MICROENER IM30-CV User manual

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

1

di

24

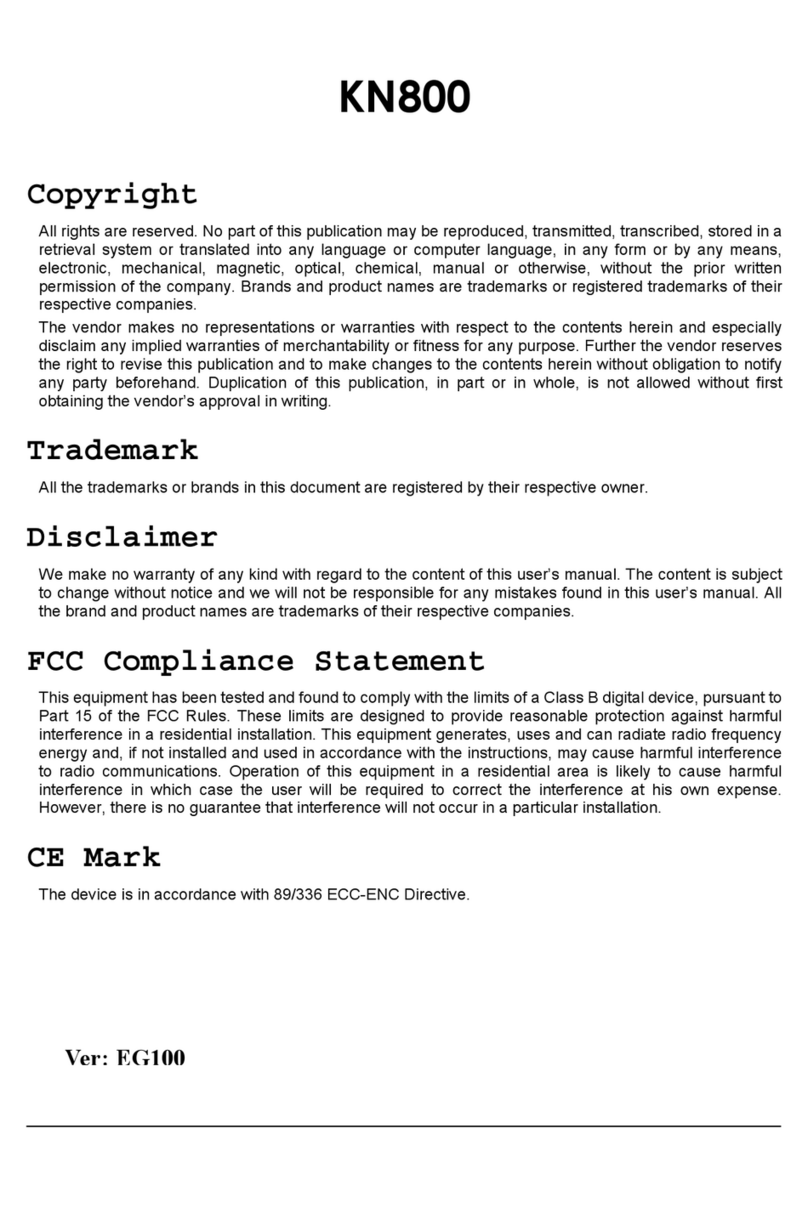

MULTIFUNCTION MICROPROCESSOR

PROTECTION RELAY

3 PHASE OVERLOAD AND UNBALANCE PROTECTION

FOR CAPACITOR BANK

TYPE

IM30-CV

OPERATION MANUAL

MUCAPACITOR

PROTECTION

RELAY TYPE

IM30-CV

ENTER/RESET

MODE

SELECT

+

-

PROG.

IL

IH

OL/OH

B.I./

F.D.

PROG/

I<

BR.

FAIL

I.R.F.

MICROELETTRICA

SCIENTIFICA

MILANO ITALIA

UL/UH

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

2

di

24

INDEX

1 General utilization and commissioning directions_____________________________________________3

1.1 Storage and transportation_____________________________________________________________ 3

1.2 Installation__________________________________________________________________________ 3

1.3 Electrical connection__________________________________________________________________ 3

1.4 Measuring inputs and power supply______________________________________________________ 3

1.5 Outputs loading______________________________________________________________________ 3

1.6 Protection earthing___________________________________________________________________ 3

1.7 Setting and calibration_________________________________________________________________3

1.8 Safety protection_____________________________________________________________________ 3

1.9 Handling___________________________________________________________________________ 3

1.10 Maintenance________________________________________________________________________ 4

1.11 Fault detection and repair______________________________________________________________ 4

2 General characteristics and operation_______________________________________________________4

2.1 Power supply________________________________________________________________________ 4

3 Controls and measurements_______________________________________________________________5

4 Signalization____________________________________________________________________________ 6

5 Output relays___________________________________________________________________________ 7

6 Serial communication____________________________________________________________________ 7

7 Digital inputs____________________________________________________________________________8

8 Test___________________________________________________________________________________ 8

9 Keyboard and display operation____________________________________________________________ 9

10 Reading of measurements and recorded parameters___________________________________________10

10.1 ACT. MEAS (Actual measure)_________________________________________________________ 10

10.2 MAX VAL (Max Value) _____________________________________________________________ 10

10.3 LASTTRIP (Last trip) _______________________________________________________________11

10.4 TRIP NUM (Trip number) ____________________________________________________________11

11 Reading of programmed settings and relay’s configuration_____________________________________ 11

12 Programming___________________________________________________________________________ 12

12.1 Programming of functions settings_______________________________________________________ 12

12.2 Programming the configuration of output relay______________________________________________ 14

Note 1 : Function I<____________________________________________________________________ 15

Note 2 : Breaker Failure Protection ________________________________________________________15

Note 3 : Circuit breaker status detection ____________________________________________________ 15

Note 4 : Wait time for the reenergization of the capacitors ______________________________________15

Note 5 : Setting of the function for inherent unbalance compensation of the capacitors _______________ 15

13 Manual and automatic test operation________________________________________________________16

13.1 Mode “TEST PROG” subprogram W/O TRIP_______________________________________________ 16

13.2 Mode “TEST PROG” subprogram With TRIP_______________________________________________ 16

14 Maintenance____________________________________________________________________________ 16

15 Power frequency insulation test____________________________________________________________ 16

16 Electrical characteristics__________________________________________________________________17

17 Connection diagram (Standard Output) ______________________________________________________ 18

17.1 (Double Output)____________________________________________________________________ 18

18 Wiring the serial communication bus_______________________________________________________ 19

19 Change phase current rated input 1 or 5A___________________________________________________ 19

20 Overall dimensions______________________________________________________________________ 20

21 Time current____________________________________________________________________________ 21

22 Direction for pcb’s draw-out and plug-in_____________________________________________________ 22

22.1 Draw-out___________________________________________________________________________ 22

22.2 Plug-in_____________________________________________________________________________ 22

23 Keyboard operational diagram_____________________________________________________________ 23

24 Setting’s form___________________________________________________________________________ 24

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

3

di

24

1. General utilization and commissioning directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - STORAGE AND TRANSPORTATION,

must comply with the environmental conditions stated on the product's instruction or by the applicable

IEC standards.

1.2 - INSTALLATION,

must be properly made and in compliance with the operational ambient conditions stated by the

Manufacturer.

1.3 - ELECTRICAL CONNECTION,

must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human

safety.

1.4 - MEASURING INPUTS AND POWER SUPPLY,

carefully check that the value of input quantities and power supply voltage are proper and within the

permissible variation limits.

1.5 - OUTPUTS LOADING,

must be compatible with their declared performance.

1.6 - PROTECTION EARTHING

When earthing is required, carefully check its efficiency.

1.7 - SETTING AND CALIBRATION

Carefully check the proper setting of the different functions according to the configuration of the

protected system, the safety regulations and the co-ordination with other equipment.

1.8 - SAFETY PROTECTION

Carefully check that all safety means are correctly mounted, apply proper seals where required and

periodically check their integrity.

1.9 - HANDLING

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits,

the electronic components and semiconductor devices mounted on the modules can be seriously

damaged by electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent but the design

reliability and the long life of the product will have been reduced. The electronic circuits reduced by

M.S. are completely safe from electrostatic discharge (8 KV IEC 255.22.2) when housed in their case;

withdrawing the modules without proper cautions expose them to the risk of damage.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

4

di

24

a. Before removing a module, ensure that you are at the same electrostatic potential

as the equipment by touching the case.

b. Handle the module by its front-plate, frame, or edges of the printed circuit board.

Avoid touching the electronic components, printed circuit tracks or connectors.

c. Do not pass the module to any person without first ensuring that you are both at

the same electrostatic potential. Shaking hands achieves equipotential.

d. Place the module on an antistatic surface, or on a conducting surface which is at

the same potential as yourself.

e. Store or transport the module in a conductive bag.

More information on safe working procedures for all electronic equipment can be found

in BS5783 and IEC 147-OF.

1.10 MAINTENANCE

Make reference to the instruction manual of the Manufacturer ; maintenance must be carried-

out by specially trained people and in strict conformity with the safety regulations.

1.11 FAULT DETECTION AND REPAIR

Internal calibrations and components should not be alterated or replaced.

For repair please ask the Manufacturer or its authorised Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

2. GENERAL CHARACTERISTICS

Input quantities are supplied to 4 Current Transformers (- three measuring phase current - one

measuring the unbalance current)

Phase current inputs can be rated either 1 or 5A: changing over from one to the other configuration is

made by movable bridges provided on the relay card.

For the unbalance current input two taps (1 or 5A) are provided on the terminal board.

Make electric connection in conformity with the diagram reported on relay's enclosure.

Check that input currents are same as reported on the diagram and on the test certificate.

The auxiliary power is supplied by a built-in interchangeable module fully isolated an self protected.

2.1 - POWER SUPPLY

The relay can be fitted with two different types of power supply module :

24V(-20%) / 110V(+15%) a.c. 80V(-20%) / 220V(+15%) a.c.

a) - b) -

24V(-20%) / 125V(+20%) d.c. 90V(-20%) / 250V(+20%) d.c.

Before energising the unit check that supply voltage is within the allowed limits.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

5

di

24

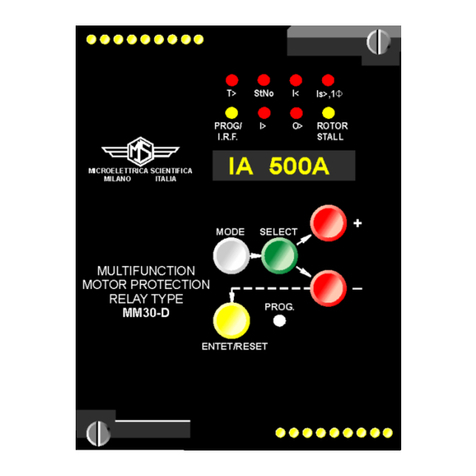

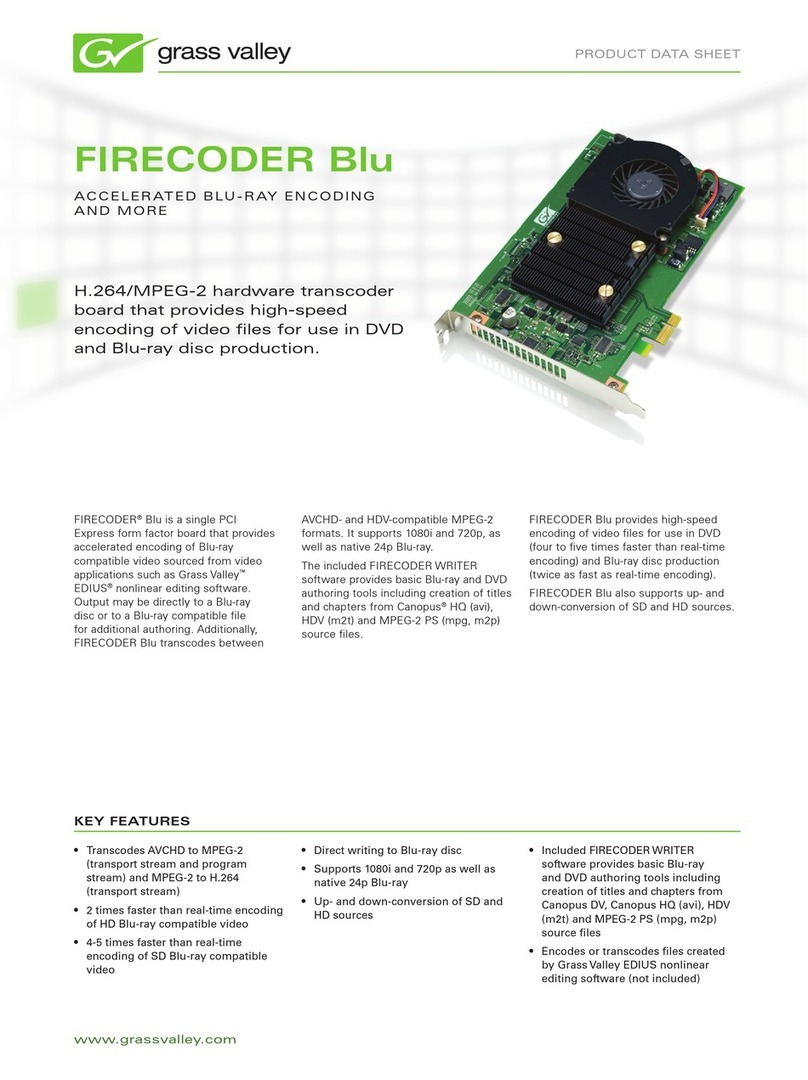

3. CONTROLS AND MEASUREMENTS

Five key buttons allow for local management of all relay's functions.

A 8-digit high brightness alphanumerical display shows the relevant readings (xxxxxxxx)

(see synoptic table fig.1)

Fig.1

MEASURES

MAX VAL.

LASTTRIP

TRIP NUM

ACT MEAS

Actual measuremant values

Max. values measured

Values measured at last tripping

N° of tripping for each function

Measurements

display

SET DISP

SETTINGS

FRELAY

Display of setting

Display of configuration of output relay

Setting Program

display

PROGR

SETTINGS

FRELAY

Setting of parameters

Configuration of output relays

Set Programming

PROG

TEST PRG

W/O TRIP

WithTRIP

Functional Test

Test with operation of signals and output relays

Test with operation of signals only

Test activation

by the key ENTER

Paramater scanning

by the key

SELECT

Parameter modification

by the key “ +” “ -”

Set validation

by the key ENTER

Scanning of

the menus by

the key

“ +” “ -”

MODE

SELECT

ENTER

+ -

(*) Enabled only if input current is zero

(*)

(*)

ENTER/RESET

MODE

SELECT

+

-

PROG.

The SELECT button chooses

which category of values within the

chosen mode to display

Pressing this button progressively

selects between

Measurements Display,

Setting Display, Programming,

and Test modes

When in Program mode, this

button stores the newly selected

value. If not in Program mode and

the relay has tripped, this button

resets the relay and all output

contacts. If not tripped, this button

restores the default display.

The + and - buttons are used to

select the actual measurement or

display desired when in

Measurements Display or Settings

Display modes. When in Program

mode, these buttons increase or

decrease the value of the

displayed setting.

When in Program mode, and when

all input currents are zero,

pressing this recessed button

places the relay into active

programming mode, allowing any

or all of the relay’s settings to be

altered.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

6

di

24

4. SIGNALIZATIONS

Eight signal leds (normally off) are provided:

a)

Red LED

IL

(OVERLOAD)

Flashing when measured current exceeds the set pick-up IL.

Illuminated on trip after expiry of the set trip time delay tIL.

b)

Red LED

IH

(PHASE FAULT)

Same as above related to IH and tIH.

c)

Red LED

OL/OH

(EARTH FAULT)

Flashing when Earth Fault current exceeds the pick-up level OL or OH.

Illuminated on trip of the time delayed element tOL or tOH.

d)

Red LED

UL/UH

(UNBALANCE)

Flashing when the UNBALANCE voltage exceeds the pick-up level UL or UH

Illuminated on trip of the time delayed element tUL or tUH.

e)

Yellow LED

PROG/IRF

Flashing during the programming of the parameters

Lit-on in case of Internal Relay Fault.

f)

Red LED

I

(RECLOSE

INHIBIT)

Flashing when the current drops below the set level I.

Illuminated on trip after expiry of the set trip time delay tI; the led

automatically extinguishes at the end of the set wait time for enabling to

reenergize the capacitor bank.

g)

Red LED

BR. FAIL.

Flashing during the reclose inhibition time tRI

Lit-on when the BREAKER FAILURE function is activated.

h)

Yellow LED

B.I./F.D.

(FUNCTION

DISABLED)

Illuminated when the operation of one or more of the relay functions has

been disactivated in the programming

Flashing when a block signal is present.

The reset of the leds takes place as follows

Leds

a,b,c,d,g

From flashing to off, automatically when the lit-on cause disappears

From ON to OFF, by "ENTER/RESET" push button only if the

tripping cause has disappeared.

Leds

e,f,h

From ON to OFF, automatically when the lit-on cause disappears.

In case of auxiliary power supply failure the status of the leds is recorded and reproduced when power

supply is restored.

IL

IH

OL/OH

UL/UH

B.I./

F.D.

PROG/

I<

BR.

FAIL.

I.R.F.

a

b

c

d

e

f

g

h

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

7

di

24

5. OUTPUT RELAYS

Five output relays are available (R1, R2, R3, R4, R5)

The relays R1,R2,R3,R4 are normally deenergized (energised on trip): these output relays are user

programmable and any of them can be associated to any of the IM30-C's functions.

For some function both instantaneous and time delayed elements are provided.

One relay eventually controlled by the instantaneous element of one function picks up or drops out

as soon as the measured input value gets respectively into the operation or the reset zone.

When the time of the delayed element of the same function has expired the relay is supposed to trip

the circuit breaker.

If after that time the input value still remains into the operation zone (Breaker Failure to open),

the relay controlled by the instantaneous element is anyhow forced to reset after a programmable

wait-time [tBF], thus eliminating any interlock of the backup protection.

It has to be remarked that the programming structure does not allow to associate the same relay at

the same time to instantaneous and delayed elements.

Therefore any relay already associated to any time delayed element cannot be associated to any

instantaneous element and viceversa.

The relay R5, normally energised, is not programmable and is deenergized on:

internal fault

power supply failure

during the programming

6. SERIAL COMMUNICATION

The relays fitted with the serial communication option can be connected via a cable bus or (with proper

adapters) a fiber optic bus for interfacing with a Personal Computer (type IBM or compatible).

All the operations which can be performed locally (for example reading of measured data and changing

of relay’s settings) are also possible via the serial communication interface.

Furthermore the serial port allows the user to read the demand recording data.

The unit has a RS232 / RS485 interface and can be connected either directly to a P.C. via a dedicated

cable or to a RS485 serial bus, thus having many relays to exchange data with a single master P.C.

using the same physical serial line. A RS485/232 converter is available on request.

The communication protocol is MODBUS RTU (only functions 3, 4 and 16 are implemented).

Each relay is identified by its programmable address code (NodeAd) and can be called from the P.C.

A dedicated communication software (MSCOM) for Windows 95/98 (or later) is available.

Please refer to the MSCOM instruction manual for more information.

Microelettrica Scientifica.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

8

di

24

7. DIGITAL INPUTS FOR FUNCTION BLOCKING AND FOR SETTING PROGRAM’S CHANGE-OVER

Three digital inputs are provided: they are active when the relevant terminals are shorted

B2

terminals

1 –2

:

it blocks the operation of the time delayed elements relevant to phase and/or

Earth Fault detection; IL, IH, OL, OH - programming allows to block one or

more of the functions.

B3

terminals

1 –3

:

it blocks the operation of the time delayed elements relevant to UNBALANCE

detection; programming allows to block the operation of the function UL only

or UH only or both.

When a function is blocked the pick-up of its time delayed output is inhibited. Programming allows to

have the inhibition either permanent as long as the blocking input is active (tBf=Dis; tBo=Dis) or

automatically removed after the expiry of the set trip time delay of the function blocked plus an additional

time 2tBF (tBf=2tBF; tBo=2tBF). By proper interconnection of the blocking inputs and different among

output relays it is possible to configurate very efficient arrangements of logic fault discrimination as well

as to feature a safe and quick breaker back-up protection.

B14

terminals

1 –14

:

input from 52a contact (Normally Open) of the capacitor bank Circuit Breaker

for monitoring the C/B open/close status.

8. TEST

Besides the normal "WATCHDOG" and "POWERFAIL" functions, a comprehensive program of self-test

and self-diagnostic provides:

Diagnostic and functional test, with checking of program routines and memory's content, run

every time the aux. power is switched-on: the display shows the type of relay and its version

number and then switches over to the default display.

Dynamic functional test run during normal operation every 15 min. (relay's operation is

suspended for less than 4ms).

Complete test activated by the keyboard or via the communication bus either with or without

tripping of the output relays.

If any internal fault is detected, the display shows a fault message, the Led "PROG/IRF"

illuminates and the relay R5 is deenergized.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

9

di

24

9. KEYBOARD AND DISPLAY OPERATION

All controls can be operated from relay's front or via serial communication bus.

The keyboard includes five hand operable buttons (MODE) - (SELECT) - (+) - (-) - (ENTER/RESET)

plus one indirect operable key (PROG) (see synoptic table a fig.1):

a)

-

White key

MODE

:

when operated it enters one of the following operation modes

indicated on the display :

MEASURES

=

Reading of all the parameters measured and of those recorded

in the memory

SET DISP

=

Reading of the settings and of the configuration of the output

relays as programmed.

PROG

=

Access to the programming of the settings and of relay

configuration.

TEST PROG

=

Access to the manual test routines.

b)

-

Green key

SELECT

:

When operated it selects one of the menus available in the

actual operation MODE

c)

-

Red key

“+”AND “-“

:

When operated they allow to scroll the different information

available in the menu entered by the key SELECT and to

increase-decrease the settings.

d)

-

Yellow key

ENTER/RESET

:

It allows the validation of the programmed settings

- the actuation of test programs

- the forcing of the default display indication

- the reset of signal Leds.

e)

-

Indirect key

:

Enables access to the programming.

ENTER/RESET

MODE

SELECT

+

-

PROG.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

10

di

24

10. READING OF MEASUREMENTS AND RECORDED PARAMETERS

Enter the MODE "MEASURE", SELECT the menu "ACT.MEAS" or "LAST TRIP" or

"TRIP NUM", scroll available information by key "+" or "-" .

10.1 ACT.MEAS

Actual values as measured during the normal operation.

The values displayed are continuously refreshed.

Display

Description

I/In

xxx

%

Highest among the 3 phase-currents displayed as % of the rated current of T.A (0 - 999)%

IA

xxxxx

A

True R.M.S. value of the current of phase A displayed as primary Amps. (0 - 99999)

IB

xxxxx

A

As above, phase B

IC

xxxxx

A

As above, phase C

Io

xxxxx

A

As above, residual current (3 x Zero Seq. Current)

Uo

x.xx

Un

As above, unbalance voltage displayed as p.u. of the rated input Un

u

xxxxx

°

Uo/IA displacement in degrees of Uo from IA (0-360° anticlockwise)

Ud

x.xx

Un

Unbalance compensated voltage as p.u. of rated input Un

10.2 MAX VAL

Max demand values recorded starting from 100ms after closing of main Circuit Breaker plus highest

inrush values recorded within the first 100ms from Breaker closing, (updated any time the breaker

closes).

Display

Description

IA

xx.x

In

Max value of phase A current after the first 100ms, displayed as p.u. of C.Ts rated current

IB

xx.x

In

As above, phase B

IC

xx.x

In

As above, phase C

Io

x.xx

In

As above, residual current (3 x Zero Sequence current)

Ud

x.xx

Un

As above, unbalance compensated voltage (0 –9,99)

SA

xx.x

In

Highest current of phase A during the first 100ms, displayed as p.u. of C.Ts rated current

SB

xx.x

In

As above, phase B

SC

xx.x

In

As above, phase C

Sd

x.xx

Un

As above, unbalance compensated voltage

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

11

di

24

10.3 LASTTRIP

Display of the function which caused the last tripping of the relay plus values of the parameters at the

moment of tripping. The memory buffer is refreshed at each new relay tripping.

Display

Description

Cause

xxx

Display of the function which caused the last tripping: IL; IH; OL; OH; UL; UH; I<

IA

xx.x

In

Current of phase A

IB

xx.x

In

Current of phase B

IC

xx.x

In

Current of phase C

Io

xx.x

In

Residual current (3 x Zero Sequence current)

Ud

x.xx

Un

Unbalance compensated voltage

10.4 TRIP NUM

Counters of the number of operations for each of the relay’s functions.

The memory is non-volatile and can be cancelled only with a secret procedure.

Display

Description

IL

xxxxxx

Low set overcurrent trips

IH

xxxxxx

High set overcurrent trips

OL

xxxxxx

Low set Earth Fault

OH

xxxxxx

High set Earth Fault

UL

xxxxxx

Low set unbalance

UH

xxxxxx

High set unbalance

I<

xxxxxx

Undercurrent trips

11. READING OF PROGRAMMED SETTINGS AND RELAY'S CONFIGURATION

Enter the mode "SET DISP", select the menu "SETTINGS" or "F

RELAY", scroll information

available in the menu by keys "+" or "-".

SETTINGS= values of relay's operation parameters as programmed

F

RELAY= output relays associated to the different functions as programmed.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

12

di

24

12. PROGRAMMING

The relay is supplied with the standard default programming used for factory test. [ Values here below reported in

the “ Display “ column ].

All parameters can be modified as needed in the mode PROG and displayed in the mode SET DISP

Local Programming by the front face key board is enabled only if no input current is detected (main switch

open). Programming via the serial port is always enabled but a password is required to access the

programming mode. The default password is the null string; in the standard application program for

communication “MS-COM” it is also provided an emergency password which can be disclosed on request

only.

As soon as programming is enabled, the Led PRG/IRF flashes and the reclosing lock-out relay R5 is

deenergized..

Enter MODE "PROG" and SELECT either "SETTINGS" for programming of parameters or

"FRELAY" for programming of output relays configuration; enable programming by the indirect

operation key PROG.

The key SELECT now scrolls the available parameters. By the key (+) , (-) the displayed values can be

modified; to speed up parameter's variation press the key SELECT while "+" or "-" are pressed.

Press key "ENTER/RESET" to validate the set values.

12.1 - PROGRAMMING OF FUNCTION SETTINGS

Mode PROG menu SETTINGS. (Production standard settings here under shown).

Display

Description

Setting Range

Step

Unit

Fn

50

Hz

Mains frequency

50 - 60

10

Hz

In

500

Ap

Rated primary current of the phase C.Ts.

0 - 9999

1

A

Un

100

V

Rated secondary voltage of the P.Ts. supplying the

unbalance voltage element .

50 - 125

0.1

V

F(IL)

D

Operation characteristic of the low-set overcurrent element

D =Independent definite time

SI = Dependent normal inverse time

D

SI

D

SI

-

IL

0.3

In

Trip level of low-set overcurrent element

(p.u. of the rated current of the phase C.Ts.)

0.3 - 1.5 - Dis

0.01

In

tIL

1

s

Trip time delay of the low-set overcurrent element

In the inverse time operation it is the trip time delay at

I = 10xI>

1 - 50

0.1

s

IH

0.6

In

Trip level of high-set overcurrent element

(p.u. of the rated current of the phase C.Ts.)

0.2 - 2 - Dis

0.01

In

tIH

0.1

s

Trip time delay of the high-set overcurrent element

0.1 –6500

(0.1-99.9)

0.1

(100-6500)

1

s

Fn 50 Hz

Hz is the unit of measure

50 is the

default setting

Fn is the name

of the variable

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

13

di

24

Display

Description

Setting Range

Step

Unit

F(OL)

D

Operation characteristic of the low-set earth fault element

D = Independent definite time

SI = Dependent normal inverse time

D

SI

D

SI

-

OL

0.1

In

Trip level of low-set earth fault element

(p.u. of the rated current of the phase C.Ts.)

0.1 - 1.0 - Dis

0.01

In

tOL

0.05

s

Trip time delay of low-set earth fault element

In the inverse time operation it is the trip time delay

at Io = 5xOL

0.05 –30

(1-9.99)

0.01

(10-30) 0.1

s

OH

0.2

In

Trip level of high-set earth fault element

(p.u. of the rated current of the phase C.Ts.)

0.1 - 2.0 - Dis

0.01

In

tOH

0.05

s

Trip time delay of the high-set earth fault element

0.05 –9.99

0.01

s

F(UL)

D

Operation characteristic of the low-set unbalance element

D = Independent definite time

SI = Dependent normal inverse time

D

SI

D

SI

-

UL

0.02

Un

Trip level of low-set unbalance element (p.u. of the rated

voltage of the P.Ts. for unbalance detection)

0.02 - 0.8 -Dis

0.01

Un

tUL

1.0

s

Trip time delay of low-set unbalance element

In the inverse time operation it is the trip time delay

at Io = 5xOL

1.0 - 30

(1-9.99)

0.01

(10-30) 0.1

s

UH

0.04

Un

Trip level of high-set unbalance element (p.u. of the rated

voltage of the P.Ts. for unbalance detection)

0.01 - 1.0 - Dis

0.01

Un

tUH

1

s

Trip time delay of the high-set unbalance element

0.1 - 300

(1-99.9) 0.1

-

(100-300) 1

s

I<

0.1

In

Trip level of undercurrent element

(p.u. of the rated current of the phase C.Ts)

Dis - 0.10 - 1.0

0.01

See note 1

In

tI<

1

s

Trip time delay of the undercurrent element

1.0 - 99.9

0.1

s

tRI<

5

m

Wait time for the reenergization of the capacitors

Dis - 0.5 - 100

0.1

m

Uc

0.00

Un

Unbalance compensation level

0.00 - 0.2

0.01

See note 2

Un

c

0

°

UoIA phase displacement (counter clockwise rotation)

0 - 359

1

°

B14

Dis

C/B status monitoring input enabled/disabled

En - Dis

-

-

tBF

0.1

s

Max reset time delay of the instantaneous element after

tripping of the delayed element

0.1-0.75

0.1

s

NodAd

1

Identification number for the connection on serial

communication bus

1 - 250

1

-

The setting Dis indicates that the function is disactivated.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

14

di

24

12.2 PROGRAMMING THE CONFIGURATION OF OUTPUT RELAYS

Mode PROG menu F

RELAY (Production standard settings here under shown).

The key "+" operates as cursor; it moves through the numbers corresponding to the four programmable relays in

the sequence 1,2,3,4,(1= relay R1, etc.) and makes start flashing the information actually present in the digit. The

information present in the digit can be either the number of the relay (if this was already associated to the function

actually on programming) or a dot (-) if the relay was not yet addressed.

The key "-" changes the existing status from the dot to the relay number or viceversa.

Display

Description

IL

-

-

3

-

Instantaneous element of low-set overcurrent

(only one or more, whatever combination)

operates relay R1,R2,R3,R4

tIL

1

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

IH

-

-

3

-

Instantaneous element of high-set overcurrent

operates relay R1,R2,R3,R4

tIH

1

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

OL

-

-

-

-

Instantaneous element of low-set earth fault element

operates relay R1,R2,R3,R4

tOL

1

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

OH

-

-

-

-

Instantaneous element of high-set earth fault element

operates relay R1,R2,R3,R4

tOH

1

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

UL

-

-

-

-

Instantaneous element of low-set unbalance element

operates relay R1,R2,R3,R4

tUL

-

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

UH

-

-

-

-

Instantaneous element of high-set unbalance element

operates relay R1,R2,R3,R4

tUH

-

2

-

-

As above, time delayed element

operates relay R1,R2,R3,R4

tI<

-

-

-

4

Time delayed element min. current

operates relay R1,R2,R3,R4

tRI

-

-

-

-

Start of reclose timer tRI

operates relay R1,R2,R3,R4

tBF

-

-

-

-

Breaker failure element

operates relay R2,R3,R4

tFRes:

M

The reset after tripping of the relays associated to the time delayed elements can take place:

(A) automatically when current drops below the trip level.

(M) manually by the operation of the "ENTER/RESET" key

Bf

-

-

-

i

The input for blocking the operation of the time delayed elements relevant to phase faults

(IL, IH, OL, OH) can act on the function (IL) only, (OL) only, (IH) only or (OH) only, or on both.

(i = IL, I = IH, o = OL, O = OH)

Bo

-u

The input for blocking the operation of the time delayed elements relevant to unbalance (UH, UL) can

act on the function (U=UH) only or (u=UL) only, or on both

tBf

2tBF

The blocking of the phase fault elements can be programmed so that it lasts as long the blocking input

signal is present (tBIf Dis) or (tBf 2xtBf); even with the blocking input still present, it only lasts for the

set trip time delay of the function plus an additional time 2xtBf

tBo

2tBF

As above for the unbalance functions

IL -2 - 4

This dash means

that output relay

number 1 is not

assigned to this

element

This is the name of

protective element

The number 2

means that

output relay 2 will

operate when

this element trips

This dash means

that output relay

number 3 is not

assigned to this

element

The number 4 means

that output relay 4 will

operate when this

element trips

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

15

di

24

Note 1: Function I

This element is enabled only when the circuit breaker is closed (see Note 3). The largest among the 3 phase

currents (Imax) is compared to the set trip level [I<]. If Imax < [I<] then the [tI<] timer is started. When such timer

expires, a trip occurs.

Note 2 Breaker Failure Protection

Setting : tBF = (0.05 –0.75)s, steps 0.01s

The element operates as follows:

After tripping of the output relay R1 the time tBF starts. If at the end of tBF Imax is still above the zero current level

Izero ( equal to 5%In), the output relay associated to the Breaker Failure protection is energized. A breaker failure

can be detected also in case the value of Imax is not consistent with the status of the B14 digital input (see Note 3).

Note 3: Circuit breaker status detection

A setting is available (B14 En/Dis) to enable or disable the B14 digital input.

When B14 is ENABLED the circuit breaker status is computed according to the following truth table :

Status of B14 (52a contact)

Value of Imax

C/B status

Closed

Imax > Izero

Closed

Open

Imax > Izero

Failure

Closed

Imax <= Izero

Closed

Open

Imax <= Izero

Open

State transitions are not instantaneous. Signals are validated if and only if no change is detected for at least 50ms.

Furthermore, in case a breaker failure condition is detected (row #2), the breaker failure timer is started (tBF).

When such timer expires, the I>Izero condition is checked again and the breaker failure function is energized only if

current is still above Izero.

When B14 is DISABLED, its status is ignored. Thus, the following table is considered:

Status of B14 (52a contact)

Value of Imax

C/B status

Any

Imax > Izero

Closed

Any

Imax <= Izero

Open

Note 4: Wait time for the reenergization of the capacitors

When the relay detects a transition of the circuit breaker status from closed to open, the reclosing inhibition timer

(tRI) is started and the tRI relay is energized. This condition is signalled by the flashing of Led g).

The reset of this function takes place in two different ways depending on the reset mode (tFRes=Auto or

tFRes=Man).

If tFRes is equal to Auto (automatic reset), tRI can be forced to 0 by pressing the ENTER button. As a

consequence, the tRI relay is de-energized and Led g) stops flashing. If the ENTER button is not pressed, the

element automatically resets itself at the end of tRI.

If tFRes is equal to Man (manual reset), the ENTER button must be pressed to reset the element. No command is

accepted before tRI has expired.

Note 5: Setting of the function for inherent unbalance compensation of the capacitors

Switch on the capacitors and read, in the mode MEASURES function ACT.MEAS., the values of Uo, αuand Ud.

Switch off the capacitors. Set for Ic and αc the values Iu,αu

When the capacitors are switched on again, the values Iu, αudisplayed remain practically unchanged, while the

value of Id will be nearly zero.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

16

di

24

13. MANUAL AND AUTOMATIC TEST OPERATION

13.1 Mode "TESTPROG" subprogram "W/O TRIP"

Operation of the yellow key activates a complete test of the electronics and the process routines.

All the leds are lit-on and the display shows (TEST RUN).

If the test routine is successfully completed the display switches-over to the default reading (I/Inxxx%).

If an internal fault is detected, the display shows the fault identification code and the relay R5 is deenergized.

This test can be carried-out even during the operation of the relay without affecting the relay tripping in case a

fault takes place during the test itself.

13.2 Mode "TESTPROG" subprogram "WithTRIP"

Access to this program is enabled only if the current detected is zero (breaker open).

Pressing the yellow key the display shows "TEST RUN?". A second operation of the yellow key starts a

complete test which also includes the activation of all the output relays.

The display shows (TEST RUN) with the same procedure as for the test with W/O TRIP. Every 15 min during

the normal operation the relay automatically initiates an auto test procedure (duration 10ms).

If any internal fault is detected during the auto test, the relay R5 is deenergized, the relevant led is activated

and the fault code is displayed.

WARNING

Running the WithTRIP test will operate all of the output relays. Care must be taken to ensure that no unexpected or

harmful equipment operations will occur as a result of running this test.

It is generally recommended that this test be run only in a bench test environment or after all dangerous output

connections are removed.

14. MAINTENANCE

No maintenance is required. Periodically a functional check-out can be made with the test procedures described

under MANUAL TEST chapter. In case of malfunctioning please contact

Microelettrica Scientifica Service or the local Authorised Dealer mentioning the relay's Serial No reported in the label

on relays enclosure.

WARNING

In case of Internal Relay Fault detection, proceed as here-below indicated :

If the error message displayed is one of the following “DSP Err”, “ALU Err” ,”KBD Err” ,”ADC Err”, switch-off

power supply and switch-on again. If the message does not disappear send the relay to Microelettrica

Scientifica (or its local dealer) for repair.

If the error message displayed is “E2P Err”, try to program any parameter and then run “W/OTRIP”.

If message disappear please check all the parameters.

If message remains send the relay to Microelettrica Scientifica (or its local dealer) for repair.

15. POWER FREQUENCY INSULATION TEST

Every relay individually undergoes a factory insulation test according to IEC255-5 standard at

2 kV, 50 Hz 1min. Insulation test should not be repeated as it unusefully stresses the dielectrics.

When doing the insulation test, the terminals relevant to serial output must always be short circuited to ground.

When relays are mounted in switchboards or relay boards that have to undergo the insulation tests, the relay

modules must be drawn-out of their enclosures and the test must only include the fixed part of the relay with its

terminals and the relevant connections. This is extremely important as discharges eventually tacking place in other

parts or components of the board can severely damage the relays or cause damages, not immediately evident to the

electronic components.

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

17

di

24

16. ELECTRICAL CHARACTERISTICS

APPROVAL: CE –RINA –UL and CSA approval File : E202083

REFERENCE STANDARDS IEC 60255 - EN50263 - CE Directive - EN/IEC61000 - IEEE C37

Dielectric test voltage

IEC 60255-5

2kV, 50/60Hz, 1 min.

Impulse test voltage

IEC 60255-5 : 5kV (c.m.), 2 kV (d.m.) - 1,2/50s

5kV (c.m.), 2kV (d.m.) –1,2/50s

Insulation resistance

> 100M

Environmental Std. Ref. (IEC 68-2-1 - 68-2-2 - 68-2-33)

Operation ambient temperature

-10°C / +55°C

Storage temperature

-25°C / +70°C

Humidity

IEC68-2-3 RH 93% Without Condensing AT 40°C

CE EMC Compatibility (EN50081-2 - EN50082-2 - EN50263)

Electromagnetic emission

EN55022 industrial environment

Radiated electromagnetic field immunity test

IEC61000-4-3

level 3

80-1000MHz

10V/m

ENV50204

900MHz/200Hz

10V/m

Conducted disturbances immunity test

IEC61000-4-6

level 3

0.15-80MHz

10V

Electrostatic discharge test

IEC61000-4-2

level 4

6kV contact / 8kV air

Power frequency magnetic test

IEC61000-4-8

1000A/m

50/60Hz

Pulse magnetic field

IEC61000-4-9

1000A/m, 8/20s

Damped oscillatory magnetic field

IEC61000-4-10

100A/m, 0.1-1MHz

Electrical fast transient/burst

IEC61000-4-4

level 3

2kV, 5kHz

HF disturbance test with damped oscillatory wave (1MHz

burst test)

IEC60255-22-1

class 3

400pps, 2,5kV (m.c.), 1kV (d.m.)

Oscillatory waves (Ring waves)

IEC61000-4-12

level 4

4kV(c.m.), 2kV(d.m.)

Surge immunity test

IEC61000-4-5

level 4

2kV(c.m.), 1kV(d.m.)

Voltage interruptions

IEC60255-4-11

Resistance to vibration and shocks

IEC60255-21-1 - IEC60255-21-2 10-500Hz 1g

CHARACTERISTICS

Accuracy at reference value of influencing factors

2% Rated Input

for trip levels

2% +/- 10ms

for times

Rated input Current

In = 1 or 5A ; On = 1 or 5A

Current overload

200 A for 1 sec; 10A continuous

Burden on current inputs

Phase : 0.01VA at In = 1A; 0.2VA at In = 5A

Neutral : 0.03VA at In = 1A; 0.2VA at In = 5A

Rated input Voltage

Un = 50 –125V

Voltage overload

2 Un

Burden on voltage input

0,08 VA at Un

Average power supply consumption

8.5 VA

Output relays

rating 5 A; Vn = 380 V

A.C. resistive switching = 1100W (380V max)

make = 30 A (peak) 0,5 sec.

break = 0.3 A, 110 Vcc,

L/R = 40 ms (100.000 op.)

Microelettrica Scientifica S.p.A. - 20089 Rozzano (MI) - Italy - Via Alberelle, 56/68

Tel. (##39) 02 575731 - Fax (##39) 02 57510940

http://www.microelettrica.com e-mail : ute@microelettrica.com

The performances and the characteristics reported in this manual are not binding and can modified at any moment without notice

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

18

di

24

17. CONNECTION DIAGRAM (SCE1726 Rev.2 Standard Output)

17.1 CONNECTION DIAGRAM (SCE1727 Rev.2 Double Output)

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

19

di

24

18. WIRING THE SERIAL COMMUNICATION BUS (SCE1309 Rev.0)

19. CHANGE PHASE CURRENT RATED INPUT 1 OR 5A

J1

Phase A

J2

Phase B

J3

Phase C

Rated

Input

Current

Rated Input

Current

Rated Input

Current

Jumper

Connector

IM30-CV

Doc. N° MO-0150-ING

Rev. 1

Date 14.07.2003

Copyright 2010 - Microener

Firmware:

1.0X

Pag

20

di

24

24. OVERALL DIMENSIONS

View of Rear

Terminal Connection

PANEL CUT-OUT 113x142 (LxH)

Table of contents

Other MICROENER Computer Hardware manuals

Popular Computer Hardware manuals by other brands

ekwb

ekwb EK-FC R9 Nano Series INSTALLATION AND MOUNTING MANUAL

Verizon Wireless

Verizon Wireless AIRCARD 595 PC CARD user manual

Infineon

Infineon AIROC IFW56810-00 Getting started

HP

HP Smart Array 5300A user manual

Primera

Primera Server XR user manual

EK-Quantum

EK-Quantum Vector Strix RTX 3070 Backplate user guide