2

3. Safety

It is only the general safety instrucons included under this

main heading ‘Safety’ that have to be followed but also the

safety instrucons provided under the specic headings.

Miksan Motor does not accept any liability for damage and

injury caused by not applying the direcons and instrucons

in this manual.

Non-compliance with the safety instrucons

Non-compliance with safety instrucons may pose a risk to

the safety of personnel, the environment and the product

itself, and also will lead to forfeiture of all rights to claims

for damages.

Non-compliance may result in for example, hazards given

below

Failure of important pump/plant funcons,

Failure of recommended maintenance and repair pro-

cess,

Exposure of people by electrical, mechanical and

chemical hazards,

Threatening the environment due to leakage of hazard-

ous substances,

Operang Personnel

All personnel parcipated in the installaon, operaon,

maintenance and inspecon of the product must be ade-

quately qualied. Responsibilies, capability and supervi-

sion of the personnel must be clearly dened by the plant

operator. Moreover, the operator is responsible for ensur-

ing that the contents of the operang instrucons are fully

understood by the personnel.

Unauthorised modicaons and procurement of spare

parts

The product has been designed and manufactured with the

greatest possible care and any modicaon may be made to

the pump only aer consultaon with the manufacturer.

Using spare parts and accessories authorised by the manu-

facturer is required to meet safety regulaons. Use of non-

original parts can invalidate any liability of the manufactur-

er for consequenal damage and may lead to a safety risk.

When operang the pump, the safety instrucons con-

tained in this manual, the relevant naonal accident pre-

venon regulaons and any other service and safety in-

strucons issued by the plant operator are to be observed.

During Operaon

If hot/cold machine components involve hazards, they

must be prevented against accidental contact.

Guards for the moving parts (e.g. coupling, fan) must

not be removed while the pump is running. Also make

sure that guards are never in contact with the moving

parts by using proper protecon parts

Any leakage of hazardous (e.g. explosive, toxic, hot)

uids must be drained away to prevent any risk to sur-

roundings.

Always close the terminal box to prevent hazards

caused by electricity.

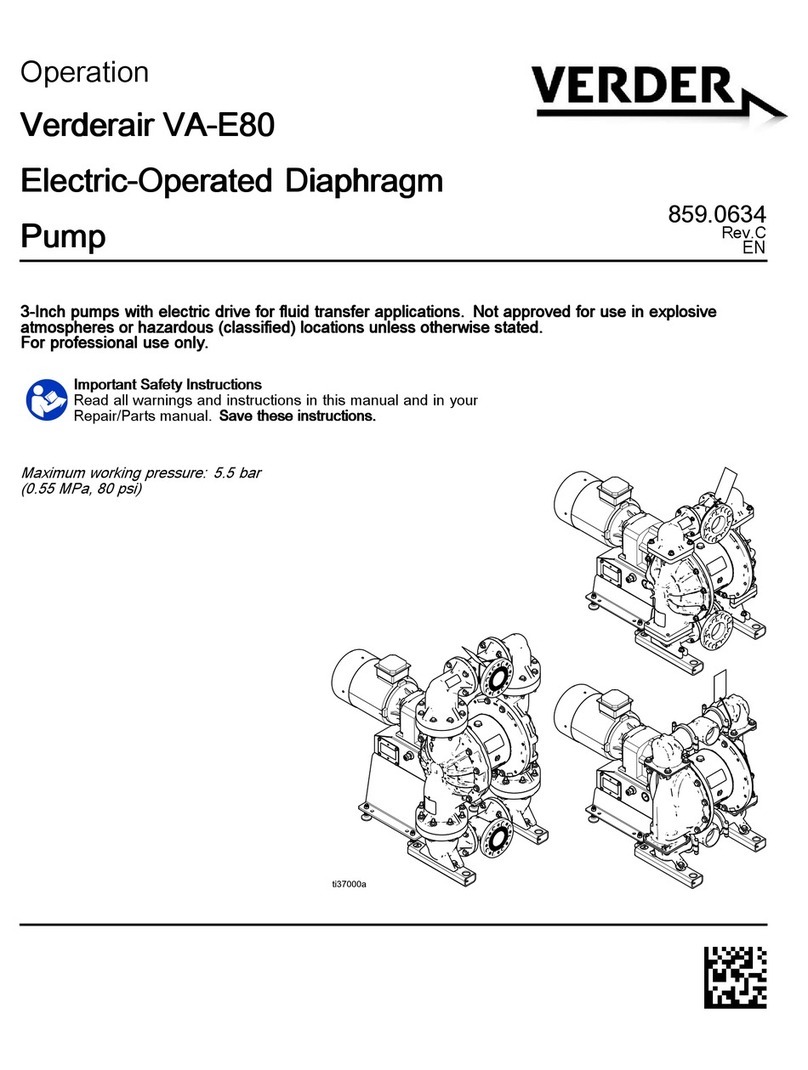

5.1 Before installaon

Check the nameplate and performance curve to ensure

that the pump meets requirements of your applicaon

(Delivery head, ow rate, viscosity etc.).

Make sure that the product operates within its working

range. Only then the product performance is guaran-

teed.

Check the condion of the pump for any damage that may

have occurred during shipping.

Keep the pump vercal and prevent from falling down.

The electrical supply should be veried so the voltage,

phase and frequency match that of the pump motor.

5. Installing the product

4. Transport and storage

Transport the pump in the posion as indicated on the

pallet or packaging.

When moving the enre pump assembly by a crane, all

ropes must be mounted around the pump

The liing capacity of the crane and rope must exceed

the weight of the pump. Only qualied personnel are

allowed to li the pump. Do NOT use the terminal box

to li the pump.

Make sure the pump is stable. Protect pump from dam-

age during transportaon. The warranty becomes invalid if

damages occur during transportaon.

Do not remove the lever or protecon from the pump

before the pump is placed and mounted correctly.

If present, observe the instrucons on the packaging.

All pumps should be stored in a clean dry place. Avoid hu-

midity, dirt and any foreign materials from the pump and

do NOT remove the protecve plasc pipe ends during stor-

age.

During Installaon, Maintenance and Inspect

Only authorised and qualied personnel may install,

maintain and inspect the product and repair electrical

components. Observe the local safety regulaons.

Always disconnect the energy supply to the product

before installaon, maintenance and repairs and se-

cure disconnecon.

Surfaces of a pump can be hot, aer connuous opera-

on. Handle the pump with dangerous liquids with the

ulmate care. Decontaminaon of the pump is recom-

mended to prevent hazardous uids.

On compleon of work all safety and protecve facili-

es must be re-installed and made operave again.

Make sure that no one can be near rotang components

when starng a pump. Before restarng the machine,

observe the instrucons listed under ‘Start up’.