MICROENER MM30-DK User manual

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 1 of 36

Copyright - 2010 - Microener

MICROPROCESSOR

MOTOR PROTECTION RELAY

WITH DIRECTIONAL EARTH FAULT ELEMENT

TYPE

MM30-DK

OPERATION MANUAL

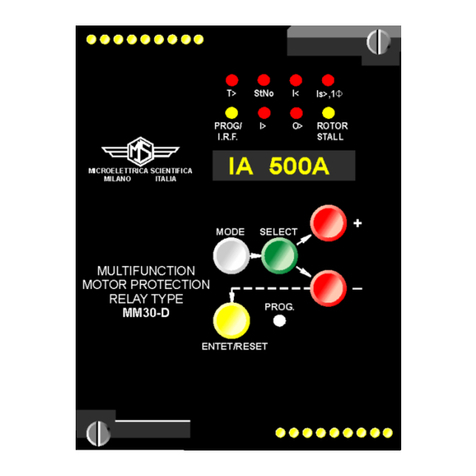

MULTIFUNCTION

MOTOR PROTECTION

RELAY TYPE

MM30-DK

MODE

SELECT

+

-

T>

St.No

I<

Is>,1

PROG/

I.R.F.

I>

ROTOR

STALL

MICROELETTRICA SCIENTIFICA

MILANO ITALY

ENTER/RESET

PROG.

O>

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 2 of 36

Copyright - 2010 - Microener

INDEX

1 General utilization and commissioning directions _____________________________________________________ 3

1.1 Storage and transportation_____________________________________________________________________ 3

1.2 Installation__________________________________________________________________________________ 3

1.3 Electrical connection__________________________________________________________________________ 3

1.4 Measuring inputs and power supply______________________________________________________________ 3

1.5 Outputs loading______________________________________________________________________________ 3

1.6 Protection earthing___________________________________________________________________________ 3

1.7 Setting and calibration_________________________________________________________________________3

1.8 Safety protection_____________________________________________________________________________ 3

1.9 Handling___________________________________________________________________________________ 3

1.10 Maintenance________________________________________________________________________________ 4

1.11 Fault detection and repair______________________________________________________________________ 4

2 General characteristics and operation_______________________________________________________________ 4

2.1 Power supply________________________________________________________________________________4

2.2 Operation an Algorithms_______________________________________________________________________ 5

2.2.1 Reference input variable__________________________________________________________________ 5

2.2.2 Input quantities_________________________________________________________________________ 5

2.2.2.1 Mains Frequency_________________________________________________________________ 5

2.2.2.2 Phase current inputs_______________________________________________________________5

2.2.2.3 Earth Fault current and voltage inputs_________________________________________________ 6

2.2.3 Function and Setting_____________________________________________________________________ 7

2.2.3.1 F49 –Thermal image______________________________________________________________ 7

2.2.3.2 F51LR –Locked Rotor Protection (Rotor jam)___________________________________________ 8

2.2.3.3 F46 –Current Unbalance (Negative Sequence current) protection___________________________ 8

2.2.3.4 F47 –Single Phasing______________________________________________________________ 8

2.2.3.5 F37 –No-Load Running protection____________________________________________________8

2.2.3.6 F51 –Overcurrent protection________________________________________________________ 9

2.2.3.7 F64 –Earth Fault protection_________________________________________________________ 9

2.2.3.8 Limitation of the Stats Number_______________________________________________________ 10

2.2.3.9 Starting Sequence control__________________________________________________________ 10

2.2.3.10 Autosetting______________________________________________________________________ 11

2.3 Operational of the directional Earth Fault Element___________________________________________________12

2.4 Clock and Calendar___________________________________________________________________________13

2.4.1 Clock synchronization_____________________________________________________________________ 13

2.4.2 Date and time setting_____________________________________________________________________ 13

2.4.3 Time resolution__________________________________________________________________________ 13

2.4.4 Operation during power off_________________________________________________________________ 13

2.4.5 Time tolerance___________________________________________________________________________ 13

3 Controls and measurements_______________________________________________________________________ 14

4 Signalization_____________________________________________________________________________________15

5 Output relays____________________________________________________________________________________ 16

6 Serial communication_____________________________________________________________________________ 17

7 Digital inputs____________________________________________________________________________________ 18

8 Test____________________________________________________________________________________________ 18

9 Keyboard and display operation____________________________________________________________________ 19

10 Reading of measurements and recorded parameters___________________________________________________ 20

10.1 ACT. MEAS (Actual measure)_____________________________________________________________ 20

10.2 MAX VAL (Max values)_________________________________________________________________ 20

10.3 LASTTRIP (Last trip)____________________________________________________________________21

10.4 TRIP NUM (Trip number)_________________________________________________________________21

11 Reading of programmed settings and relay’s configuration_____________________________________________ 21

12 Programming____________________________________________________________________________________ 22

12.1 Programming of functions settings__________________________________________________________ 22

12.2 Programming the configuration of output relay_________________________________________________ 24

13 Manual and automatic test operation________________________________________________________________ 25

13.1 Mode “ TESTPROG “ subprogram “ W/O TRIP “_______________________________________________ 25

13.2 Mode “ TESTPROG “ subprogram “ With TRIP “_______________________________________________ 25

14 Maintenance_____________________________________________________________________________________ 25

15 Power frequency insulation test_____________________________________________________________________25

15 Electrical characteristics___________________________________________________________________________26

16 Connection diagram (Standard Output)_______________________________________________________________ 27

16.1 Connection Diagram (Double Output)___________________________________________________________ 27

17 Wiring the serial communication bus________________________________________________________________ 28

18 Change phase rated input 1A or 5A__________________________________________________________________ 28

19 Thermal image curves_____________________________________________________________________________29

20 Inverse time unbalance protection element___________________________________________________________ 30

21 Direction for pcb’s draw-out and plug-in_____________________________________________________________ 31

21.1 Draw-out______________________________________________________________________________ 31

21.2 Plug-in________________________________________________________________________________ 31

22 Overall dimensions / Mounting_____________________________________________________________________ 32

23 Keyboard operational diagram______________________________________________________________________ 33

24 Setting’s form____________________________________________________________________________________34

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 3 of 36

Copyright - 2010 - Microener

1. General utilization and commissioning directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - STORAGE AND TRANSPORTATION,

must comply with the environmental conditions stated on the product's instruction or by the applicable

IEC standards.

1.2 - INSTALLATION,

must be properly made and in compliance with the operational ambient conditions stated by the

Manufacturer.

1.3 - ELECTRICAL CONNECTION,

must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human

safety.

1.4 - MEASURING INPUTS AND POWER SUPPLY,

carefully check that the value of input quantities and power supply voltage are proper and within the

permissible variation limits.

1.5 - OUTPUTS LOADING,

must be compatible with their declared performance.

1.6 - PROTECTION EARTHING

When earthing is required, carefully check its effectiveness.

1.7 - SETTING AND CALIBRATION

Carefully check the proper setting of the different functions according to the configuration of the

protected system, the safety regulations and the co-ordination with other equipment.

1.8 - SAFETY PROTECTION

Carefully check that all safety means are correctly mounted, apply proper seals where required and

periodically check their integrity.

1.9 - HANDLING

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits,

the electronic components and semiconductor devices mounted on the modules can be seriously

damaged by electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent but the design

reliability and the long life of the product will have been reduced. The electronic circuits reduced by

M.S. are completely safe from electrostatic discharge (8 KV IEC 255.22.2) when housed in their

case; withdrawing the modules without proper cautions expose them to the risk of damage.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 4 of 36

Copyright - 2010 - Microener

a. Before removing a module, ensure that you are at the same electrostatic potential

as the equipment by touching the case.

b. Handle the module by its front-plate, frame, or edges of the printed circuit board.

Avoid touching the electronic components, printed circuit tracks or connectors.

c. Do not pass the module to any person without first ensuring that you are both at

the same electrostatic potential. Shaking hands achieves equipotential.

d. Place the module on an antistatic surface, or on a conducting surface which is at

the same potential as yourself.

e. Store or transport the module in a conductive bag.

More information on safe working procedures for all electronic equipment can be found

in BS5783 and IEC 147-OF.

1.10 - MAINTENANCE

Make reference to the instruction manual of the Manufacturer ;

maintenance must be carried-out by specially trained people and in strict conformity

with the safety regulations.

1.11 - FAULT DETECTION AND REPAIR

Internal calibrations and components should not be altered or replaced.

For repair please ask the Manufacturer or its authorised Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

2. GENERAL

Input currents are supplied to 3 current transformers: - two measuring phase current (the third current is

computed as vector summation of the two others) - one measuring the earth fault zero-sequence

current.

Phase current rated input can be 1 or 5A (Selectable by movable bridges on relay card)

Zero sequence rated input is 1A.

Zero sequence voltage input is supplied to one voltage transformer.

Rated input voltage 100V –50/60Hz.

Make electric connection in conformity with the diagram reported on relay's enclosure.

Check that input currents are same as reported on the diagram and on the test certificate.

The auxiliary power is supplied by a built-in interchangeable module fully isolated an self protected.

2.1 POWER SUPPLY

The relay can be fitted with two different types of power supply module :

24V(-20%) / 110V(+15%) a.c. 80V(-20%) / 220V(+15%) a.c.

a) - b) -

24V(-20%) / 125V(+20%) d.c. 90V(-20%) / 250V(+20%) d.c.

Before energising the unit check that supply voltage is within the allowed limits.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 5 of 36

Copyright - 2010 - Microener

2.2 –Operation and Algorithms

2.2.1 –Reference input variables

Display

Description

Setting Range

Step

Unit

NodAd 1

Identification number for connection serial communication

1 - 250

1

1

Fn 50 Hz

Mains frequency

50 - 60

10

Hz

In 500Ap

Rated primary current of the phase C.Ts.

1 - 9999

1

A

On 500Ap

Rated primary current of the C.Ts. or of the tore C.T.

detecting earth fault current

1 - 9999

1

A

Im 1.0In

Motor full-load current (p.u. of phase C.Ts. rated current)

0.1 –1.5

0.01

In

Ist 6Im

Motor starting current (p.u. of motor full load current)

0.5 –10

0.1

Im

tst 5s

Motor starting time

1 –120

1

s

Itr0.5Ist

Switch-over current for control of two-step motor starter

(p.u. of motor starting current)

Dis –0.1 –1

0.1

Ist

tTr 6s

Max switch-over time from start-up

0.5 –50

0.1

s

2.2.2 –Input quantities

2.2.2.1 –Mains Frequency

The relay can operate either in 50Hz or 60Hz systems.

The rated Mains Frequency “ Fn “ must be set accordingly.

2.2.2.2 –Phase Current inputs

The relay directly displays the r.m.s. value of the Phase Currents “ IA “, “ IB ”, “ IC ” flowing in the

Primary of the input Current Transformers and refers all its measurements to that value.

To make the relay properly working with any C.T., when programming the relay settings we have

to input the value of the Rated Primary Current “ In “ of the phase C.Ts.

For the Phase Current inputs, 1A or 5A configuration can be selected by moving the jumpers J1

and J2 provided on the C.T. input card (See § 19).

Example :

Phase CTs 1500/5A and Core Balance CT 100/1A

Set In = 1500A and On = 100A

Configure CT input card with jumpers J1, J2 in the 5A position.

Only phase A and C currents are measured, whereas the current of the phase B is computed as

vector summation of the currents of the other two phases.

The algorithm is based on the following considerations coming from well-known vector relations

among the three-phase currents and the zero sequence current.

-In any circumstance –currents balanced or not, sinusoidal or not –it is always true that:

0IIII10CBA

-When no Earth Fault exists (I0= 0)

CABCBA III0III2

The earth fault protection element is independently supplied by the residual current coming either

from the residual connection of the 3 system C.Ts. or from the core balance C.T.

If any Earth Fault is experienced (I0 0) the Earth Fault Protection Element trips independently

from the phase current measuring elements.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 6 of 36

Copyright - 2010 - Microener

If no Earth Fault is present (I0 = 0), the equation (2) is valid, no matter if currents are balanced or

not, sinusoidal or not.

The third phase current is calculated, in real time, as vector summation of the other two-phase

currents.

Similarly, the Positive Sequence Current Component “ Id “ and Negative Sequence component

“ Is “, with no Earth Fault, are computed according to the normal equations of the system

symmetrical components, using two currents only:

In case of Earth Fault the Earth Fault Element trips before tripping of the unbalance element.

- During Faults

A) Single phase to earth Fault

Trip of the earth fault element directly measuring the Residual Current.

B) Two Phase Fault

In any case one of the currents directly measured is involved, so the relay trips correctly.

C) Two Phase to Earth Fault

Same as A + B

D) Three Phase Fault

All the three currents are correctly measured (in any case two directly).

2.2.2.3 –Earth Fault Current and Voltage Inputs

The real-time measurement of the r.m.s. Earth Fault Current is displayed as percent of the rated

current of the Zero sequence Current measuring C.T. (Io= xxxx %On).

The input of the Earth Fault element is supplied by a separated Core Balance C.T., with 1A rated

Secondary Current.

The Earth Fault element can operate as a normal Zero Sequence O/C element or as a Directional

Zero Sequence O/C element.

In this case to discriminate the direction the relays uses as polarizing quantity the Zero Sequence

Residual voltage supplied by the Open-Delta windings of the system P.Ts.

The display directly gives the measurement “ Uo “ of the Secondary Zero sequence voltage and

the measurement “ o ” of the phase displacement of the Zero Sequence Current Fasor from the

Zero Sequence Voltage Fasor.

120

AC

120

AC

2

A

2

C

2

AC

2

C

A

II3Id

II3Is

IdII

IsII

IsIdI

IsIdI

j

j

e

e

ααα

ααα

αα

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 7 of 36

Copyright - 2010 - Microener

2.2.3 –Functions and Settings

2.2.3.1 –F49 –Thermal Image (See curves § 20)

The current “ I“ producing motor warming-up is computed as a conventional composition of

Positive Sequence “ Id “ and Negative Sequence “ Is “ components of the motor current.

-Computed current:

-Allowed overloading time (See Curve § 19)

The trip time delay “ t“ of the thermal element, depends on the warming-up time constant

“ tm “ of the motor, on the previous thermal status (Ip), on the admissible continuous overload

(Ib) and, of course, on the actual load (I)

tm

=

(1-60)min.

I

=

computed current

Ip

=

preheating current

Ib

=

continuously admissible current

(1-1.3)Im, step 0.01Im

Im

=

motor rated current

(0.1-1.5)In, step 0.1In

-Steady motor cooling-down time constant: to = (1-10)tm, step 1tm

The cooling-down time constant of the motor when running is “tm”; it is automatically changed

to " to " when the motor current drops below 0.1 lm (running/steady motor discrimination

level).

-Thermal prealarm : Ta/n = (50-110)%Tn, step 1%Tn

An alarm signal is issued when the simulated warming exceeds the set percentage of the

motor rated temperature Tn.

Automatic 1% drop out percentage.

-Restart inhibition: Ts/n = (40-100)%Tn, step 1%Tn

To inhibit a new motor starting before cooling down to 99% Ts/n, reset after tripping of the

thermal element takes places when T< 0.99[Ts].

22 3IsIdI

22

22

(Ib/Im)(I/Im) (Ip/Im)(I/Im)

Intmt

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 8 of 36

Copyright - 2010 - Microener

2.2.3.2 –F51LR –Locked Rotor Protection (Rotor jam)

At motor starting this function is disabled for the set time “ 2tSt “ : when this time has elapsed, if

current exceeds the set level “ ILR ”, the relay trips with a delay of “ tLR ” sec.

-Current level :

ILR = (1-5)Im, step 0.1Im. lf ILR = DIS. the function is disactivated.

tLR = (1-25)s, step 1s

-Inhibition time of the locked rotor function:

2tSt

tSt = (1-120)s, step 1s = motor start-up time

2.2.3.2 - F46 - Current Unbalance (Negative Sequence Current) protection (See curve 21)

Besides its contribution to the thermal image algorithm, current unbalance also controls another

inverse time element

-Minimum Negative Sequence current operation level

Is> = (0.1-0.8)Im, step 0.1lm. lf ls> = DIS. the function is disactivated.

-Time current curve

tIs> = (1-8)s, step 1s

Actual trip time delay is given by:

“ Is ” is the actual Negative Sequence Current

2.2.3.4 –F47 –Single Phasing

When the relay detects the loss of the current of one phase while the currents of the other two

phases are present, the Single Phasing element “ 1“ is tripped with a fixed 3 sec. time delay.

2.2.3.5 - F37 - No-Load Running protection

This function performs the protection against no-load running: it is activated by motor under

current.

-Under current level

I< = (0.15-1)Im, step 0,01Im. lf I< = DIS. the function is disactivated.

When current is below 0.1lm in all phases the function is activated.

-Trip time delay = 3 sec.

Im)Isattimetrip(tIstIs

0.1Is/Im

0.9

t

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 9 of 36

Copyright - 2010 - Microener

2.2.3.6 - F51 - Overcurrent protection

-Minimum Pick-up Current level in at least one phase :

I> = (1-5)Ist, step 0.1 Ist (limited to 20 times In)

Ist (motor locked rotor current) = (0.5-10)Im, step 0.1Im

lf I> = DIS. the function is disactivated

-Trip time delay

tI> = (0.05-1)s, step 0,01s.

Any of the output relays can be associated to the time delayed element “tI>” as well as to the

instantaneous element “I>” of this function for signalling or for blocking other relays. The

output relay controlled by the I> level remains energized for the time tI> + tBO.

After this delay the relay it is anyhow reset.

tBO = (0.05-0.5)s, step 0.05s.

2.2.3.7 - F64 - Earth Fault protection

-Minimum Pick-up Zero Sequence Residual Current level :

O> = (0.1 - 4)%On, step 0.1%On. lf O> = DIS. the function is disactivated.

-Trip time delay:

tO> = (0.05-5)s, step 0.01s.

-Minimum Residual Voltage level to enable the operation of the Zero Sequence O/C element

when in the Directional mode:

Uo> = (2-25)secondary V, step 1V.

-Max torque angle in the Directional operation mode (see § 2.3):

= (0-359-Dis)°, step 1°.

When “ “ is set to Dis, the Earth Fault element works as normal non directional Overcurrent

relay and the “ Uo “ level is disregarded.

As for function F51, any of the output relays can be associated to the instantaneous element

of “O>” as well as to the time delayed element “ tO> “.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 10 of 36

Copyright - 2010 - Microener

2.2.3.8 - Limitation of the Starts Number

-Allowed Number of startings:

St No = (1-60), step 1 lf St No = DIS the number of startings is unlimited.

-Time interval in which the StNo is counted:

tStNo = (1-60)min. step 1 min.

lf during the time “tStN” the “StNo” is attained, a new start is inhibited for the time tBst.

-Restart Inhibition time:

tBst = (1-60)min., step 1min.

On the set tBst= 0 the inhibition is disactivated

On the set tBst= Rm the inhibition is permanent until the RESET key is operated.

2.2.3.9 - Starting Sequence Control

During start-up of the motor, the unit can control an output relay used to operate the switch-over of

motor starter (star-delta, resistance or impedance, autotransformer, etc...) thus allowing to

automatically manage the starting transition by controlling the following parameters:

-Switch-over (transition) current:

ITr = (0.1-1)Ist, step 0.1Ist

-Maximum switch-over (transition) time delay:

tTr = (0.5-50)s, step 0.1s.

At motor start counting of “ tTr “ begins. If during “ tTr ” the motor current drops below “ ltr “,

switching-over is operated; if motor current stays above “ ltr “ longer than “ tTr “, the Locked Rotor

element is activated.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 11 of 36

Copyright - 2010 - Microener

2.2.3.10 - Autosetting

The complexity of properly set a motor protection, frequently produces undesired tripping or

non-operation of some of the functions.

The relay MM30-DK can automatically select the best setting of the parameters according to motor

and system basic data. These data are:

-

System frequency

=

Fn

=

50 o 60

Hz

-

Rated primary current of phase C.Ts.

=

In

=

0-9999

A

step 1A

-

Rated primary current of earth fault C.T

=

On

=

0-9999

A

step 1A

-

Motor rated current

=

lm

=

0.1-1.5

In

step 0.01In

-

Motor starting current

=

lst

=

0.5-9.9

Im

step0.1 Im

-

Starting time

=

tst

=

1-120

s

step 1s

-

Transition current level

=

ITr

=

0.11

Ist

step 0.1 Ist

-

Transition time

=

tTr

=

0.5-50

s

step 0,1s

Once these settings have been programmed, the “AUTOSET” function can be activated by the key

"ENTER" and all the parameters are computed and automatically set at values suitable for a

normal duty of the motor.

Particularly the motor warming-up time constant “tm” is computed so that the motor, when stopped

after having run continuously at Rated Power (Rated current Im), can be immediately restarted at

least one time.

The parameters can anyhow be manually modified if different setting is needed.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 12 of 36

Copyright - 2010 - Microener

2.3 - OPERATION OF THE DIRECTIONAL EARTH FAULT ELEMENT

It is assumed :

O>

=

Set minimum pick-up residual current : (3Io)

Uo>

=

Set minimum residual voltage (3Uo) to enable Is pick-up

o

=

Set characteristic angle (max. torque displacement of residual current 3Io from residual

voltage 3Uo).

3Io

=

Actual earth fault relay’s input current

3Uo

=

Actual earth fault relay’s input voltage

o

=

Displacement of 3Io from 3Uo

Io

=

Component of 3Io in the direction

Io= 3Io cos(o-o)

The relay measurement is:

3Io x cos( o -o) = Io

The relay trips (3Uo>[Uo>]) when Io>[O>] (fig.2) i.e, when the component of the input current in the

measuring direction of the relay exceeds the set trip level Is. [O>]

Operation is enabled only if the input zero-sequence voltage 3Uo is above the set level [Uo>].

The sensitivity of the relay is then proportional to cos(o -o), it is maximum when o= o

and its operation field is limited within the range:

(o - 90°) < o < (+ 90) (fig.1)

The characteristic angle of the relay must be selected according to the kind of earthing of the installation

which has to be protected against earth fault; typical setting are:

UNEARTHED NEUTRAL

o

=

90°

NEUTRAL EARTHED VIA RESISTOR

o

=

0°

SOLIDLY EARTHED NEUTRAL

o

=

60°

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 13 of 36

Copyright - 2010 - Microener

2.4 CLOCK AND CALENDAR

The unit features a built in clock calendar with Years, Months, Days, Hours, Minutes, Seconds,

Tenths of seconds and Hundredths of seconds.

2.4.1 Clock synchronization.

The clock can be synchronized via a digital input (terminals 1 –14) or the serial communication

interface. The following synchronization periods can be set: 5, 10, 15, 30, 60 minutes.

Synchronization can also be disabled, in which case the only way to modify the current date and

time is via the front panel keyboard (SETTINGS menu) or the serial communication interface.

In case synchronization is enabled, the unit expects to receive a sync signal at the beginning of

every hour and once every Tsyn minutes. When a sync signal is received, the clock is

automatically set to the nearest expected synchronization time.

For example: if Tsyn is 10min and a sync signal is received at 20:03:10 January the 10th, 98, then

the clock is set to 20:00:00 January the 10th, 1998.

On the other hand, if the same sync signal were received at 20:06:34, the clock would be set to

20:10:00, January the 10th 98.

Note that if a sync signal is received exactly in the middle of a Tsyn period, the clock is set to the

previous expected synchronization time.

2.4.2 Date and time setting.

When the PROG/SETTINGS menu is entered, the current date is displayed with one of the

groups of digits (YY, MMM or DD) blinking.

The DOWN key operates as a cursor. It moves through the groups of digits in the sequence

YY => MMM => DD => YY => …

The UP key allows the user to modify the currently blinking group of digits.

If the ENTER button is pressed the currently displayed date is captured.

On the other hand pressing the SELECT button leaves the current date unchanged and scrolls

the SETTINGS menu. Current time can now be modified using the same procedure described

above. If synchronization is enabled and the date (or time) is modified, the clock is stopped until

a sync signal is received (via digital input or the serial port). This allows the user to manually set

many units and have them to start their clocks in a synchronized fashion.

On the other hand if synchronization is disabled the clock is never stopped.

Note that the setting of a new time always clears 10ths and 100ths of sec.

2.4.3 Time resolution.

The clock has a 10ms resolution. This means that any event can be time-stamped with a 10ms

resolution, although the information concerning 10ths and 100ths of sec. can be accessed only

via the serial communication interface.

2.4.4 Operation during power off.

The unit has an on board Real Time Clock which maintains time information for at least 1 hour in

case of power supply failure.

2.4.5 Time tolerance.

During power on, time tolerance depends on the on board crystal (+/-50ppm typ, +/-100ppm

max. over full temperature range).

During power off, time tolerance depends on the RTC’s oscillator (+65 –270 ppm max over full

temperature range).

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 14 of 36

Copyright - 2010 - Microener

3. CONTROLS AND MEASUREMENTS

Five key buttons allow for local management of all relay's functions.

A 8-digit high brightness alphanumerical display shows the relevant readings (xxxxxxxx)

(see synoptic table fig.1)

FIG.1

MEASURES

MAX VAL.

LASTTRIP

TRIP NUM

ACT MEAS

Actual measurement values

Max. values measured

Values measured at last five events

N° of tripping for each function

Measurements

display

SET DISP

SETTINGS

FRELAY

Display of setting

Display of configuration of output relay

Setting Program

display

PROGR

SETTINGS

FRELAY

Setting of parameters

Configuration of output

relays

Set Programming

PRO

G

TEST PRG

W/O TRIP

WithTRIP

Functional Test

Test with operation of signals and output relays

Test with operation of signals

only

Test activation

by the key ENTER

Paramater scanning

by the key

SELECT

Parameter modification

by the key “+” “-”

Set validation

by the key ENTER

Scanning of

the menus by

the key

“+” “-”

MODE

SELECT

ENTER

+ -

(*) Enabled only if input current is zero

(*)

(*)

ENTER/RESET

MODE

SELECT

+

-

PROG.

The SELECT button chooses

which category of values within the

chosen mode to display

Pressing this button progressively

selects between

Measurements Display,

Setting Display, Programming,

and Test modes

When in Program mode, this

button stores the newly selected

value. If not in Program mode and

the relay has tripped, this button

resets the relay and all output

contacts. If not tripped, this button

restores the default display.

The + and - buttons are used to

select the actual measurement or

display desired when in

Measurements Display or Settings

Display modes. When in Program

mode, these buttons increase or

decrease the value of the

displayed setting.

When in Program mode, and when

all input currents are zero,

pressing this recessed button

places the relay into active

programming mode, allowing any

or all of the relay’s settings to be

altered.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 15 of 36

Copyright - 2010 - Microener

4. SIGNALIZATIONS

Eight signal leds (normally off) are provided:

a)

Red

LED

T>

Flashing when the motor heating “T” exceeds the set alarm level [Ta].

Illuminated on over-temperature trip. –Also illuminated on activation of RTD

input.

b)

Red

LED

St No

Flashing on tripping of the element for limitation of the number of

consecutive startings.

Illuminated at the end of [tBSt].

c)

Red

LED

I<

Flashing as soon as motor current drops below the set level [I<]

Illuminated at the end of trip time delay.

d)

Red

LED

Is>,1

Flashing as soon as motor unbalance exceeds the set level [Is>]

Illuminated on trip after [tIs>] time delay or on tripping of the single phasing

element.

e)

Yellow

LED

PROG/

I.R.F.

Flashing when in PROGRAM MODE

Illuminated when relay internal fault is detected.

f)

Red

LED

I>

Flashing when motor current exceeds the set level [I>]

Illuminated on trip after [tI>] time delay.

g)

Red

LED

O>

Flashing when earth fault current exceeds the set level [O>]

Illuminated on trip after [tO>] time delay.

h)

Yellow

LED

ROTOR

STALL

Illuminated on trip of the Locked Rotor element (I>ILR) and/or on activation

of the Speed Control input SpC.

The reset of the leds takes place as follows:

Leds

a

From flashing to off automatically when motor heating drops below

the alarm level [Ta].

From steady light to off by the Reset control (front button or serial

command) provided motor heating is below the restart temperature

[Ts].

Leds

b

From flashing to off by the Reset control (front button or serial

command) only when the restart inhibition time is set to “manual”:

[tBSt]=Rm.

From illuminated to off when [tBSt] has expired.

Leds

c,d,e,f,g

From flashing to off, automatically when the lit-on cause disappears.

From ON to OFF, by "ENTER/RESET" push button only if the

tripping cause has disappeared.

Leds

h

From flashing or illuminated to off, automatically when the lit-on

cause disappears.

T>

StNo

I<

Is>,1

ROTOR

STALL

PROG/

I.R.F.

I>

a

b

c

d

e

f

g

h

O>

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 16 of 36

Copyright - 2010 - Microener

In case of auxiliary power supply failure the status of the leds is recorded and reproduced when power

supply is restored.

5. OUTPUT RELAYS

The unit MM30-DK includes four (R1, R2, R3, R4) user programmable plus one diagnostic (R5) output

relays.

In the version MM30-DKX the number of output relays can be increased by the addition of one or two

optional Relay Expansion modules REX-8.

The modules REX-8 are for protruding mounting and are controlled by the master module MM30-DKX

via a screened twisted pair of cables connecting dedicated RS485 serial ports (see diagram herebelow).

The module REX-8 includes eight (RA, RB, RC, RD, RE, RF, RH, RG) user programmable plus one

(R-Diag) diagnostic output relays

The master module MM30-DK can control altogether up to sixteen output relays

-4 internal R1 –R2 –R3 –R4

-8 from the first optional REX-8 module RA –RB –RC –RD –RE –RF –RG –RH

-4 from a second optional REX-8 module RI(RA+RB) –RJ(RC+RD) –RK(RE+RF) –RL(RG+RH)

This second unit REX-8 is configured (by internal Dip-Switch) to operate the eight relays two by two in

parallel (only four user programmable outputs with double number of available contacts)

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 17 of 36

Copyright - 2010 - Microener

Any of the functions featured by the MM30-DK can be programmed to control up to four out of the

sixteen user programmable output relays

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 18 of 36

Copyright - 2010 - Microener

The user programmable relays (all but R5, RDIAG) are normally deenergized, i.e. energized on trip.

These relays pick-up as soon as the tripping cause appears (relays controlled by the instantaneous

functions) or at the end of the set trip time delay (relays controlled by time delayed functions).

The reset after trip takes place automatically as soon as the relevant tripping cause has been cleared.

The relays R5, R DIAG are not user programmable; they are normally energized and get deenergized

on :

- internal fault of MM30-DK - Internal fault of REX-8

R5 - MM30-DK power supply failure R DIAG - REX-8 power supply failure

- during the programming - Interruption/fault on the serial

control communication

6. SERIAL COMMUNICATION

The relays fitted with the serial communication option can be connected via a cable bus or (with proper

adapters) a fiber optic bus for interfacing with a Personal Computer (type IBM or compatible).

All the operations which can be performed locally (for example reading of measured data and changing

of relay’s settings) are also possible via the serial communication interface.

Furthermore the serial port allows the user to read the demand recording data.

The unit has a RS232 / RS485 interface and can be connected either directly to a P.C. via a dedicated

cable or to a RS485 serial bus, thus having many relays to exchange data with a single master P.C.

using the same physical serial line. A RS485/232 converter is available on request.

The communication protocol is MODBUS RTU (only functions 3, 4 and 16 are implemented).

Each relay is identified by its programmable address code (NodeAd) and can be called from the P.C.

A dedicated communication software (MSCOM) for Windows 95/98/NT4 SP3 (or later) is available.

Please refer to the MSCOM instruction manual for more information Microelettrica Scientifica.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 19 of 36

Copyright - 2010 - Microener

7. DIGITAL INPUTS

The relay is fitted with three digital inputs activated when the relevant terminals are shorted by a cold

contact :

-

R.T.

(terminals 1-2)

Remote Trip control.

Activation of the input R.T. (Terminals 1-2 shorted) produces the

following operation :

The output relay associated to the function R.T. is energized

The Trip Number Counter R.T. is incremented by 1 unit

The event recording is activated and shows “CAUSE: RT”

-

S.p.C.

(terminals 1-3)

Switch speed Control.

The Speed Control input is connected to an external N/O contact which

closes as soon as the motor is running. If the contact does not close

within the set start time [tst] from the moment the motor is energised,

the Locked Rotor function is tripped. The relay and the signal led

associated to ILR are energised, the recording on Last Trip will show

cause SpC and trip N° LR will be increased.

If the Speed Control function is not used, it must be disactivated by

programming the variable [Spc] = OFF (see § 12.1)

-

RTD

(terminals 1-14)

Thermal probe.

This function is enabled by programming the variable

[RTD] = ON (see § 12.1)

If the function is enabled, the input RTD is activated when the resistance

connected to the terminals 1-14 exceeds the limits 50> R1-14 > 2900.

This limits respectively correspond to “Shorted Probe” (<50) or to

“Overtemperature” (R>2900)

The activation of the input 1-14 produces the following operation:

The relay associated to R.T. is energized

The Led T> is lit-on.

The counter of Trip Number of the function T> is incremented

LastTrip recording shows : "CAUSE RTD"

8. TEST

Besides the normal "WATCHDOG" and "POWERFAIL" functions, a comprehensive program of self-test

and self-diagnostic provides:

Diagnostic and functional test, with checking of program routines and memory's content, run every

time the aux. power is switched-on: the display shows the type of relay and its version number.

Dynamic functional test run during normal operation every 15 min. (relay's operation is suspended

for less than 10 ms). If any internal fault is detected, the display shows a fault message, the Led

"PROG/IRF" illuminates and the relay R5 is deenergized.

Complete test activated by the keyboard or via the communication bus either with or without tripping

of the output relays.

MM30-DK

Doc. N° MO-0050-ING

Rev. 2

Pag. 20 of 36

Copyright - 2010 - Microener

9. KEYBOARD AND DISPLAY OPERATION

All controls can be operated from relay's front or via serial communication bus.

The keyboard includes five hand operable buttons (MODE) - (SELECT) - (+) - (-) - (ENTER/RESET)

plus one indirect operable key (PROG) (see synoptic table a fig.1):

a)

-

White key

MODE

:

when operated it enters one of the following operation modes

indicated on the display :

MEASURES

=

Reading of all the parameters measured and of those recorded

in the memory

SET DISP

=

Reading of the settings and of the configuration of the output

relays as programmed.

PROG

=

Access to the programming of the settings and of relay

configuration.

TEST PROG

=

Access to the manual test routines.

b)

-

Green key

SELECT

:

When operated it selects one of the menus available in the

actual operation MODE

c)

-

Red key

“+”AND “-“

:

When operated they allow to scroll the different information

available in the menu entered by the key SELECT

d)

-

Yellow key

ENTER/RESET

:

It allows the validation of the programmed settings

the actuation of test programs

the forcing of the default display indication

the reset of signal Leds.

e)

-

Indirect key

:

Enables access to the programming.

ENTER/RESET

MODE

SELECT

+

-

PROG.

Table of contents

Other MICROENER Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Freescale Semiconductor

Freescale Semiconductor TWR-WIFI-G1011MI user manual

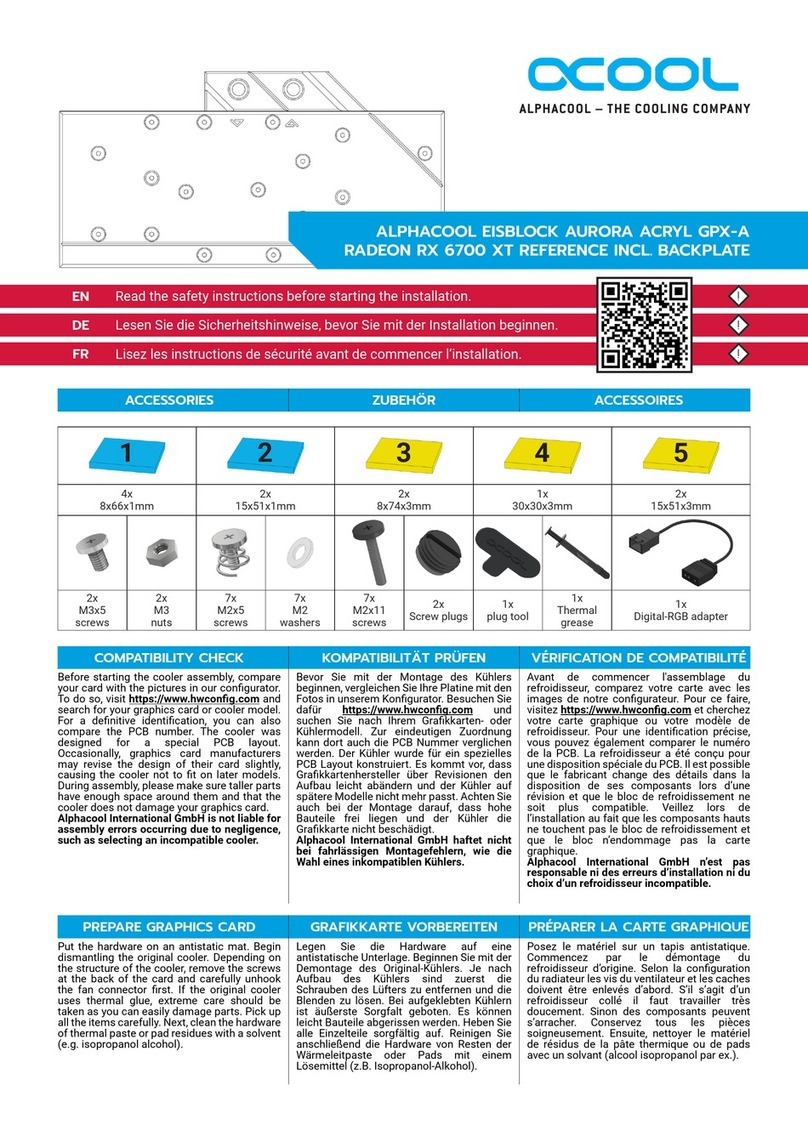

Alphacool

Alphacool NexXxoS GPX-N 1080pro-M21 instruction manual

GIGAIPC

GIGAIPC QBiP-1165G7A user manual

Symbol

Symbol LA-5030 user guide

Texas Instruments

Texas Instruments TPS65910 EVM user guide

ZALMAN

ZALMAN CNPS9X OPTIMA user manual

Intellinet

Intellinet 524056 user manual

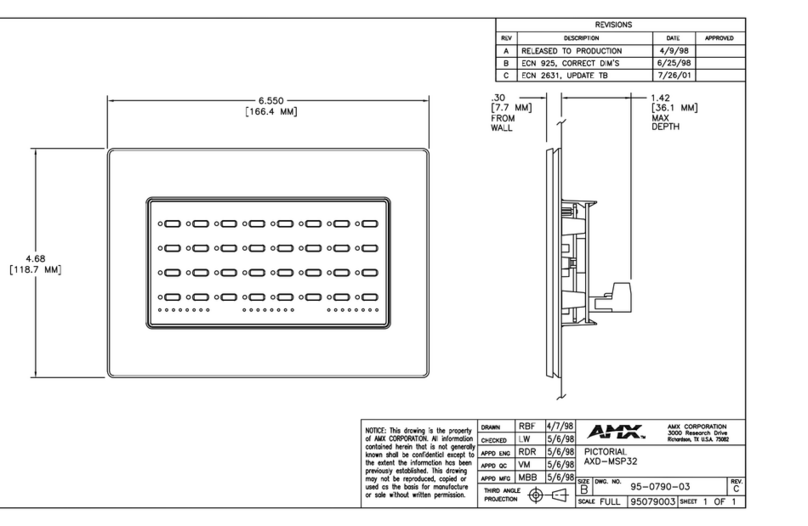

AMX

AMX AXD-MSP32 Schematic diagram

Z3 Technology

Z3 Technology Z3-Q603-RPS user guide

Victron energy

Victron energy VE.Direct Bluetooth Smart Dongle manual

Teradici

Teradici PCoIP Zero TER1206003 Administrator's guide

Alphacool

Alphacool EISBLOCK AURORA ACRYL GPX-A RADEON RX 6700 XT REFERENCE INCL.... manual