Mi-Flues SYSTEM 39 User manual

Tel: +353 46 95 58030

Fax: +353 46 95 58034

Web: www. miflues.ie

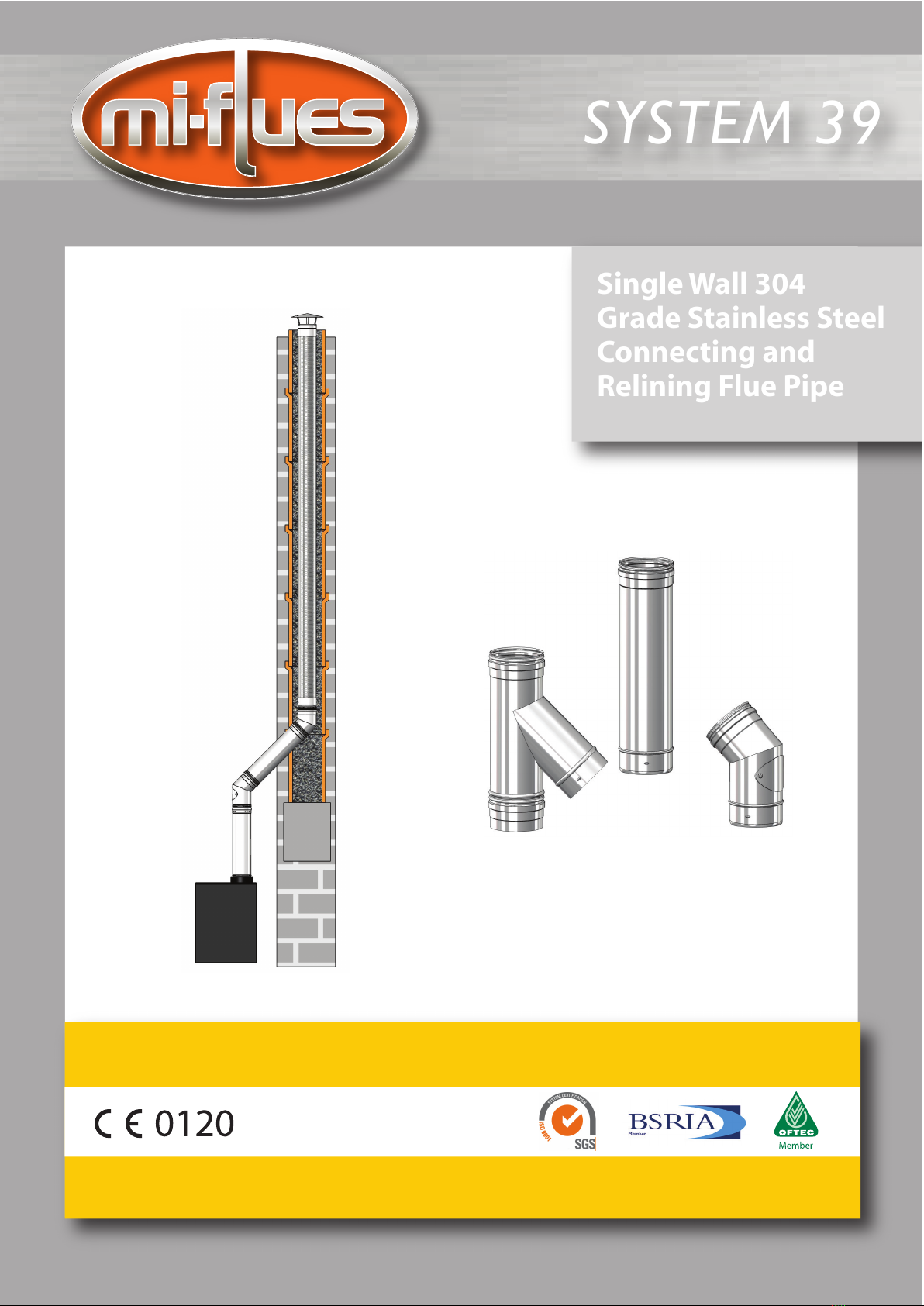

SYSTEM 39

Single Wall 304

Grade Stainless Steel

Connecting and

Relining Flue Pipe

APPLICATION

PRODUCT DESCRIPTION

Mi-Flues System 39 is a factory made single wall flue

system comprising of a range of lengths, tees, bends

and associated fittings and supports.

System 39 is available in five standard diameters:

100mm, 125mm, 150mm, 180mm and 200mm.

All lengths and flue gas carrying fittings are made

from 304-grade stainless steel. This is a high quality

annealed austenitic stainless steel.

The pipe seams are continuously seam welded

which provides an excellent gas sealed joint and

offers minimum resistance to flue gas flow.

System 39 is suitable for the following applications :

Flue gas system for gas and oil fired appliances, as

recommended by the appliance manufacturer

For relining existing chimneys using oil and gas

fired appliances

Ventilation—boiler rooms, laundries and kitchens

Fume extraction

It has been designed for flue gas temperatures not

exceeding 300°C.

It is not suitable for condensing applications.

INTRODUCTION

Mi-Flues System 39 Single Wall Stainless Steel Chimney

APPROVALS

COMPONENTS

Mi-Flues System 39 has been designed to be

installed quickly, safely and simply.

The system comprises of plain lengths, adjustable

lengths, bends, bends with inspection/cleaning

access, tees complete with cleaning inspection caps,

cowls and support brackets.

Mi-Flues System 39 is manufactured and conforms

to :

EN1856-2 T300 N1 D Vm L20040 O(**)

Note : **3 times diameter of the flue

Mi-Flues System 39 is designated suitable for a

connecting flue pipe and rigid chimney liner.

INSTALLATION

1. Select the components required for installation.

2. Ensure the male end of the liner chimney system

always points downwards in the direction of the heating

appliance.

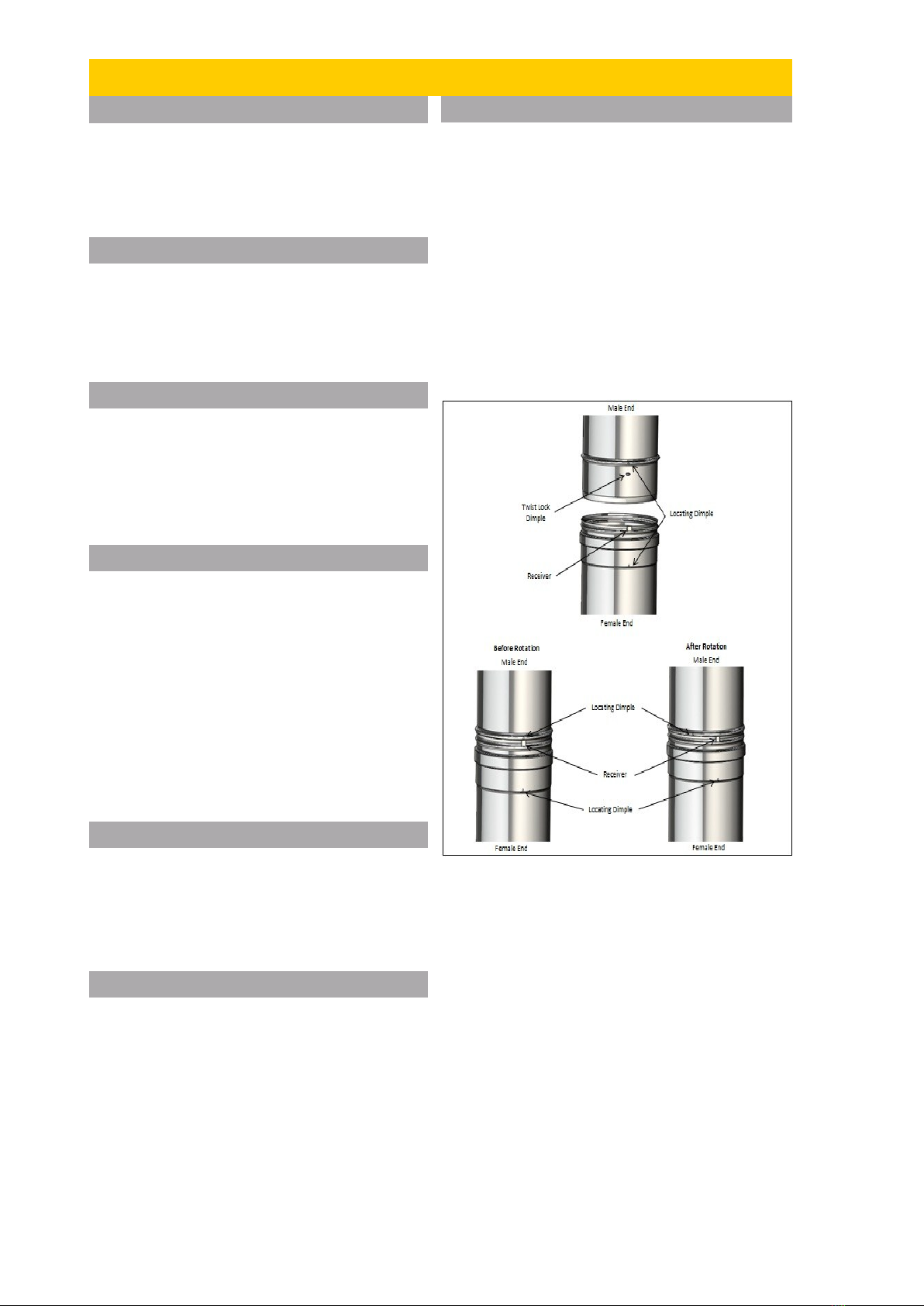

3. Align the locating dimple and twist-lock dimple on

the male end of the chimney liner system with the

locating dimple and receiver on the female end of the

chimney system as shown below.

4.Firmly push both chimney sections together ensuring

to keep locating dimple system in complete alignment .

5. Hold lower chimney section and gently twist

uppermost section to achieve desired twist lock system

Seal using Mi-Flues high temperature sealant (rated

to 1000°C) or a suitable fire cement.

See illustration below

Installation must be in accordance with Building

Regulations Document J.

System 39 operates most efficiently where there is a

vertical run from the appliance to the terminal.

A selection of bends are available to provide an offset

from the vertical. The chimney should not make an

angle more than 45° with the vertical, except where the

flue is connected to the back outlet of the appliance.

To prevent excess condensation of the flue gases and

potential freezing, System 39 is not permitted for

external runs.

Components are joined together by fitting the male

end of the first section into the female end of the

second section (as shown opposite).

Mi-Flues System 39 has a unique press fit jointing

system, which provides structural stability.

This jointing system ensures a quick and easy

installation offering excellent gas tightness

properties.

System 39 has a unique clik clak system which

does not require the use of a locking band.

JOINTING SYSTEM

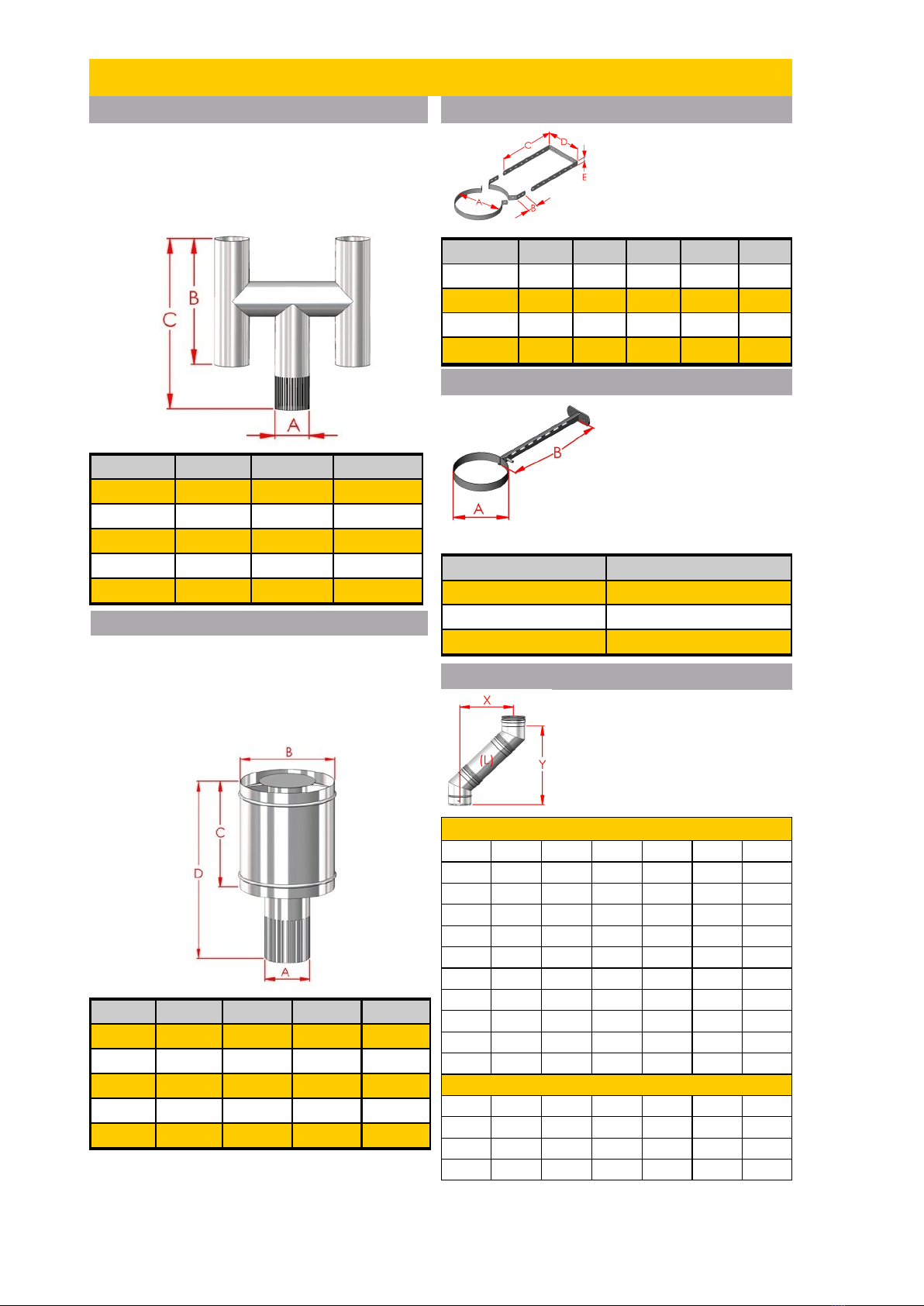

LENGTHS

Lengths are available in 250mm,

500mm, 1000mm and 1250mm.

(A) Dia (B)250 (B)500 (B)1000 (B)1250

100 196 446 946 1196

125 196 446 946 1196

150 196 446 946 1196

180 196 446 946 -

200 196 446 946 -

Product (A) (B) (C) (D) (E)

Sys.39 100 130 100 50 35

Sys.39 125 138 105 57 42

Sys.39 150 142 109 60 43

Sys.39 180 155 115 67 45

Sys.39 200 162 115 75 54

45° BENDS WITH DOOR

ADJUSTABLE LENGTH

DIA(A) (B) (C) (D) (E) (F)

100 173 135 52 35 35

125 195 163 55 35 69

150 195 165 61 35 70

180 242 185 67 48 99

200 250 200 70 50 120

Product Dia. (A) (B) (C)

Sys.39 100 94 150

Sys.39 125 110 150

Sys.39 150 115 165

Sys.39 180 140 190

Sys.39 200 148 205

90° BENDS WITH DOOR

90° BEND

Product Dia. (A) (B) (C)

Sys.39 100 94 150

Sys.39 125 110 150

Sys.39 150 115 165

Sys.39 180 140 190

Sys.39 200 148 205

45° BEND

Product Diameter (A) ADJ Short (B) Min

-Max

Sys.39 100 340-490

Sys.39 125 340-490

Sys.39 150 340-490

Sys.39 180 340-490

Sys.39 200 340-490

Adjustable lengths are available to

assist achieving the exact length

required where a standard length is

not suitable. Adjust the pipe to the

required length and secure directly

above the overlap joint using a

support bracket. The joint is sealed

using Mi-Flues high temperature

sealant (rated to 1000°C) or a

suitable fire cement. Caution must

be taken that the overlap between

the two pipes must never be less

than 80mm.

Used to provide a 45°

change of direction or can

be used in pairs to create an

offset. Two by 45° bends

can be used to create a 90°

bend.

Used to provide a 45° change of

direction or can be used in pairs

to create an offset. The

inspection door provides access

for cleaning.

Used to provide a 90°

change in direction. It can

be taken to be equal to 2 x

45° bends.

Used to provide a 90°

change in direction. The

inspection door provides

access for cleaning. It can

be taken to be equal to 2 x

45° bends.

Mi-Flues System 39 Single Wall Stainless Steel Chimney

45° TEE

Product (A) (B) (D) (C) Dia.

Sys.39 255 100 25 30 100

Sys.39 255 100 25 30 125

Sys.39 255 100 30 25 150

Sys.39 280 112 30 25 180

Sys.39 305 125 25 30 200

90° TEE

Dia. (A) (B) (C) (D) Product

100 255 206 160 25 Sys.39

125 275 220 200 25 Sys.39

150 336 270 220 25 Sys.39

180 366 298 257 25 Sys.39

200 420 335 290 25 Sys.39

CHIMNEY TERMINATION—COWLS

Used to provide a 45° change

of direction. Also used as an

inspection/cleaning

component.

Used to provide a 90° change

of direction. Also used as an

inspection/cleaning

component.

A cowl is the top rain cap for a chimney. Its purpose is

to stop the infiltration of rain or snow to the inside of the

chimney. For oil fired appliances a stainless steel cowl

is attached to the end of the flue pipe (cowls with bird

guards are not available for oil appliances). For gas

appliances a cowl with mesh should be used.

ADAPTORS—START OFF

Product (A) (B)

Sys.39 100 85

Sys.39 125 85

Sys.39 150 85

Sys.39 180 85

Sys.39 200 85

ADAPTOR—REDUCING (Tapered)

Mi-Flues System 39 Single Wall Stainless Steel Chimney

STORM COWL

The Storm Cowl offers the

greatest protection against rain

and adverse weather

conditions. It reduces the

possibility of wind affecting the

appliance. It can be used on oil

fired appliances. It should be

secured in position with the use

of stainless steel self

tappers or rivets (not provided

by Mi-Flues)

Product (A) (B) (C)

Sys.39 100 272 155

Sys.39 125 295 155

Sys.39 150 320 155

Sys.39 180 347 155

Sys.39 200 370 155

Dia. (A) (B)

100 76

125 76

150 76

180 76

200 76

Product (A) (B) (C)

Sys.39 100 80 130

Sys.39 125 100 130

Sys.39 150 125 130

Sys.39 180 150 130

Sys.39 200 180 130

The System 39 start off adaptor

can only be used on oil and gas

appliances where recommended

by the appliance manufacturer.

(The table below gives the

nominal diameter prior to

crimping).

The System 39 reducing adaptor

can only be used on oil and gas

appliances where recommended by

the appliance manufacturer.

Product (A) (B) (C) (D) (E)

Sys.39 125 45 258 152 20

Sys.39 150 45 258 152 20

Sys.39 180 45 258 152 20

Sys.39 200 45 258 152 20

WALL BRACKET

Mi-Flues System 39 Single Wall Stainless Steel Chimney

A Wall Bracket provides

lateral support. It should

be used at 1.5mtr intervals.

This component is

adjustable between 60mm

and 250mm off a wall face.

H COWL

A H Cowl is used to reduce the possibility of down

draught problems occurring. The H Cowl slides

telescopically inside the previous length. It can be

used on oil fired appliances. It can be secured in

position with the use of stainless steel self tappers or

rivets (not provided by Mi-Flues)

ANTI DOWNDRAUGHT COWL

An Anti Downdraught cowl is used to reduce the

possibility of a down draught problem. It slides

telescopically inside the previous length. It can be

secured in position with the use of stainless steel

self tappers or rivets (not provided by Mi-Flues)

(A) (B) (C) (D) Product

100 205 250 529 Sys.39

125 230 250 545 Sys.39

150 276 305 564 Sys.39

180 322 356 764 Sys.39

200 369 405 919 Sys.39

ECONOMY WALL BRACKET

Product (A) (B) (C)

Sys.39 100 350 592

Sys.39 125 457 751

Sys.39 150 457 751

Sys.39 180 490 795

Sys.39 200 560 900

Dia. (A) (B)

100 250

125 250

150 250

The Economy Wall Bracket

provides lateral support. The

T piece is fixed to the wall

with fittings adequate for the

purpose. The wrap around

section is clamped around

the flue section and fastened

to the T Piece with the nut

and bolt supplied.

This offset chart uses the

recommended Mi-Flues System

39 45° bends. Within a run of

system 39 flue no more than two

offsets should be used. Two

bends are used to create one

offset.

(L) 100mm 125mm 150mm 180mm 200mm

0 X

Y

250 X

Y

500 X

Y

1000 X

Y

1250 X

Y

OFFSET CHART

Distance to Combustible materials

Mi-Flues System 39 should be fitted at least three

times the diameter of the pipe away from any

combustible materials.

Cleaning / Maintenance

Adequate provision should be made for inspecting

and cleaning the chimney system. Lengths and

bends are available with access doors in the product

range. A 90° Tee is also available as an Inspection/

Cleaning component. Cleaning/Inspection access

should be provided to suit the installation, unless

sweeping can be undertaken through the appliance.

The chimney should be inspected regularly and

cleaned at least twice a year, depending on usage

and type of fuel used. This should be carried out with

the use of a brush which should not be made from

black steel.

The chimney should be maintained to ensure that the

construction remains in good condition.

Any components showing signs of deterioration

which may affect performance should be replaced

under professional advice, any evidence of leakage

identified by smoke staining should be rectified

immediately.

Please ensure that labels are removed from

product prior to installation and relevant

information transferred to chimney plate.

SAFETY /INSTALLATION/REGULATION

Handling and Storage

All System 39 components are individually labelled.

They should be stored in a dry suitable storage

location. The product is easy to handle, but care

should be taken when holding, fitting or assembling

any part of the system.

Users are advised to use suitable precautions such

as gloves etc to avoid injury.

Life Expectancy

Under normal operating conditions, and providing the

system is installed and maintained correctly,

Mi-Flues System 39 should provide many years

service and is provided with a 10 year conditional life

expectancy.

Mi-Flues System 39 Single Wall Stainless Steel Chimney

Mi-Flues Ltd , Summerhill Enterprise Centre., Summerhill, County Meath, IRELAND

Telephone: +353 46 95 58030 Fax: +353 46 95 58034

Email: sales@miflues.ie Website www.miflues.ie

All flue systems must be installed according to current Building Regulations. Mi-Flues has adopted a policy of continuous product review, and in the interests of

development and improvement the Company reserves the right to vary the appearance and performance of any of its products without prior notice. Correct at time of

print. For updates please check our website.

System 39 EN1856-2 T300 N1 D Vm L20040 O(**)

System 39 EN1856-2 T300 N1 D Vm L20040 O

Standard

Temperature Level

Pressure Level

N, P or H

Condensate Resistance

W:Wet or D:Dry

Corrosion Resistance

(durability against

corrosion)

Material specification

Sootfire resistance and distance to combustibles

G:Yes or O:No / distance to combustibles in mm

NM (Not Measured) or M (Measured)

PRODUCT DESIGNATION

Technical Data

SYSTEM 39 CONNECTION TO EXISTING CHIMNEY

Note: **3xdiameter of the flue

System 39 length

System 39 bend

with cleaning door

System 39 lengths or

System 4 flexible flue

Chimney Plate

The chimney plate provides information regarding

the Manufacturer, designation, nominal size,

distance to combustibles, Installer name, installation

date, chimney location and thermal distance.

It is to be completed by the Installer and securely

fixed in an unobtrusive but obvious position within

the building such as next to the electricity or gas

consumer unit, next to the chimney or hearth or next

to the water supply stop cock.

Chimney Plate

Table of contents

Other Mi-Flues Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Dacor

Dacor DH3006 Use & care manual

Baumatic

Baumatic BTC6740SS instruction manual

Zephyr

Zephyr Twister AK8000AS Use, care and installation guide

Omega

Omega OA2416W Installation and operating instructions

Monogram

Monogram ZV830 installation instructions

Miele

Miele DAS 4940 Operating and installation instructions