Micrel SFP+ Guide

SFP+ Module Reference Design

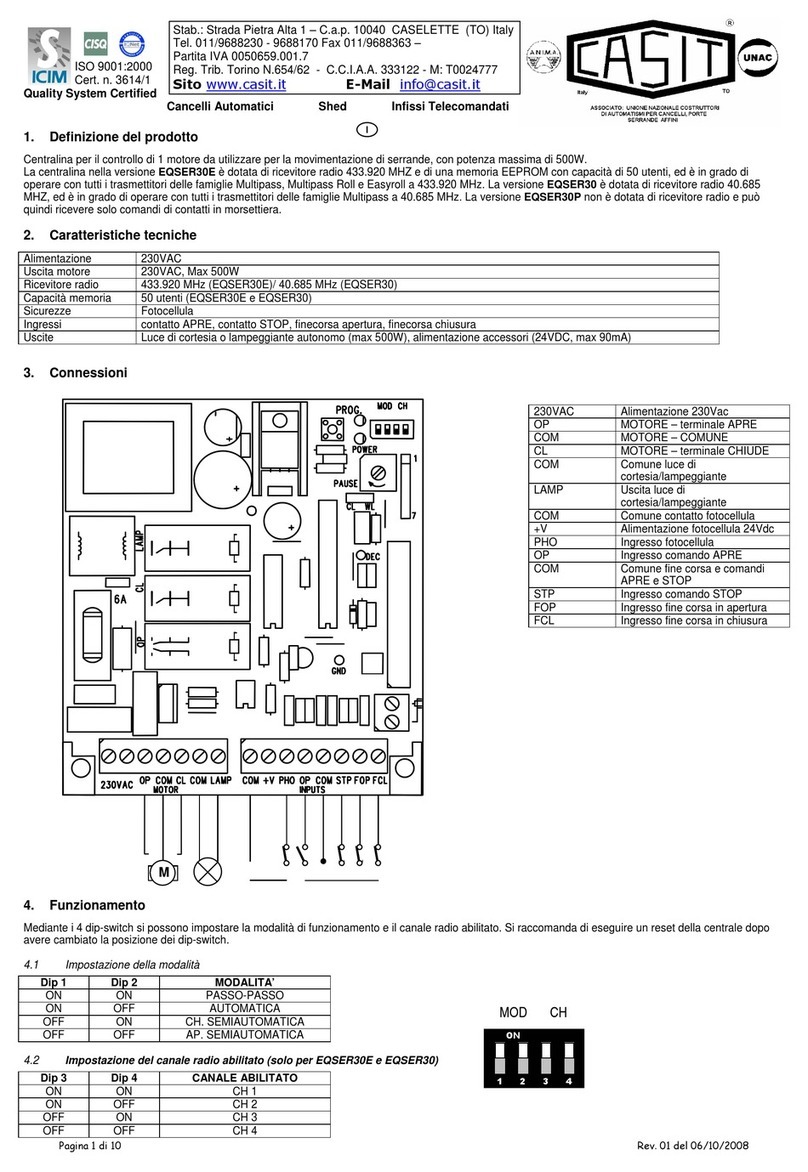

SFP_022AL_R0

Micrel Inc. • 2180 Fortune Drive • San Jose, CA 95131 • USA • tel +1 (408) 944-0800 • fax + 1 (408) 474-1000 • http://www.micrel.com

May 13, 2015

Revision 1.0

General Description

This evaluation board is a complete SFP+ module as

defined in the SFP+ MSA document. The design uses

Micrel’s MIC3003 controller, the 10G DFB/FP laser driver

SY88022AL, and any of the following 10G limiting

amplifiers: SY88053C/073L. A picture of the fully loaded

board is shown on the next page.

Datasheets and support documentation are available on

Micrel’s web site at: www.micrel.com.

Related Support Documentation

•MIC3003 datasheet: Fibre optic module controller

featuring digital diagnostic monitoring interface, as per

SFF-8472/SFF-8432, with internal/external calibration

and full laser control with bias and modulation current

compensation for temperature variations using lookup

tables.

•SY88022AL datasheet

•SY88053CL datasheet

•SY88073L

•MIC3003 software user’s guide.

Features

•Compliant with SFP+ MSA

•Allows for easy and fast evaluation of Micrel’s chipset

for SFP+ module

•Multi-rate operation up to 10Gbps

•Single, wide range power supply: 3.3V ±10%

•Industrial temperature range: –40°C to +85°C

Transmitter – FP/DFP Laser Diode Driver

•Operates from a single 3.3V supply

•Modulation current up to 60mA

•Fast edge rates of 25ps

•Bias current up to 80mA

•Input equalizer

•Small form factor 3mm × 3mm QFN package

Receiver – Limiting Post Amplifier

•External crosspoint adjustment (053CL/073L)

•Digital offset correction (063CL/083L)

•Wide differential input range (5mVPP to 1800mVPP)

•Wide SD de-assert or LOS assert threshold range

−3mVPP to 30mVPP with 4dB typical electrical

hysteresis

•Fast SD/LOS assert/de-assert time (053CL/063CL)

−75ns typical; 120ns maximum

•Selectable LOS or SD status signal indicator

•Selectable RXOUT+/RXOUT- polarity (053CL/073L)

•Available in a tiny 3mm × 3mm QFN package

Controller

•Extensive temperature range

•Alarms and warnings interrupt and TXFAULT masks

•Capability to support up to four chips on the serial

interface

•Integrated digital temperature sensor

•Temperature compensation of modulation, bias, and

fault levels via NVRAM lookup tables

•User-writeable EEPROM scratchpad

•Option to be used with Cisco security chip

•Diagnostic monitoring interface per SFF-8472/8432

•Space saving 3mm × 3mm package available

(MIC3003GFL)

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 2 Revision 1.0

Evaluation Board

Evaluation Board Setup

TOSA and ROSA Installation

Check the pin configuration of the TOSA and ROSA and

install them according to the diagram shown in Figure 1.

Driver Laser Coupling

The laser is AC-coupled to the driver. Compensation for

laser parasitics can be improved by choosing appropriate

values for R9 and C1. The laser’s response can be

improved by tuning, in addition to R9/C1, R1/R5 and

L1/L2/L5/L6/R6/R7. The optimal values of these

components depend on the length of the laser leads/flex

and can vary from one family of lasers to another. It is up

to the user to tune the values in order to achieve the best

compensation for the laser used with this board.

Receiver Sensitivity and Hysteresis Setting

The limiting amplifier has a receive signal LOS/SD

indicator. The LOS/SD sensitivity is set by the voltage at

SD/LOSLVL (pin 8) adjusted by the value of R28, which

forms a voltage divider with the 2.8kΩ internal resistor

terminated to VCC-1.3V.

Figure 1. Mounting of TOSA and ROSA

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 3 Revision 1.0

Setup and Operation

1. Set the desired frequency on a pattern generator with

amplitude between 200mVPP and 1800mVPP. Typical

data patterns are 27-1 or 223-1 PRBS patterns,

depending on the application. Because the inputs to

the board are AC-coupled, the voltage offset of the

pattern generator is not significant, so it can be set

between GND and VCC.

2. Connect the pattern generator with differential outputs

as a data source to the TXIN+ and TXIN- inputs on the

host board. Use matched length differential cables.

3. Connect the USB plug-in of the host board to the USB

port of the computer.

4. Connect the 3.3V red post on the host board to the

output of the 3.3V power supply and the black post to

the GND and install a jumper between pin 2 and pin 3

of SW1.

5. Plug the SFP module into the host board connector

and connect the laser to the optical plug-in of the

scope.

6. Turn on the power supply.

7. Launch the MIC3003 software, select the serial

address of the device to be scanned (A0 is the default

address), and then click initialization. The main

window will open.

8. Memory content can be read and/or modified on the

panels or by accessing the registers directly by

selecting ALL REGISTERS, enter the serial address

and register address, then select GET to read the

content or enter a new value, and select SET NEW to

write. In this procedure, the bits are set on the panels.

9. Refer to the MIC3003 Software User’s Guide for the

detailed settings and illustrations.

10. On the Panels list, select OEM CONFIG 3-4 and

select EXTERNAL CALIBRATION (default setting),

LOS COMPARATOR ENABLE, SHDN, RXLUT

INPUT TEMPERATURE, and RSOUT. If needed, later

set ISTART to a different value to speed up the APC

loop during laser turn ON after a FAULT occurrence.

Close this window to return to the main window.

11. On the Calibration list, select EXTERNAL

CALIBRATION. Set all the OFFSETS to 0 and

SLOPES to 1. For RXPWR, set only RX_PWR(1) to 1.

These parameters might need to be changed later to

correct the measured values (calibration). Close this

window to return to the main window.

12. On the Panels list, select OEM CONFIG 0-2 to open

the OEM configuration windows for registers 0, 1, and

2. Check the default setting of each and reset the

parameters to the correct values (below) if needed.

a. In the OEM Configuration Register 0 window, set

ENABLE/DISABLE to DISABLE, and set VMOD

REFERENCE to GND.

b. In the OEM Configuration Register 1 window, set

APC OP-AMP TYPE to EMITTER FOLLOWER,

select the voltage to report VINH:VINL, and set the

feedback voltage source to 1.22V. Also set

FEEDBACK BIAS REF and RES TERMINATION

to GND and set VBIAS DRIVE to SOURCE

(NPN). Set INTERNAL FEEDBACK RESISTOR

to INF.

c. In the OEM Configuration Register 2 window, the

MIC3003 address can be modified.

13. In the OEM Configuration Register 0 window, set

ENABLE/DISABLE to ENABLE.

14. On the Panels list, select User. Check APCSET0 and

MODSET0 in the USER CONTROL REGISTER

(default setting). All the other parameters’ functionality

can be checked later. Return to the main window.

15. On the Panels list, select OEM Settings and enter the

following values:

a. Enter 255 for the IBIAS FAULT and TX PWR

FAULT thresholds.

b. Enter 0 for LOSS-OF-SIGNAL threshold and 0 for

FAULT SUPPRESSION TIMER.

c. Enter desired DAC values for bias and modulation

between 0 and 255.

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 4 Revision 1.0

d. After entering these values, select SET NEW.

Select GET CURRENT to ensure the set values

are written to the registers. You may come back to

this panel to mask the faults by checking them at

the bottom of the window. Now return to the main

window.

16. On the Panels list, select Result. The values of the

five monitored parameters as per the SFF-8472 should

now display. Set the alarm and warning thresholds

(optional) and select SET NEW LIMITS. Select GET

CURRENT LIMITS to check that the set values are

written into the registers. Return to the main window.

17. After setting the new value for bias or modulation

current, toggle TXDISABLE/TXENABLE in the main

window or WARMRESET in the OEMCFG0-2 window.

18. Connect the laser to a variable optical attenuator

(VOA) and adjust the attenuation to bring the optical

power to the desired level at the input of the receiver.

Then connect the output of the VOA to the input of the

receiver using an appropriate fiber jumper.

19. If the installed receiver has RSSI signal, the value of

the received power should display, but may need

calibration.

20. At this stage, the masked faults should be unmasked.

If there is a fault indication, mask the indicated fault in

the OEMCONFG register (step 9) and try to find the

cause of the fault by checking the monitored values

and taking appropriate measurements.

21. Once the module runs without fault indication, proceed

to BER measurement, eye diagram analysis, and laser

driver and post amplifier performance evaluation.

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 5 Revision 1.0

Laser Response Tuning

Overshoot/Undershoot

The damping resistors R1 and R5 installed in series with

the laser are 5Ω. This value might be replaced with higher

values to minimize or suppress any overshoot or

undershoot on the optical signal out of the laser. Keep in

mind that higher value damping resistors will lead to higher

rise/fall time and less modulation current driving the

laser.The compensation network comprised of R6/C15 can

also be used for that purpose and to compensate for the

laser package’s parasitic inductance. The values indicated

on the schematic and pre-installed on the board

accordingly to the BOM may be replaced with different

values to optimize the laser response. Other components

that can be adjusted to improve the laser response are the

elements of the output termination network (L2, L3, R2,

R3, R4, R13).

Evaluation Board Schematic

Power and Receiver

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 6 Revision 1.0

Evaluation Board Schematic (Continued)

Transmitter

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 7 Revision 1.0

PCB Assembly

Top

Bottom

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 8 Revision 1.0

Bill of Materials

Item Part Number Manufacturer Description Qty.

C1 ECJZEC1E010C Panasonic(1)CAP CER 1PF 0201 1

C5-8 GRM033R71A103KA01D Murata(3)0.01µF, 25V, 10% Ceramic Capacitor, Size

0201, X5R, Dielectric 4

C17, C21-23,

C26 C1005X7R1E103K050BB TDK

(Error! Reference

source not found.)0.01µF, 25V, 10% Ceramic Capacitor, Size

0402, X5R, Dielectric 5

C20 ECJ0EB1C183K Panasonic 0.018µF, 25V, 10% Ceramic Capacitor, Size

0402, X5R, Dielectric 1

C2-4, C9, C18-

19, C24-25, C27-

34 C1005X7R1C104K050BC TDK CAP CER 0.1µF 16V 10% X7R 0402 16

C11-14 ECJZEB1A104M Panasonic CAP CER 0.1µF 16V 10% X7R 0201 4

C4 C1005X5R0J106M050B TDK CAP CER 10µF 6.3V 20% X5R 0402 1

L4-6, L8-10 BLM15BD121SN1 Murata Ferrite, Filter Chip, 120 OHM@100Mhz 1.5A,

0402 6

L1-3, L7 HZ0402A601R-10 or

BLM15HG601

Laird

Technologies(Error!

Reference source not found.)

or Murata

Ferrite, 600 OHM@100Mhz 100mA, 0402 2

R1, R5 ERJ-1GEF15R0C Panasonic RES 15 OHM 1/10W 1% 0201 SMD 2

R21-22, R33-34 ERJ-2GEJ100X Panasonic RES 10 OHM 1/10W 5% 0402 SMD 4

R20, R35 ERJ-2RKF24R9X Panasonic RES 24.9 OHM 1/10W 1% 0402 SMD 1

R6-7 ERJ-2GEJ101X Panasonic RES 100 OHM 1/10W 5% 0402 SMD 2

R18 ERJ-2GEJ131X Panasonic RES 130 OHM 1/10W 1% 0402 SMD 1

R9 ERJ-1GEF1470C Panasonic RES 147 OHM 1/10W 1% 0201 SMD 1

R20 ERJ-2RKF4993X Vishay

(6)

RES 499K OHM 1/10W 1% 0402 SMD 1

R32 ERJ-2GEJ102X Panasonic RES 1K OHM 1/10W 5% 0402 SMD 2

R15, R19, R28,

R31 ERJ-2GEJ103X Panasonic RES 10K OHM 1/10W 5% 0402 SMD 4

U3-4 NST3001 ON Semi

(7)

Dual PNP transistor 2

U1 MIC3003GML Micrel, Inc.(7)FOM Controller 1

U2 SY88022AL Micrel, Inc. 10G DFB Laser Diode Driver 1

U5 MIC94161-5 Micrel, Inc. Dual output LDO 1

U6 SY88053CL Micrel, Inc. 10 Limiting Post Amplifier 1

SFP_022AL_R0 Micrel, Inc. SFP+ module PCB 1

Note:

1. Panasonic: www.panasonic.com.

2. Murata: www.murata.com.

3. TDK: www.tdk.com.

4. Laird Technologies: www.lairdtech.com.

5. Vishay: www.vishay.com.

6. On Semi: www.onsemi.com.

7. Micrel, Inc.: www.micrel.com.

Micrel, Inc.

SFP_022AL_R0 Reference Design

May

13, 2015 9 Revision 1.0

TCG Support

Hotline: 408-955-1690

Email Support: tcghelp@micrel.com

Application Hints and Notes

For application notes on high-speed termination on high

bandwidth FOM and clock synthesizer products, SONET

jitter measurement, and other high bandwidth products, go

to Micrel’s website at: http://www.micrel.com.

MICREL, INC. 2180 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL +1 (408) 944-0800 FAX +1 (408) 474-1000 WEB http://www.micrel.com

Micrel, Inc. is a leading global manufacturer of IC solutions for the worldwide high performance linear and power, LAN, and timing & communications

markets. The Company’s products include advanced mixed-signal, analog & power semiconductors; high-performance communication, clock

management, MEMs-based clock oscillators & crystal-less clock generators, Ethernet switches, and physical layer transceiver ICs. Company

customers include leading manufacturers of enterprise, consumer, industrial, mobile, telecommunications, automotive, and computer products.

Corporation headquarters and state-of-the-art wafer fabrication facilities are located in San Jose, CA, with regional sales and support offices and

advanced technology design centers situated throughout the Americas, Europe, and Asia. Additionally, the Company maintains an extensive network

of distributors and reps worldwide.

Micrel makes no representations or warranties with respect to the accuracy or completeness of the information furnished in this datasheet. This

information is not intended as a warranty and Micrel does not assume responsibility for its use. Micrel reserves the right to change circuitry,

specifications and descriptions at any time without notice. No license, whether express, implied, arising by estoppel or otherwise, to any intellectual

property rights is granted by this document. Except as provided in Micrel’s terms and conditions of sale for such products, Micrel assumes no liability

whatsoever, and Micrel disclaims any express or implied warranty relating to the sale and/or use of Micrel products including liability or warranties

relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right.

Micrel Products are not designed or authorized for use as components in life support appliances, devices or systems where malfunction of a product

can reasonably be expected to result in personal injury. Life support devices or systems are devices or systems that (a) are intended for surgical implant

into the body or (b) support or sustain life, and whose failure to perform can be reasonably expected to result in a significant injury to the user. A

Purchaser’s use or sale of Micrel Products for use in life support appliances, devices or systems is a Purchaser’s own risk a

nd Purchaser agrees to fully

indemnify Micrel for any damages resulting from such use or sale.

© 2015 Micrel, Incorporated.

Table of contents

Popular Control Unit manuals by other brands

Colby Instruments

Colby Instruments PDL-200A-625PS Operating and programming manual

Shure

Shure A15AS manual

AMCI

AMCI 7551 Manual addendum

thermital

thermital TBOX BASIC R Installation, operation and maintenance manual

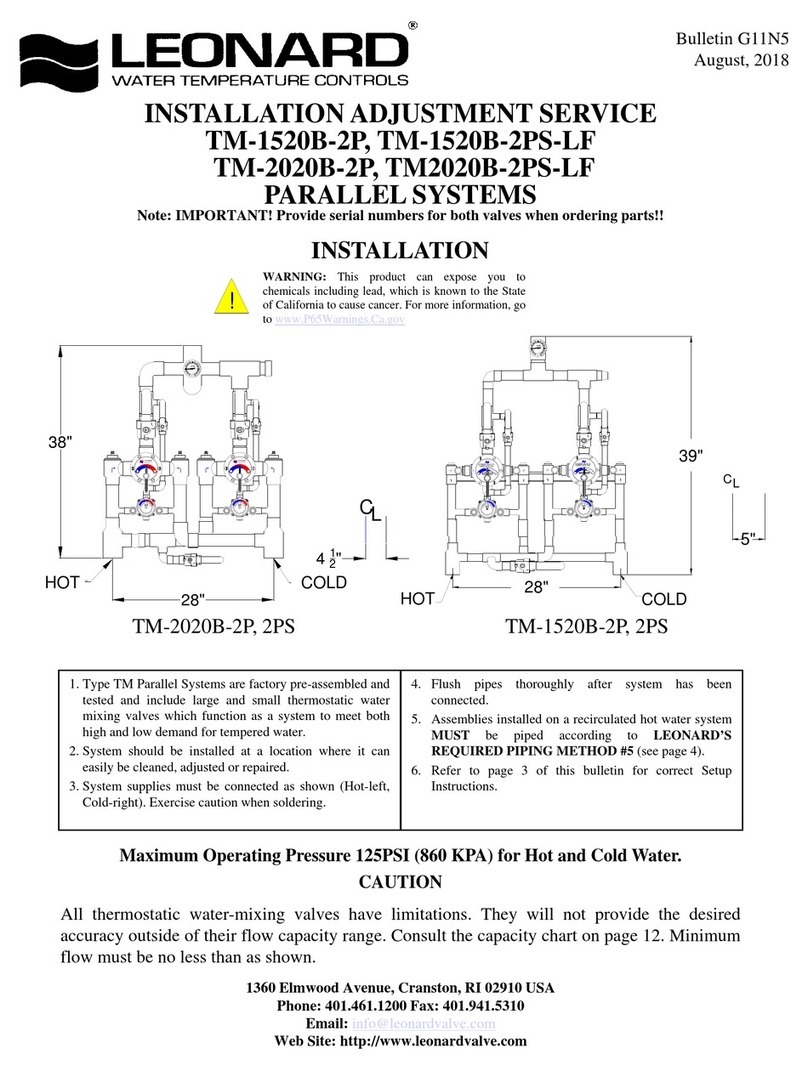

Leonard

Leonard TM-1520B-2P INSTALLATION ADJUSTMENT SERVICE

Embedded Works

Embedded Works EW5270UM user manual

Phytec

Phytec phyCORE-i.MX 6UL Soldering instruction

Texas Instruments

Texas Instruments AFE79 Series Programming & user guide

Allen-Bradley

Allen-Bradley 1756-EN2TSC user manual

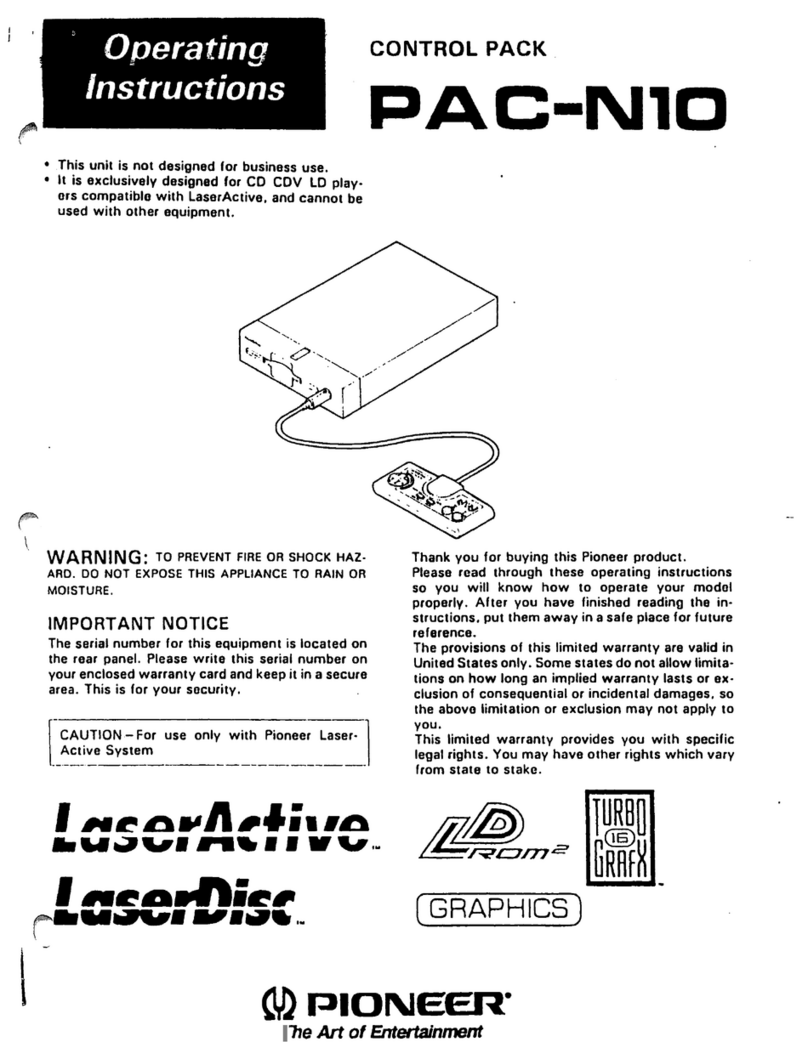

Pioneer

Pioneer PAC-N10 operating instructions

Casit

Casit EQSER30E manual

Hayward

Hayward PVC Series Installation, operation and maintenance instructions