Mi-Flues SYSTEM 1 User manual

Tel: +353 46 95 58030

Fax: +353 46 95 58034

Web: www. miflues.ie

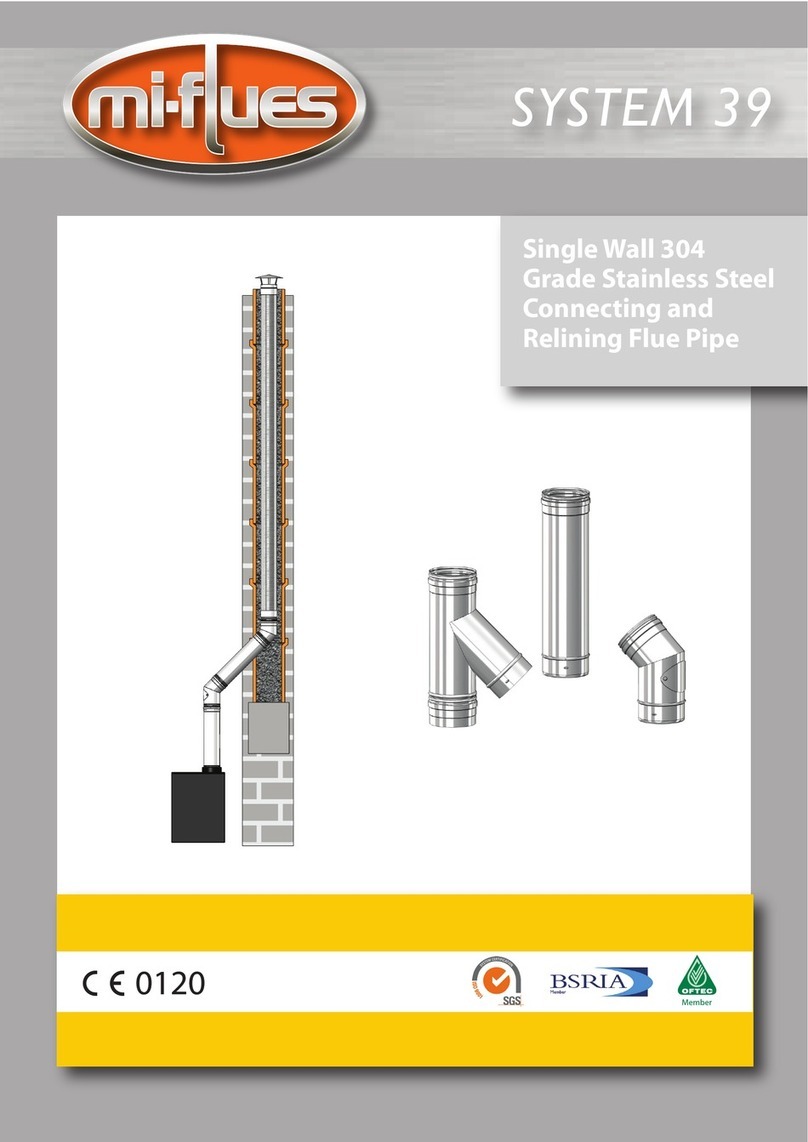

SYSTEM 1

Single Wall Connecting

Flue Pipe for Multi-Fuel

Appliances

System1 Single.indd 1 28/06/2013 14:47

September 2014

2

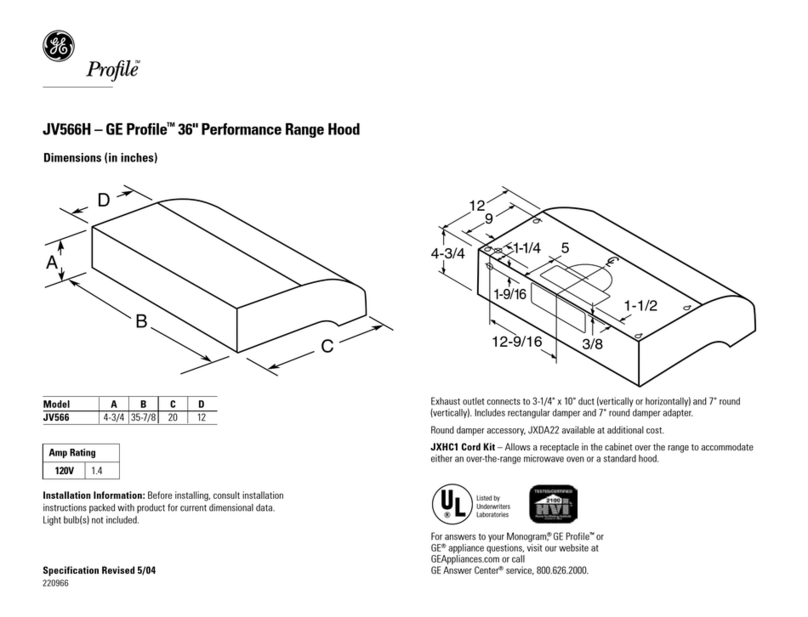

Mi-Flues System 1 allows for a 50mm overlap distance

per joint. All sockets (female end) should be installed

upwards, with the male end dropping into the socket.

To install Mi-Flues system 1 components simply

position the male end into the female socket end and

seal with Mi-Flues high temperature sealant (rated to

1000°C) designed specifically for flues, stoves or fires,

or similar rated fire cement.

PRODUCT DESCRIPTION

JOINTING SYSTEM

Mi-Flues System 1 is a 1mm thick 316 grade

stainless steel single wall connecting flue pipe

suitable for gas, oil, wood and multi-fuel appliances.

It can also be used as a rigid flue liner.

It has been specifically engineered to give an

authentic visual look, whilst at the same time being

manufactured using the latest technology to ensure

years of trouble free use.

The system is available in four standard diameters

125mm, 150mm, 180mm and 200mm.

System 1 is not suitable for condensing applications.

APPLICATION

Mi-Flues System 1 is a single wall connecting flue

pipe suitable for multi-fuel appliances.

It is also suitable for relining existing chimneys.

System 1 pipes are not insulated. Their use as an

external flue is not permitted as they can generate

excessive condensation and disrupt the draw due to

cold outside temperatures.

Mi-Flues System 1 316 grade stainless steel single

wall is suitable for use on applications fired by gas, oil

and solid fuel .

The longitudinal seam on all components is fully

welded to prevent leakage and to ensure a uniform

high quality of manufacture throughout.

Components have been designed to be installed

quickly, safely and simply. Mi-Flues System 1 single

wall flue is designed to be installed with the socket

(female end) directed upwards.

By fitting the flue components together in this manner

ensures debris and moisture will run internally down

the flue.

INTRODUCTION

Mi-Flues System 1 Single Wall Connecting Flue Pipe and Rigid Flue Liner

APPROVALS

COMPONENTS

MI-Flues System 1 components have been designed

to be installed quickly, safely and simply.

The system comprises of plain lengths, adjustable

lengths, bends, bends with inspection/cleaning

access, tees complete with cleaning inspection caps,

cowls and support brackets.

INSTALLATION

Installation in a Masonry Chimney

System 1 is also suitable for relining existing chimneys.

If relining a masonry chimney it should firstly be

cleaned to ensure free passage of the pipe.

The space between the flue and the masonry liner

should be back filled to improve the performance of the

chimney. Mi-Flues System 1 can be connected directly

to the appliance and can also be used to reline a

chimney when installed with the manufacturers

installation instructions. When using as a rigid liner

System 1 should be installed from the bottom up

ensuring that all joints are adequately sealed. The

weight of the System 1 rigid liner should be supported

at the lower end of the chimney with the use of two

rigid members (two metal beams—not supplied by

Mi-Flues) and a half bracket (see page 4 for details).

System 1 has been specifically designed for use as a

connecting flue pipe to facilitate connection from the

outlet of a multi-fuel appliance to the chimney.

Where appropriate it can be used to connect to either

our twin wall System 2 product or in the case of an

existing brick chimney, our System 35 Multi fuel flexible

liner .

In all cases the product must be installed in

accordance with Local Building Regulations Document

J and the manufacturers installation instructions.

The diameter of the pipe used must be equal to or

greater than the outlet of the appliance.

The diameter of pipe used should not be less than the

diameter specified by the appliance manufacturer.

Mi-Flues System 1 is manufactured and conforms to

EN 1856-2 and has the following designation code:

EN 1856-2 T600 N1 D Vm L50100 G(**)

Note: ** 3 x diameter of the flue

Socket-

Female end

Male End

Mi-Flues System 1 should be fitted at least three times

the diameter of the pipe away from any combustible

materials. For example 125mm pipe should be a

minimum of 375mm away from any combustible

material. All sockets (female end) should be upward,

with the male end dropping into the socket .

This ensures that no condensate can escape and spoil

the appearance of the finished installation.

3

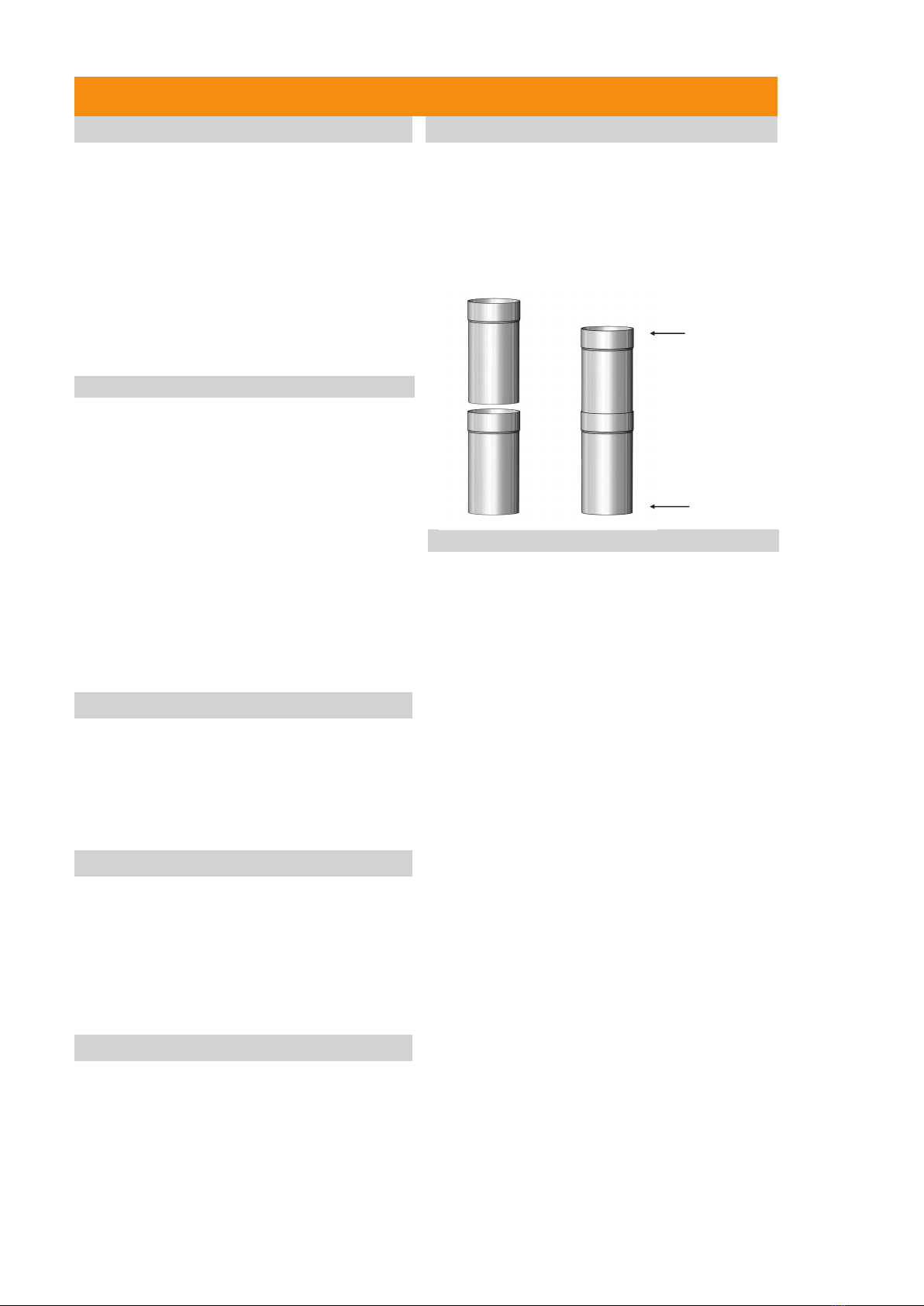

90 ° BEND

LENGTHS 45 ° Bend

Dia(mm) ‘A’ 250(B) 500(B) 1000(B)

125 200 450 950

150 200 450 950

180 200 450 950

200 200 450 950

Dia (A) (B) (C) (D) (E)

125 143 100 55 40

150 155 110 60 42

180 165 118 70 45

200 175 125 70 50

Diameter (A) (B) (C)

125 105 162

150 120 170

180 145 195

200 148 198

ADJUSTABLE LENGTHS

Diameter (mm) (A) ADJ Short

(B) Min—Max

125 255-370

150 255-370

180 255-370

200 255-370

45 ° BEND & DOOR

Dia. (A) (B) (C) (F)(E)(D)

125 200 165 694055

150 200 160 704360

180 235 185 994867

200 250 200 1205070

Lengths are available in 250mm, 500mm and

1000mm.

An adjustable length is used to achieve an exact

required length where a standard length is not

suitable.

Used to provide a 45°

change of direction or can

be used in pairs to create

an offset. Two by 45°

bends can be used to

create a 90° bend.

Used to provide a 90°

change of direction. It

may be taken to be

equal to two 45°

bends.

Mi-Flues System 1 Single Wall Connecting Flue Pipe and Rigid Flue Liner

90 ° BEND & DOOR

ADJUSTABLE LENGTH INSTALLATION

To install an adjustable length, adjust the telescopic

component to the required length, keeping caution

that the overlap between the two pipes must never

be less than 80mm. Seal telescopic joint using

Mi-Flues high temperature sealant (rated to 1000°C)

or fire cement. Once adjusted to the required length,

secure the telescopic length with the use of an

Mi-Flues wall bracket located directly above the

overlap.

This component provides

access for cleaning and

inspection. It is used to provide

a 45° change of direction.

Manufactured with a non

corrosive stainless steel access

door with high temperature

gasket and corrosion proof

re-usable locking nuts.

Used to provide a 90° change

of direction and includes a non

corrosive stainless steel

access door to facilitate

cleaning of the chimney

system. It may be taken to be

equal to two 45° bends. (For

dimensions see above table for

90° bend)

4

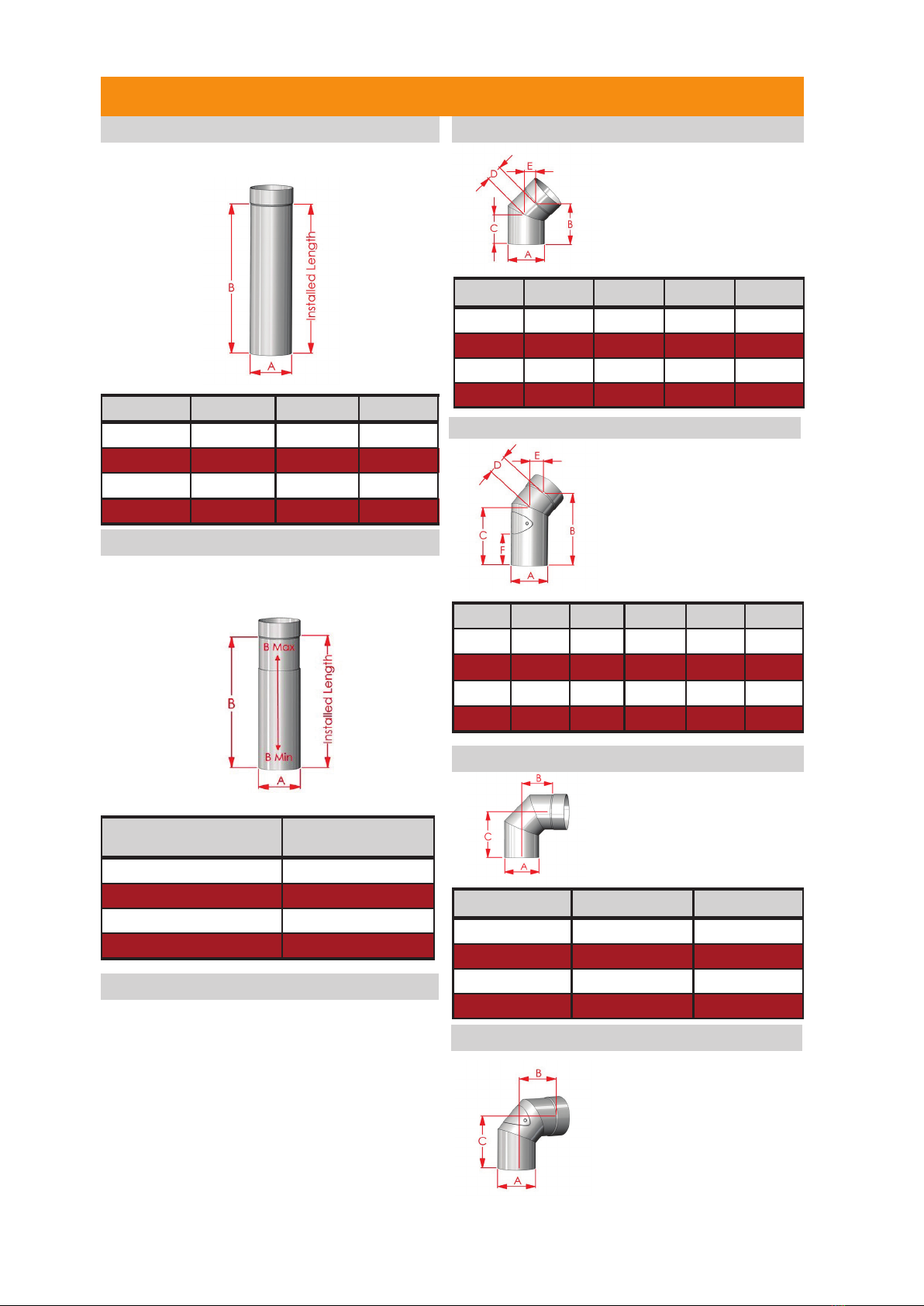

45 ° TEE

90 ° TEE

Diameter (B) (C) (D)(A)

125 235 240 35281

150 270 270 35334

180 298 307 35364

200 335 332 35418

COWL

Dia (A) (B)

125mm, 150mm,180mm,200mm 90

SUPPORT COMPONENT—WALL BRACKET

(A) (B) (C) (D)Diameter

233 93 80 35125

260 106 80 35150

281 116 80 35180

308 130 80 35200

Used to provide lateral

support for the System 1

components. This

component is adjustable

between 60mm—250mm of

a wall face.

START OFF ADAPTOR

Mi-Flues System 1 Single Wall Connecting Flue Pipe and Rigid Flue Liner

Diameter (A) 125 150 180 200

B45 45 45 45

C258 258 258 258

D152 152 152 152

E20 20 20 20

Each bracket comes individually packaged with the

following included:

Wall Section x 1, Joiner Section x 1

Clamping Section x 1, M6x25mm Hex Head Bolt x 2

M6x12mm Hex Head Bolt x 4, M6 Nut x 6

Diameter

(A) 121.5 146.5 176.5 196.5

B130 130 130 130

Mi-Flues System 1 Start Off

Adaptor is used on smaller fitting

diameter spigots, where the

standard size component diameter

will not fit the appliance. This

adaptor is available to ensure

Mi-Flues System 1 pipes can be

fitted. When making the joint

between the appliance outlet and

the System 1 pipe Mi-Flues high

temperature sealant (rated to 1000°

C) or fire cement should be applied.

Tapered reducing adaptors are also

available on request.

A 45° Tee is used to create

a bend in a flue run. It can

be used to change a

chimney run from a

horizontal to a vertical run

when used with a 45° bend.

This component minimises

the resistance to flow

because of the angle

created with the vertical

axis. This component

comes complete with a

removable inspection cap.

A 90° Tee is used to

create a bend in a flue

run. It is used to change

a chimney run from a

horizontal run to a

vertical run.

This component comes

complete with a

Removable inspection

cap . It may also be used

for the fitting of a draught

stabilizer device.

A cowl is the top rain cap for a chimney. Its purpose is

to stop the infiltration of rain or snow to the inside of the

chimney. It does not impede the movement of the

products of combustion. It is pushed down into the last

length of the installation and sealed using Mi-Flues

high temperature sealant (rated to 1000°C).

This cowl is also available with a solid fuel bird guard

protection.

SUPPORT COMPONENT— HALF BRACKET

When using as a rigid liner

System 1 should be

installed from the bottom up

ensuring that all joints are

adequately sealed. The

weight of the System 1 rigid

liner should be supported at

the lower end of the chimney

with the use of two rigid

members (two metal beams—

not supplied by Mi-Flues) and

a half bracket as shown. Each

half bracket comes bubble

wrapped and labelled. Included

are the required two screws and

two nuts for assembling.

Diameter

(A) 125 150 180 200

B20 20 20 20

5

Mi-Flues System 1 should be fitted at least three times

the diameter of the connecting flue pipe away from any

combustible materials.

Excessive runs of single wall connecting flue pipe

should be avoided and limited to no more than a

maximum of 1.8 metres.

Connection to the appliance

Height of Connecting flue pipe

Bends in Connecting Flue pipes

Top Outlet Appliance—The connecting flue pipe

should have no more than two bends in its length

with an angle no greater than 45° when measured

from the vertical.

Where possible the connecting flue pipe should rise

vertically straight.

Rear Outlet Appliance—Connection to a rear

outlet appliance may be made using the 90° Tee

where the removable tee cap will be accessible.

The maximum horizontal distance from the outlet of

the spigot should be no more than 150mm on solid

fuel appliances, subject to the appliance

manufacturers installation

Distance to Combustible Materials

Connection to System 2 twin wall chimney

Connection to Flexible liner within a brick

chimney

Connection to Mi-Flues System 35 flexible flue liner

can be made either from directly under the chimney

where the appliance is positioned within a fireplace

or through the side of the chimney using a System

35 adaptor (see illustration on front cover).

Mi-Flues System 1 Single Wall Connecting Flue Pipe and Rigid Flue Liner

System 1 is designed to fit straight into the

appliance outlet spigot without the need for an

adaptor.

System 1 should only be used to make the

connection between the appliance outlet spigot and

the chimney. It should not pass through any roof

space, partition wall or floor, except to pass directly

into a chimney through a wall of the chimney (see

installation illustration on page 6).

All System 1 joints should be sealed with Mi-Flues

high temperature sealant (rated to 1000°C) or fire

cement should be applied.

Safety / Installation / Regulations

Chimney Plate

On completion of installation a chimney plate should be

completed. The chimney plate provides information

regarding the Manufacturer, designation, nominal size,

distance to combustibles, Installer name, installation

date, chimney location and thermal distance.

It is to be completed by the Installer and securely fixed

in an unobtrusive but obvious position within the

building such as next to the electricity or gas consumer

unit, next to the chimney or hearth or next to the water

supply stop cock.

Cleaning / Maintenance

Adequate provision should be made for inspecting and

cleaning the chimney system. Access components are

available in the product range (bends with doors and

tees) and should be installed to suit the installation,

unless sweeping can be undertaken through the

appliance.

The chimney should be inspected regularly and

cleaned at least twice a year, depending on usage and

type of fuel used. This should be carried out with the

use of a brush which should not be made from black

steel.

The chimney should be maintained to ensure that the

construction remains in good condition.

Any components showing signs of deterioration which

may affect performance should be replaced under

professional advice, any evidence of leakage identified

by smoke staining should be rectified immediately.

Handling and Storage

All System 1 components are labelled. Fitting

instructions appear on the label where applicable.

These labels should be removed from the product prior

to installation and relevant information transferred to

chimney plate. Products should be stored in a dry

suitable storage location.

The product is easy to handle, but care should be

taken when holding, fitting or assembling any part of

the system.

Users are advised to use suitable precautions such as

gloves, eye/face protection, protective clothing etc to

avoid injury.

Installers should be aware of the possibility of

disturbing asbestos when working in older properties.

This should be dealt with in accordance with the strict

guidance documents. Particular attention should be

taken to ensure suitable PPE is used when applying

certain fireclays which can be of a caustic nature, as

well as when using any other substances which may

be harmful.

Life Expectancy

Under normal operating conditions, and providing the

system is installed and maintained correctly,

Mi-Flues System 1 should provide many years

service and is provided with a 10 year life

expectancy.

Structural Considerations

As System 1 does not rely on Locking Bands to

secure the joint, it is critical that the system is

installed between two fixed and secured points

(appliance outlet and chimney inlet).

Where an offset is installed, each bend must be

adequately braced using suitable support

components to restrict any movement of the joint.

Safety / Installation / Regulations

When a System 1 flue pipe is joined to our System 2

twin wall insulated chimney which penetrates a

ceiling, the System 2 chimney should protrude

425mm below the ceiling on a 125mm diameter

chimney and three times the diameter for 150mm,

180mm and 200mm .

Connecting flue pipe components should extend a

distance of 600mm off a solid fuel appliance.

This connection can be sealed using Mi-Flues high

temperature sealant (rated to 1000°C) or a fire

cement and the connection must be made in the

same room as the appliance itself.

6

Mi-Flues System 1 Product Designation

System 1 Technical Data

Fuel—Solid Fuel, Oil and Gas

Material 1mm 316 stainless steel

Min. Distance to

combusbles 3 mes diameter of the ue

Mi-Flues System 1 products carry the following

designation code:

EN 1856-2 T600 N1 D Vm L50100 G (**)

Note: ** 3 x diameter of the flue

System 1 EN1856-2T600 N1 DVm L50100 G(**)

Standard

Temperature Level

Pressure Level

N, P or H

Condensate Resistance

W:Wet or D:Dry

Corrosion Resistance

(durability against

corrosion)

Material specification

Sootfire resistance and distance to

combustibles

G:Yes or O:No / distance to combustibles

in mm

NM (Not Measured) or M (Measured)

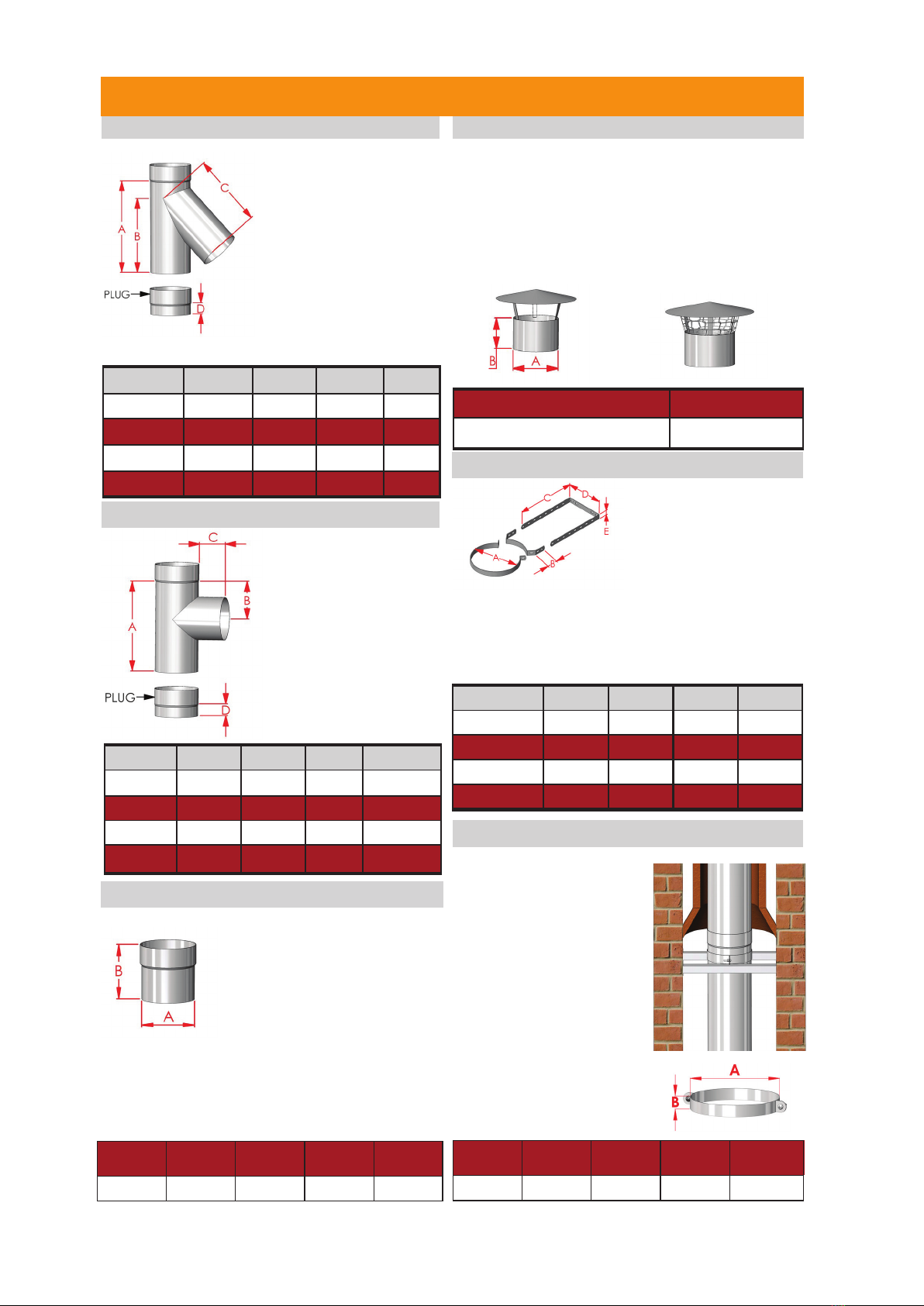

OFFSET CHART

This offset chart uses

the recommended

Mi-Flues System 1 45°

bends. Within a run of

system 1 flue no more

than two bends should

be used. Two bends

are used to create one

offset.

System 1 Oset Chart

Diameter

(L) Oset 125mm 150mm 180mm 200mm

0X119 126 135 140

Y285 303 327 338

250 X264 271 280 285

Y430 448 472 483

500 X436 447 457 462

Y607 625 648 660

1000 X794 801 811 815

Y961 978 1002 1013

Adjustable Length

X Min 299 306 316 320

X Max 377 384 393 398

Y Min 466 483 507 518

Y Max 539 556 580 591

Mi-Flues System 1 Single Wall Connecting Flue Pipe and Rigid Flue Liner

System 1 connection to System 2 twin wall

insulated stainless steel chimney

System 1 used as Rigid Flue Liner

System 1 length

System 1 bend with door

System 2 Adaptor

System 2 Insulated sleeve

System 2 Base

Wall Support

System 2 45° Tee

with removable

cap

System 2 length

System 2 bracket

System 2 45° bend

System 2 Cowl

Mi-Flues Ltd , Summerhill Enterprise Centre, Summerhill, County Meath, IRELAND

Telephone: +353 46 95 58030 Fax: +353 46 95 58034

All flue systems must be installed according to current Building

Regulations. Mi-Flues has adopted a policy of continuous product

review, and in the interests of development and improvement the

Company reserves the right to vary the appearance and performance

of any of its products without prior notice. Correct at time of print

(September 2014). For updates please check our website.

Chimney

Plate

System 1 length

System 1 Cowl

System 1 length

System 1 45° bend

Two metal beams (not

supplied by Mi-Flues)

and half bracket used to

support weight of System

1 when used as rigid

liner (see page 4).

System 1 45° bend

Chimney Plate

System 1 length

Table of contents

Other Mi-Flues Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Frigidaire

Frigidaire FJWA369TBIS instruction manual

KOBE

KOBE CH2230SQ Installation instructions and operation manual

Electrolux

Electrolux EFC 9411 Operating and installation instructions

Gaggenau

Gaggenau AI 230 700 use and care manual

Hob2Hood

Hob2Hood X79263MV1 user manual

Electrolux

Electrolux EFG50021 user manual