© Miller Diving All Rights Reserved Document # 030715001

8

SECTION 2

OPERATING INSTRUCTIONS AND PROCEDURES

8. To test for external water leaks: Connect Helmet to

gas supply., Close both exhausts, lightly open Free Flow

Valve , submerge Helmet, upside down in tank of water,

just covering neck ring. Keep Neck Seal above water,

pinched together with one hand. Rising air bubbles in

the water will indicate any leaks. Correct with new O-

ring and silicone sealant. A small leak from Exhaust

Handle is normal.

WARNING: In the event the Helmet is to

be used with pure oxygen (such as 02 decom-

pression) the entire Helmet must be clean and

freeofanytype oil orgreasewhichcouldignite.

Onlysiliconetypeoxygencompatiblelubricants

may be used.

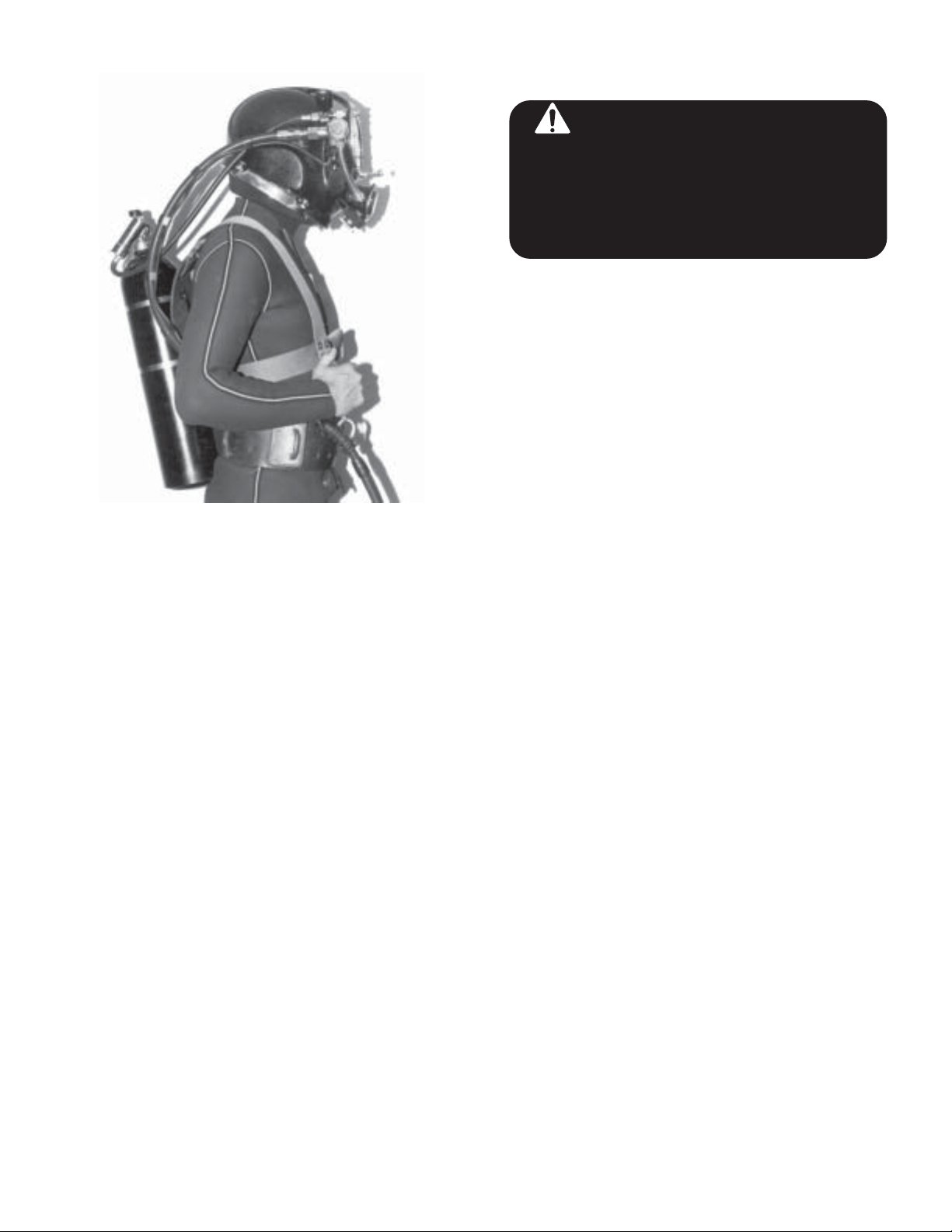

NOTE:Itis recommended that thediverfully acquaint

himself with all valves, components, and accessories

in a training tank or shallow water, before making a

working dive.

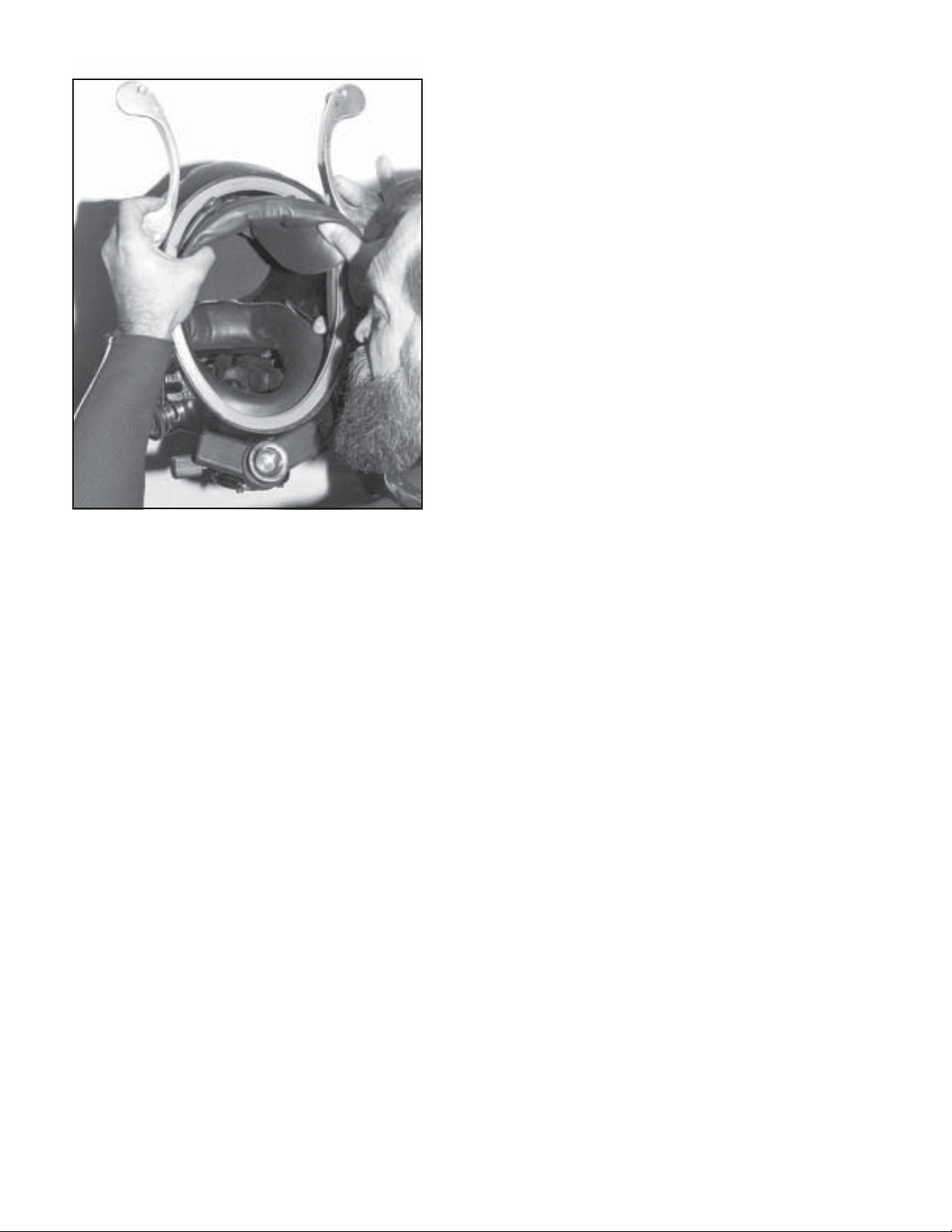

2-B DRESSINGINTOTHEMILLER HELMET

Check for proper adjustment. The Head Harness is eas-

ily adjusted by moving theAdjustment Buttons. Do not

over tighten. The Upper Mounting Washer and Screw

have three adjustment holes in the upper pad which will

change the angle of position on the head.

Pull Neck Ring and Neck Seal over the head with-the

Screw heads facing down. The Neck Seal should be

turned down and may be tucked into the wet suit jacket.

2-A PRE-DIVE PROCEDURE:

1. Inspect Helmet shell for any damage or loose valves

or fittings.

2. Inspect all rubber parts for wear, cracking, and proper

installation.

3. Inspect exhaust valves to see that they are free of for-

eign matter and in good condition.

4. The Helmet should be hooked up to a suitable gas

supplyand allvalves &exhausts checkedfor properfunc-

tion as follows: Open Free-flow Valve to assure suffi-

cient airflow.With Free-flow Valve closed, ascertain that

theDemand Regulatoris breathingproperly. Inspecteach

exhaust valve by opening and closing it while Free-flow

Valve is open.

5.Test radiocommunications by talking both toand from

the diver.

6. Test Non-return Check Valve for proper function with

at least one of the following :

Ist test: This test must be made with Free-flow Valve

open and the supply umbilical removed from Helmet.

Place your mouth on inlet fitting and suck while placing

tongue over orifice. The tongue should stick, due to the

vacuum created if the check valve is operating properly.

If the tongue does not stick, or air can be sucked out of

valve, there is a leak and it must be corrected before

diving.

2nd test: This test must be made with Free Flow Valve

closed and the supply umbilical removed from Helmet.

Disconnect the Demand Tube from Regulator Inlet Fit-

ting.Attempt to blow in end of tube. It should be impos-

sible if check valve works and all connections are tight.

3rd test: The Check Valve must be removed from the

Helmet and supply umbilical. Test by attempting to blow

against arrow direction. It should be impossible (no leak-

age) if valve is functioning correctly.

7.Verify emergency gas cylinder is full to rated capacity

and is properly connected to Helmet.

With the tender holding the Helmet in a convenient posi-

tion, the diver places both thumbs on the lower pad, stretch-

ing it back and open. The back of the head is inserted first

and the Helmet is then

rolleddown over theface.

TheNeck Ring isinserted

into the Helmet and the

Cam Handles are closed.

Then the buckle halves of

thepositive locking straps

are pulled forward and

snapped together, locking

the cams.