Mi-Flues SYSTEM 7 User manual

Tel: +353 46 95 58030

Fax: +353 46 95 58034

Web: www. miflues.ie

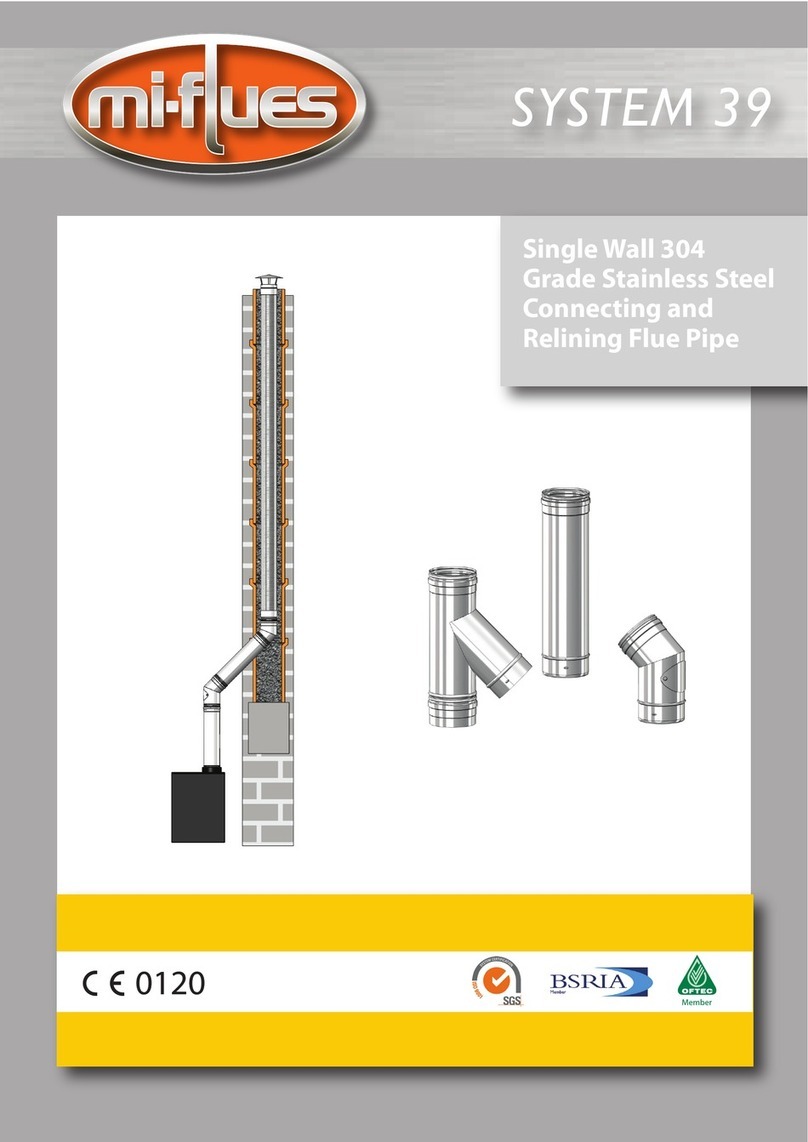

SYSTEM 7

Vitreous Enamelled

Steel Stove Pipes

System7 Single.indd 1 28/06/2013 14:58

September 2014

2

MI-Flues System 7 Vitreous Enamelled Stove Pipe

APPROVALS

COMPONENTS

INSTALLATION

Mi-Flues System 7 vitreous enamelled stove pipe

has been specifically engineered to give an authentic

visual look, whilst at the same time being

manufactured using the latest technology to ensure

years of trouble free use.

All enamelled components are made from 1.2mm

thick zero carbon steel. All joints are fully welded

which provides an excellent gas sealed joint and

offers minimum resistance to flue gas flow.

The system then has two coats of Class A quality

enamel applied to both the inside and the outside of

the pipes and accessories.

Components have been designed to be installed

quickly, safely and simply. The system comprises of

plain pipes, pipes with high temperature ceramic

sealed doors, bends, tees complete with cleaning

inspection caps, appliance adaptors and wall

rosettes.

Mi-Flues System 7 should be fitted at least four times

the diameter of the pipe away from any combustible

materials.

All sockets (female end) should be upward, with the

male end dropping into the socket

(see illustration below).

This ensures that no condensate

can escape and spoil the

appearance of the finished

installation.

The diameter specified by the

appliance manufacturer dictates the

chimney diameter and this should

never be reduced.

Mi-Flues recommend a maximum

run of 1.8m of System 7.

In all cases the product must be

installed in accordance with Local

Building Regulations Document J and the

manufacturers installation instructions.

APPLICATION

Mi-Flues System 7 stove pipe should only be used to

connect from the appliance into an existing lined

chimney, or to our System 2 twin wall insulated

stainless steel chimney, using an appropriate adaptor

(as per illustrations on page 8).

System 7 flue should not be used externally or

should not be used to line an existing chimney.

INTRODUCTION

PRODUCT DESCRIPTION

JOINT ASSEMBLY

The male end of the pipe should sit inside the spigot

outlet of the stove and should be sealed with Mi-Flues

high temperature sealant (rated to 1000°C) or fire

cement in accordance with appliance manufacturers

guidelines.

There is a hole in the spigot end of the pipe. This hole

is used in the manufacturing process and is in no way

used for installation purposes.

If the fit is quite loose it is possible to pack the joint with

fire rope prior to using the high temperature sealant

(rated to 1000°C) or suitable fire cement.

Produced in zero carbon steel, it has two coats, both

internally and externally, of superior class A quality

enamel applied.

The system is available in five standard diameters

100mm, 125mm, 150mm, 175mm and 200mm.

Mi-Flues System 7 is available in three standard

colours, Matt Black, Gloss Black and Brown.

System 7 is not suitable for condensing applications.

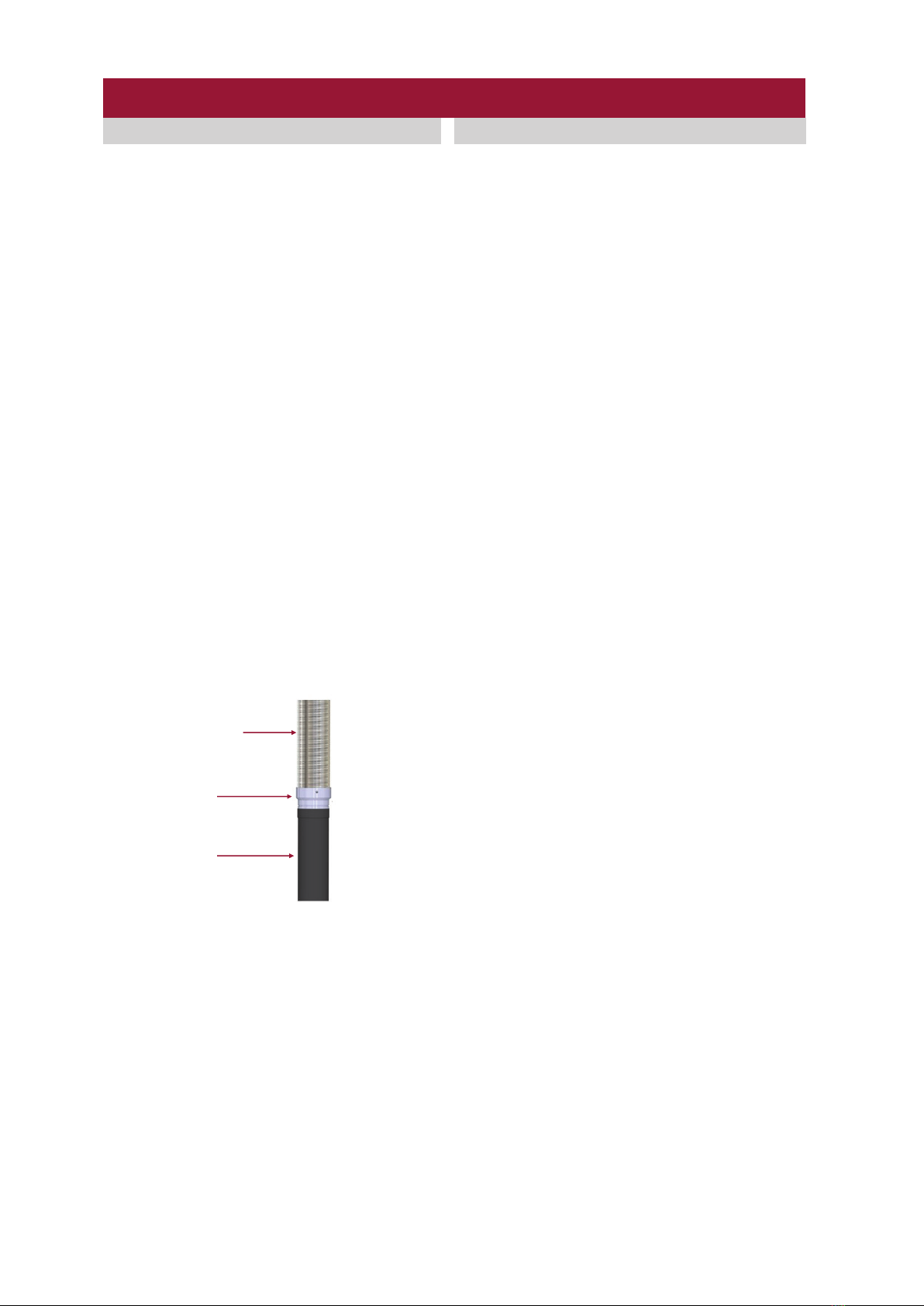

Locking Clips are available to

suit 100mm, 125mm and

150mm System 7 pipes. They

are recommended on runs of

more than three components.

Mi-Flues do not recommend cutting vitreous enamel

pipes. This is because it is the vitreous enamel

coating that protects the mild steel pipe underneath

from corrosion and attack from combustible deposits.

Once the pipe is cut the mild steel will be exposed.

Adjustable lengths are available to assist in

achieving an exact required length.

Mi-Flues System 7 should not be used on Insert

Stoves. If a connecting flue pipe is required for an

Insert Stove Mi-Flues System 1 or Mi-Flues Insert

Stove kits should be used.

Flue Gas

Direction

To install the locking clip fit the male end of the pipe

into the socket end of the pipe as shown below. Seal

the joint using Mi-Flues high temperature sealant (rated

to 1000°C) or fire cement. Once sealed, fit the locking

clip around the pipe ensuring connection is made with

both pipes. Once in correct position secure the

locking clip by tightening the tensioning screw with a

suitable allen key or flat head screw driver.

Socket (Female)

Male

Mi-Flues System 7 conforms to:

BS 1344 Part 1 Thermal shock resistance

BS 1344 Part 7 Heat resistance

BS EN 14483 Part 1 Acid resistance

BS 6999 Specification for VE low carbon steel flue

pipes

EN 1443:2003 Chimney General Requirements

EN1856-2 T600 N1 D Vm L80180 G(**)

Note: ** 4 x diameter of the flue

3

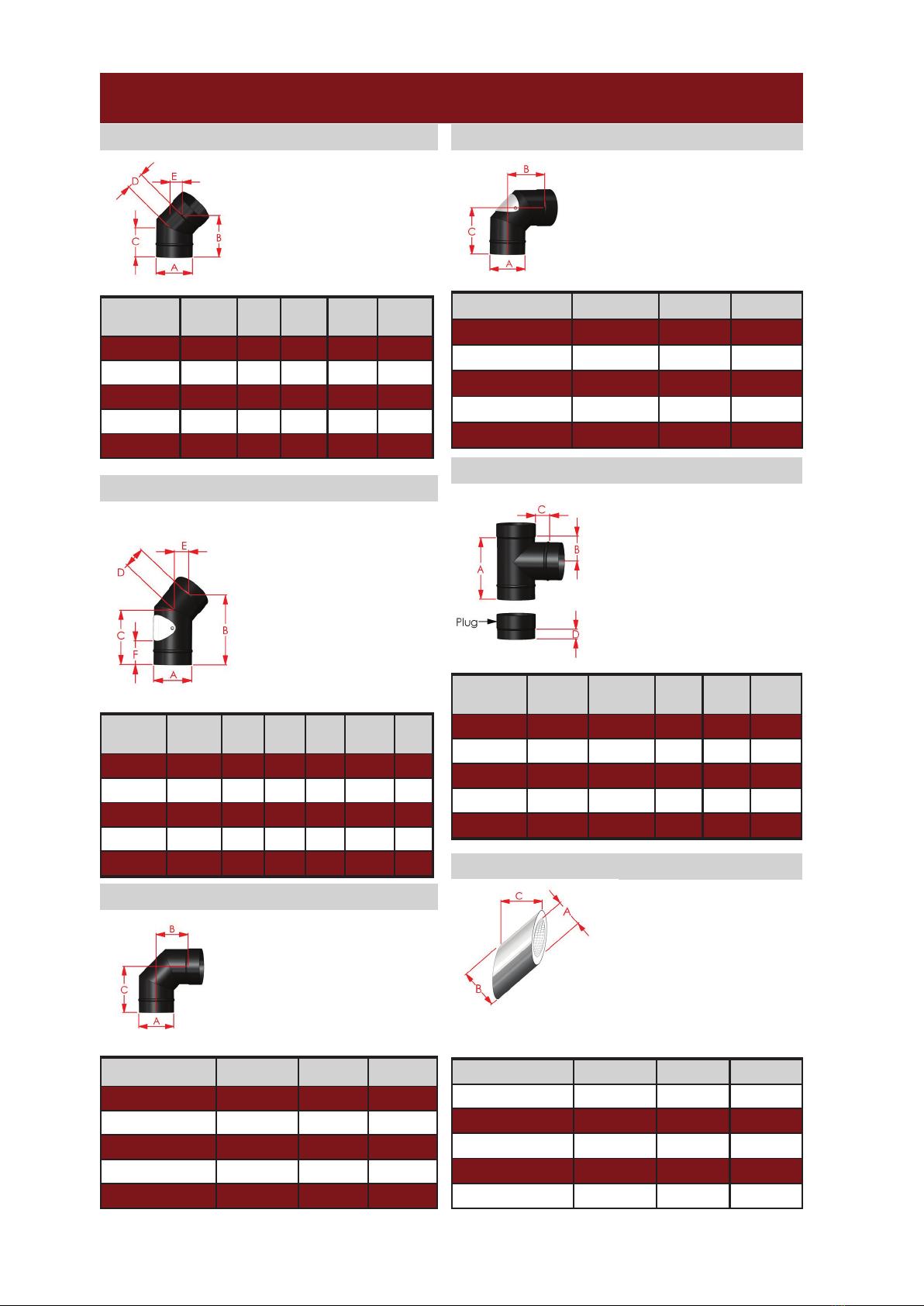

LENGTH -WITH CLEAN OUT DOOR

Provision for inspecting a chimney system must be

made. Lengths with doors are provided for this

purpose. Manufactured with a non corrosive stainless

steel access door with high temperature gasket and

corrosion proof re-usable locking nuts. Lengths are

available in 300mm, 500mm, 1000mm and 1200mm.

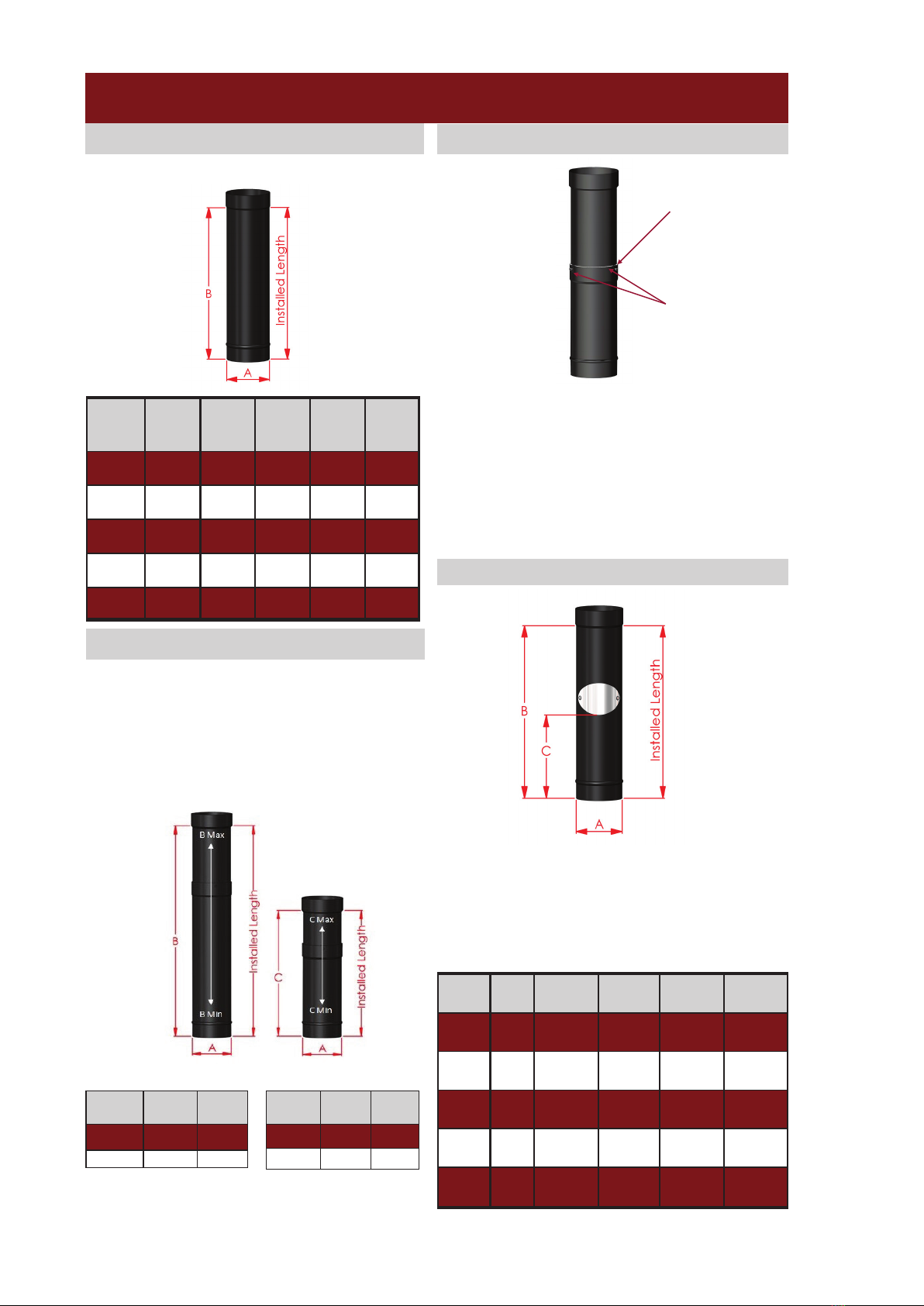

LENGTHS

Code Dia. (A)

300

Length

(B)

500

Length

(B)

1000

Length

(B)

1200

Length

(B)

Sys. 7 100 260 460 960 1160

Sys. 7 125 260 460 960 1160

Sys. 7 150 260 460 960 1160

Sys. 7 175 260 460 960 -

Sys. 7 200 260 460 960 -

Code Dia.

(A)

300

Length

500

Length

1000

Length

1200

Length

Sys. 7 100 B=260

C=97

B =460

C =197

B=960

C=447

B=1160

C=547

Sys. 7 125 B=260

C=97

B=460

C=197

B=960

C=447

B=1160

C=547

Sys. 7 150 B=260

C=97

B=460

C=197

B=960

C=447

B=1160

C=547

Sys.7 175 -B=460

C=197

B=960

C=447 -

Sys. 7 200 -B=460

C=197

B=960

C=447 -

Mi-Flues do not recommend cutting vitreous enamel

pipes. Adjustable lengths are available to assist in

achieving the exact length required.

They are available in 125mm and 150mm diameters.

Adjustable lengths are available in a matt black,

gloss black or brown finish. The short component is

adjustable from 310 -480mm. The long component

is adjustable from 510 -880mm.

Available in 300mm, 500mm, 1000mm and 1200mm.

MI-Flues System 7 Vitreous Enamelled Stove Pipe

ADJUSTABLE LENGTHS

Dia (A) 125 150

B Max. 880 880

B Min. 510 510

Long Adjustable Short Adjustable

Dia (A) 125 150

C Max. 480 480

C Min. 310 310

ADJUSTABLE LENGTHS

Telescopic Joint

Locking

Screws

To fit an adjustable length, loosen the locking screws

with a suitable screw driver. Adjust the telescopic

pipes to the required length, ensuring that the overlap

between the two pipes must not be less the 80mm.

Once adjusted to required length, secure the telescopic

lengths by fastening the locking screws. Seal the

telescopic joint using Mi-Flues high temperature

sealant (rated to 1000°) or fire cement.

4

MI-Flues System 7 Vitreous Enamelled Stove Pipe

90°TEE -with Cleaning Inspection Cap

A 90°Tee is used at the bottom

of a flue run and allows the flue

system to be easily cleaned. It

is only to be used when

installing the flue at the rear

outlet of a stove. This is also

designed to take a draught

stabiliser.

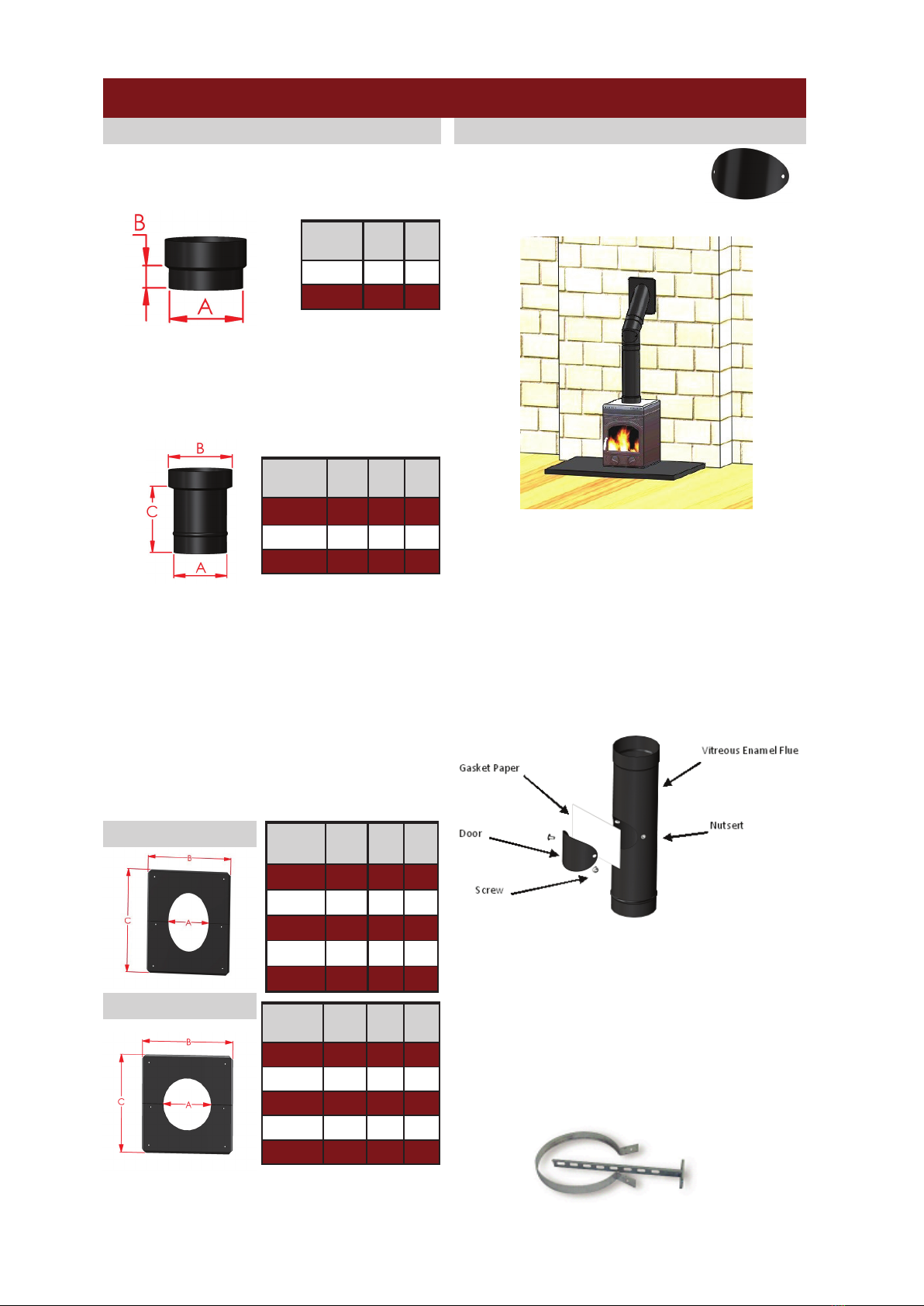

45° Bend

45° Bend -with clean out door

Product

Code Dia.(A) (B) (C) (D) (E)

Sys. 7 100 145 105 65 45

Sys. 7 125 155 110 70 50

Sys. 7 150 150 110 65 40

Sys. 7 175 170 116 76 54

Sys. 7 200 183 122 87 61

Product

(A) (B) (C) (D) (E) (F)

Sys. 7 100 215 165 65 45 73

Sys. 7 125 215 167 70 50 73

Sys. 7 150 210 160 65 45 73

Sys. 7 175 202 149 76 54 63

Sys. 7 200 215 154 86 61 73

Product

Code Dia. (A) (C)(B) (D)

Sys. 7 100 204 4080 35

Sys. 7 125 251 40108 35

Sys. 7 150 267 40113 35

Sys. 7 175 260 110 40 35

Sys. 7 200 320 140 40 35

90° Bend With Door

Product Dia.(A) (B) (C)

Sys. 7 100 114 154

Sys. 7 125 128 168

Sys. 7 150 132 173

Sys. 7 175 148 188

Sys. 7 200 164 199

Product Dia.(A) (B) (C)

Sys. 7 100 114 154

Sys. 7 125 128 168

Sys. 7 150 132 173

Sys. 7 175 148 188

Sys. 7 200 164 199

90° Bend

45° Insulated Sleeve

Product Dia.(A) (B) (C)

Sys 7 100 150 140

Sys. 7 125 180 140

Sys. 7 150 200 140

Sys 7 175 225 140

Sys 8 200 250 140

Used to provide a 45°

change of direction or can

be used in pairs as an

offset. Two by 45° bends

can be used to create a 90°

bend.

Used to provide a 90°

change of direction. It

may be taken to be

equal to two 45° bends.

Used to provide a 90° change

of direction and includes a

non corrosive stainless steel

access door to facilitate

cleaning of the chimney

system. It may be taken to be

equal to two 45° bends.

Where System 7 passes

through a non combustible

wall, Mi-Flues recommend

that an insulated sleeve is

used around the pipe. An

insulated sleeve is used to

pass the pipe through the

wall thus providing a

continuous uninterrupted

run through it.

This component provides

access for cleaning and

inspection. It is used to

provide a 45° change of

direction. Manufactured

with a non corrosive stain-

less steel access door with

high temperature

gasket and corrosion proof

re-usable locking nuts.

5

MI-Flues System 7 Vitreous Enamelled Stove Pipe

COMPONENTS

Increasing Adaptor

Designed to enable three diameters of System 7

pipe to be stepped up one diameter as appropriate.

It increases the diameter from 100mm to 125mm,

125mm to 150mm and 150mm to 175mm.

Rosette Plates

A rosette plate is used for aesthetic purposes to

improve the finish of a flue as it penetrates a wall.

Available in diameters from 100 mm to 200mm.

Rosette plates are available in 90° and 45°

angles. They are also available in split form for retro

fitting. Each rosette plate comes individually

packaged. The pack contains one plate, two half

plates in the case of the split rosette, plugs and

screws.

To install, fit the plate/plates around the flue pipe and

secure to a non combustible wall using the fixings

provided.

Adjustable Wall Bracket

A wall bracket provides lateral support to a chimney

run. It is not a load bearing support. Available in

various diameters— Wall bracket length can be

adjusted from 50mm to 250mm by cutting extended

bar.

Brackets are supplied with a stainless steel band and

galvanised stem as shown.

Brackets are not available in a vitreous enamel finish.

They can however be sprayed using a suitable enamel

paint which is available from your local merchant.

Product Dia.

(A) (B) (C)

Sys. 7 100 125 155

Sys. 7 125 150 155

Sys. 7 150 175 155

Product Dia.

(A) (B) (C)

Sys. 7 100 207 207

Sys. 7 125 230 230

Sys. 7 150 254 254

Sys. 7 175 281 281

Sys. 7 200 307 307

45° Rosette Plate

90° Rosette Plate

Coloured finish access door

Start Off Adaptor

This is used to connect an appliance to a System 7

pipe. It is available in 125mm and 150mm.

Product Dia.

(A) (B)

Sys. 7 115 35

Sys. 7 140 35

Product Dia.

(A) (B) (C)

Sys. 7 100 207 250

Sys. 7 125 230 284

Sys. 7 150 254 318

Sys. 7 175 281 356

Sys. 7 200 305 392

To install Mi-Flues System 7 door (as shown below),

firstly remove original door by opening the screws with

a suitable sized Allen key. Ensure surface of pipe is

clean and smooth before fitting new door. To fit the

new door, mate the gasket paper up with the inner face

of the door and pierce two holes to allow for the fitting

of the new screws. While firmly pushing the door

against the pipe in order to maintain a good seal, tight-

en the two screws, fastening the door to the pipe.

Mi-Flues System 7 door comes complete with the

following components: 1x Vitreous enamelled door and

1x Gasket Paper

Mi-Flues can supply a coloured

finished door (on request) as an

alternative to the standard steel finish.

Coloured finish door plus Rosette plate

6

Cleaning / Maintenance

Adequate provision should be made for inspecting and

cleaning the chimney system. Lengths and bends are

available with access doors in the product range. A

90° Tee is also available as an Inspection/Cleaning

component. Cleaning/Inspection access should be

provided to suit the installation, unless sweeping can

be undertaken through the appliance.

The chimney should be inspected regularly and

cleaned at least twice a year, depending on usage and

type of fuel used. This should be carried out with the

use of a brush which should not be made from black

steel.

The chimney should be maintained to ensure that the

construction remains in good condition.

Any components showing signs of deterioration which

may affect performance should be replaced under

professional advice, any evidence of leakage identified

by smoke staining should be rectified immediately.

If removing the access door during the cleaning

process the existing gasket paper should be removed

and replaced.

Replacement gasket paper is available through your

local merchant.

MI-Flues System 7 Vitreous Enamelled Stove Pipe

When a System 7 flue pipe is joined to our System 2

twin wall insulated chimney which penetrates a

combustible ceiling, the upper end of the System 7

pipe should terminate four times the diameter of the

pipe below a combustible ceiling level

Connecting flue pipe components should extend a

distance of 600mm off a solid fuel appliance.

This connection can be sealed using Mi-Flues high

temperature sealant (rated to 1000°C) or a fire

cement and the connection must be made in the

same room as the appliance itself.

Safety / Installation / Regulations

Distance to Combustible materials

Mi-Flues System 7 should be fitted at least four times

the diameter of the pipe away from any

combustible materials.

Chimney Plate

The chimney plate provides information regarding the

Manufacturer, designation, nominal size, distance to

combustibles, Installer name, installation date, chimney

location and thermal distance.

It is to be completed by the Installer and securely fixed

in an unobtrusive but obvious position within the

building such as next to the electricity or gas consumer

unit, next to the chimney hearth or next to the water

supply stop-cock.

Connection to the Chimney

Safety / Installation / Regulations

System 7 must only be used to make the

connection between the appliance outlet spigot and

the chimney. It should not pass through any roof

space, partition wall or floor, except to pass directly

into a chimney through a wall of the chimney (see

installation illustration on final page).

System 7 should be guarded if there could be a risk

of damage or if the burn hazard it presents is not

immediately apparent.

Connection to System 2 twin wall chimney

Connection to Flexible liner through a non

combustible wall

Connection to Mi-Flues System 35 flexible flue liner

can be made either from directly under the chimney

where the appliance is positioned within a fireplace

or through the side of the chimney using one of our

System 35 adaptors suitable for the purpose (see

installation illustration on final page).

Connection to the appliance

System 7 is designed to fit straight into the

appliance outlet spigot without the need for an

adaptor. However, for smaller fitting diameter

spigots, where the joint between the appliance

outlet spigot and the flue pipe is quite loose, an

adaptor is available to improve the tightness of the

joint.

When making the connection between the appliance

outlet and the System 7 pipe Mi-Flues high

temperature sealant (rated to 1000°C) or fire cement

should be applied.

Height of Connecting flue pipe

A run of System 7 Vitreous Enamel pipe should be

limited to no more than a maximum of 1.8 metres.

Bends in Connecting Flue pipes

Top Outlet Appliance—System 7 should have no more

than two bends in its length with an angle no greater

than 45° when measured from the vertical.

Where possible System 7 flue pipe should rise

vertically straight.

Rear Outlet Appliance—Connection to a rear

outlet appliance may be made using the 90° Tee or

bend. The maximum horizontal distance from the

outlet of the spigot should be no more than 150mm on

solid fuel appliances, subject to the appliance

manufacturers installation instructions.

System 7 length

System 35 Adaptor

System 35 flexible flue

7

Life Expectancy

Under normal operating conditions, and providing the

system is installed and maintained correctly,

Mi-Flues System 7 should provide many years

service and is provided with a 10 year conditional life

expectancy. Prolonged periods of slow burning can

however reduce the life expectancy of the product.

Handling and Storage

All System 7 components are individually boxed or

packaged and labelled. Relevant information from the

label should be transferred to the chimney plate.

Product should be stored in a dry suitable storage

location.

The product is easy to handle, but care should be

taken when holding, fitting or assembling any part of

the system.

Users are advised to use suitable precautions such as

gloves, eye/face protection, protective clothing etc to

avoid injury.

Installers should be aware of the Safety, Health and

Welfare at Work Act 2005 & Safety, Health and

Welfare at Work (general application) regulations 2007.

Installers should be aware of the possibility of

disturbing asbestos when working in older properties.

This should be dealt with in accordance with the strict

guidance documents. Particular attention should be

taken to ensure suitable PPE is used when applying

certain fireclays which can be of a caustic nature, as

well as when using any other substances which may

be harmful.

System 7 Technical Data

Fuel Solid Fuel, Oil, Gas

Material

1.8mm Double sided vitreous

enamelled steel

Min. Distance to

combustibles Four times diameter of flue

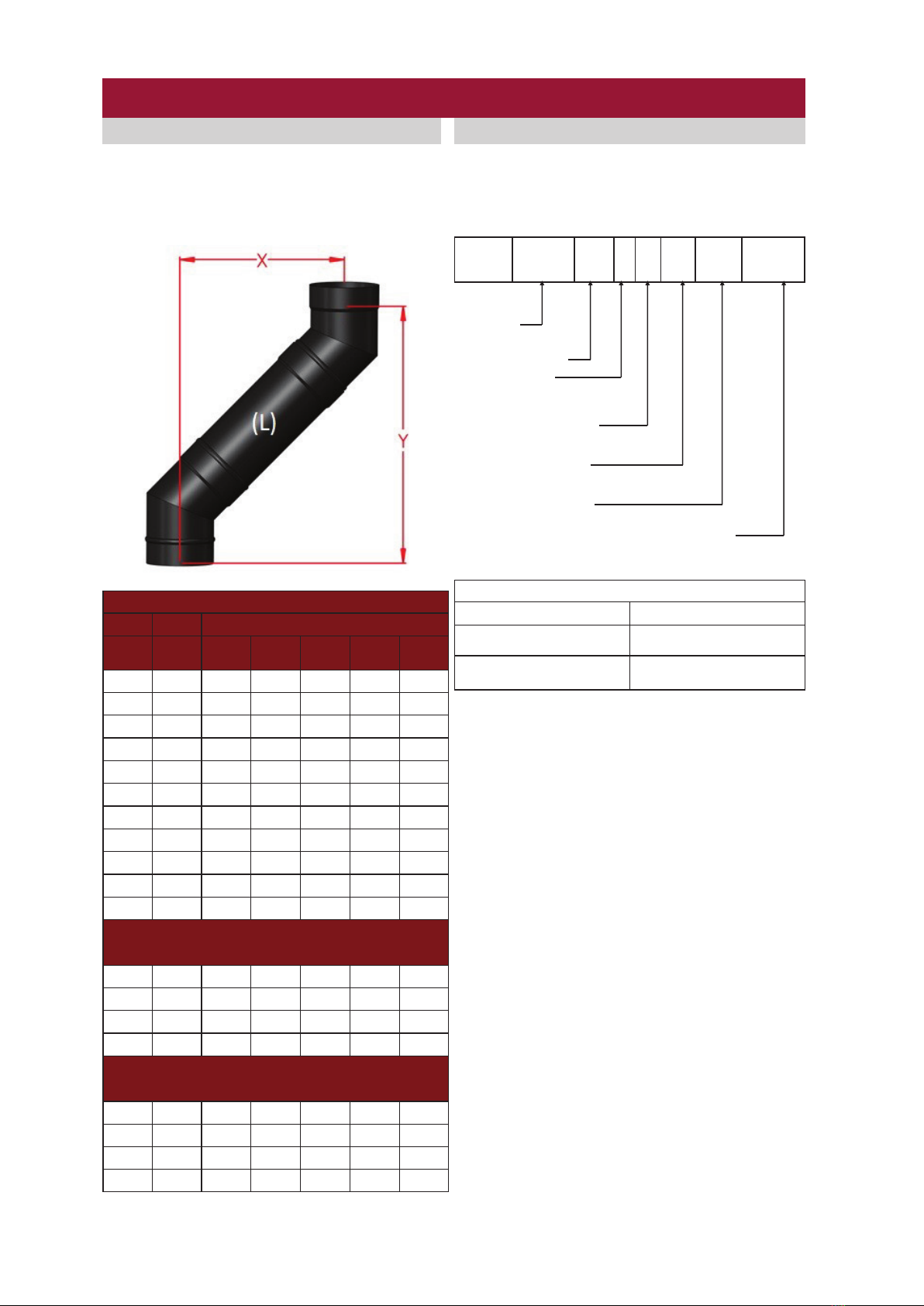

OFFSET CHART

The offset chart below is using the

recommended Mi-Flues System 7 45° bends.

Within a run of system 7 flue no more than two

bends should be used. Two bends are used to

create one offset.

PRODUCT DESIGNATION

Mi-Flues System 7 carries the following product

designation code.

EN1856-2 T600 N1 D Vm L80180 G (**)

Note: **4 x diameter of the flue

System 7 EN1856-2T600 N1 DVm L80180 G(**)

Standard

Temperature Level

Pressure Level

N, P or H

Condensate Resistance

W:Wet or D:Dry

Corrosion Resistance

(durability against corrosion)

Material specification

Sootfire resistance and distance to combustibles

G:Yes or O:No / distance to combustibles in mm

System 7 Offset Chart

Diameter

(L) Offset

100m

m

125m

m

150m

m

175m

m

200m

m

0X118 123 125 137 144

Y284 308 302 337 352

300 X302 311 309 325 331

Y468 492 486 524 540

500 X443 453 450 466 472

Y610 634 628 666 681

1000 X797 801 804 820 826

Y963 987 981 1020 1034

1200 X938 948 945 961 967

Y1105 1129 1123 1161 1176

300mm Adjustable

Length

X Min 309 319 316 332 338

X Max 429 439 437 452 458

Y Min 475 500 494 532 546

Y Max 596 620 614 652 667

500mm Adjustable

Length

X Min 450 460 458 473 480

X Max 712 722 719 735 741

Y Min 617 641 635 673 688

Y Max 878 903 897 935 950

MI-Flues System 7 Vitreous Enamelled Stove Pipe

8

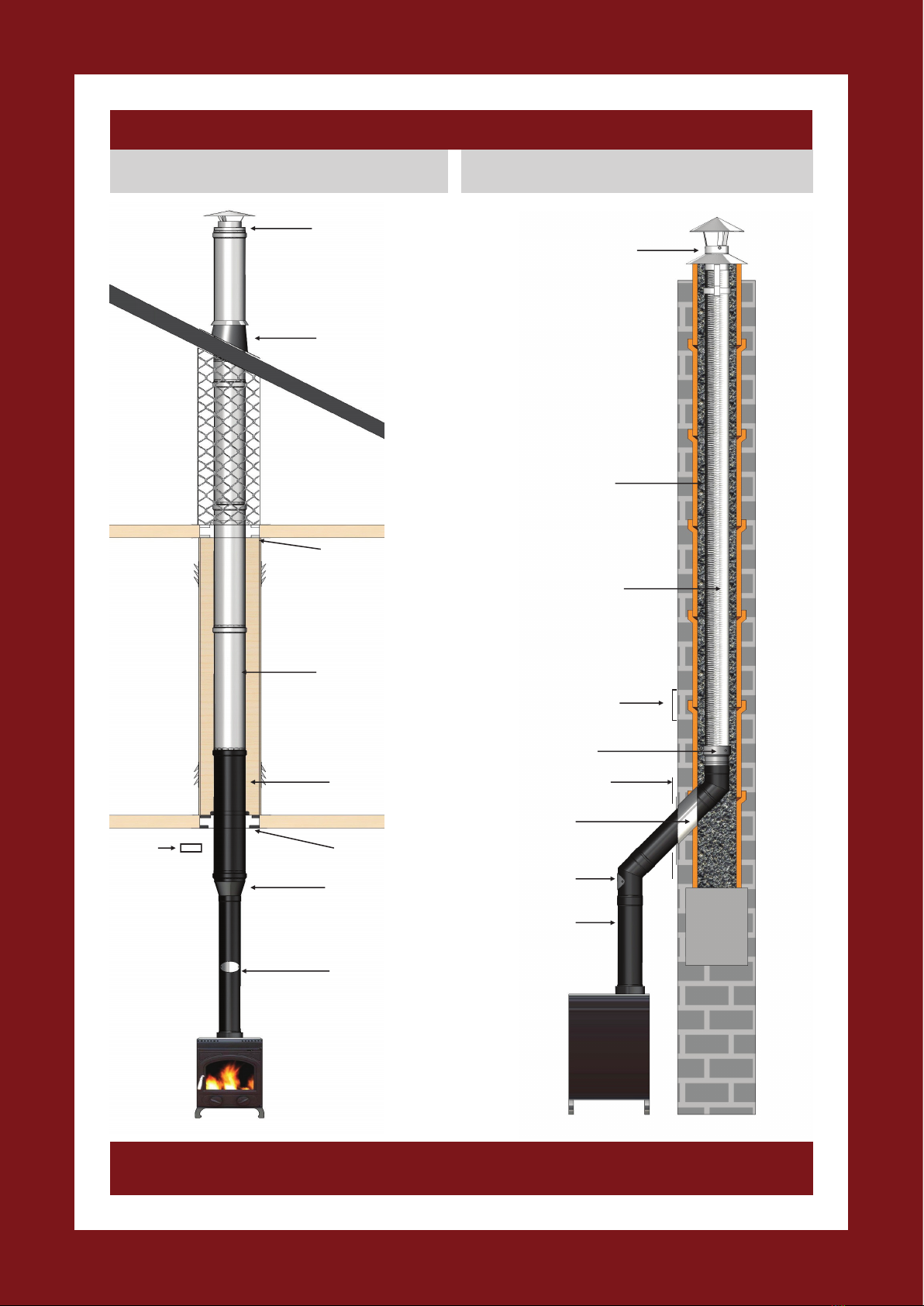

MI-Flues System 7 Vitreous Enamelled Stove Pipe

System 7 Length

with cleaning door

System 2 Twin Wall

Tapered Adaptor

System 2 Firestop

System 2

Length Black

System 2 Length

System 2 Firestop

System 2 Flashing

with Storm Collar

System 2 Cowl

System 7 Length

System 7 Bend

with cleaning door

System 7 Mesh

Insulated Sleeve

System 7 Rosette Plate

System 35 Adaptor

System 35 Flexible Flue

System 35 Pot Hanger Cowl

All flue systems must be installed according to current Building Regulations. Mi-Flues has adopted a policy of continuous product review, and in

the interests of development and improvement the Company reserves the right to vary the appearance and performance of any of its products

without prior notice. Correct at time of print (September 2014). For updates please check our website.

Mi-Flues Ltd , Summerhill Enterprise Ctr., Summerhill, County Meath, IRELAND

Telephone: +353 46 95 58030 Fax: +353 46 95 58034

System 7 connection to an existing brick chimneySystem 7 connection to System 2 twin wall

insulated stainless steel chimney

Back Fill flexible flue

Chimney

Plate

Chimney

Plate

Table of contents

Other Mi-Flues Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Electrolux

Electrolux EFT 50466 user manual

Whirlpool

Whirlpool RH7630XL installation instructions

LG

LG DC9201SAU Installation and operating instructions

Electrolux

Electrolux LFG315X user manual

Sirius Range Hoods

Sirius Range Hoods SCH31A installation instructions

ELICA

ELICA Circus Instruction on mounting and use

Franke

Franke FDF 6354 XS Instructions for use and installation

Prizer Hoods

Prizer Hoods CFM300 installation instructions

EF

EF CK-SPECCHIO user manual

NuTone

NuTone RANGEMASTER RM60000 Series Installation instructions and user manual

Miele

Miele DA 6690 W Operating and installation instructions

Franke

Franke FBI 537 XS Instructions for use and installation