meywalk 2000 User manual

2

These instructions for use contain information on the assembly and adjustment of

MEYWALK® 2000, how to maintain it, things to watch out for and other important

items.

Introduction 3

Prior to first use 4

Joining the top part and bottom frame 4

Mounting af accessories 4

Adjustment af basic model 4

Trunk support and seat height 4

Trunk support locking 5

Spring Loading 5

Seat position and angle 5

Rea stop 6

Handelbar 6

Getting in and out 6

Use of brakes 6

Adustment af brakes 6

Mounting an Adjustmedt of Accessories 7

Height reduction fitting 7

Anti-tip supports 7

Swivel lock on front casters 8

Leg separation plate 8

Leg guides 9

Hip-pads 9

Mounting and use of drag brakes 10

Mounting and use of non-reserve brakes 10

Sefety precautions 11

Warning 11

Limitations on use 11

CE-marking 11

Checking for tightness 11

Maintenance 11

Technical data 12

Contens

3

Introduction

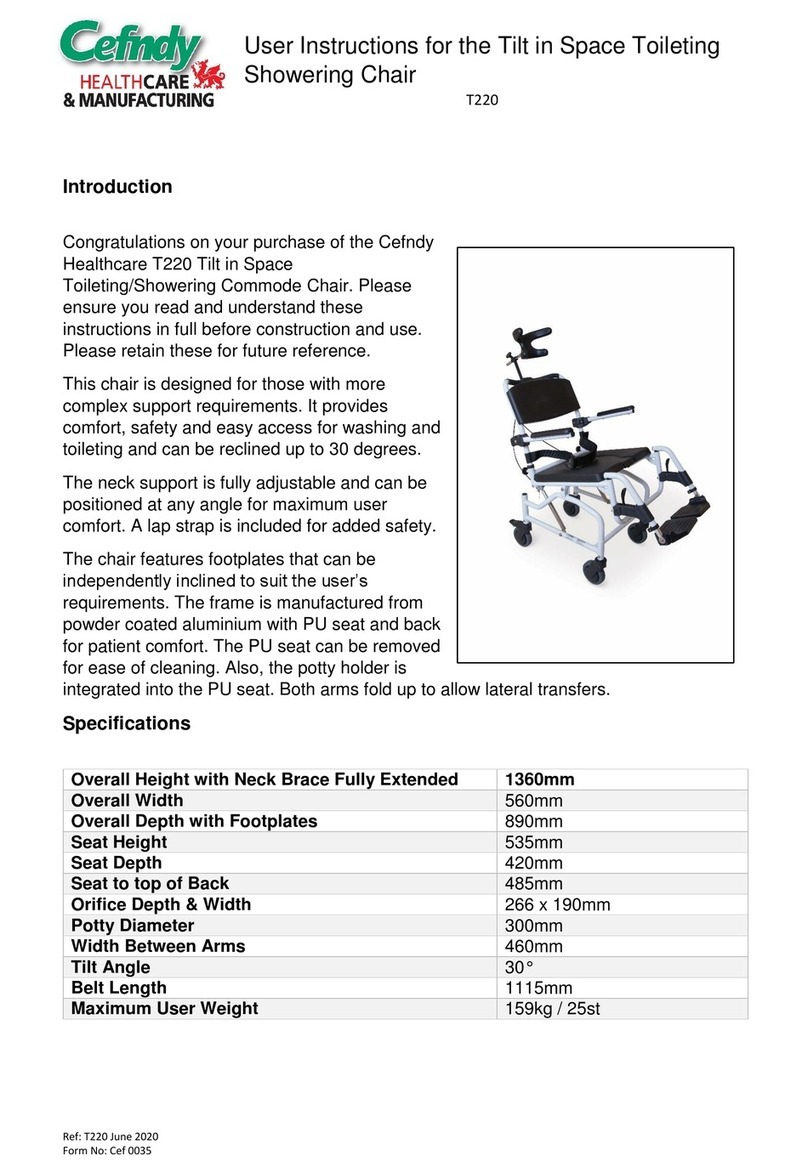

MEYWALK® 2000 Small, Medium

and Large are walking aids suitable

for children from about 6 years old

right up to adults, height from proxim-

ately 120 cm (47”) to 200 cm

(78”). MEYWALK® 2000 is intented

for walking disabled who cannot

stand up without support from a seat.

MEYWALK® 2000 can be adjusted to

give a good and individually fitted

support. The trunk support gives sup-

port to keep the torso upright

and makes the user feel safe. The

rear stop prevents the user from

sliding off the seat, and the handlebar

gives support to the arms. Using the

integral lifting and lowering

system the seat unit can be brought

down to the height of a wheelchair

seat, making it quick and easy to

transfer the user over to the MEY-

WALK® 2000 and raise them

up again. Both user and helper will

find it much less tiring to get in and

out of the MEYWALK® 2000 than

other walking aids. Due to the large

wheels MEYWALK® 2000 is suitable

for both indoors and outdoors use.

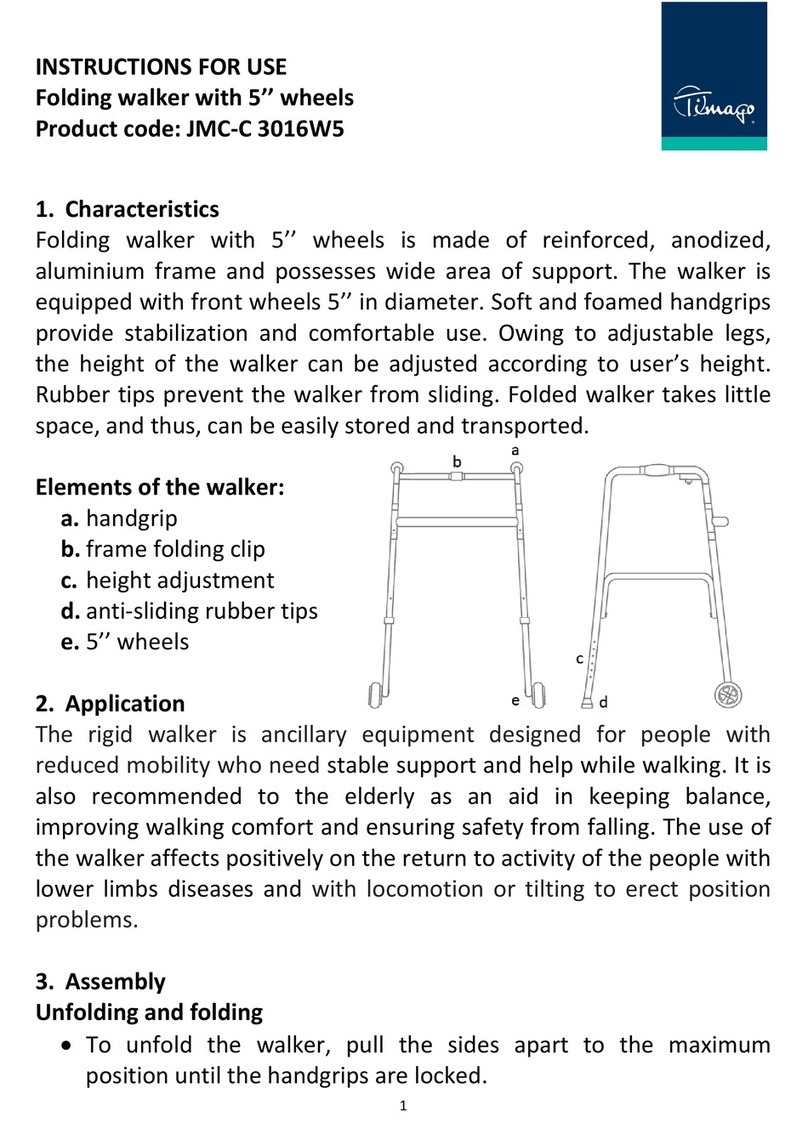

The Figure shows the names of some

of the different parts of MEYWALK®

2000 referred to in the text.

Meywalk

®

2000

: :

Trunk support

: : Handlebar

: : Upper tube

: : Height marking

: : Cone

: : Seat tube

: : Spanner grip

: : Rear stop

: : Lower tube

: : Tilt bar

: : Locking button

: : Fender wheel

: : Swivelling front wheel

: : Brake

: : Rear wheel

4

Prior to first use

Prior to first use MEYWALK® 2000 is

supplied almost fully assembled.

Check that the package contains the

following parts:

: : Bottom frame with wheels and bra-

kes etc.

: : Top part with seat and trunk sup-

port etc.

Note that a 5 mm and a 6 mm Allen

key is supplied with MEYWALK®

2000. This is located under the

rear stop.

Joning the top part and bottom

frame:

Place the two springs in the top of

the down tubes on the bottom frame

and fit the top part into the two down

tubes on the bottom frame.

Remember to position the top part so

the handlebar is in direction towards

the swiveling front wheels.

Mounting af accessories:

A description of how to mount acces-

sories, both those supplied with the

walking aid and those acquired later,

is given in the section: “Mounting and

adjustment of accessories”.

Trunk support and Seat height:

Note that the seat height will be al-

tered when the height of the trunk

support is altered.

The height of the trunk support and

the seat is adjusted according the

rulers on each side of MEYWALK

®

2000. Both adjustments are double

secured. The spanner grips can easi-

ly withstand the load alone, but the

adjustments can be extra

secured with the Allen screws. This

extra securing can be useful when

MEYWALK

®

2000 is used by only

one user or if there is a risk that

“a busybody” loosens the spanner

grips.

The height of the trunk support is al-

tered by loosening the bottom two

Allen screws and then the bottom

two spanner grips. This enables

the two rings to be slid up or down

the upper tubes. Place the rings at

the desired height using the height

markings to ensure they are at the

same height on both sides. At last

retighten the spanner grips (and if

necessary Allen screws).

Set the seat height in the same way

by loosening the top two Allen screws

and then the top two spanner grips.

This enables the seat tube to be slid

up or down the upper tubes. Place

the seat tube at the desired height

using the height markings to ensure it

is at the same height on both sides.

At last retighten the spanner grips

(and if necessary Allen screws).

Adjustment of

basic model

5

Trunk support locking:

When closing the trunk support one

can “lock” the two rear tubes by giv-

ing them a firm push downwards.

In this way one can secure them

from accidently slide open or being

opened by “a busybody” !

Spring Loading:

The two springs inside the down

tubes can be changed to give a hard-

er or softer suspension.

As a guideline, it should be possible

to collapse the springs completely

with the weight of the user.

There are four different spring hard-

ness’s available, corresponding to the

following minimum weights:

• white springs for at least 20 kg

(45 b.),

• yellow springs for at least 45

kg (100 lb.),

• blue springs for at least 65 kg

(145 lb.),

• red springs for at least 80 kg

(175 lb.).

Seat position and angle:

The seat can be adjusted forwards or

backwards by slackening the Allen

screw below the seat fitting. When

the desired position has been found,

retighten the Allen screw.

The angle of the seat can also be

adjusted by slackening the four nuts

under the seat. An 11 mm (7/16”)

spanner will be needed here. After

adjustment retighten the nuts.

6

Rear stop:

The rear stop behind the seat can be

adjusted in lengthways direction. First

lift up the rear stop and tilt it back-

wards. This reveals an Allen screw

inside the U-profile When the Allen

screw is loosened, the rear stop can

be slid forwards or backwards in

the external tube. After adjustment,

retighten the Allen screw.

Handlebar:

The handlebar is mounted on each

side in a tube section located on a

cone. The cones are fixed in position

with Allen screws, and when these

are loosened, the handle bar can be

rotated around the cones. The hand-

lebar can also be slid forwards or

backwards in the two tube sections by

additionally slackening the two Allen

screws on the side of the handlebar.

Once the right positions have been

found, retighten the Allen screws.

Getting in and out:

MEYWALK® 2000 has an integral

lifting/lowering system, which facilita-

tes getting in and out for the user. We

recommend two helpers when getting

the user in and out. Press in the lock

fitting at the front of the MEYWALK®

2000 and raise the tilt bar.

On the MEYWALK® 2000 Small this

will lower the seat unit by about 13

cm (5”), on the MEYWALK® 2000

Medium by about 15 cm (6”), and on

the MEYWALK®2000 Large by about

25 cm (10”) . Then lift up and tilt back-

wards the rear stop and open the

trunk support. When the user is in

position on the seat, close the trunk

support and rear stop and raise the

seat unit by pressing the tilt bar

down until it locks with an audible

click. The integral gearing in the lif-

ting/ lowering system means that

downwards pressure need only be

about one third of the user’s weight.

Use of brakes:

The brakes are parking brakes which

function by directly blocking the rear

wheels with a fitting which presses

against the tire. To brake the walking

aid, pull the brake levers all

the way back until they come to a

definite stop. In this position the bra-

kes are self- locking. The brakes are

released by pushing the brake levers

forward again.

Adjustment af brakes:

First release the brakes by pushing

the brake levers forwards. Now slack-

en the two nuts which fi x the

brake mechanism to the bottom

frame. This will require a 10 mm

(13/32”) spanner. The whole brake

mechanism can now slide backwards

or forwards. Set it with a clearance of

3-5 mm (0,1”- 0,2”) between the bra-

ke fitting and the tire. Finally

retighten the two nuts and test the

brake action.

7

Accessories:

Height reduction fitting:

The trunk support and seat height

can also be reduced approximately 8

cm (3”) with a set of height reduction

fittings. These must be mounted in

the hinge mechanism between the

down tubes and the tilt bar. Unscrew

the Allen screw heads and remove

the tilt bar. Then fi t the two fittings

over the hinge eyes on the down tu-

bes and tighten. Finally slide the two

bright internal hinge sleeves

supplied into the hinge eyes on the

fittings, fit the tilt bar over them and

fasten with the Allen screw

heads supplied.

Anti-tip:

Anti-tip supports are mounted on

each side by first removing the cen-

tercap on the outside of the rear

wheel and unscrewing the nut from

the bolt which pass through the whe-

el hub. Two 19 mm (¾”) spanners will

be needed for this. The longer

bolt supplied with the anti-tip sup-

ports is fitted in the wheel hub

instead of the existing bolt. Keep the

old bolt safe in case the anti-tip sup-

ports later are removed. Then slide

the U-fitting on the anti-tip

support over the end of the frame

where the wheel was mounted.

Push the bolt through while placing

a washer between the wheel and

the U-fitting. Screw the nut back on.

Remember to tighten firmly. Finally

put on the centercap again.

The height of the anti-tip supports

from the ground is adjusted by

slackening the counter nut on the

adjusting screw. This will require

a 13 mm (½”) spanner. If necessary

slacken the nut on the wheel bolt.

The anti-tip support is tilted up

so the head of the adjusting screw

rests against the end of the frame

and the adjusting screw is screwed

forward or back to get the correct

height. Then retighten the counter

nut and the nut on the wheel bolt.

8

Swivel lock on front casters:

The swivel locks are delivered

mounted on two new front casters.

For mounting first remove the two

front wheels from the casters, use a 6

mm Allen key here. Remove the nut-

cap and unscrew the front casters

from the bottom frame by unscrewing

the lock nut on top of the fender

wheel. This will require two 19 mm

(¾”) spanners. Then push the bolt

on the new front casters into the bot-

tom frame from below, place the tube

fitting and the fender wheel on

top of the bolt, and screw the lock nut

back on. Make sure that the front

wheels are pointing straight

forward and parallel aligned, when

the swivel locks are activated. At last

install the front wheels in the front

casters again and put on the nut-

caps.

Leg separation plate:

The crossbar for the leg separation

plate is mounted between the front

wheels. The fittings at both ends of

the crossbar are fastened with the

supplied small top plates around the

fittings holding the front wheels. At

each side two Allen screws are scre-

wed into the top plate from below

through the holes in the fitting at the

end of the crossbar. At the front the

leg separation plate is equipped with

a square tube, and this is slid into the

square tube at the middle of the

crossbar. The leg separation plate

can be adjusted in height by loose-

ning the hand screw on the crossbar.

On the Small, there is a extra Wa-

sher. It has to stay on, when you

mount the Leg separation plate.

9

Hip-pads:

The hip-pads are mounted on the

two upper tubes below the seat tube

and above the two height adjust-

ment rings.

To mount the hip-pads first lift off the

top part of MEYWALK® 2000 from

the bottom frame. At each side

unscrew and remove the Allen

screw and the spanner grip from the

height adjustment ring and then re-

move the ring from the upper

tube. The hip-pad is slid in over the

upper tube and screwed together

with the inner tube through the slit.

Then mount the height adjustment

rings at each side again with the

included inner tubes. The hip-pads

are adjusted away from or closer to

the seat by loosening the hand

screws on the spanner boxes which

hold the square tubes.

The height of the hip-pads are adju-

sted by loosening the Allen screws

that hold the fittings on the upper

tubes and slide these fittings up and

down on the tube. After adjustment

retighten the screws and grips.

Leg guides:

Leg guides for MEYWALK® 2000

are delivered in a set of a left and a

right rail. They are mounted on the

inside at each side of the bottom

frame. Before mounting unscrew the

Allen screw heads at the lower end

of the tubes connecting the tilt bar

and the bottom frame.. The front end

of the leg guides are fastened to

these hinge connections with the

supplied Allen screw heads and the

longer threaded rods. The rear end

of the leg guides are fastened to the

bottom frame with the U-shaped

plastic covered threaded rod.

10

Mounting and use of non-

reverse brakes:

The non-reverse brakes are mounted

inside of the existing brakes. Use a

10 mm spanner to unscrew the

nuts from the two bolts which fix the

brake mechanism to the frame. The

two bolts are removed and

replaced with the supplied longer

bolts. Then fit the non-reverse brake

facing backwards over the two

bolts. If the non-reverse brakes shall

be used together with anti-tip sup-

ports the spacer fitting must be fitted.

Next put back on the brake mecha-

nism and screw the nuts back on.

The non-reverse brake

is adjusted so the curved fitting is

pressed against the rear tire by the

spring loaded button. When the cor-

rect position is found for the non-

reverse brake - and also for the bra-

ke mechanism - retighten the nuts

firmly. The non-reverse brakes can

be deactivated by pushing

the curved fitting forwards until the

spring loaded button locks it in a po-

sition raised from the tire.

Mounting and use af drag bra-

kes.

The drag brakes are fitted on the out-

side of the existing brakes. Use a 10

mm (13/32”) spanner to unscrew the

nuts from the two bolts which fix the

brake mechanism to the frame. The

bolts are removed and replaced with

the supplied longer bolts. If the drag

brakes shall be used together with

anti-tip supports the spacer-fitting

must be fitted. Fit the drag brake

over the two bolts with the hand

screw facing forwards and screw up

the nuts again. Finally remove the

elastic band holding the roller in pla-

ce. The drag brakes work by the rol-

ler at the back pressing into the tire.

First slacken off the nut on the threa-

ded shank behind the hand screw.

Then turn the hand screw until the

roller presses into the tire. Finally

tighten off the nut against the drag

brake housing. Use trial and error to

find the best pressure against the

tire.

11

Warning:

: : MEYWALK® 2000 is a therapy

product - and should only be used

as such!

: : The spring system used in MEY-

WALK® 2000 can involve a certain

risk of the walking aid toppling over

if used by a very restless user.

: : MEYWALK® 2000 rolls very

easy, and one should always consi-

der potential dangers the user can

roll over to.

Therefore:

Never leave the user in

MEYWALK® 2000 unattended!

Warning:

: : Always hold the tilt bar securely

when a user is being lifted or lowe-

red. Especially when opening

the tilt bar to lower the user, be pre-

pared for an upwards-directed force

which gradually increases

as the tilt bar rises. Never let go of

the tilt bar in the middle of a lifting or

lowering operation, even if taken by

surprise by the heavy weight effect.

Warning:

: : If fittings are removed, open tube

ends may be revealed. These may

have sharp inner edges and be dan-

gerous for probing fingers. MEY-

WALK® 2000 is designed to avoid

the necessity for open tube ends! If,

however, a situation with open tube

ends should arise, it is recommen-

ded that they are closed off with pla-

stic plugs.

Limitations on use:

: : The maximum user weight per-

mitted is 100 kg (220 lb.).

: : The walking aid should only be

used on flat, level and stable surfac-

es.

CE-marking

Meywalk® 2000 is CE-marked. This

warrants that Meywalk® 2000 is

conforming to all relevant safety re-

quirements in Council Directive

93/42/EEC concerning medical de-

vices.

Meywalk® 2000 is tested by Berlin

Cert, Prüf- und Zertifi zierstelle für

Medizinprodukte GmbH, an der

Technischen Universität Berlin.

Maintenance:

The walking aid can be washed

down with hot water and a normal

detergent. However, the padding on

the trunk support, handle bar and

rear stop should be avoided.

With repeated use of detergent, the

painted frame may gradually take on

a matt appear ance. It can then

be polished up with car polish. Fol-

low the instructions on the polish .

Checking for tightness:

Regularly check that all bolts,

screws and nuts are

fully tightened and if necessary re-

tighten.

The product is not made with

natural rubber latex.

Maintenance

Meyland-Smith A/S ٠ Mads Clausens Vej 1 ٠ 9800 Hjørring

Phone: +45 98 96 19 85 ٠ Fax.: +45 98 96 19 86

www.meyland-smith.dk ٠ E-mail: info@meyland-smith.dk

Producent: Dealer

141

Technical data

Dimensions: Small Medium Large

Length: 85 cm 95 cm 95 cm

External width: 68 cm 70 cm 70 cm

Internal width: 48 cm 48 cm 48 cm

Seat height: 48-66 cm 62-86 cm 76-100 cm

Trunk support height: 81-100 cm 94-117 cm 108-131 cm

Trunk support options : 70, 90, 105 cm 70, 90, 105, 120, 130 cm 70, 90, 105, 120, 130 cm

Weight: 22 kg 25 kg 26 kg

Max load: 100 kg 100 kg 100 kg

Materials

Frame: Powder-coated steel tubes

Fittings: Electrolytically galvanized steel

Padding: Polyurethane foam

Seat cover: Synthetic leather

Diverse:

Wheels:

Colors: Green RAL 6018/ Navy Blue, RAL 5022

Soft solid rubber tires on synthetic rims with self-lubricating ball bearings.

Heights are measured with half compression af springs

Table of contents

Popular Mobility Aid manuals by other brands

Invacare

Invacare 65650R Assembly, installation and operating instructions

Timago

Timago JMC-C 3016W5 Instructions for use

Moretti

Moretti MOPEDIA RP820 instruction manual

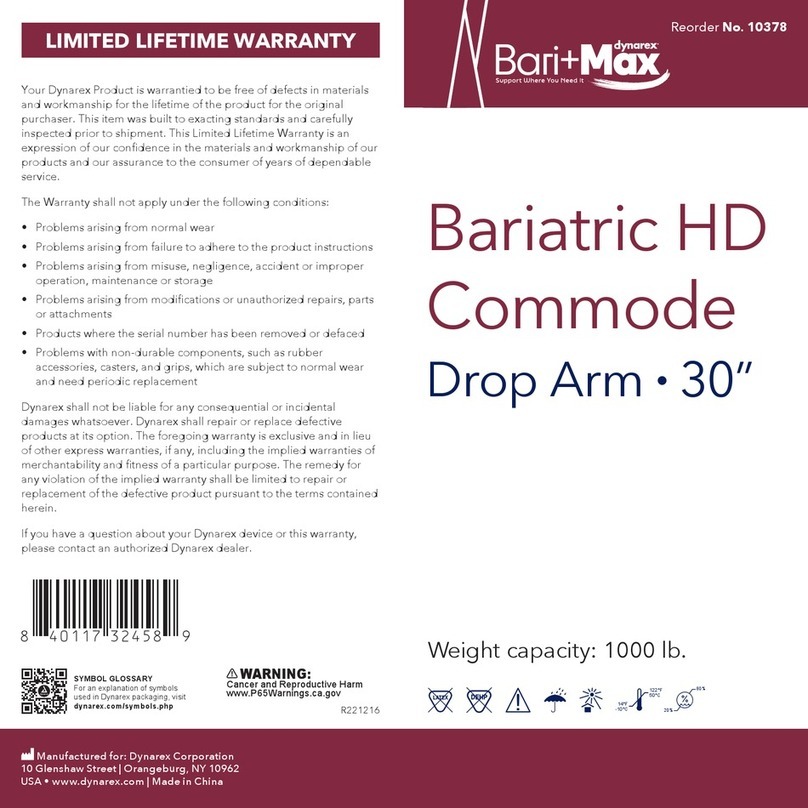

dynarex

dynarex Bari+Max Bariatric HD Commode manual

Guardian

Guardian G2-300KRX1 User instructions and warranty

Patterson

Patterson Bathmaster Deltis user manual