Mex MPC-1054-FV User manual

MEX MPC-1054-FV

MPS-1054-FV

Water Purifier

MPC-1054-FV/MPS-1054-FV

Installation & Operation

Instruction Manual

User Installation and Instruction;

Model FV-10005 MANUAL FILTER

VALVE

THAI/ENG

2

PEN K INTER TRADIND CO., LTD.| TH

-

–

FV-10005 ………………………………………………………………………………………………………………………………………. –

TH| PEN K INTER TRADING CO.,LTD.

3

–

–

4.98–71.12psi (0.35 –5.0 )

%

PTFE)

4

PEN K INTER TRADIND CO., LTD.| TH

(

-

–

–

%

TH| PEN K INTER TRADING CO.,LTD.

5

Service@ 4.99 psi ……………………………………………………………………………………. 8.8

Backwash@ 4.99 psi ………………………………………………………………….…. 8.8

Fast Rinse@ 4.99 psi ……………………………………………………………………………. 8.8

1/2 –,

..... BSPF,

..... BSPF,

BSPF,

–……………………. 4.98-71.12 psi (0.35–5.0 )

……………………………...……………… - oF (- )

……………….…………………… - oF (- )

6

PEN K INTER TRADIND CO., LTD.| TH

TH| PEN K INTER TRADING CO.,LTD.

7

riser riser

bottom distributor)

2. riser

riser riser riser

Manual

Manual riser Manual

Service, Backwash Rinse

2.

MPC-1054-FV MPS-1054-FV

MPC-1054-FV MPS-1054-FV

Bypass valve

8

PEN K INTER TRADIND CO., LTD.| TH

adapter fitting)

½

1. Service

Backwash-

B’WASH Backwash

Backwash

Rinse

Service

TH| PEN K INTER TRADING CO.,LTD.

9

10

PEN K INTER TRADIND CO., LTD.| TH

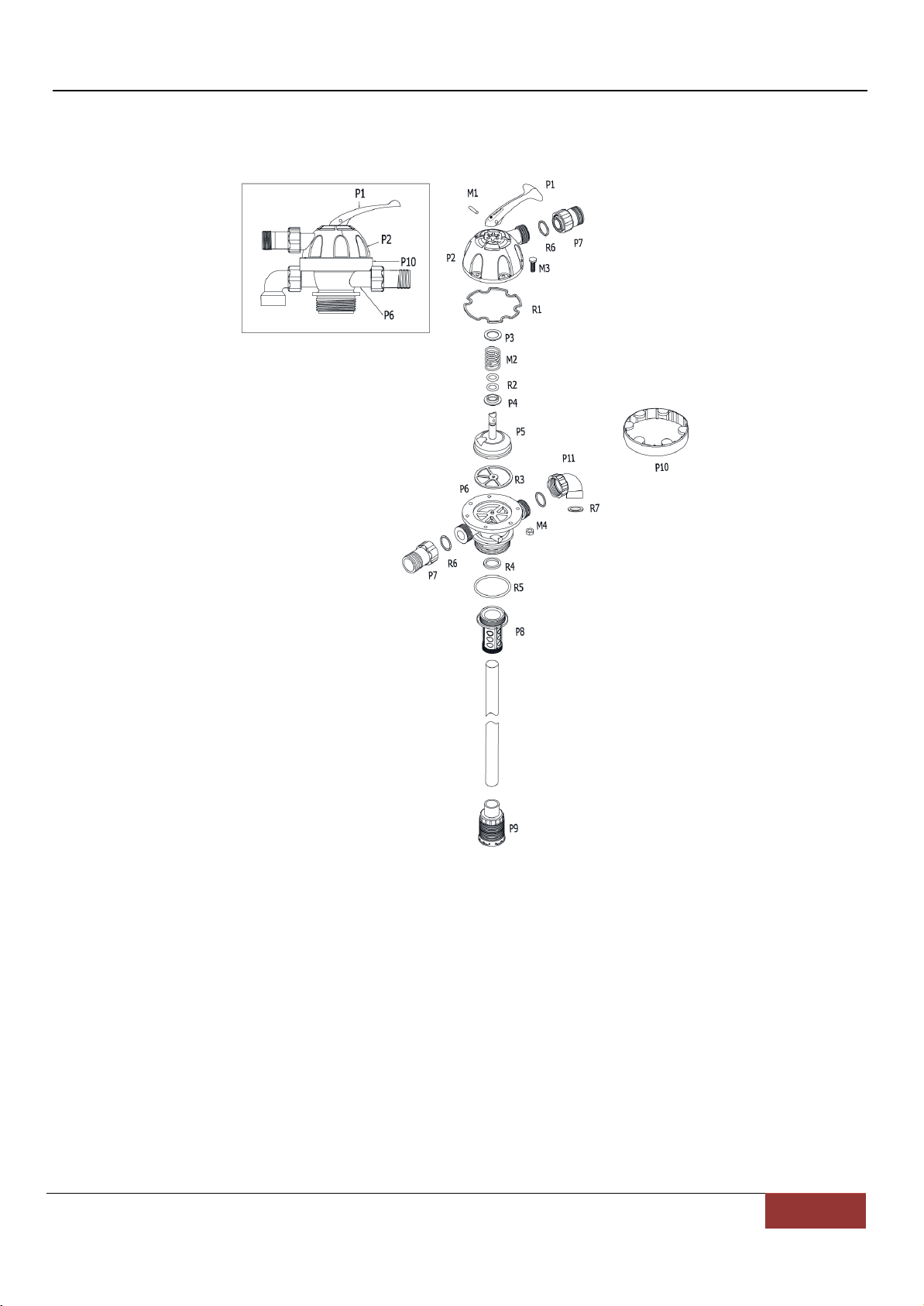

Part No.

1

P1

2

P2

3

P3

4

P4

5

P5

6

P6

7

P7

8

P8

9

P9

10

P10

11

P11

12

M1

13

M2

14

M6x25

M3

15

M6

M4

16

R1

17

R2

18

R3

19

R4

20

R5

21

R6

22

R7

TH| PEN K INTER TRADING CO.,LTD.

11

1

, ,

*

--

Oxidation agent (, ,

12

PEN K INTER TRADIND CO., LTD.| TH

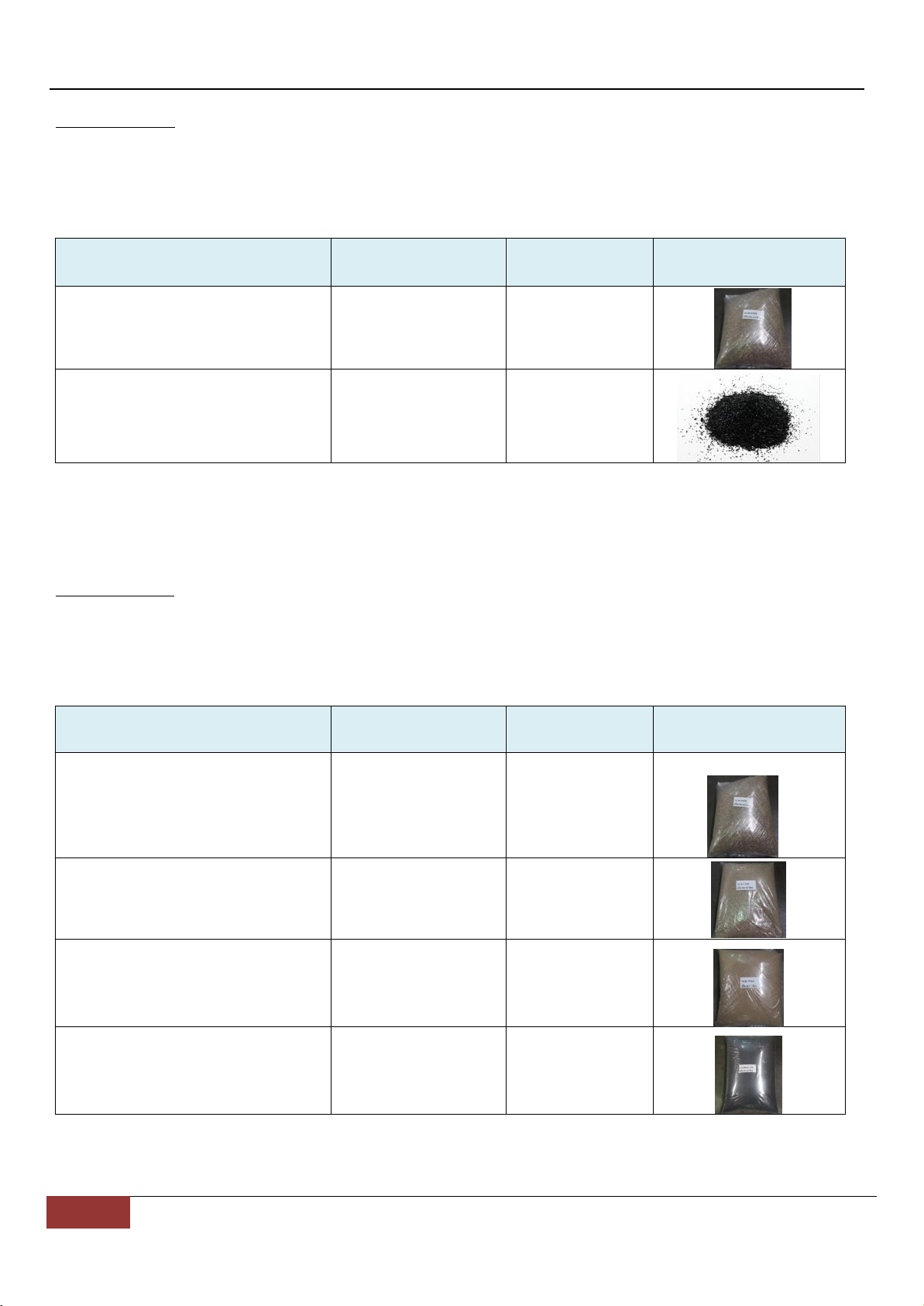

: MPC-1054-FV

(Media)

4 (Gravel 4 mm)

6.5

115.00

(Activated Carbon)*

20

,20

* MPC-1054-FV

: MPS-1054-FV

(Media)

4 (Gravel 4 mm)

6.5

115.00

2 (Gravel 2 mm)

10

(Sand No.0)

(Anthracite)

515.00

2

PEN K INTER TRADING CO.,LTD. |ENG

CONTENT

Safety Information ......................................................................................................................................................................................... 3 - 4

Typical Tools and Fittings Required ............................................................................................................................................................. 4

Specifications ..................................................................................................................................................................................................... 5

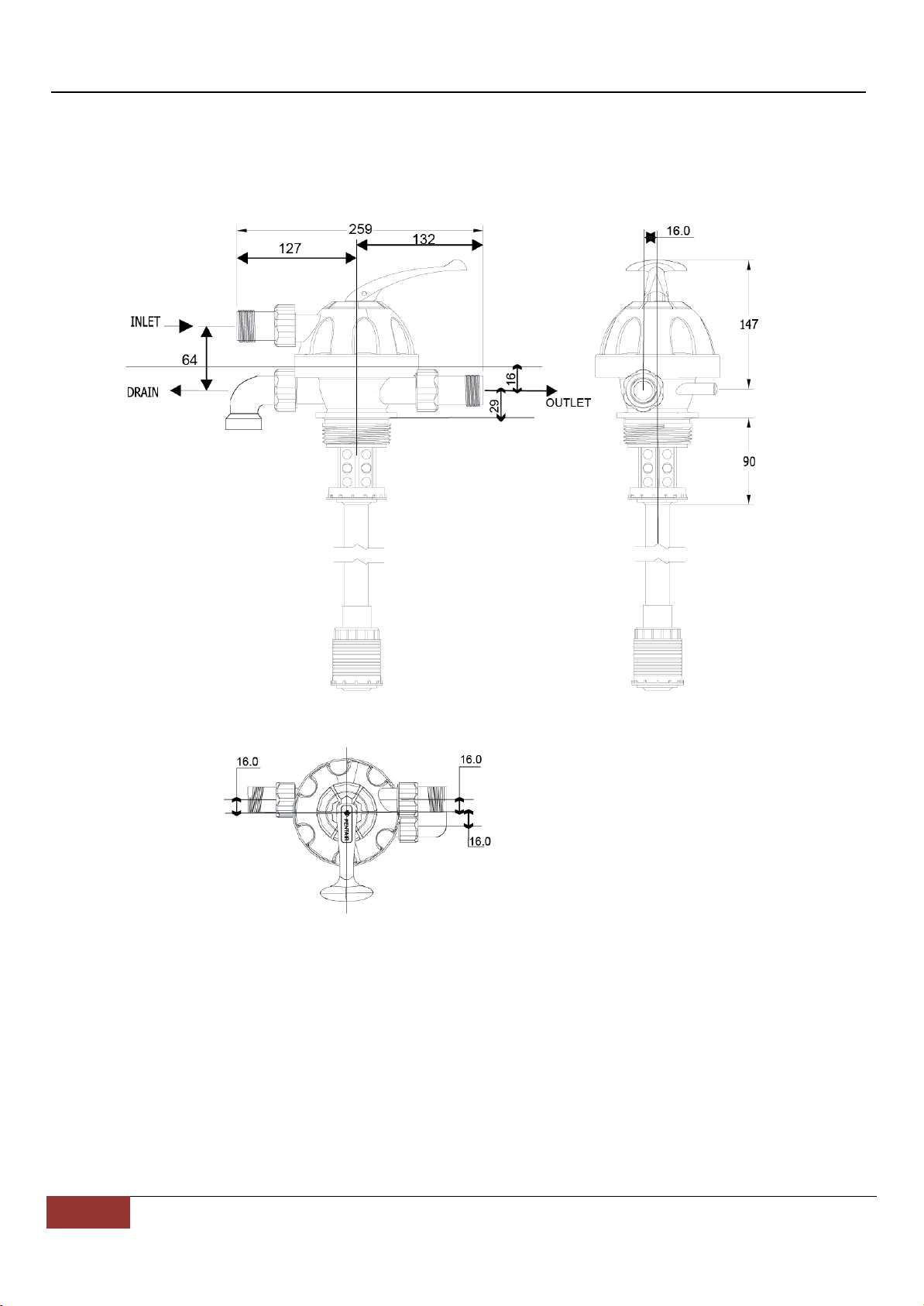

Valve Dimension and Valve Layout ............................................................................................................................................................. 6

Equipment Installation .................................................................................................................................................................................... 7

Operation of valve ........................................................................................................................................................................................... 7

Installation Procedure ……………………………………………………………….……………………………………………………………………….…………………….. 7 - 8

Operation ………………………………………………………………………………………………………………………………………………………………………………….… 8

Valve Assembly Model FV-10005 ………………………………………………………………………………………………………………………………..………. 9 –10

Warranty Terms and Conditions ………………………………………………………………………………………………………………………………………………... 11

Media …………………………………………………………………………………………………………………………………………………………………………………………… 12

PEN K INTER TRADING CO.,LTD. |ENG

3

Safety Information

General

Observe all warnings that appear in this manual.

This system is not intended to be used for treating water that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

Keep the unit in the upright position. Do not turn on side, upside down, or drop. Turning the tank upside down

will cause media to enter the valve.

Operating ambient temperature is between 34°F (1°C) and 120°F (49°C).

Operating water temperature is between 34°F (1°C) and 100°F (38°C).

Working water pressure range is 4.98 to 71.12 psi (0.35 to 5.0 bar).

Follow state and local codes for water testing.

When filling media tank, do not open water valve completely. Fill tank slowly to prevent media from exiting the

tank.

Always make modifications to house plumbing first. Connect to valve last.

Mechanical

All plumbing must be completed according to local codes.

Observe local drain line requirements.

Do not use petroleum-based lubricants such as petroleum jelly, oils, or hydrocarbon-based lubricants. Use only

100% silicone lubricants.

All plastic connections should be hand tightened. Plumber tape should be used on connections that do not use

an O-ring seal. Do not use pliers or pipe wrenches.

Soldering of the plumbing should be done before connecting to the valve. Excessive heat will cause interior

damage to the valve.

Do not use lead-based solder for sweat solder connections.

Do not support the weight of the system on the control valve fittings, plumbing, or the bypass.

It is not recommended to use sealants on the threads. Use plumber tape (PTFE) on all threads.

4

PEN K INTER TRADING CO.,LTD. |ENG

Safety Information (Cont.)

Location Selection

Location of a water treatment system is important. The following conditions are required:

Level platform or floor.

Total minimum pipe run to water heater of ten feet (three meters) to prevent backup of hot water into system.

Local drain or tub for discharge as close as possible.

Water line connections with shutoff or bypass valves.

Room to access equipment for maintenance.

Outdoor Locations

It is recommended that the equipment be installed indoors. When the water conditioning system must be installed

outdoors, several items must be considered.

Direct Sunlight —The materials used will fade or discolor over time in direct sunlight. The integrity of the

materials will not degrade to cause system failures.

Temperature —Extreme hot or cold temperatures may cause damage to the valve or controller. Freezing

temperatures will freeze the water in the valve. This will cause physical damage to the internal parts as well as

the plumbing.

Typical Tools and Fittings Required

Pipe Cutter

Tubing Cutter

File

Pliers

Tape Measure

Soldering Tools

Lead Free Solder

Bucket

Towel

Plumber Tape

Adjustable Wrench

Tube 100% Silicone Grease

PEN K INTER TRADING CO.,LTD. |ENG

5

Specifications

Flow Rates (Valve Only)

Service @ 4.99 psi ……………………………………………………………………………………………………………………………………………. 8.8 gpm (33.33 lpm)

Backwash @ 4.99 psi ………………………………………………………………………………………………………………………….……………. 8.8 gpm (33.33 lpm)

Fast Rinse @ 4.99 psi ………………………………………………………………..……………………………………………………….……………. 8.8 gpm (33.33 lpm)

Valve Connections

Tank Thread .................................................................................................................................................. 2 1/2 inch (63.5 mm.) – 8, male

Inlet Thread ....................................................................................................................................................... 1 inch (22.5 mm.) BSPF, male

Outlet Thread ................................................................................................................................................... 1 inch (22.5 mm.) BSPF, male

Drain Line ........................................................................................................................................................... 1 inch (22.5 mm.) BSPF, male

Distributor Tube Diameter ........................................................................................................................................................ 1 inch (25 mm)

Design Specifications

Operating Pressure ............................................................................................................................................. 4.98-71.12 psi (0.35–5.0 bar)

Water Temperature ................................................................................................................................................................ 34-100°F (1-38°C)

Ambient Temperature*........................................................................................................................................................... 34-120°F (1-49°C)

* Recommended for indoor use only

6

PEN K INTER TRADING CO.,LTD. |ENG

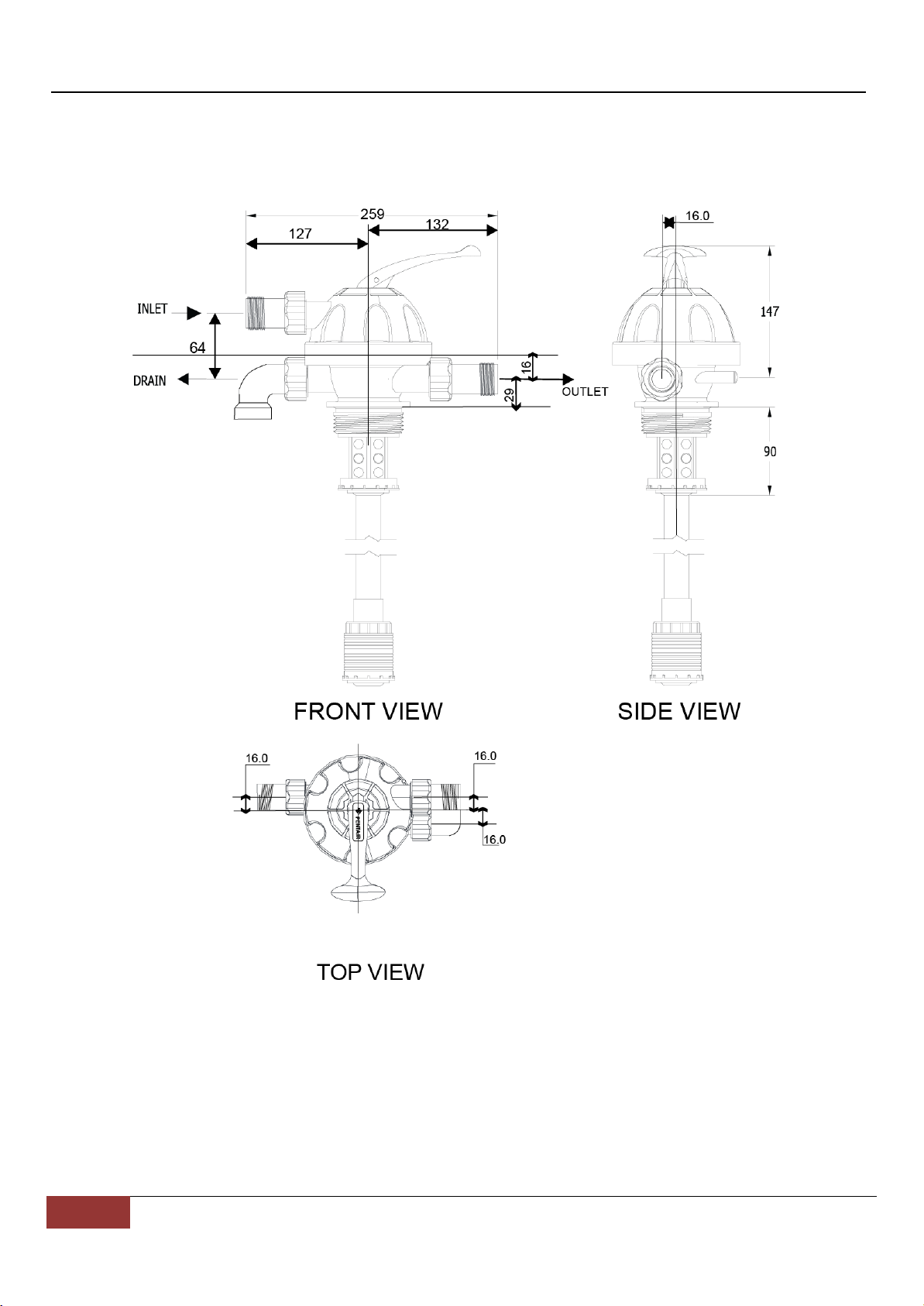

Valve Dimension and Valve Layout

Figure 1 Valve Dimension and Valve Layout

PEN K INTER TRADING CO.,LTD. |ENG

7

Equipment Installation

1. Take a 20NB Rigid PVC riser pipe, approximately the height of the vessel and solvent cement the bottom distributor to

one end of the pipe.

2. Insert this riser pipe into the vessel and cut the pipe from the top ensuring that the height of the pipe (with the

distributor touching the bottom) is the same as the top of the vessel.

3. Pour gravel and then filter media into the vessel. Cover the mouth of the riser pipe while doing this so that media

doesn't enter the pipe. Align the riser pipe so that it is in the Centre of the vessel opening.

4. Screw on the top distributor to the bottom of the MPV.

5. Screw on the MPV to the vessel ensuring that the riser pipe goes through the top distributor into the MPV.

6. Make the inlet, outlet and drain connection.

Operation of Manual valve

1. Always press the handle down before turning the handle to the desired position viz. Service, Backwash or Rinse.

2. If the line pressure is more, it is advisable to close the inlet valve before turning handle.

Installation Procedure

The following installation procedures shall be carried out by a qualified person. Read the installation and operation

manual carefully.

Installation

1. Place the MPC-1054-FV or MPS-1054-FV system where you want to install the unit.

2. Turn off the mains water supply.

3. Connect the inlet and outlet pipe of the system correctly using piping of the suitable diameter.

4. Cut a section of plastic hose of desired length. Connect it to the drain line of the system and fasten with hose hoop.

The other end of the hose runs to a drain and is secured in place.

5. Manual valve shall be installed at the inlet/outlet of the MPC-1054-FV or MPS-1054-FV system. A bypass valve is

recommended to be installed between the inlet and outlet of the system so that normal usage of water is not affected

during the maintenance of the system.

8

PEN K INTER TRADING CO.,LTD. |ENG

Drain line connection

Note: Standard commercial practices are expressed here. Local codes may require changes to the following suggestions.

Check with local authorities before installing a system.

1. The unit should be above and not more than 20 feet (6.1 m) from the drain. Use an appropriate adapter fitting to

connect 1-inch plastic tubing to the drain line connection of the control valve.

2. Where the drain line is elevated but empties into a drain below the level of the control valve, form a 7-inch (18 cm)

loop at the far end of the line so that the bottom of the loop is level with the drain line connection. This will provide an

adequate siphon trap. Tie or wire the hose in place at the drain point. Also provide an air gap of at least 1½ inch between

the end of the hose and the drain point.

3. Where the drain empties into an overhead sewer line, a sink-type trap must be used.

4. Secure the end of the drain line to prevent it from moving.

Figure 2 Drain Line Connection

NOTE: Waste connections or drain outlet shall be designed and constructed to provide for connection to the sanitary

waste system through an air gap of two pipe diameters or one inch (22 mm), whichever is larger.

WARNING: Never insert drain line directly into a drain, sewer line, or trap (Figure 2Drain Line Connection).

Always allow an air gap between the drain line and the wastewater to prevent the possibility of sewage being back-

siphoned into the filter.

Operation

1. Get started, Always press the handle down before turning the handle to the service position to filter the water.

2. You should be backwash after 1-3 days to clear the dirt from the filter. Always press the handle down before turning

the handle to the B'WASH position. Take 40 minutes to backwash.

3. After backwashing, wash for 20 minutes with the handle down before turning the handle to the Rinse position.

4. Then always press the handle down before turning the handle to the service position to filter the same.

PEN K INTER TRADING CO.,LTD. |ENG

9

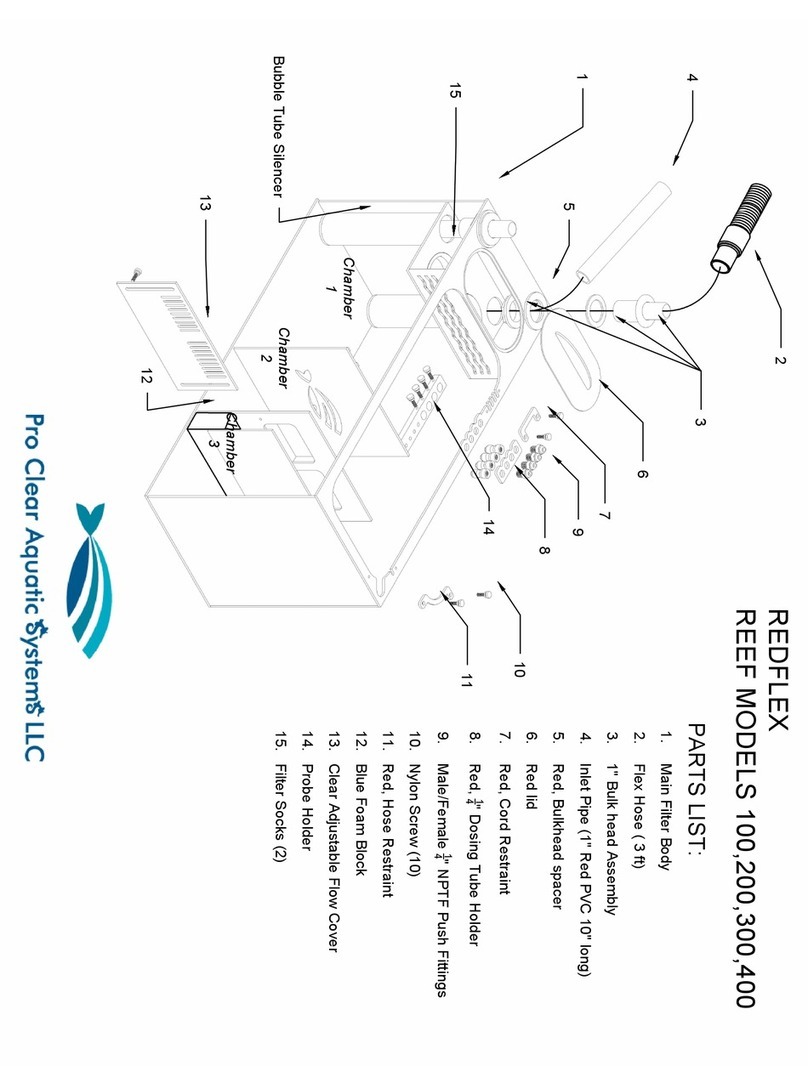

Valve Assembly Model FV-10005

Figure 3 Valve Assembly Model FV-10005

This manual suits for next models

1

Table of contents

Languages:

Popular Water Filtration System manuals by other brands

Emerson

Emerson A-W instruction sheet

Deltec

Deltec MCE 600 Operating instructions and spare parts list

First Choice

First Choice PRO CLEAN PCCF-075 owner's manual

KENT

KENT Grand+ Mineral RO Instruction handbook for installation, operation and maintenance

Pro Clear Aquatic Systems

Pro Clear Aquatic Systems REDFLEX REEF instructions

Fiberplex

Fiberplex Waveguide WGF-6 user manual