Device description GF0 MICRO PANEL

Contents

4

Technical subject to change

M000235-01.DOC

© by Micro Innovation

Contents

1Explanation of symbols...................................................................................... 6

2Introduction......................................................................................................... 7

3Device Versions .................................................................................................. 8

3.1 Scope of Delivery .................................................................................................... 8

4Device mounting ................................................................................................. 9

4.1 General mounting instructions................................................................................. 9

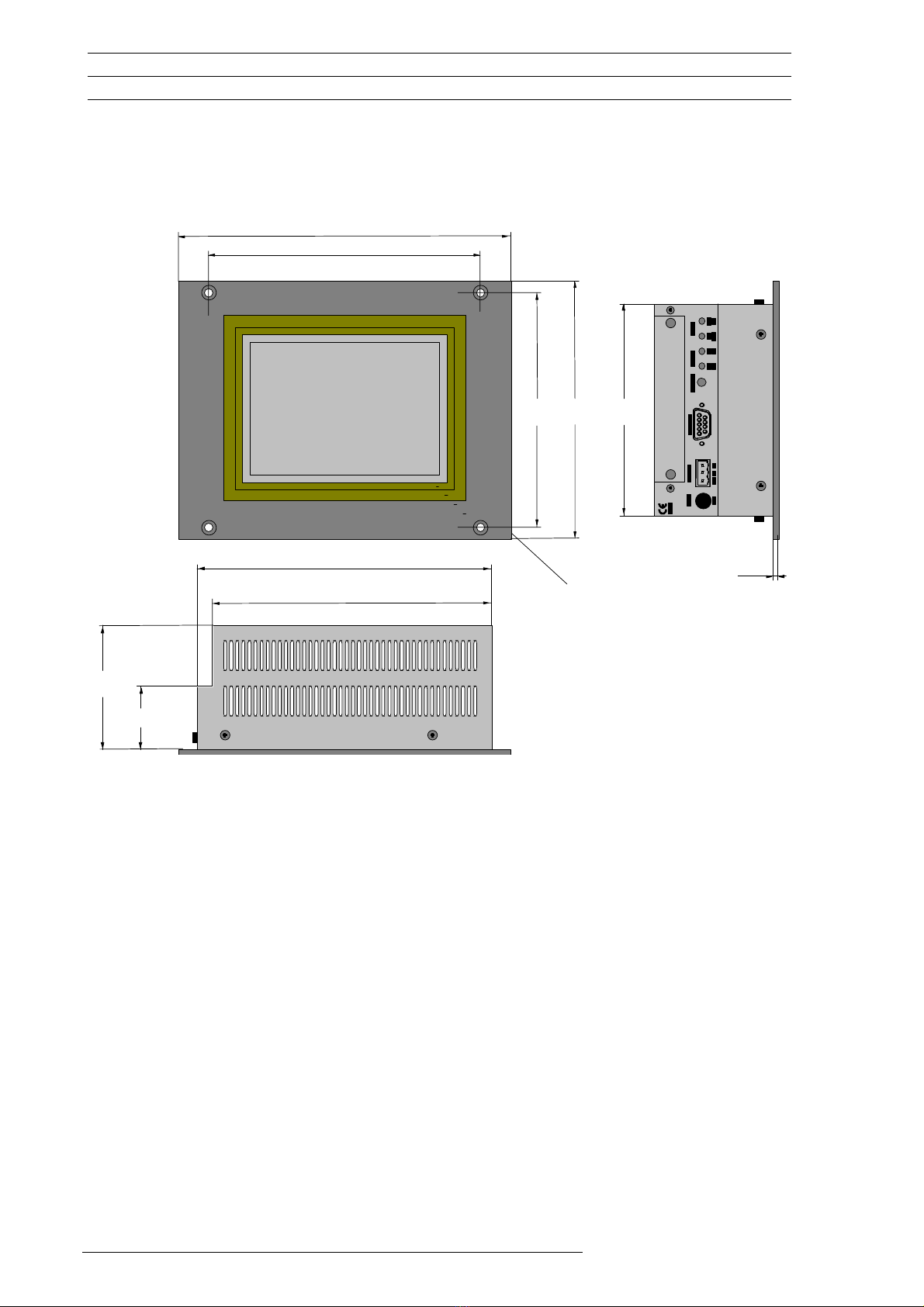

4.2 Dimensions of the 5.7" devices ............................................................................. 10

4.3 Front panel cutouts for 5.7" devices ...................................................................... 11

4.4 Dimensions of the 10" devices .............................................................................. 12

4.5 Front panel cutouts for 10" devices ....................................................................... 13

5Mounting instructions ...................................................................................... 14

5.1 Mounting (without special degree of protection).................................................... 14

5.2 Mounting according to degree of protection IP 65................................................. 14

6Connecting the system power supply ............................................................ 15

7Connection to the communication interface .................................................. 16

7.1 Preparing the connection cable (EMC).................................................................. 16

7.2 Preparing the shield connections .......................................................................... 17

8Connection and function of the programming port (PROG PORT) .............. 18

9Data transfer to the Micro Panel GF0 (Download button) ............................. 19

9.1 Loading the runtime (GRSW) ................................................................................ 20

9.2 Loading the project data (Download)..................................................................... 21

10 Communications Cards and COM SLOT ........................................................ 22

11 Expansion and configuration options............................................................. 23

11.1 General requirements......................................................................................... 23

11.2 Memory Expansion............................................................................................. 23

11.3 Additional 5V power supply on programming port (PROG PORT)..................... 24

12 Function and control LEDs .............................................................................. 25

13 Touch Screen .................................................................................................... 26

13.1 Prinzipielle Funktion des Touch-Screen............................................................. 26

13.2 Power up function test........................................................................................ 26

13.3 Cleaning and maintenance of the Touch Screen ............................................... 26

efesotomasyon.com - Klockner Moeller - inverter