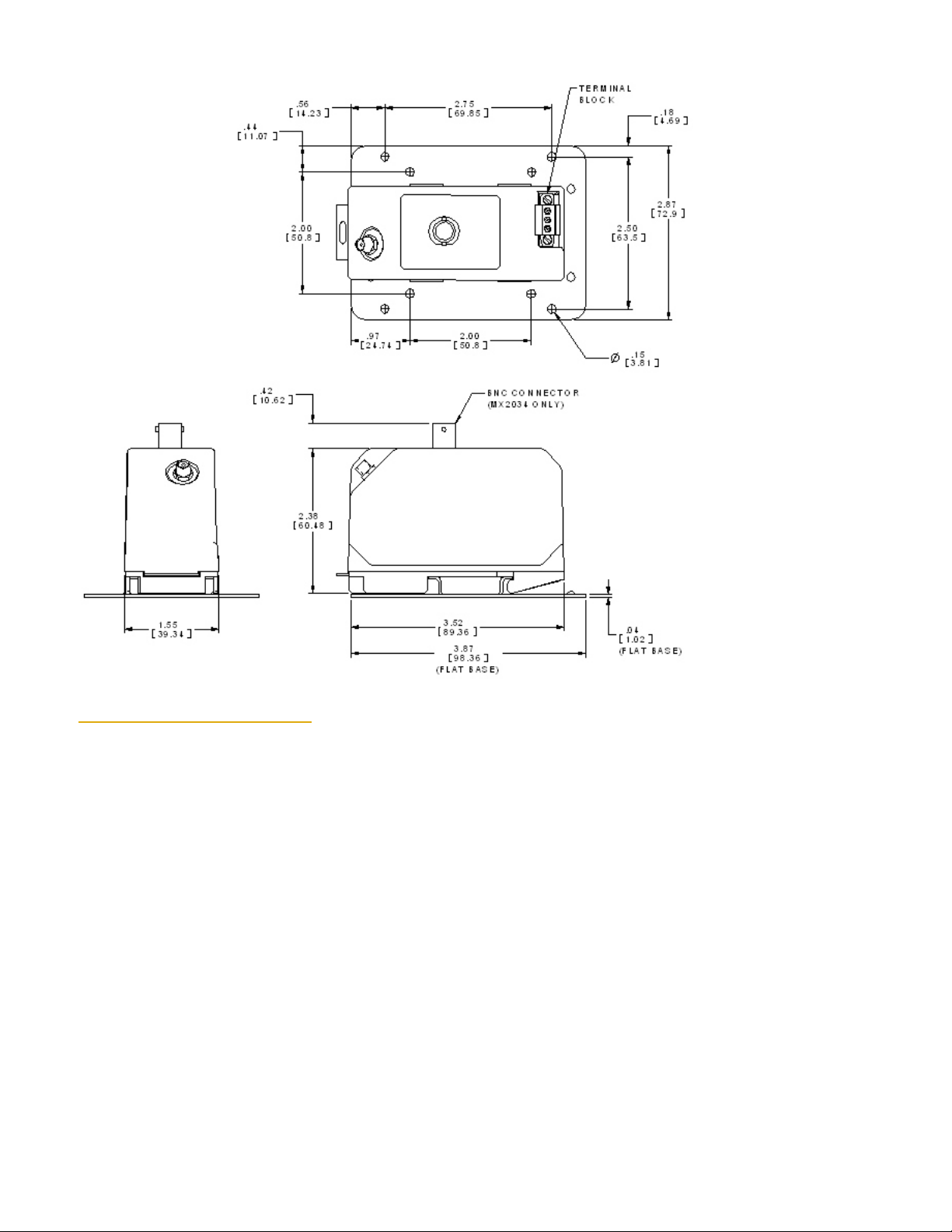

Mount the DPS in a suitable enclosure in a location that is compatible with its environmental specifications (See Datasheet 10870151). The

driver or transmitter comes as a DIN rail mount. The below figure shows the unit with the optional flat base mounting plate, part number

9647. The 9647 mounting plate has two different hole patterns. One is for Metrix 5465/5488 transmitters and the other pattern is for Metrix

5533, MX3300 and most other manufacturers’ probe drivers.

Before proceeding to wire and install the Model

MX2033 or MX2034 Digital Proximity System (DPS),

read and thoroughly understand these instructions.

They are intended for experienced personnel who

require only basic installation guidance, and

assume that the DPS has already been selected and

applied properly for the machinery at hand. Please

contact Metrix or its local representative for

additional assistance. See also section 2 of this

manual for additional technical resources available

free-of-change on our website at

www.metrixvibration.com

This electronic equipment was manufactured

according to high quality standards to ensure safe

and reliable operation when used as intended.

Due to its nature, this equipment may contain small

quantities of substances known to be hazardous

to the environment or to human health if released into the

environment. For this reason, Waste Electrical and Electronic

Equipment (commonly known as WEEE) should never be

disposed of in the public waste stream. The “Crossed-Out Waste

Bin” label affixed to this product is a reminder to dispose of this

product in accordance with local WEEE regulations. If you have

questions about the disposal process, please contact Metrix.