microHAM © 2022 All rights reserved

2 - ARXC - HARDWARE ETUP

Installation of ARX consists of hardware and software parts. Mechanical part of setup is to

insert rubber sealing into the slot in the module case lid. Trim its length as necessary. Sealing

might be installed by factory, in this case skip to next.

ARX .REL can be mounted anywhere with cable grommets facing down to avoid water ingress.

Although not necessary, it is advisable to mouth box on place protected against rain, snow or

direct sunlight.

ARX .LoRa is good to mount on place where antenna is not close to metal structures, best

when cable entry grommet is facing down and module is protected against rain, snow or direct

sunlight.

ARX .MAG sensor has to be mounted on bottom side of antenna boom in any orientation, as

far as possible from tower and fixed by zip tights included in the package. Keep alligator clamp

screws and nuts in case you are removing it, they made of nickel plated brass, steel screws

would influence magnetic sensor functionality.

Before proceeding to software setup it is necessary to set ARX module address (only on

ARX .REL) and connect it to AR O.

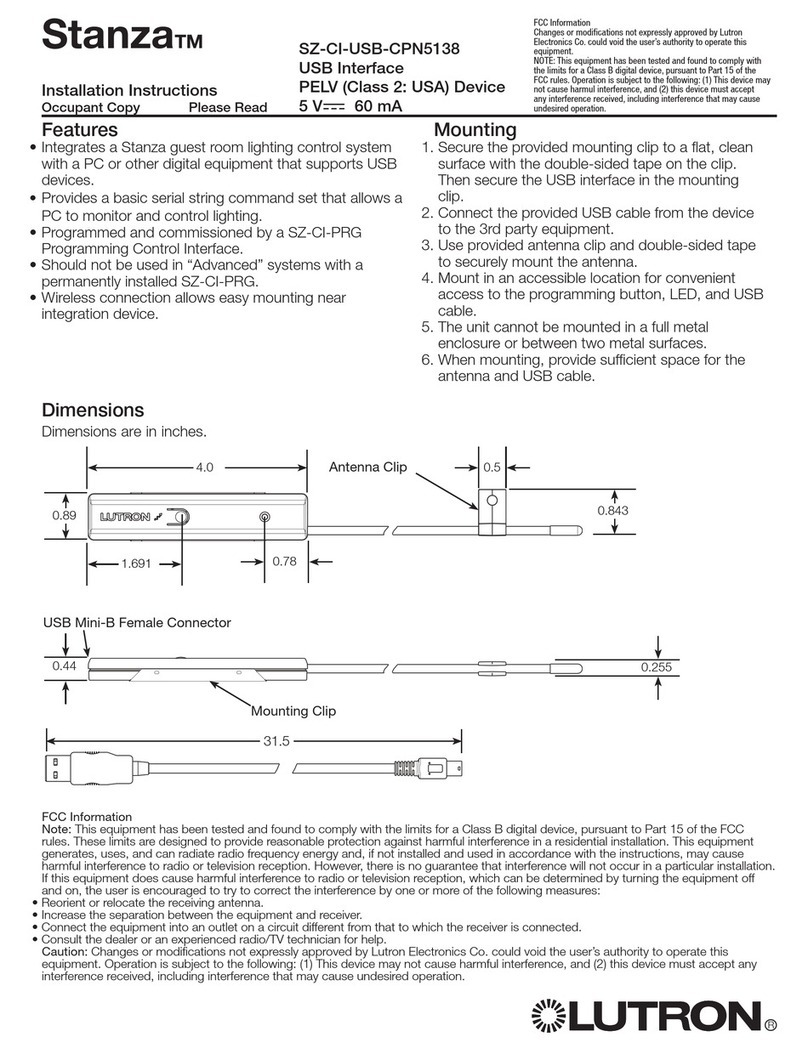

ARXC.REL addressing

To recognize and properly control particular

ARX .REL module, each module needs to have a

unique address. Address is set by combination of

two DIP switches according to drawing on P board

next to DIP switch. It is possible to set up to 4

different addresses: 1 (shown on picture), 2, 3, 4.

Each ARX .REL module has then its own setup in AR O System menu on respective tabs

ARX 1 – ARX 4. ARX .MAG has its address set internally and ARX .LoRa has no address.

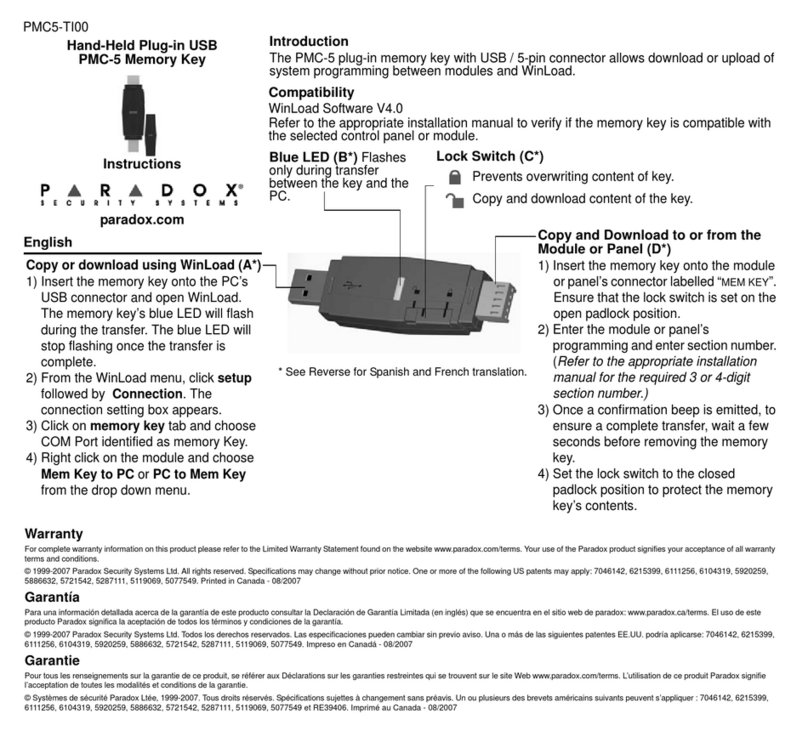

ARXC wiring

In order to control ARX module, it must be connected to AR O first. On AR O, the

connection port is located at D-SENSOR connector. ommunication layer is RS-485 requiring

twisted pair of wires connected to port Z (ZA and ZB pins) and two additional wires for module

power. 12VD power is provided by AR O at D-SENSOR port on +12V and GND pins.

If control cable between AR O and ARX module; or between different ARX modules for any

reason cannot be installed, communication can be established by RF link using pair of ARX

LoRa modules. In this case, external 12V supply must be provided on ARX side of RF link.

Each ARX module has a 4 pole terminal for connecting wires of the communication cable.

ZA and ZB poles serve for communication wires, +12V and GND poles serve for power. On

ARX .REL there are two sets of terminals for simpler daisy-chain connection to additional

modules. Both terminals are connected in parallel, it is not important which one is used if you

are connecting a single module.

4