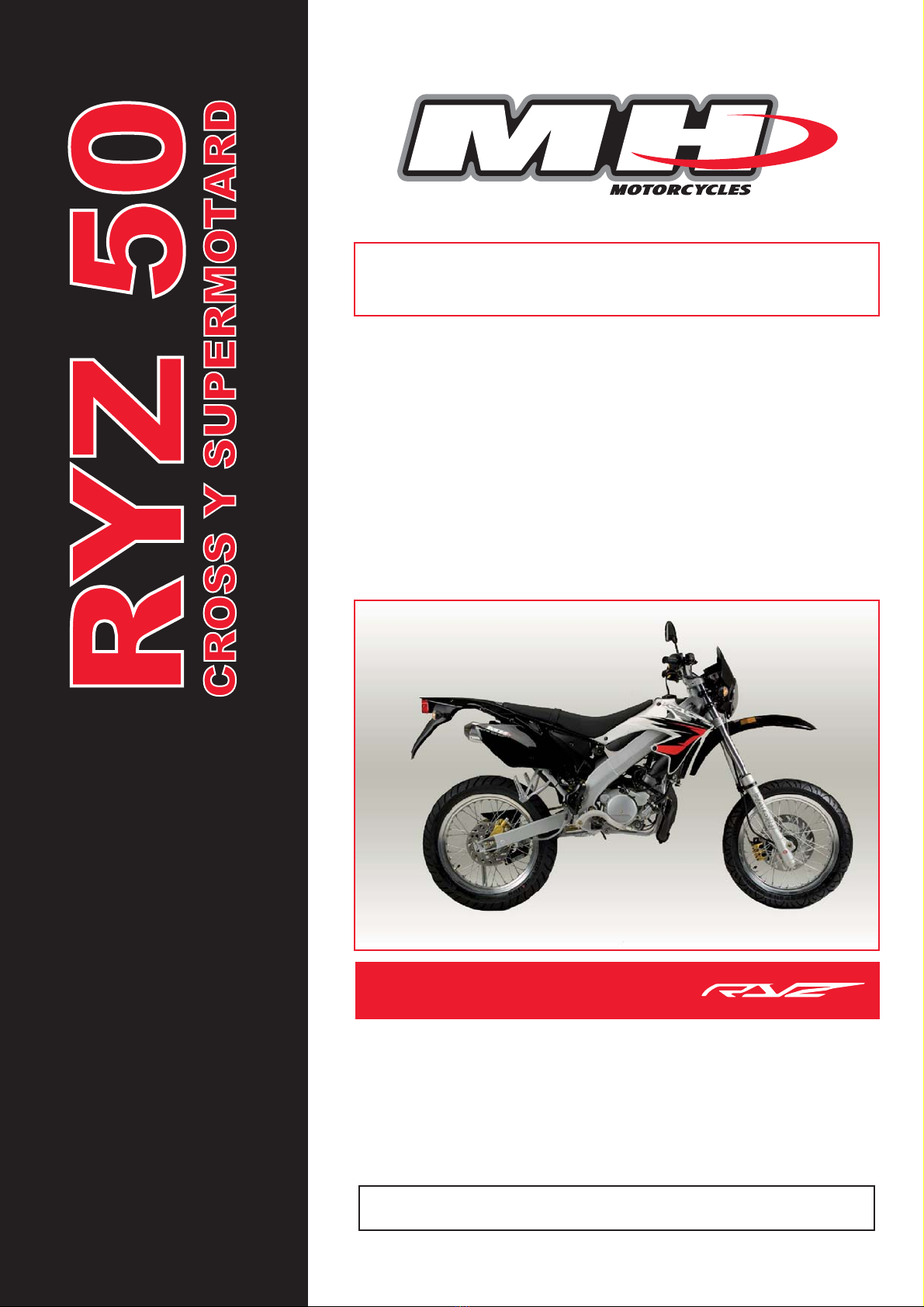

MH RYZ 50 Cross C User manual

REF. OF PUBLICATION:

0634111000004

1AEDITION

2007-10

USE THIS SERVICE MANUAL WITH THE RELATED MANUALS INDICATED IN

THE FOREWORD TO THIS MANUAL

w w w . m o t o r h i s p a n i a . e s

SERVICE MANUAL

RYZ

IMPORTANT

Read this manual and follow the instructions carefully. Especia-

lly important information is indicated with the words WARNING,

CAUTION and N.B., which have quite precise meanings.

Pay special attention to the instructions that follow these titles.

WARNING:

Contains a potential danger that may cause injury or even

death.

CAUTION:

Contains a potential danger that may damage the machine.

N.B.:

Contains special information to aid maintenance or clarify

some point in the instructions.

WARNING:

This service manual has been prepared for authorised G.H.E.

ENGINEHISPA – NIA, S.L. dealers, and should only be used

by qualified Technical Service department mechanics. Mecha-

nics without experience or without the proper tools and equi-

pment cannot carry out the service work described in this ma-

nual properly.

A bad repair may cause injury to the mechanic, and the machi-

ne may not be in a condition to ensure the safety of rider and

passengers.

RYZ

FOREWORD

This manual describes the procedures for the diagnosis, maintenance, adjustments, basic service work, changing of

parts and the dismantling and assembling of the main parts.

Model applicable: RYZ 50 CROSS (C) and RYZ 50 SUPERMOTARD (SM) with the following VIN numbers and later ones:

VTVDV0C00XXXXXXXX ~

VTVDV0CE2XXXXXXXX ~

VTVDV1CE2XXXXXXXX ~

This text is classified into sections, each of which has a section number, as can be seen in the Contents on the following page, and

on the first page of every individual section there is a contents list for that section.

Keep this manual to hand so that it can be consulted quickly when carrying out service work.

The specified points must be carefully observed to ensure that the machine functions perfectly in accordance with the specification.

When changing parts or carrying out service work that involves dismantling, it is recommended to use genuine G.H.E. ENGINEHIS-

PANIA, S.L. spare parts, tools and service materials, as specified in the corresponding descriptions.

All the information, figures and specifications in this manual are based on the latest approved product information available at the

time of publication.

The main model used for the description throughout this manual is the model with basic specifications. Therefore the figures may

appear slightly different from the model in the workshop. G.H.E.

ENGINEHISPANIA, S.L. reserves the right to make changes without prior warning.

RELATED MANUALS

TITLE OF THE MANUAL

RYZ50 SPARE PARTS CATALOGUE

MANUAL NO.

0634111000001

APPLICABILITY

Manual with all the spare parts for the RYZ50 model.

G.H.E. ENGINEHISPANIA, S.L.

DEPARTAMENTO DE SERVICIO

© COPYRIGHT G.H.E. ENGINEHISPANIA, S.L. 2006

RYZ

NOTES:

RYZ

NOTES:

RYZ

SECTION 1

GENERAL INFORMATION

CONTENTS

USING THIS MANUAL ...................................................................................................................................................................1-2

IDENTIFICATION ........................................................................................................................................................................... 1-3

Machine identification .......................................................................................................................................................... 1-3

Engine identification ............................................................................................................................................................ 1-3

GENERAL INFORMATION 1-1

RYZ

1-1 GENERAL INFORMATION

USING THIS MANUAL

At the beginning of this manual there is a GENERAL CON-

TENTS LIST, enabling the SECTION containing the informa-

tion needed for the service to be found quickly. In addition,

each section has its own contents list on its first page with a

description of its main points.

In each section of this manual the page numbers start from the

beginning. The numbers appear at the top of the page together

with the name of the section.

This manual includes units of measurement in the international

system (SI).

The use of the SPECIAL TOOLS and of the TIGHTNESS TOR-

QUE SPECIFICATIONS are indicated in bold type, as in the

following example:

Immobilise the clutch dog with the special tool.

Special tool (C)

Tighten the nut.

Tightness torque:

7.5 daN•m (75 N•m)

Fold back the clutch nut tab washer.

Fit the clutch control lever with its spring and its washer.

1)

2)

3)

4)

2)

3)

4)

5)

RYZ

GENERAL INFORMATION 1-1

IDENTIFICATION

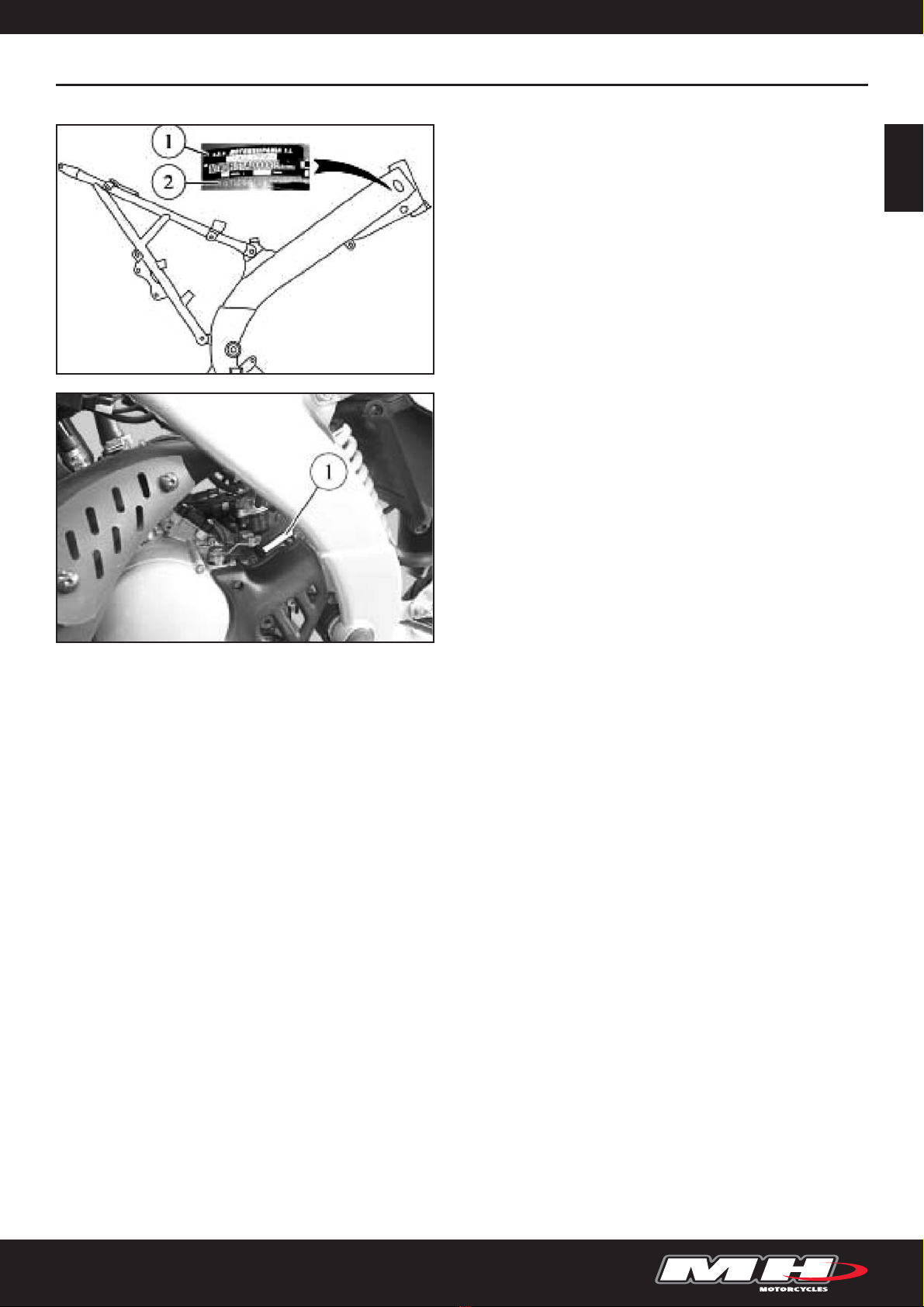

IDENTIFICATION OF THE MACHINE

The machine is marked with a plate (1), situated on the right-

hand side of the chassis. This plate has the VIN (VEHICLE

IDENTIFICATION NUMBER) engraved on it.

The VIN (VEHICLE IDENTIFICATION NUMBER) is engraved

on the right-hand chassis beam (2).

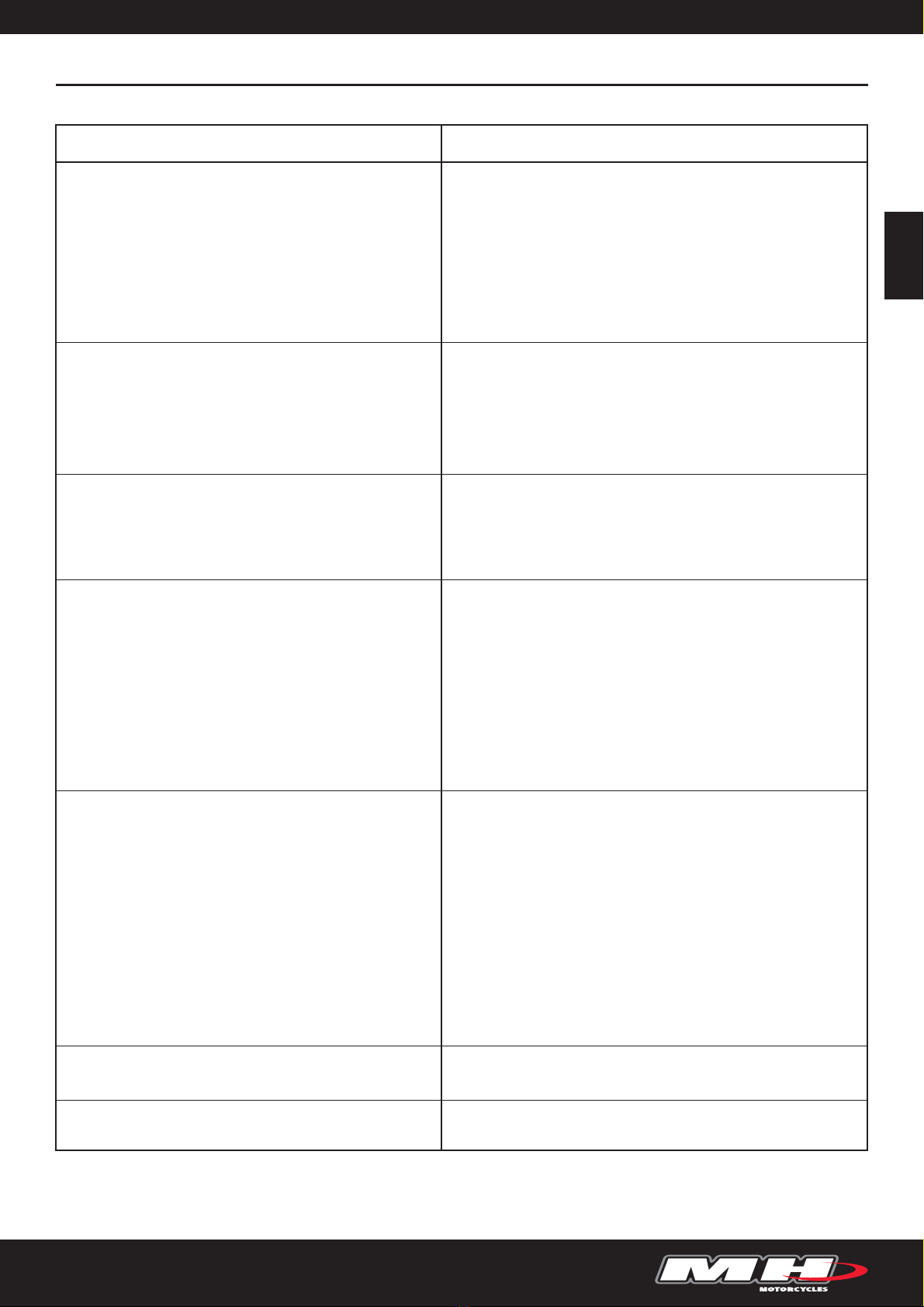

ENGINE IDENTIFICATION

The Engine Identification Number (1) is marked on the engine, on

the left-hand side of the machine.

1)

2)

1

RYZ

NOTES:

RYZ

SECCION 2

SPECIFICATIONS

CONTENTS

GENERAL SPECIFICATIONS ........................................................................................................................................................ 2-2

ENGINE SPECIFICATIONS ............................................................................................................................................................ 2-2

CHASSIS SPECIFICATIONS ........................................................................................................................................................... 2-4

TIGHTENING TORQUES ................................................................................................................................................................ 2-5

SPECIFICATIONS 2-2

2

RYZ

2-2 SPECIFICATIONS

2

GENERAL SPECIFICATIONS

ELEMENT

Model code

DIMENSIONS

Total length

Total width

Height without rear-view mirror

Distance between axles

WEIGHT

Weight empty

Weight running

Maximum permittable weight

Top speed

SPECIFICATION

RYZ TL

RYZ SM

RYZ UB

RYZ TL: 2.095 mm

RYZ SM y UB: 1.980 mm

820 mm

RYZ TL: 1.210 mm

RYZ SM: 1.170 mm

RYZ UB: 1.150 mm

820 mm

RYZ TL: 97 kg

RYZ SM: 98 kg

RYZ UB: 101 kg

RYZ TL: 97 kg

RYZ SM: 98 kg

RYZ UB: 101 kg

255 kg

45 km/h

ENGINE SPECIFICATIONS

ELEMENT

ENGINE

Engine type

Make

Cubic capacity

Stroke x diameter

Maximum power

Maximum torque

Volumetric compression ratio

FUEL

Recommended fuel

Total capacity of fuel tank

(including reserve)

SPECIFICATION

AM6.(EU.2)-liquid cooled 2-stroke

Minarelli 50 cc

49,7 cm³

40,3 x 39 mm

1,4 Kw a 5.000 rev/min

2.89 Nm a 4.000 rev/min

12.0 ± 0.1 : 1

Only 95 octane lead-free petrol

6 litres ± 0.5

RYZ

ELEMENT

LUBRICATION

Type

Recommended oil

Oil tank capacity

COOLING

Type

Cooling circuit capacity

IGNITION

Type

Spark plug

CARBURETTOR

Make / Type

Idle rate

Initial position of air screw

Needle

Main jet

Idle jet

TRANSMISSION

Type

Primary transmission

Secondary transmission

Gearbox

Gearbox capacity

Clutch

Magneto

Starter motor

ESPECIFICACIÓN

Separate lubrication by a variable rate piston pump, synchronised

with the throttle and driven by geared take-off from the crankshaft.

The oil is injected directly into the carburettor.

Semi-synthetic Motul 510 2St special

“anti-smoke” two-stroke oil

1.1 Litres

Circulation of water coolant by a pump driven by geared take-off

from the crankshaft.

0,7

Litres

CDI

NGK BR 9ES

DELL’ORTO / PHBN 16

930±50 rev/min

1.5 turns

A8 – 3rd notch

84

34

By sprocket and crown gear, with the gearbox and rear wheel

joined by a 126 link roller chain.

(12.7 pitch)

20x71

11x52

6 speed

0.75 litres Motul TRANSOIL (SAE 10W30)

Multi-disk with oil bath and cable control

Ducati 85 W

Ducati

SPECIFICATIONS 2-2

2

RYZ

2-2 SPECIFICATIONS

2

CHASSIS SPECIFICATIONS

ELEMENT

WHEELS

Front wheel

Front tyre

Front pressure

Rear wheel

Rear tyre

Rear pressure

FRONT BRAKES

Type

Ø brake pistons

Disk Ø

Disk thickness

Ø main piston (cylinder)

REAR BARKES

Type

Ø brake pistons

Disk Ø

Disk thickness

Ø main piston (cylinder)

FRONT SUSPENSION

Type of suspension

Type of front forks

Forks capacity

Travel

SPECIFICATION

RYZ TL: 1,85”X21”

RYZ SM: 2,5”X17”

RYZ UB: 1,85”X16”

Disk with hydraulic calliper

RYZ TL: 90/90X21”

RYZ SM: 100/80X17”

RYZ UB: 90/90X16”

RYZ TL: 1,9 ± 1 bar

RYZ SM: 2.0 ± 1bar

RYZ UB: 2.3 ± 1 bar

RYZ TL: 2,5”X18”

RYZ SM: 3,5”X17”

RYZ UB: 2,5”X16”

RYZ TL: 120/80X18”

RYZ SM: 130/70X17”

RYZ UB: 120/80X16”

RYZ TL: 2.1 ± 1 bar

RYZ SM: 2.3 ± 1 bar

RYZ UB: 2.7 ± 1 bar

25 mm (2)

RYZ TL: 200 mm; RYZ TOP TL: 220 mm

RYZ SM: 200 mm; RYZ TOP SM: 220 mm

RYZ UB: 220 mm; RYZ TOP UB: 220 mm

4 mm

12 mm

Disk with hydraulic calliper

32 mm (2)

RYZ TL: 240 mm; RYZ TOP TL: 260 mm

RYZ SM: 260 mm; RYZ TOP SM: 280 mm

RYZ UB: 260 mm; RYZ TOP UB: 280 mm

4 mm

12 mm

Telescopic forks

Hydraulic fluid shock absorber

0.3 litres per tube

230 mm

RYZ

ELEMENT

REAR SUSPENSION

Type of suspension

Travel of central single hydraulic shock absorber

STEERING

Type

SPECIFICATION

Variable flexibility swinging arm, combined with a 44 mm central

single hydraulic shock absorber

44 mm

Steering column mounted on ball bearings

SPECIFICATIONS 2-2

2

RYZ

2-2 SPECIFICATIONS

2

TIGHTENING TORQUES

ELEMENT

BODY

Side covers

Front mudguard

Rear mudguard

Skirting

CHASSIS

Front wheel shaft

Rear wheel shaft

Rear wheel shaft nut

Suspension arm nut

Chassis engine mounting

Shock absorber top mounting

Shock absorber top mounting

Forks T-sections

Front brake calliper

Rear brake calliper

Front brake disk

Rear brake disk

Support on chassis

Steering lock

ESTÁNDAR

5.mm diameter nut and bolt

6 mm diameter nut and bolt

8 mm diameter nut and bolt

10 mm diameter nut and bolt

12 mm diameter nut and bolt

TIGHTENING TORQUE

0,1 daN·m (1 N·m)

0,1 daN·m (1 N·m)

0,8/0,1 daN·m (8/1 N·m)

0,8/0,1 daN·m (8/1 N·m)

4,5 daN·m (45 N·m)

1,2 daN·m (12 N·m)

6,5 daN·m (65 N·m)

6,5 daN·m (65 N·m)

2,8 daN·m (28 N·m)

4,3 daN·m (43 N·m)

4,3 daN·m (43 N·m)

1,5 daN·m (15 N·m)

2,5 daN·m (25 N·m)

2,5 daN·m (25 N·m)

1 daN·m (10 N·m)

1 daN·m (10 N·m)

1,9 daN·m (19 N·m)

0,6 daN·m (6 N·m)

0,5 daN·m (5 N·m)

1 daN·m (10 N·m)

2,2 daN·m (22 N·m)

3,5 daN·m (35 N·m)

5,5 daN·m (55 N·m)

RYZ

SECTION 3

MAINTENANCE AND COMMISSIONING

CONTENTS

INTRODUCTION............................................................................................................................................................................... 3-2

MAINTENANCE PLAN ................................................................................................................................................................. 3-2

Checking ............................................................................................................................................................................... 3-2

Renewing .............................................................................................................................................................................. 3-2

Checking and decarbonising ................................................................................................................................................. 3-3

Checking and greasing ......................................................................................................................................................... 3-3

Checking and adjusting ......................................................................................................................................................... 3-3

Cleaning and adjusting .......................................................................................................................................................... 3-3

COMMISSIONING............................................................................................................................................................................. 3-4

Battery preparation (except maintenance-free batteries) ...................................................................................................... 3-4

Checking levels ..................................................................................................................................................................... 3-4

Commissioning the fuel and oil circuits ................................................................................................................................ 3-4

Checks before delivery to customer ..................................................................................................................................... 3-5

TIGHTENING TORQUE SPECIFICATIONS ................................................................................................................................... 3-6

SERVICE MATERIALS REQUIRED ............................................................................................................................................... 3-6

MAINTENANCE AND COMMISSIONING 3-1

3

RYZ

3

INTRODUCTION

This section includes all the information needed to perform the recommended maintenance and commissioning operations. Obser-

ving these procedures will ensure the machine functions more reliably and has a longer useful life, while reducing the need for costly

repair work.

All maintenance technicians must be familiar with the whole of this section.

MAINTENANCE PLAN

Reinforced maintenance is designed for machines used in “severe” conditions: driver temperament, short journeys with a cold engine,

dusty regions or environments with a temperature higher than 30ºC.

3-2 MAINTENANCE AND COMMISSIONING

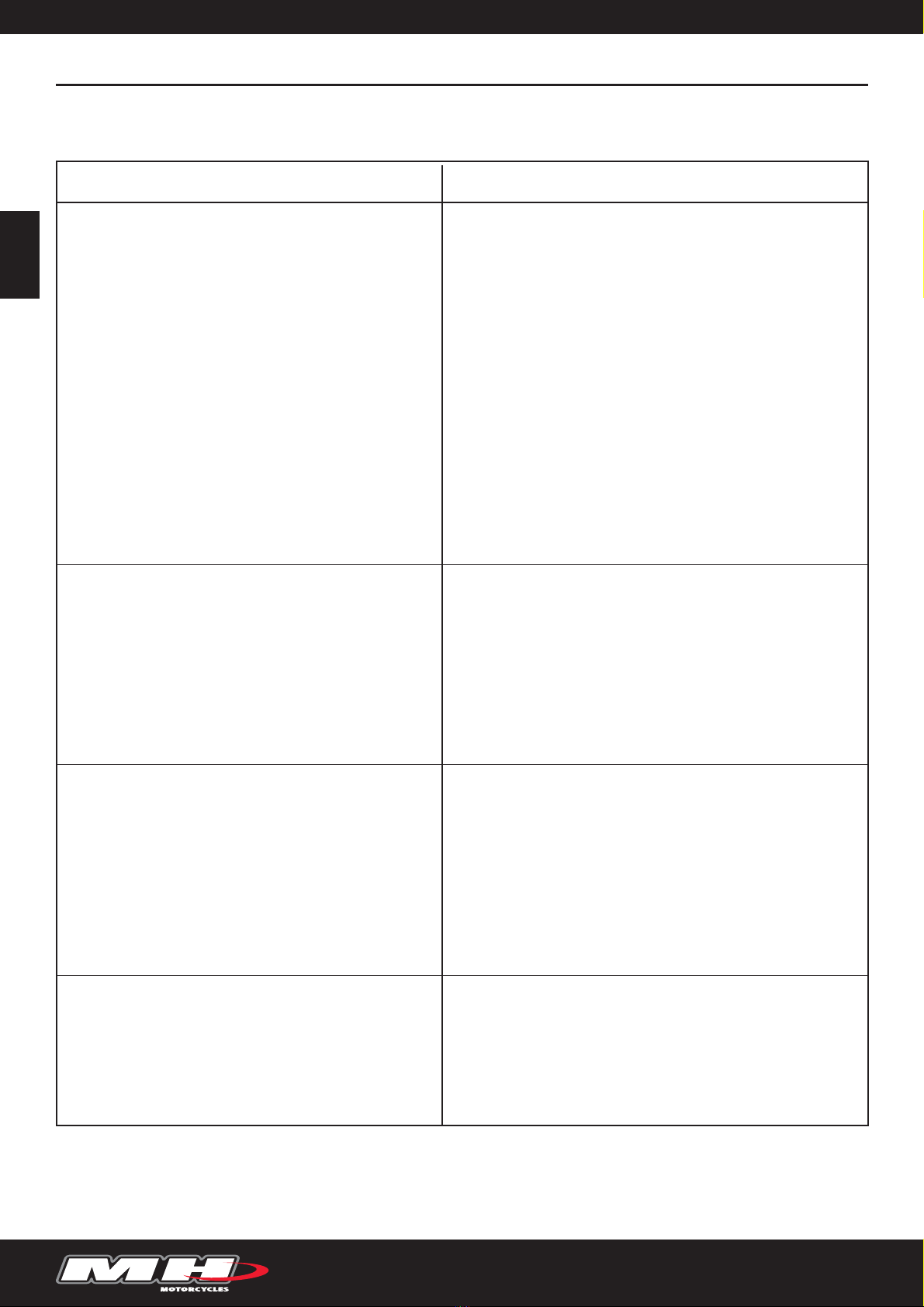

CHECKING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Adjusting idle speed

Throttle cable and oil pump

Front and rear brake cable

Functioning of the electrical equipment

Fuel circuit

Oil circuit

Front and rear brake fluid piping

Coolant circuit

Carburettor heating circuit

Tyre pressures

Condition, pressure and wear of tyres

Front and rear brake fluid level

Coolant level

Battery electrolyte level

Tightening nuts and bolts

Charging the battery

500 KM

OR 3 MONTHS

Every 1.500 km

EVERY 3,000 KM EVERY 6,000 KM

Every 3.000 km

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

X

XX

XXX

XXX

XXX

XXX

XX

RENEWING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Intake filter element

Front and rear brake pads (where appropriate)

Gearbox oil

Chain – sprocket- crown gear (where appropriate)

Clutch disks (where appropriate)

500 KM

OR 3 MONTHS

Every 1.500 km

EVERY 3.000 KM EVERY 6.000 KM

Every 3.000 km

XX

XX

XX

XX

X

RYZ

MAINTENANCE AND COMMISSIONING 3-3

3

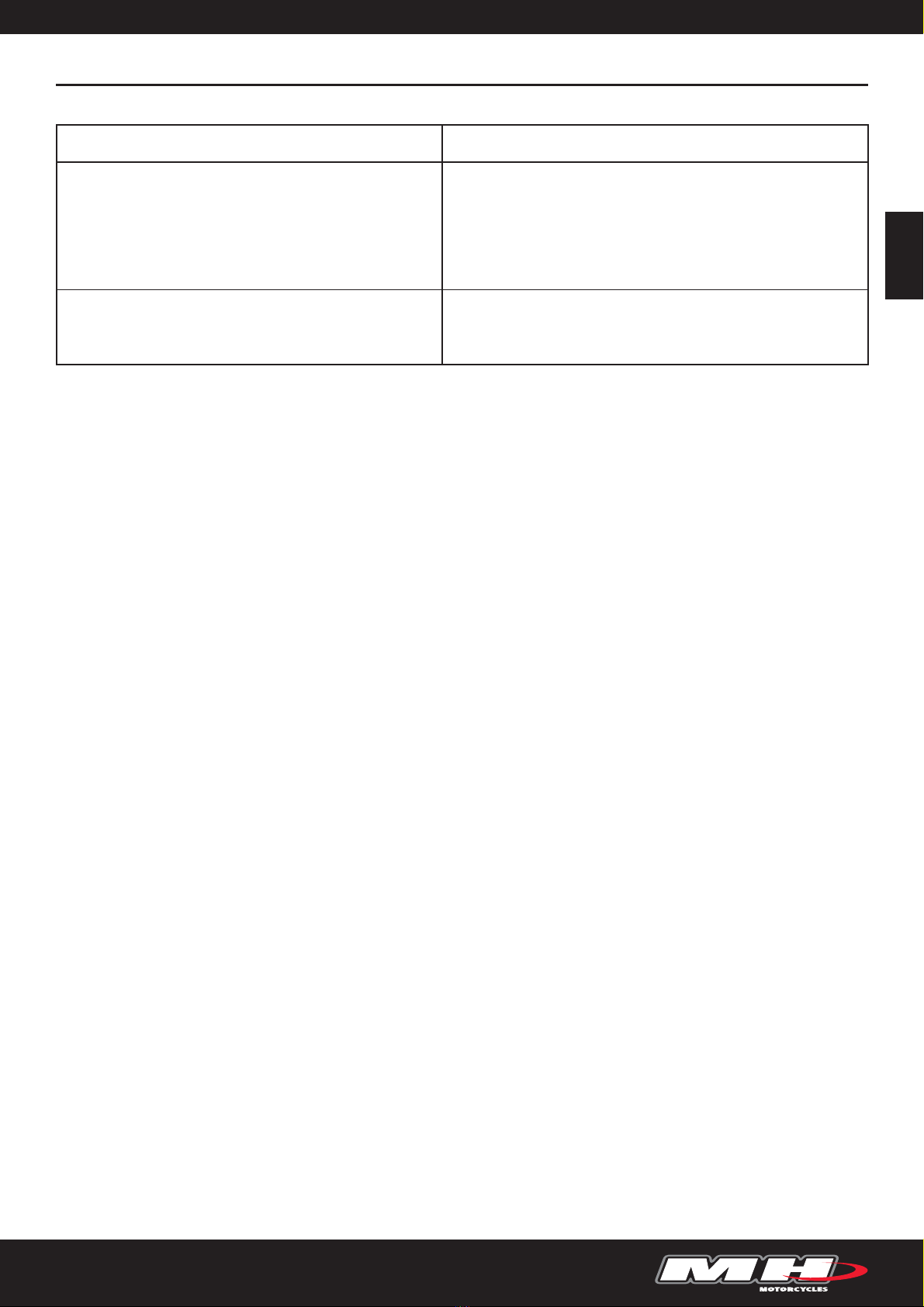

CHECKING AND DECARBONISING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Piston (1)

Cylinder head (1)

Exhaust port (1)

500 KM

OR MONTHS

Every 1.500 km

EVERY 3.000 KM EVERY 6.000 KM

Every 3.000 km

Every 10.000 km

Every 10.000 km

Every 10.000 km

(1) The need to decarbonise can be estimated by checking the quantity of carbonisation present in the cylinder exhaust outlet.

CHECKING AND GREASING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Chain tension and condition

500 KM

OR MONTHS

Every 1.500 km

EVERY 3.000 KM EVERY 6.000 KM

Every 3.000 km

XXX

CHECKING AND ADJUSTING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Clutch cable

Oil pump control

Spark plug

Tension of the wheel spokes

500 KM

OR MONTHS

Every 1.500 km

EVERY 3.000 KM EVERY 6.000 KM

Every 3.000 km

X

X

X

X

X

X

X

X

CHECKING AND ADJUSTING

MAINTENANCE OPERATIONS

REINFORCED MAINTENANCE

Carburettor

500 KM

OR MONTHS

Every 1.500 km

EVERY 3.000 KM EVERY 6.000 KM

Every 3.000 km

XX

RYZ

3-4 MAINTENANCE AND COMMISSIONING

BATTERY PREPARATION (EXCEPT MAIN-

TENANCE-FREE BATTERIES)

Remove the battery

Remove the six filler plugs and the air vent plug.

Replenish with electrolyte up to the

“UPPER LEVEL” mark.

Electrolyte:

(35% sulphuric acid = 1.28 g/cm)

Allow the battery to stand for approximately half an hour.

Top up if necessary.

Charge the battery for at least 2 hours at an intensity of 400 mA

(0.4 A).

Refit the battery and connect the vapour vent pipe.

Connect the red cable to the positive battery terminal and the black

cable to the negative battery terminal.

CHECKING LEVELS

Check the gearbox oil level.

Check the coolant level.

Check the brake fluid level.

COMMISSIONING THE FUEL AND OIL

CIRCUITS

Put 1 litre of unleaded petrol in the fuel tank. This should be 95 or

98 octane mixed with 3% Motul 510 semi-synthetic 2-stroke oil.

Put Motul 510 semi-synthetic 2-stroke oil in the oil tank.

Engine oil:

Motul 510 semi-synthetic 2-stroke oil

Start up the engine and disconnect the special tube entering

the carburettor to check that the oil is flowing drop by drop (the

speed of the drops increases with the engine revs).

Complete the filling of the fuel tank with unleaded 95 or 98

octane petrol without oil mixture.

1)

2)

3)

4)

5)

6)

7)

8)

1)

2)

3)

1)

2)

3)

4)

3

COMMISSIONING

WARNING:

A continuación, eventualmente se deberá restablecer el

nivel de la batería después de una carga completa, utili-

zando exclusivamente agua destilada.

This manual suits for next models

1

Table of contents

Popular Motorcycle manuals by other brands

KTM

KTM 50 SX 2015 Setup instructions

BSA

BSA Victor grand prix b44 instruction manual

Yamaha

Yamaha YZ250F(S) Owner's service manual

Cagiva

Cagiva Roadster 521 Workshop manual

BSA

BSA D14/4 BANTAM SUPREME D14/4 BANTAM SPORTS instruction manual

APRILIA

APRILIA RSV MILLE - DEALER INSTRUCTION SHEET 2004 instruction sheet