2

IMPORTANT SAFETY INSTRUCTIONS

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in serious in-

jury. Save all warnings and instructions for future

reference.

•Use the bench and accessories in accordance

with these instructions and in the manner in-

tended, taking into account the working conditions.

Use of the bench for operations different from those

intended could result in a hazardous situation.

•Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

•Fully assemble the bench according to the as-

sembly instructions. Do not leave off any pieces.

•Do not modify the bench in any way. Use only

specifically recommended accessories. Drilling

holes or modifying the bench will lower the load

capacity, which can cause the bench to collapse,

resulting in injury.

•Lock wheels when bench is not being moved.

Unlocked wheels can allow the bench to move

unexpectedly.

•Keep the bench on a level surface. Do not load,

unload, or park bench on an incline. The bench

may become unbalanced and tip, resulting in injury.

•Always balance the bench load to avoid tipping.

Unbalanced benches are more likely to tip when be-

ing moved or when using the bench work surfaces.

Evenly distribute the weight front to back and side

to side. To help prevent the bench from tipping,

load the product starting with the bottom drawers.

•Do not exceed the maximum product weight,

including contents. Do not exceed the maximum

weight for each drawer. Overloaded benches can

tip, collapse, or damage drawer slides.

•Do not open more than one drawer at a time.

Bench may tip, causing injury.

•Keep children and bystanders away while load-

ing, unloading, and moving bench. Distractions

can cause you to lose control.

•Only lift the bench according to the instructions

in this manual. Other methods may be dangerous,

resulting in injury.

•Only transport the bench when empty. Properly

secure when transporting.

•Do not mount the bench on a truck bed or any

other moving object.

•Lock all drawers before rolling the bench. The

drawers could come open and make the bench

unstable and tip.

•Only roll the bench short distances by using the

handle provided.

•Secure all items before rolling the bench. Loose

items could shift, causing the bench to become

unstable.

•Do not use drawers as steps. Do not stand

on the bench. Bench may tip, causing injury.

•Do not step on side shelf. Shelf may collapse or

break. Bench may tip, causing injury.

•Do not use bench in explosive atmospheres,

such as in the presence of ammable liquids, gases

or dust. This equipment has internal arcing or spark-

ing parts. Bench should not be located in a recessed

area or below oor level.

•Bench plugs must match the outlet. Never mod-

ify the plug in any way. Do not use any adapter

plugs with earth (grounded) chest/cabinet power

strips. Unmodied plugs and matching outlets will

reduce risk of electric shock.

•Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

•Maintain bench. Check for misalignment or binding

wheels, breakage or bending of drawer slides or

other parts and any other condition that may affect

the bench's operation. Do not use damaged bench.

•Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

•Have your bench serviced by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the bench is

maintained.

SYMBOLOGY

Warning

Read Operator's Manual

Electrical Shock Hazard

Do not open more than one drawer at a

time. Bench may tip, causing injury.

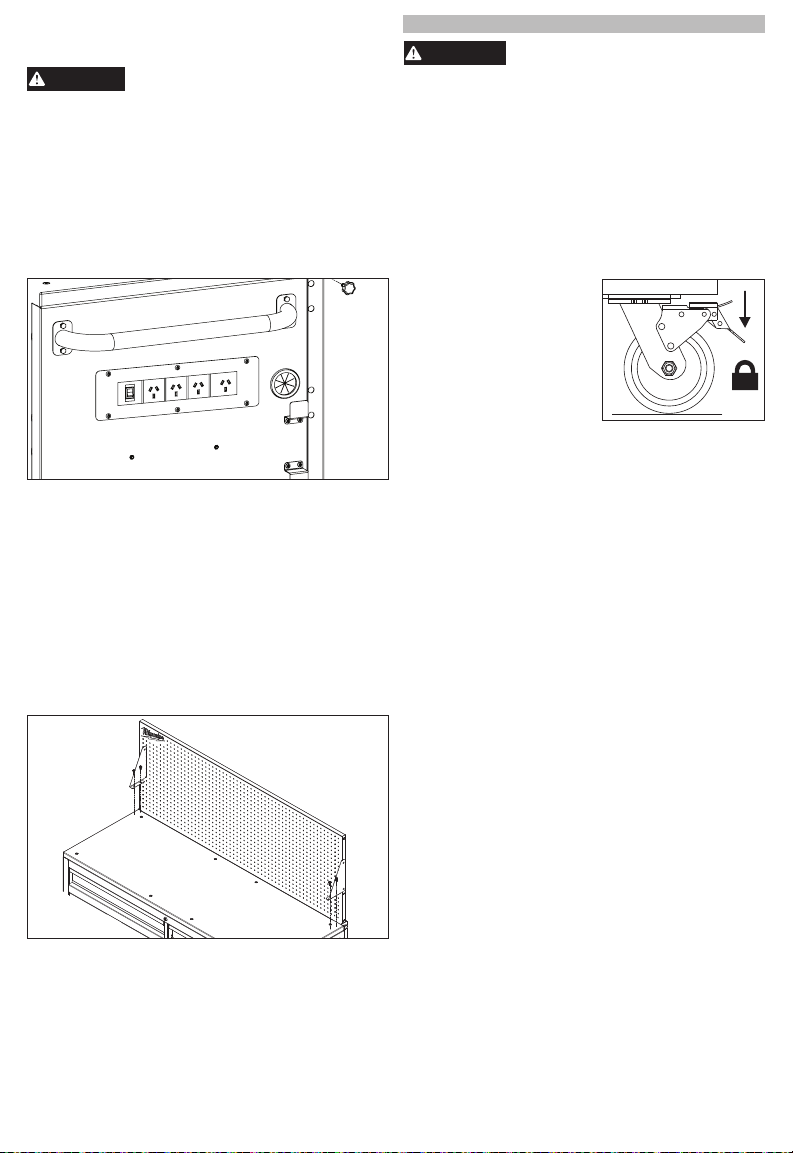

Lock wheels when bench is not

being moved. Unlocked wheels can

allow the bench to move

unexpectedly.

Do not use drawers as steps. Bench

may tip, causing injury.

FPO

Lock all drawers before moving the bench.

Do not step on side shelf. Shelf may

collapse or break. Bench may tip, causing

injury.

SPECIFICATIONS

Cat. No....................................................48228560

Two-Slide Drawer Capacity .........45.4 kg (100 lbs.)

Four-Slide Drawer Capacity ........90.7 kg (200 lbs.)

Peg Board Capacity.....................90.7 kg (200 lbs.)

Total Capacity ..........................997.9 kg (2200 lbs.)