Millennium R/C Micro-SS Micro SSX User manual

Dimensions: 21 ½” wing span

Flying Weight: 4 ½ -5 ¼ oz.

(with recommended setup)

MillenniumRCpresentsMicroSSXBuildKit

Introduction:

This is the Micro SSX™ build-it-yourself kit. It is identical to the ARF version with some

enhancements to make it easier to build. All the parts are laser cut and interlocking so no pins are

needed to assemble this kit. The wing can be assembled in ½ an hour by most modelers.

The MicroSSX™ is a miniature version of the Millennium R/C Slow Stick X™ Electric Park

Flyer. It is a fun-to-fly fully aerobatic electric R/C airplane that can be taken anywhere! Fly it indoors

or out!!

Adult supervision recommended for children 15 and under. R/C Airplanes should be flown

following safety guidelines provided by the AMA (Academy of Model Aeronautics).

CAUTION: This is not a toy!

Recommendations:

1. Read through each step before starting assembly.

2. After removing all the pieces from packaging, inspect to make sure there are no broken or

missing parts.

3. Check off each completed step to help keep from losing your place.

DISCLAIMER:

Millennium R/C assumes no responsibility for any accident or injury to persons or damage to property.

TM

IMPORTANT:

DO NOT GLUE UNTIL INSTRUCTED TO DO SO!

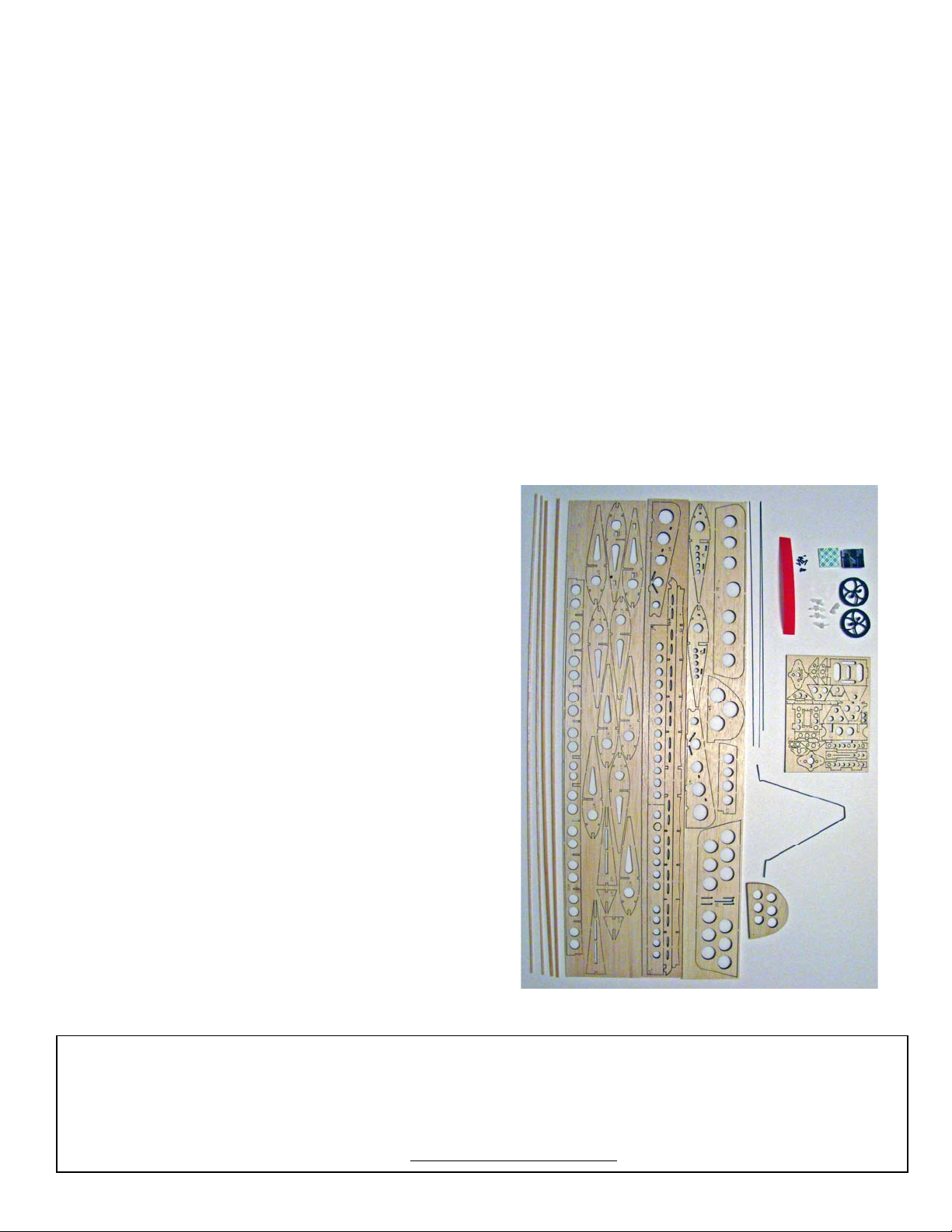

List of Provided Kit Parts:

1. Laser-cut balsa parts for Micro SSX™ wing/tail

sections

2. 4 micro control horns

3. 2 micro light wheels

4. 2 wheel retainers

5. Wire for push rods, aileron linkage and tail skid

6. Preformed wire main landing gear

7. 15” Wrapped carbon fuselage

8. Velcro pads

9. Velcro “One Wrap” Battery strap (RED)

10. Servo tape (Used to hold speed control in

position)

11. 6 # 0 - ¼ sheet metal screws (Servos)

12. 2 # 1 – ¼ sheet metal screws (Motor)

Additional Items Required:

1. Cyanoacrylate or CA Glue (thin and thick)

2. Hobby knife

3. 220-grit sandpaper

4. Sanding block

5. Hinge tape (recommend 3M Scotch ™ ¾”

Transparent Tape)

6. Ruler

7. Square

8. Razor saw

9. Hand drill or small drill with #56 (.046”) drill bit.

10. 1/16” drill bit.

11. Micro screwdriver set

12. Micro-receiver (recommend Castle Creations

Berg)

13. Motor (recommend Hacker A10-12S brushless

outrunner motor, 2900 Kv)

14. Speed control (recommend 5-9 amps, as

recommended by motor)

15. Propeller (as recommended by motor

manufacturer)

16. Three servos (less than 6 grams each,

recommended. Ideal is 4 grams)

17. Battery (recommend 2-cell lithium polymer

battery, 300-480 mAh) Please adhere to

manufacturer’s safety guidelines.

* * * * * * * * * * * * * * * * * * * * * * * * * * *

Check out the Micro SSX build thread

on R/C Groups with full-color

pictures and instruction updates.

Find the link at our website:

www.millenniumrc.com

ADDENDUM:

Part P8 (plywood piece) is no longer

needed for main spar brace, as it has

been determined that wing design

provides sufficient strength.

* * * * * * * * * * * * * * * * * * * * * * * * * *

Parts provided in Micro SSX Build Kit

If you should find a part missing or damaged, or have any questions about assembly, please contact us:

Millennium R/C

12859 Lower River Blvd., Orlando, FL 32828

Phone: 407-208-9745 / Fax: 866-799-2372

3

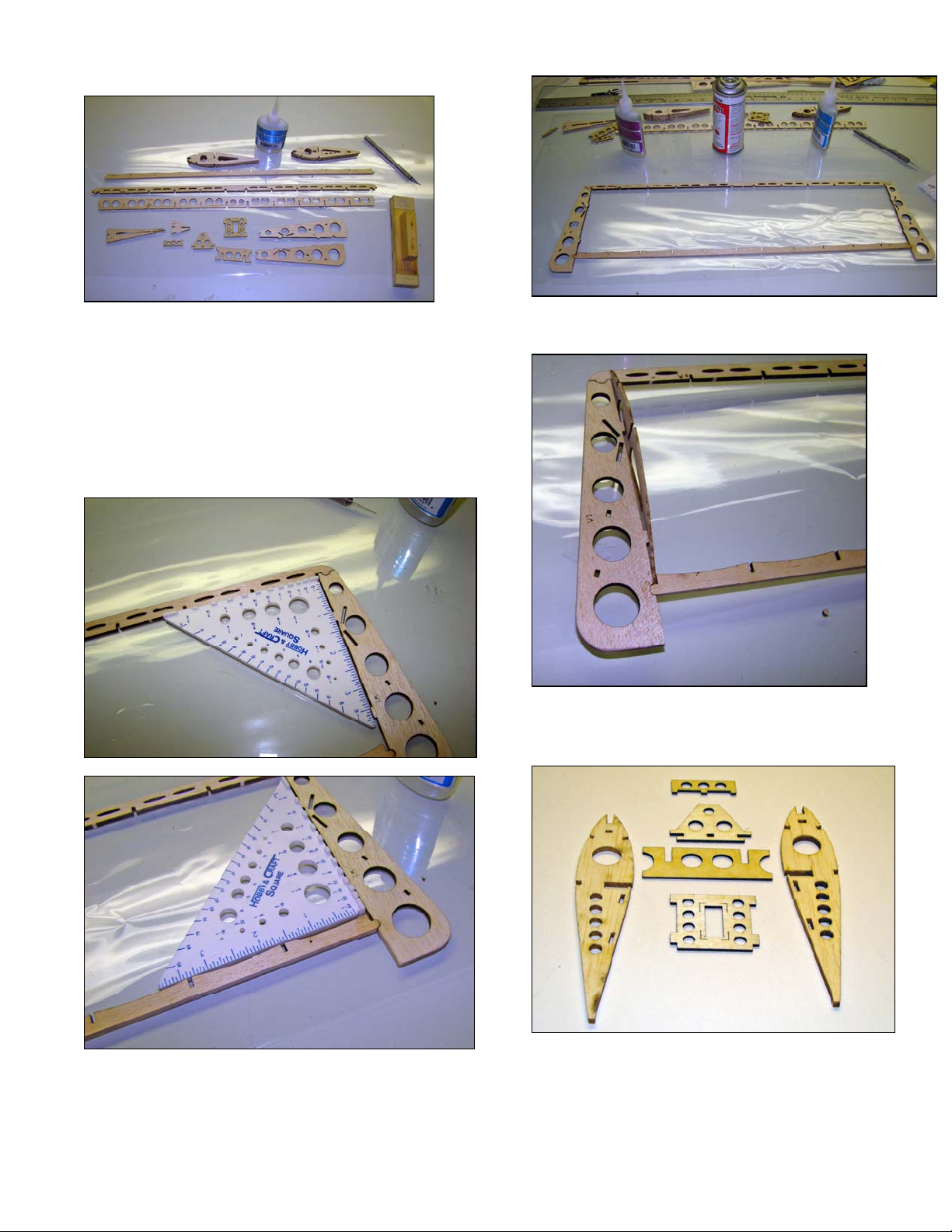

Assembly Instructions:

1. Cut - don’t break the balsa and plywood

parts from the parts sheets. Breaking the

parts out of the sheets can damage the

parts. Remove all “W” balsa parts and P8,

P9, P10 and P11 plywood parts. Sand

smooth the break points. Parts above are

prepped and ready for assembly.

2. Assemble a frame from parts W1, W4 and

W5. Use a small square to insure a square

corner. Use thin CA at corners.

Completed wing frame

3. Install ribs W6 at wing tips. Bend the part

slightly to fit in place.

Center ribs W2, servo deck P10, front wing

saddle P11, P9 and main spar brace

4. Assemble wing center section from parts

W2, P8, P10 and P11. (Note: P8 no longer

used)

4

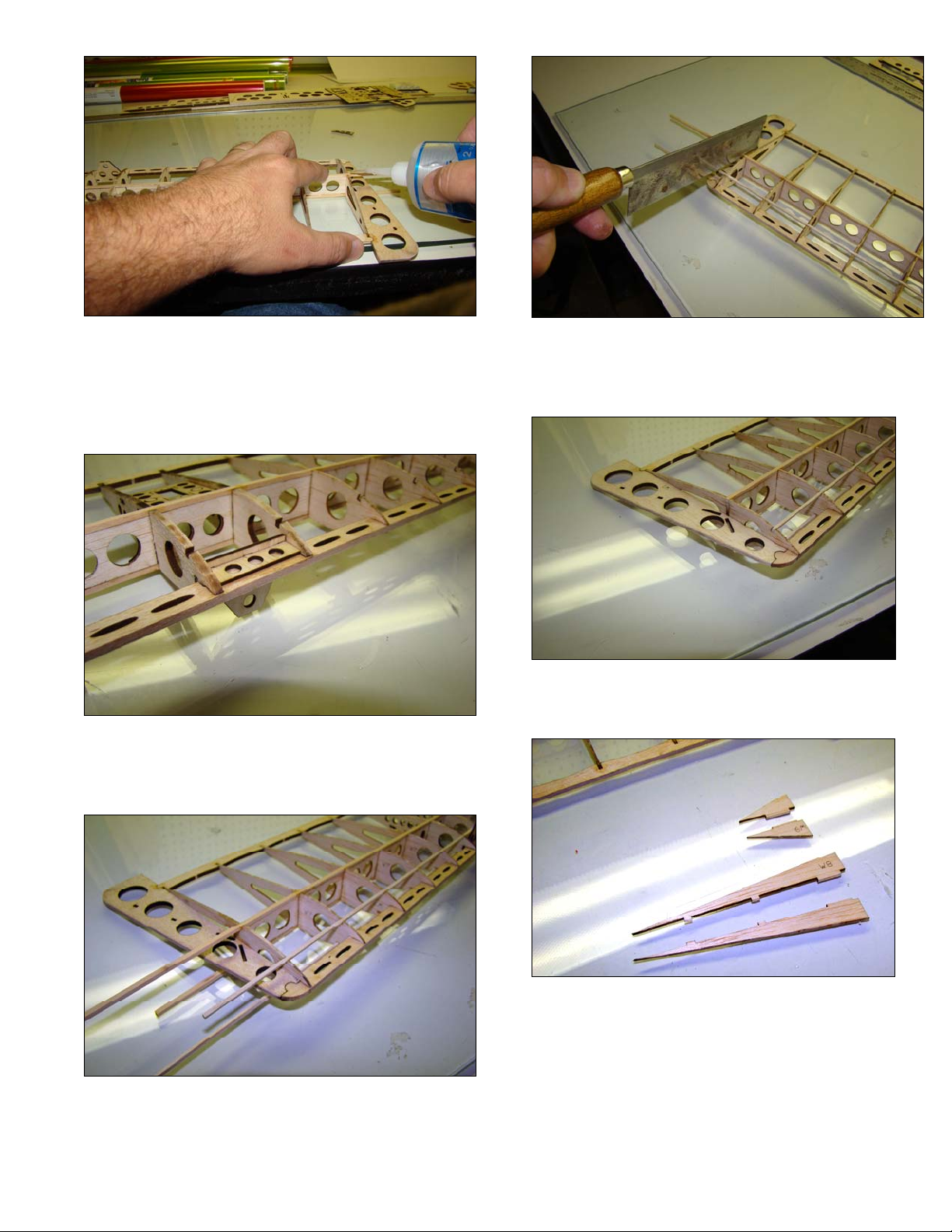

5. Install the servo deck P10 so that the flush

mounting tabs are closest to the spar.

6. Install front wing saddle P11. (P8 shown,

but no longer used)

Assembled wing center section from parts

W2, P8, P10 and P11 (P8 no longer used)

7. Install Center section into the leading edge.

8. Insert remaining ribs W7 into the leading

edge.

9. Install spar crutch W10, Use caution!

10. Sand smooth one side of the 3/32 spar

sticks. Test fit them into the ribs. If sticks

protrude beyond the ribs then sand the

sticks till they are flush with the top of ribs.

Center ribs on trailing edge and tack glue.

5

11. Hold spar stick in position and glue. Be sure

that the spar stringers are butted up against

the spar crutch W10. This forms a very

strong “ I ” beam.

12. Install front wing saddle brace P9. Make

sure front wing saddle is square to the wing

frame and glue with thin CA.

13. Install leading edge stringers top and

bottom. Make sure they are flush with ribs

and sanded on one side before gluing. Glue

all remaining joints of the wing.

14. Remove excess spar stick and leading edge

stringers.

15. Sand flush with rib W6.

16. Prepare wing tip braces for installation.

(Sand and Split)

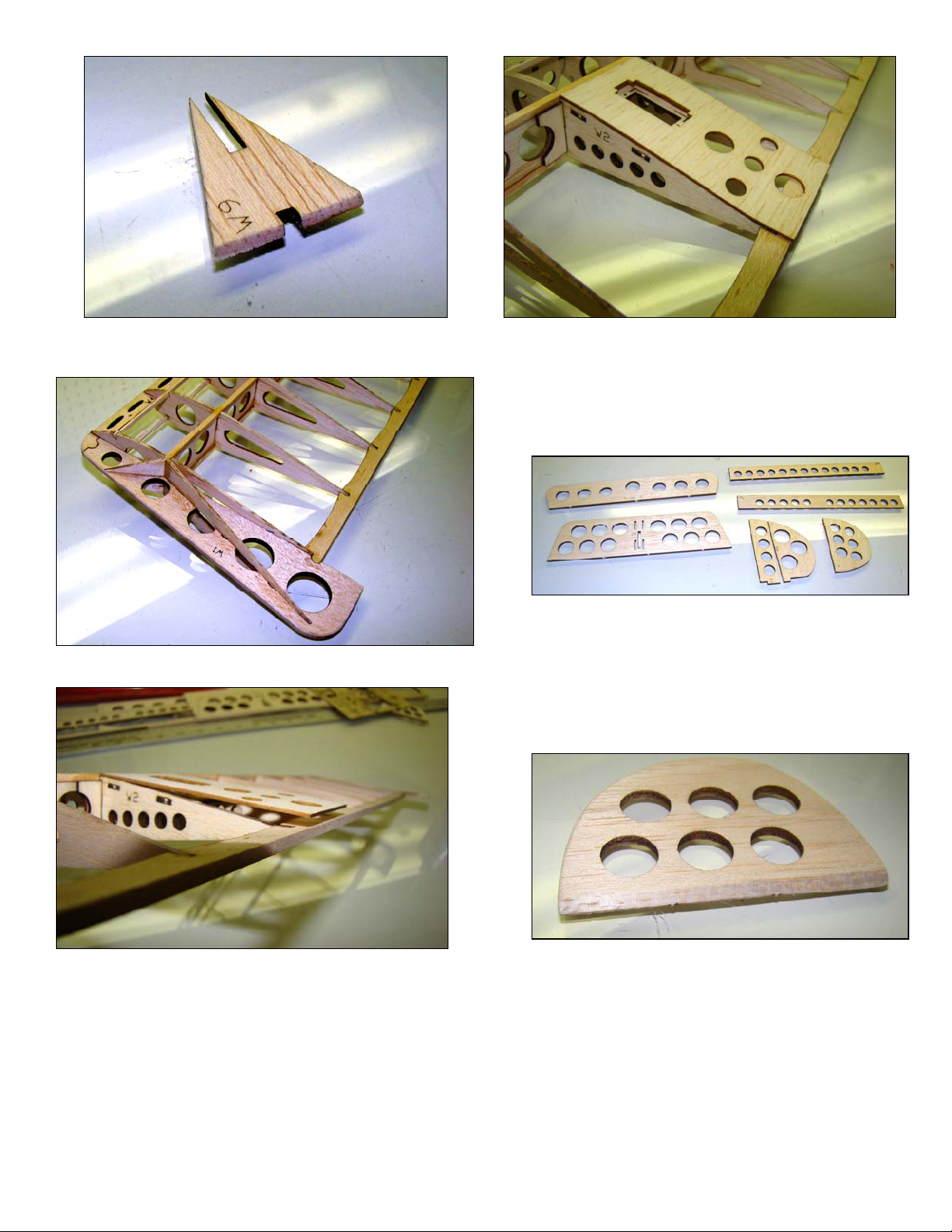

6

17. Bevel wide end of W9 before assembly.

Completed wing tip

18. Install servo deck cover. First glue to spar.

Then, following the contour of rib; glue the

trailing edge.

19. Flip the wing over and glue the cover to the

inside. Sand cover flush with trailing edge.

Tail Section

1. Glue together vertical stab pieces S3 and

S4. Prepare remaining parts to be covered.

Remove burnt edges with 220 sand paper

and round off corners. Stop sanding when

burnt edge is faint. Do not distort the original

shape of the part.

2. Bevel leading edge of rudder elevator and

ailerons 45 degrees.

3. Cover tail section and wing with light model

covering such as World Model Lightex or So

Lite, following manufacturer’s instructions.

7

Assembly of the control surfaces

1. Start by removing the horizontal stabilizer

and vertical stabilizer from the packing

bags. Remove the four pieces of masking

tape holding the elevator to the stabilizer.

2. Tape a length of Scotch tape™ along the

rear trailing edge of the horizontal stabilizer

and secure with your finger (either side is

fine). Now, flip the stabilizer and place on a

work surface. See diagram below:

3. Now, take the elevator. You will see that the

elevator has a ‘beveled’ edge. This is

important in creating the hinge. Ensure that

the beveled edge is pointing up, and while

holding at a 45° angle, place up against the

trailing edge of the horizontal stabilizer and

secure the hinge tape to the elevator with

your finger. See diagrams below:

4. Turn the stabilizer assembly over, and

carefully fold the elevator back onto the

stabilizer.

5. Tape another length of Scotch tape™ along

the bottom hinge line and secure with your

finger.

6. Fold the elevator back to normal position.

Test the hinge by pulling gently on the

control surface. Cut off any excess tape

overhanging the stabilizer sides.

7. Repeat the steps 1. thru 6. for the rudder

and ailerons.

8. Install the control horns by pushing the

horns through the holes located in the

vertical and horizontal stabilizers. The

vertical stabilizer control horn must be

installed on the opposite side of the beveled

edge. The horizontal stabilizer horn will be

installed through the top on the opposite

side of the vertical stabilizer horn. Secure

the control horns with thick CA glue.

Assembly of the plywood hardware

1. Open the bag containing the plywood

pieces carefully. The hardware bag contains

many small items that can get misplaced

easily. Remove the parts for the tail support

bracket and assemble with thick CA glue as

shown in the diagram below. Ensure that no

excess glue travels into the holes for the

fuselage. The small square cross pieces are

installed with one located at the leading

edge of the mount and other centered on

the tail skid slot. Refer to the next diagram:

Note: New style tail mount.

2. Build two servo mounts with the parts

provided using thick CA glue. Ensure that

no excess glue travels into the holes for the

fuselage. Refer to the picture below:

8

3. Assemble the battery mount pieces with

thick CA Glue. Ensure that no excess glue

travels into the holes for the fuselage. Refer

to the picture below:

Main Wing & Fuselage Construction

1. Carefully trim the covering from the servo

mount on the top center of the wing, being

careful not to tear the covering. Trim the

servo mount if necessary. Feed the servo

wire through the hole and install the servo.

Use provided #0 -1/4 black screws to mount

the servo.

2. Take the fuselage carbon stick and slide the

servo mounts previously assembled in #11

onto the fuselage. If necessary, shave a

little material around the holes off the

mounts so that they fit onto the fuselage.

DO NOT sand or lubricate the fuselage

stick.

3. Mount the servos as shown in the diagram

below. Use provided #0 -1/4 black screws to

mount the servo. DO NOT glue the mounts

to the fuselage stick until instructed to do

so. The servo mounts will accommodate

servos up to 7 grams.

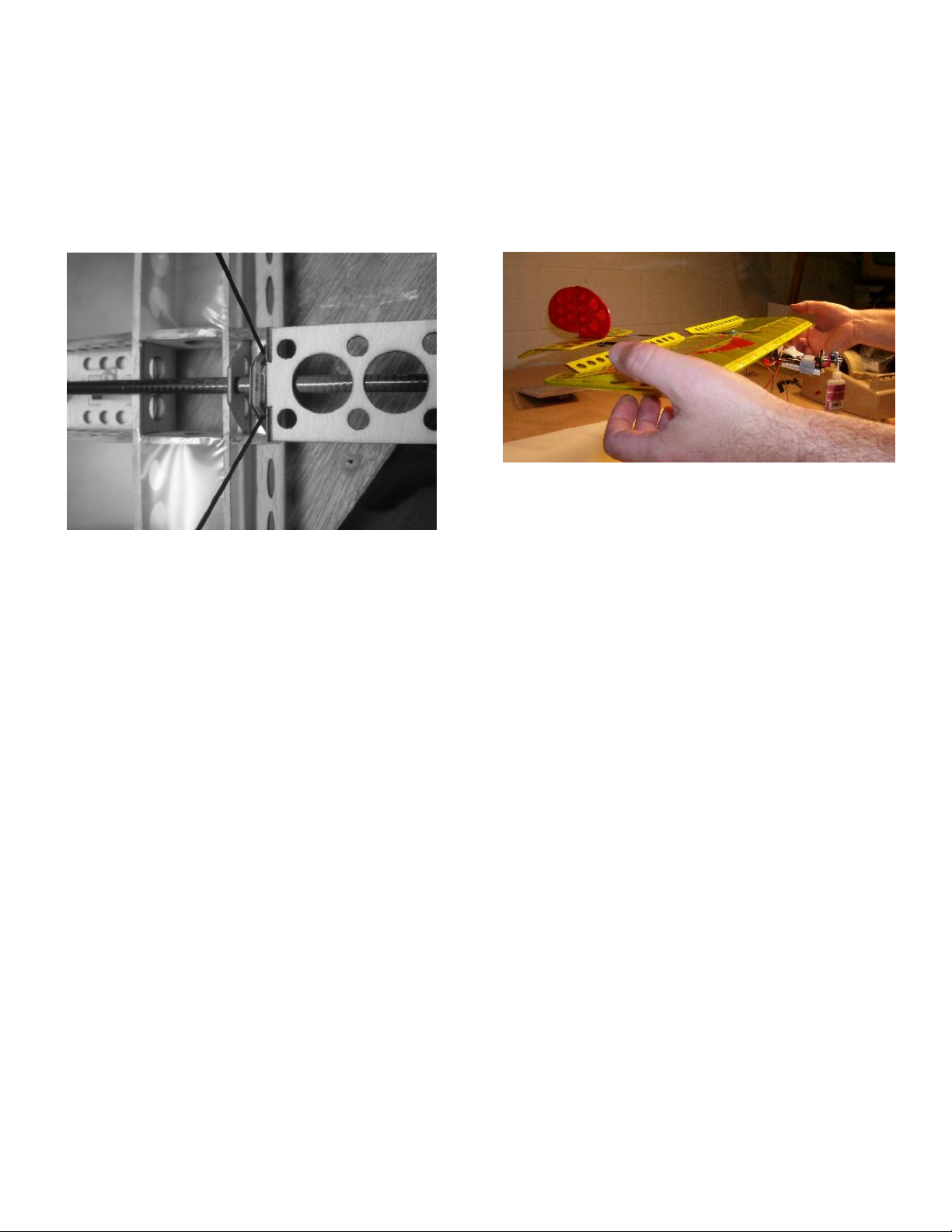

4. Slide the fuselage and servo assembly

through the front wing saddle, carving any

excess from the hole ONLY if necessary.

Feed servo wires through the holes in the

center spar towards the front of the wing.

Refer to the picture below:

5. Slide P12A onto the fuselage stick and glue

6-3/4” from the tail mount leading edge.

Slide P12 onto the fuselage and leave it

loose. Slide the tail mount onto the fuselage

end and align it so that it is square with the

flat edge of P12A. Glue it and allow the glue

to dry. Secure P12 to P12A with 2 #0-1/4

screw. Do not glue P12 to P12A. Slide the

servo assembly onto the front of the

fuselage, align it so that it is square with the

flat edge of P12A and glue it with CA glue.

Slide the fuselage assembly through the

front lower wing mount. P12 should be

9

glued to the leading edge of the trailing

edge piece of the wing. Align the wing so

that it -is parallel to the tail mount. Glue the

tail section vertical and horizontal stabilizer

together so they are square.

(Below) Installed rear wing saddle

Main Assembly

6. Return to the horizontal stabilizer,

previously assembled in sections 1. thru 8.

Depending on which side you chose to

install the control horn, depends on which

side you install the tail support bracket.

WITH THE CONTROL HORN ON THE

OTHER SIDE OF THE STABILIZER

carefully cut the covering away from the

slots in the stabilizer by using a sharp

modeling knife. Install the mount into the

horizontal stabilizer using thick, or slow

drying CA glue. The three circles of the tail

support bracket should point to the leading

edge of the stabilizer.

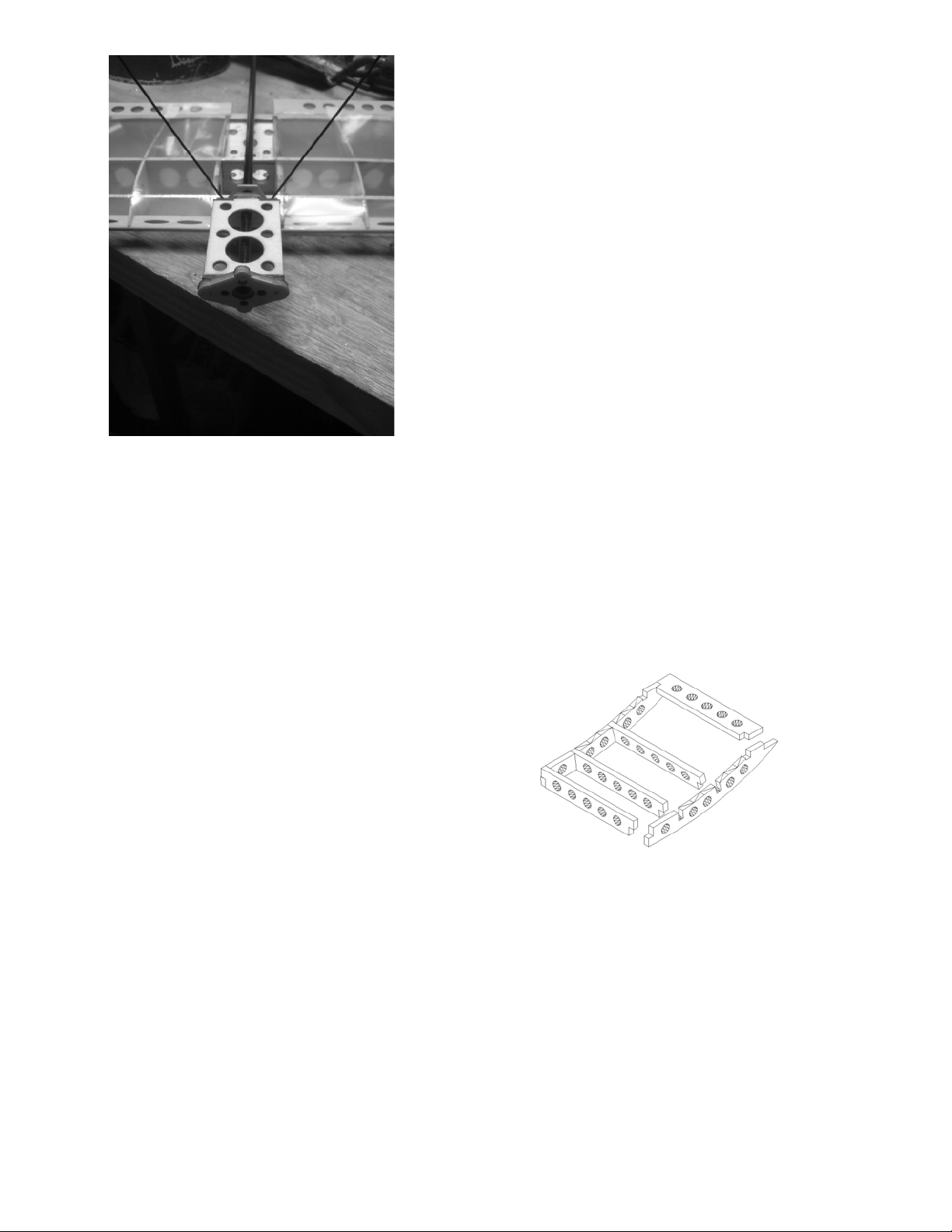

7. Now, slide the fuselage stick into the tail

mount support bracket, and secure using

thin CA glue. REAR TAIL MOUNT

SHOULD BE 3/8TH” PAST THE END OF

THE FUSELAGE STICK.

8. Locate the tail skid slot on the tail mount

bracket. Using a micro drill bit, drill a small

hole through the fuselage stick at the front

of the tail skid slot. Install the tail skid into

the drilled hole and locate in the slot.

Secure with thick CA glue. See next picture:

10

Drill hole to accept tail skid

Install tail skid into the tail support bracket

And secure with thick CA glue

9. Assemble the two motor mounts by gluing

the two pieces together with thick CA.

These will be glued onto the battery support

previously assembled in #11 later in these

directions. Refer to the following diagram:

10. The landing gear consists of 4 plywood

pieces. Locate these and assemble using

thick C.A glue as shown in the diagrams

below. Some light sanding of the internal

landing gear mounting pieces may be

required to maintain alignment.

11. Slide the landing gear onto the fuselage as

shown in the diagram below. Using thick

C.A glue, secure the landing gear bracket

onto the front wing saddle and leading edge

of the wing. DO NOT glue to the fuselage

stick yet. Attach the wheels with the

provided plastic collars.

11

12. Install the pushrod guide on the fuselage

stick. It is located half way down the

fuselage between the trailing edge of the

wing and the leading edge of the horizontal

stabilizer.

13. Slide the battery mount onto the front of the

fuselage. Again DO NOT glue the battery

mount to the fuselage.

Balancing & final fuselage assembly

In order to balance this model, a ‘dry’ assembly of

the fuselage is performed. The model is then

balanced and finally secured with C.A glue. Follow

the steps below to balance the model and finish

assembly.

1. Position the wing so that the front of the

landing gear mount is approximately 2 1/8”

from the front of the fuselage tube and lined

up with the leading edge of the wing. The

distance between the aileron trailing edge

and the leading edge of the horizontal stab

should be approximately 5-1/4”. Do not glue

the wing to the fuselage.

2. Setup motor and speed control as per

manufactures recommendations. Fit battery

and power unit to model so that wires are as

short as possible. This is a light model and

every little bit of extra weight counts.

3. Temporarily attach propeller, receiver,

antenna, motor, speed control, and battery

(using narrow Velcro strap) before

balancing. The receiver is typically strapped

or taped to the fuselage and a micro

antenna is used for this model.

4. The CG for this model is 1/8”inch to the rear

of the main spar. Balance the plane at the

CG by holding wings with your fingertips as

shown in the image below. Try to maintain

the distance from the front fuselage to the

leading edge of the wing at 2 1/8” by

adjusting positions of your hardware first. If

necessary, change position of your wing to

balance.

5. Once aircraft is balanced, adjust the

horizontal stabilizer so it is parallel to the

wing. Then glue the front and rear wing

saddles to the fuselage stick.

6. Position servo, battery and motor mounts.

The motor should have 2 ° of right and 2 °

of down thrust. This can be achieved by

shimming the motor or by offsetting the

motor mount during gluing. Glue the motor

mount to the fuselage and battery mount

using thick CA glue.

7. Square the vertical stabilizer to the

horizontal stabilizer. Glue the vertical

stabilizer to the horizontal stabilizer by

bleeding thin CA into the mount.

8. Install the control linkage. The aileron

control horns must be mounted through the

top of the control surface at this time and

glued at the same angle as aileron push

rods. Feed the rudder and elevator

pushrods through the rear pushrod guide

before attaching to servos. Use Z bends for

rudder and elevator servos. Be sure to

center your servos first.

9. Glue the motor mount to the front of the

battery holder. See picture below:

12

10. Permanently install receiver, motor and

speed control. Make sure your antenna

does not touch the carbon fiber fuselage or

any metal. Use double stick foam tape to

mount speed control to the top of battery

mount.

Control throws

Control throws are as follows:

Use Exponential if your radio has it the facility.

Elevator: 45 ° up and down 20° low rate

Rudder: 45 ° left and right

Ailerons: 45 ° up and down 20° low rate

Motor & Battery Setup

1. Use the motor mount provided with your

motor. Trim the motor mount so that it does

not extend beyond the plywood mount.

2. Keep wire leads as short as possible. Every

little bit of weight counts.

3. Use the provided double-sided foam tape to

secure the ESC to the plywood battery

holder.

4. Use the provided sticky back Velcro to

mount the battery to the plywood battery

holder. Place the hook side on the plywood

holder and the loop side on the battery. This

will hold the battery in place while you

secure the battery with the red Velcro strap.

Servo/Radio Setup Tips

•Use the small arms for all servos.

•Connect pushrods at outermost hole of

control horns and servo arms.

•Micro servo cases are typically press fit.

The bottom can easily be pulled apart and if

you don’t put it back correctly, you can ruin

the servo. I recommend using a piece of

clear tape and placing it so that it straddles

the bottom of the servo. This will keep the

bottom from falling off.

•Use a micro receiver such as the Berg 4L or

Micro Spectrum receiver.

•The spectrum receivers can easily be

placed inside the wing between the center

ribs.

•The Berg 4L can be secured to the fuselage

with a Velcro strap or tape.

•Use a Micro antenna with the Berg 4L

receiver, if possible.

•Do not allow your antenna to touch the

fuselage or pushrods during flight. This can

reduce the range of your receiver. The

fuselage of the Micro SSX is carbon fiber,

carbon is a conductor.

•Tip: Run servos for several cycles before

first flight. This will improve centering.

New Optional Receiver Hatch:

Main Wing Decal

1. Cut excess material from decal before

removing the backing.

2. Remove the protective backing to expose

the adhesive.

3. Add about 3 drops of dish soap to 2 pints of

clean water. Put it in a spray bottle and

spray the back of the decal.

4. Slide the decal into position and squeegee

the excess water from under the decal.

5. Allow the decal to dry overnight.

ENJOY YOUR NEW MICRO SSX!

Popular Toy manuals by other brands

ROBBE

ROBBE Corsair ARF FW004006 Building and operating instructions

CustomWorks

CustomWorks Enforcer GSX2 Assembly manual

V-tech

V-tech Marble Rush Starter Set Parents' guide

Spinmaster

Spinmaster DreamWorks GABBY'S DOLLHOUSE Pillow Cat's Sweet Dreams... Instruction guide

V-tech

V-tech Alphabert s Sonic Phonics user manual

ThinkGizmos

ThinkGizmos TG654 user manual

V-tech

V-tech Nitro Vision user manual

De Agostini

De Agostini Model Space MiG-29 manual

V-tech

V-tech SWITCH & GO DINOS Overseer the T-Rex Parents' guide

Modeltech

Modeltech Magic Extra 300L Instructions for final assembly

KNEX

KNEX Amazing Value Tub manual

V-tech

V-tech Toot-Toot Friends Pirate Ship Parents' guide