FOREWORD .........................................................................................................................................................4

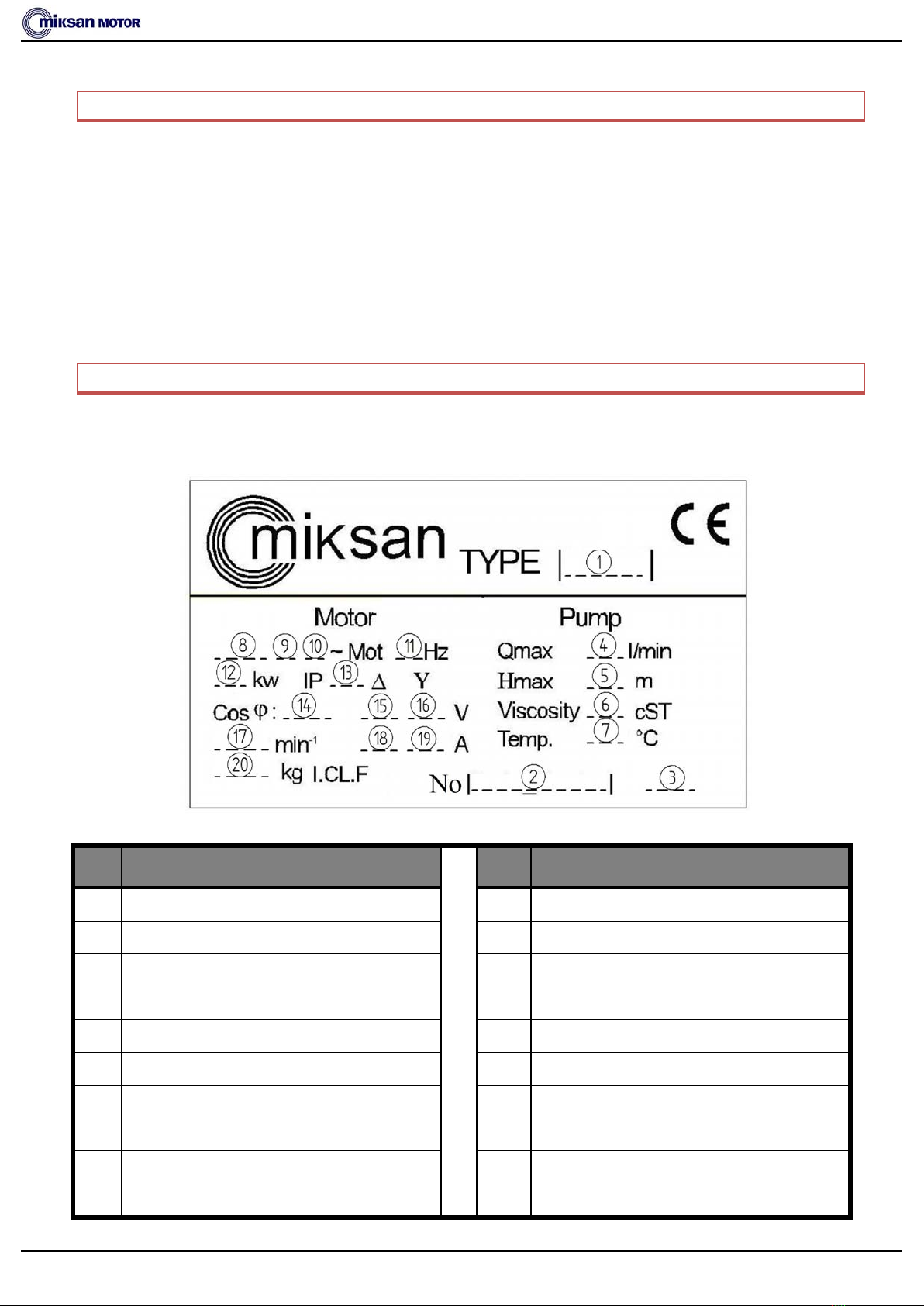

IDENTIFICATION ..................................................................................................................................................4

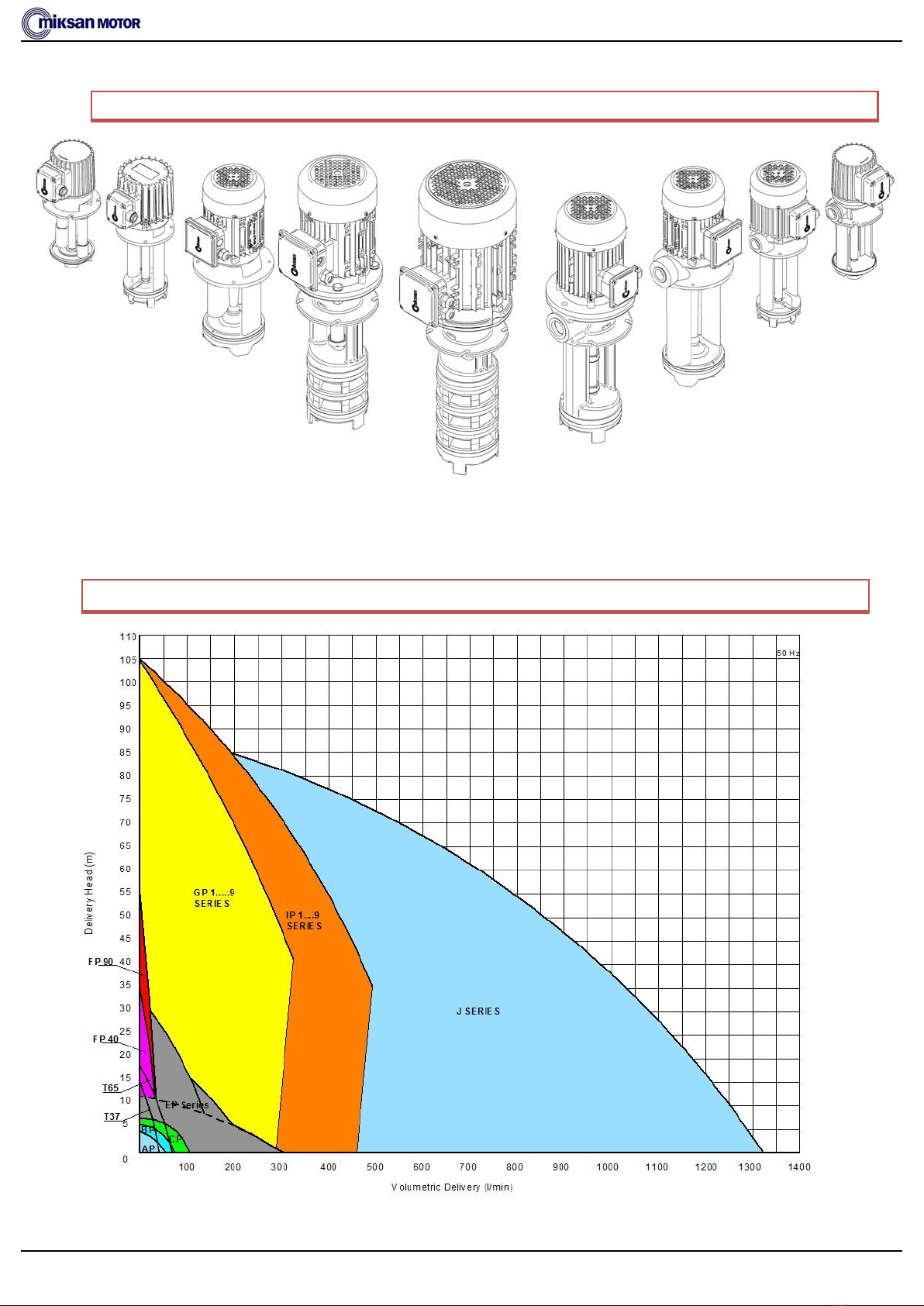

GENERAL .............................................................................................................................................................5

PERFORMANCE RANGE OF PRODUCTS .................................................................................................................5

EXPLODED VIEWS ................................................................................................................................................6

AP PUMP ..................................................................................................................................................6

BP PUMP ..................................................................................................................................................8

CP PUMP.................................................................................................................................................10

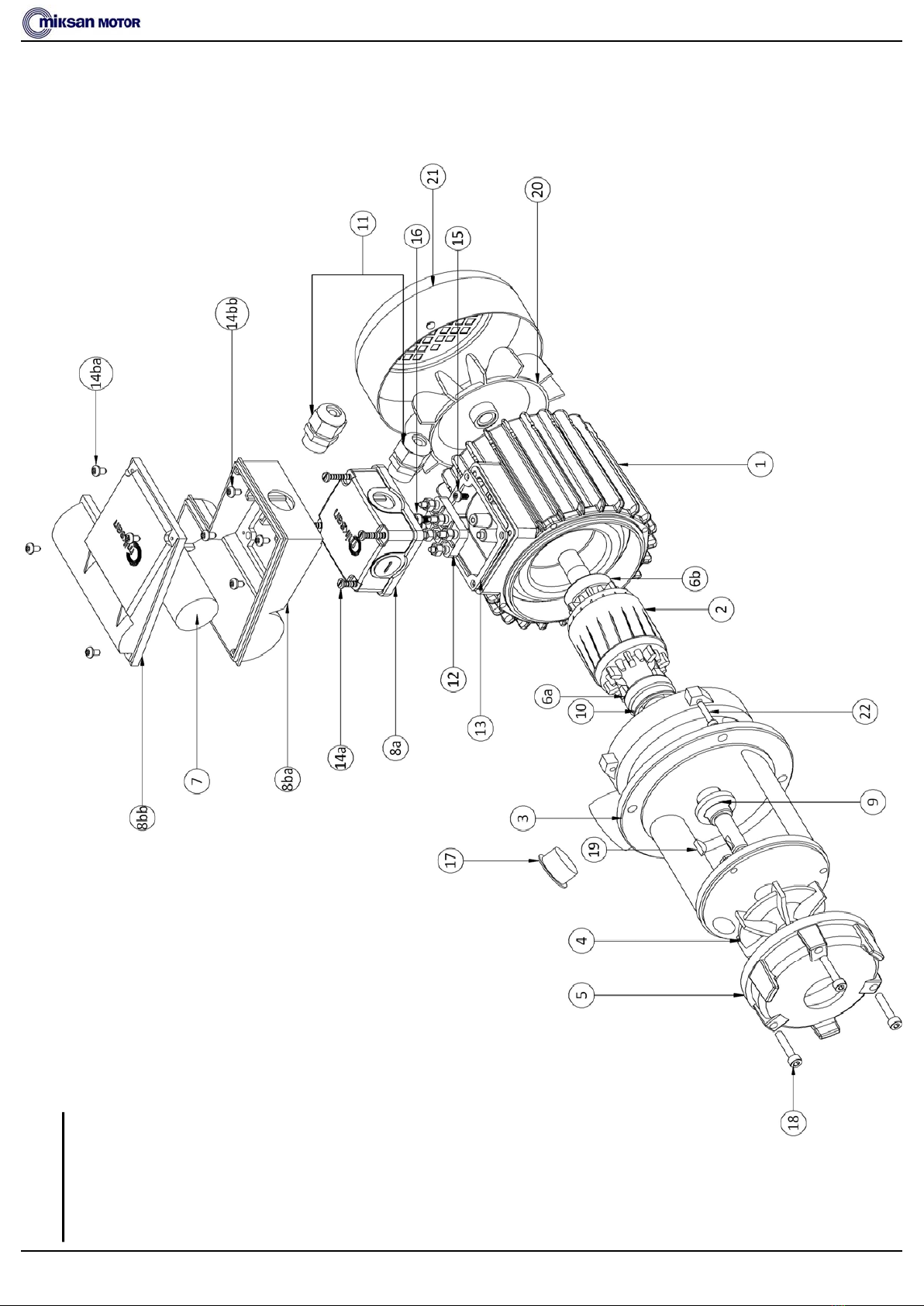

EP PUMP.................................................................................................................................................12

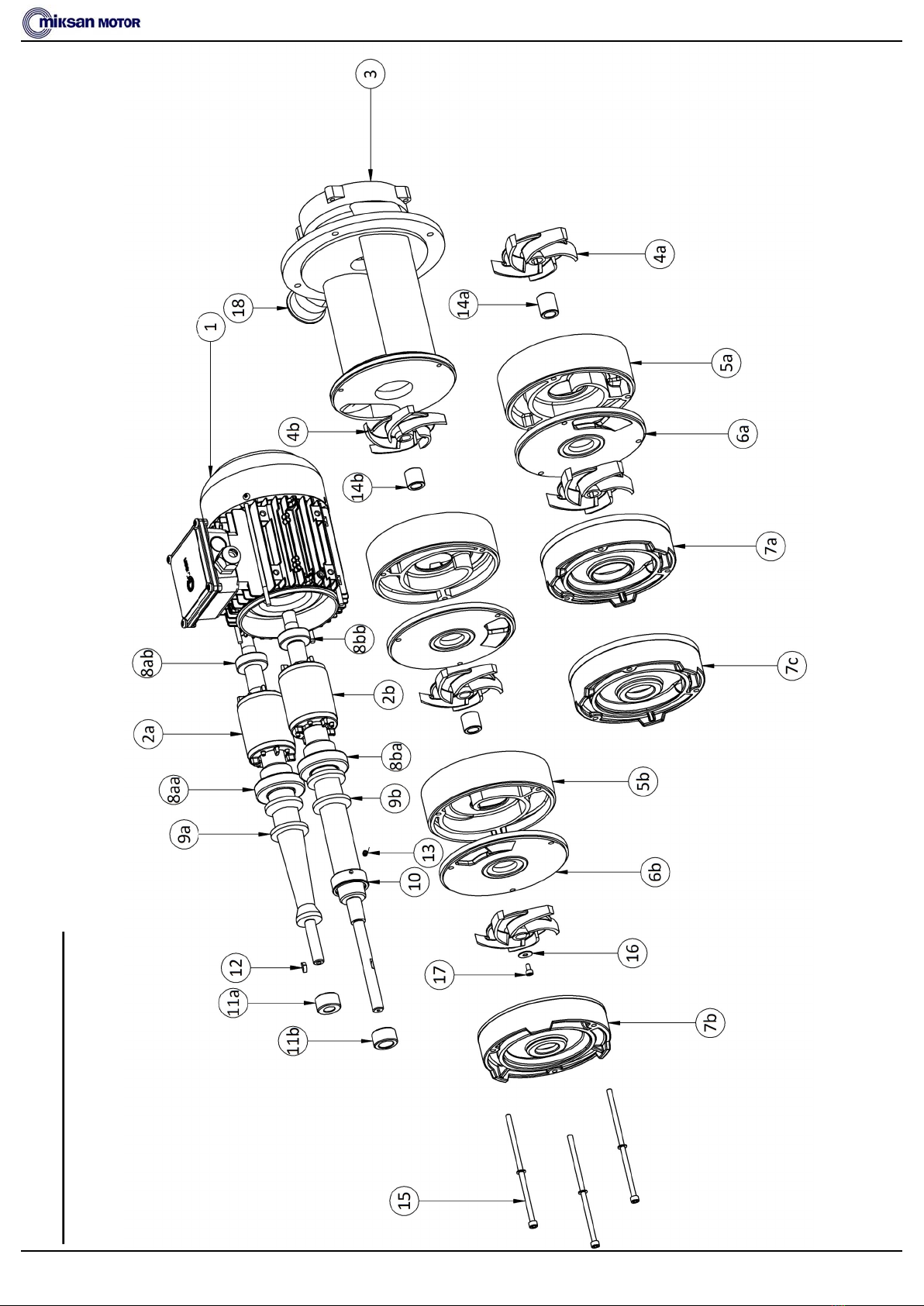

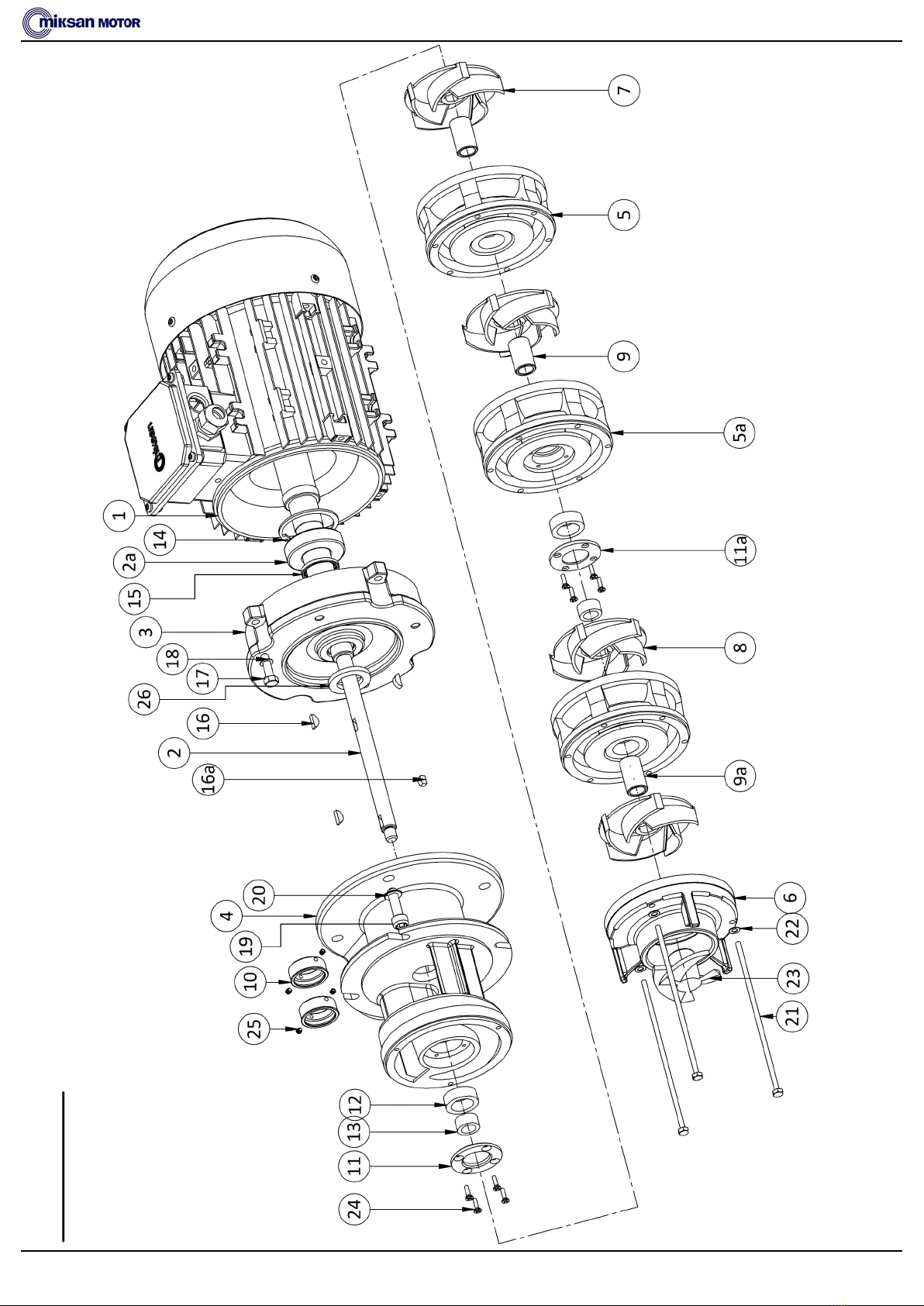

GP PUMP ................................................................................................................................................14

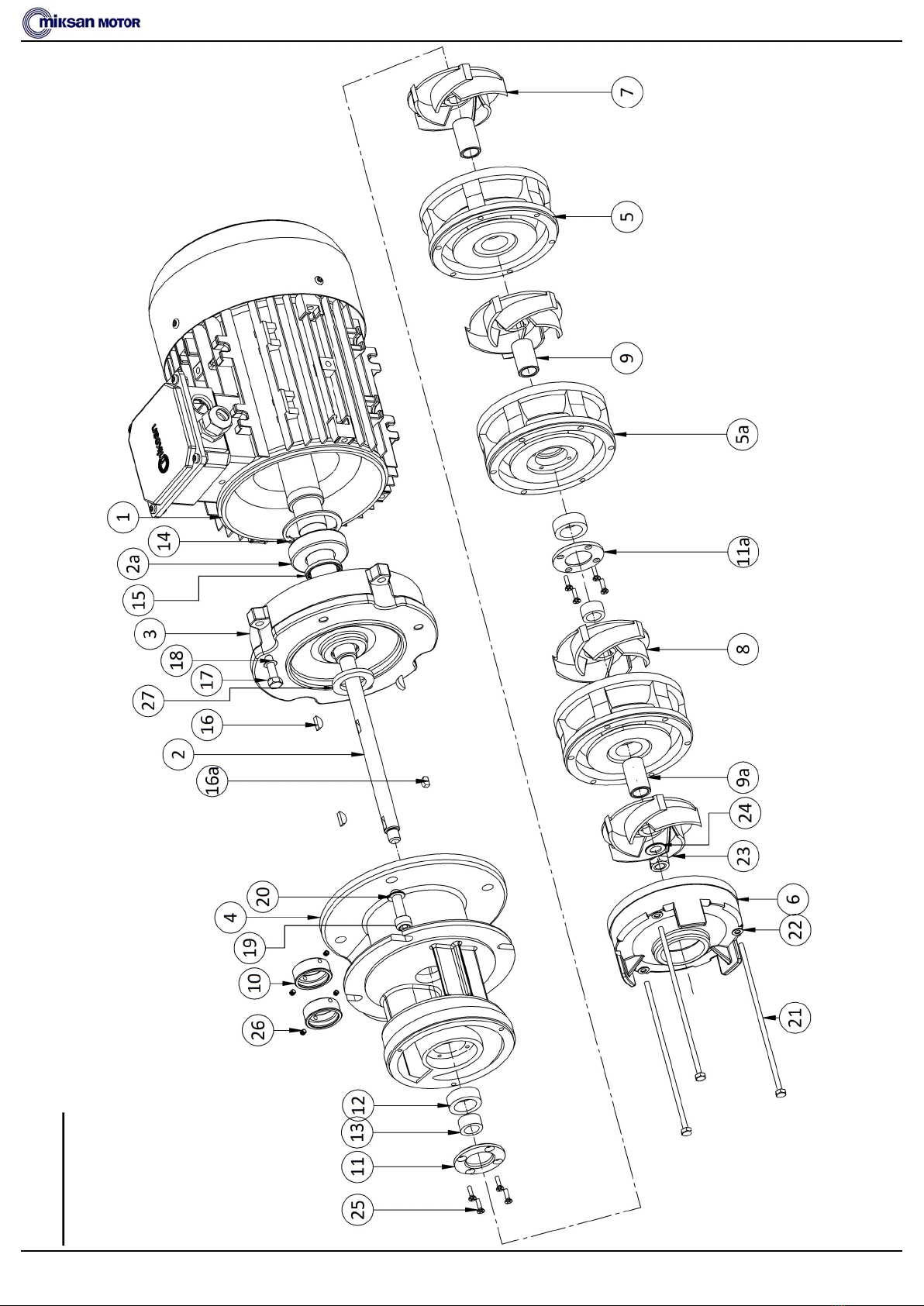

GPA PUMP ..............................................................................................................................................16

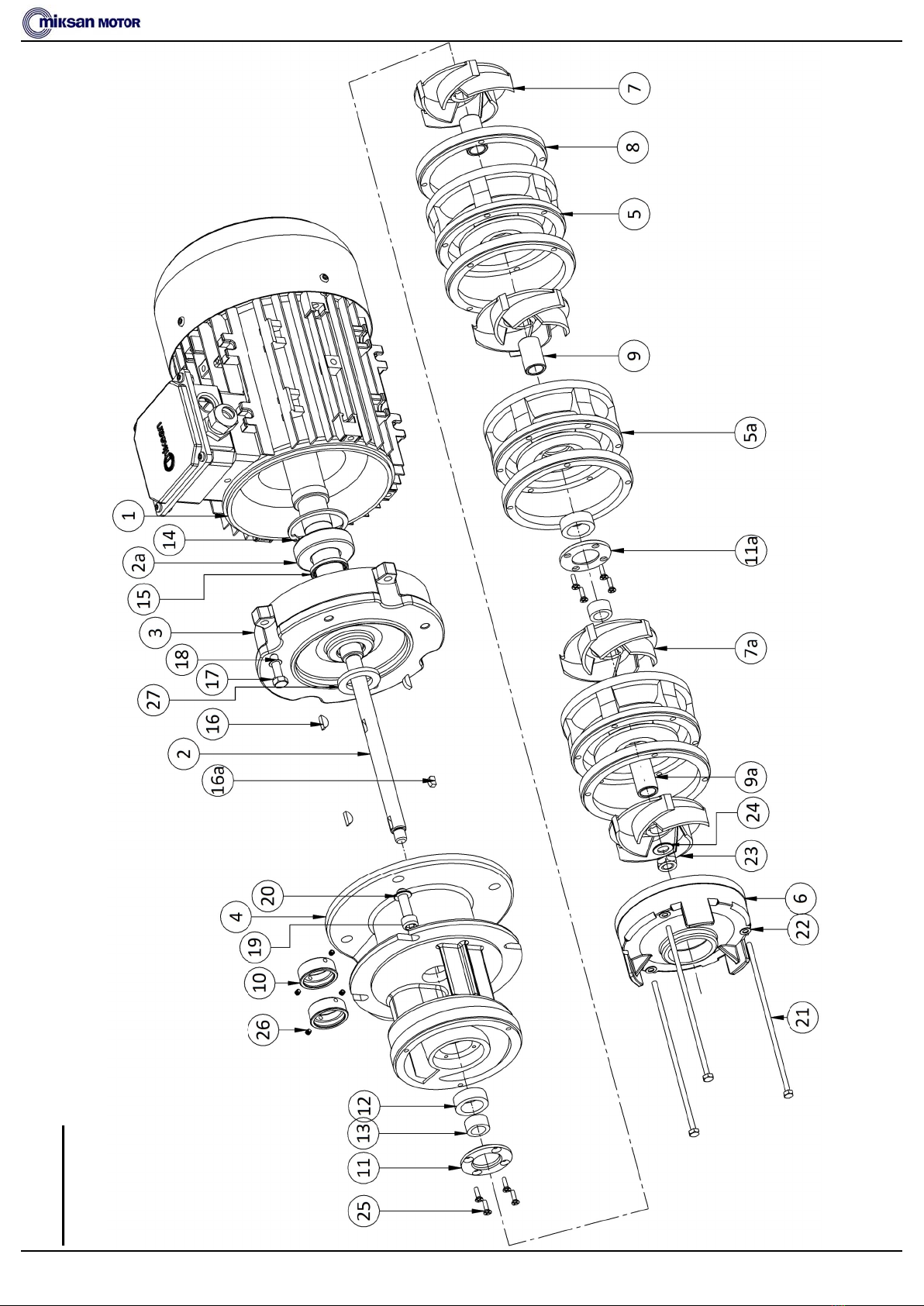

IP PUMP..................................................................................................................................................18

IPA PUMP...............................................................................................................................................20

J SERIES MODULAR PUMP (Single-Stage) ..................................................................................................22

JB SERIES PUMP ......................................................................................................................................24

WARRANTY .......................................................................................................................................................26

SAFETY INSTRUCTIONS ......................................................................................................................................27

TRANSPORT AND STORAGE ...............................................................................................................................29

BEFORE INSTALLATION ......................................................................................................................................29

INSTALLATION ...................................................................................................................................................30

ELECTRICAL CONNECTIONS ................................................................................................................................31

OPERATION .......................................................................................................................................................32

SERVICING AND MAINTENANCE.........................................................................................................................33

TROUBLESHOOTING ................................................................................................................................33

INSTALLATION OF GP, GPA and IP, IPA STAGES WITH BEARING RINGS................................................................34

GENERAL SAFETY NOTES ....................................................................................................................................35