4 Manual Number 9019288 • Revision F, June 23, 2022

SECTION 1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The TB40 series Advanced Lithium-ion Battery, part numbers 6430040-( ), are designed to deliver

high current capability to start piston and turbine aircraft engines and subsequently, provide power

to the aircraft electrical bus in the event of generator function loss. The TB40 is a sophisticated

energy storage and power system that utilizes state-of-the-art Nanophosphate® lithium-ion battery

cell technology to optimize performance, safety, life and weight when compared to traditional or

competing aircraft batteries. The design of the battery includes detailed focus on key electrical,

mechanical, and software elements that combine to provide exceptional performance and safety

that meets and exceeds the latest regulatory and industry standards. The TB40 is a complete

battery solution providing significant value and benefit to an aircraft designer, owner and operator.

Key features of the TBX series (inclusive of the TB20, TB30, TB40 and TB60) include real-time

state of charge and capacity reporting, programmable battery parameters configurable to individual

installations, and maintenance-free operation with on-condition end of life. Multiple safety

protections, continuous data monitoring, and an on-board status indicator also add value,

reliability, and reduced cost of ownership for the life of the product.

The TBX series Advanced Lithium-ion Batteries require professional use and minimal service to

deliver maximum performance and value as designed. This manual contains information related to

the specifications, installation, operation, storage, scheduled service and other related topics

associated with the proper care and use of this product.

1.2 PHYSICAL ATTRIBUTES

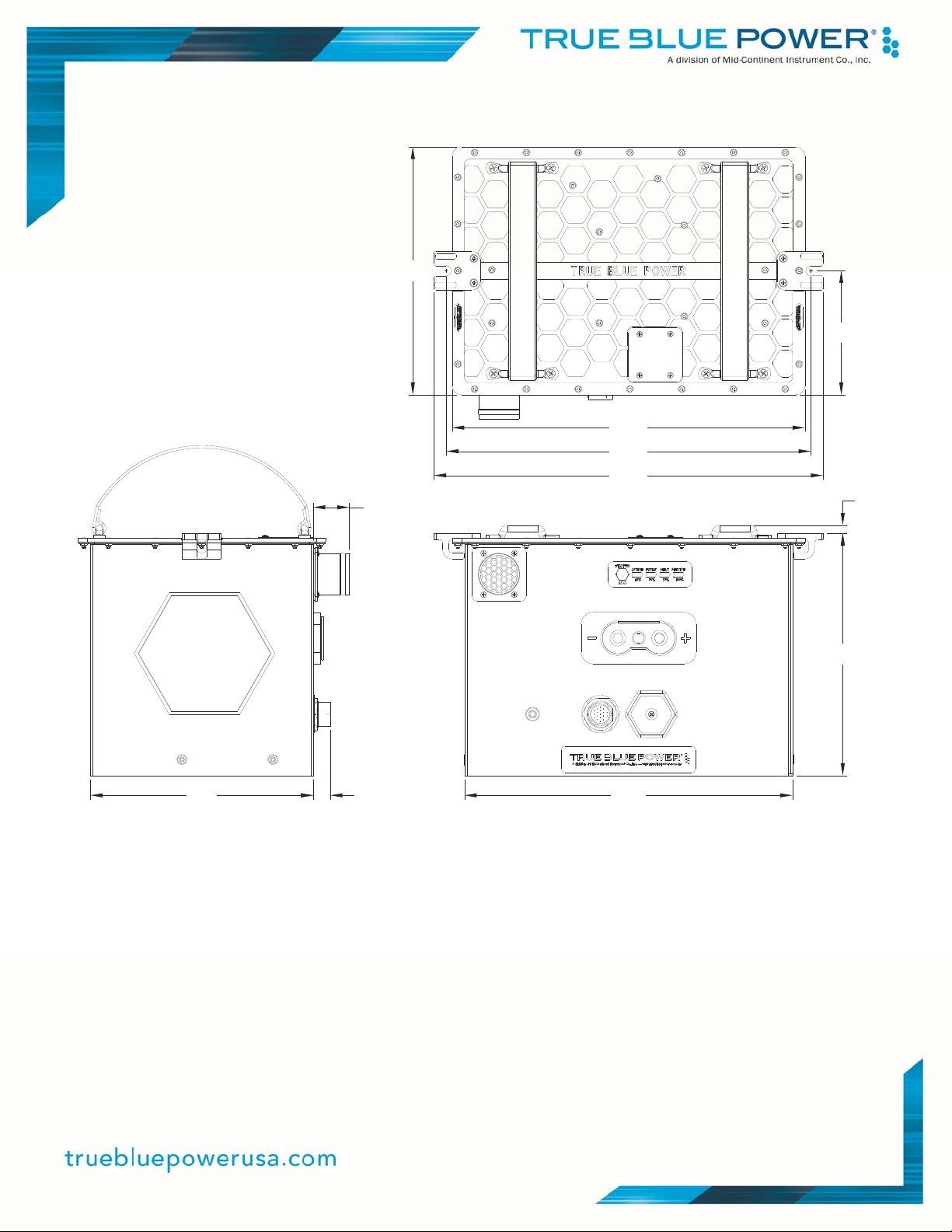

The TB40 is a single, integrated component contained in a metal enclosure with multiple interface

connections. There is a primary 2-pin, industry standard mil-spec quick disconnect power

receptacle, an 18-pin circular communications connector, and a threaded grounding location. A

USB service port and an integrated push-button status indicator with LED indicators are available

for ground operations as well. The lid of the enclosure includes two hold-down features on either

side to support typical aircraft mounting. Handles integrated into the lid of the enclosure provide

ease of lifting and carrying for installation, removal and transport. The 1.50 inch diameter vent port

can be located on either the front or top of the unit for an exhaust connection that directs any

released emissions appropriately.