Milwaukee MDP 41 User manual

Other Milwaukee Drill manuals

Milwaukee

Milwaukee 0100-20 User manual

Milwaukee

Milwaukee M18 BDD User manual

Milwaukee

Milwaukee 2503-20 User manual

Milwaukee

Milwaukee 0613-20 User manual

Milwaukee

Milwaukee 4272-21 User manual

Milwaukee

Milwaukee T-TEC 201 User manual

Milwaukee

Milwaukee 2610-20 User manual

Milwaukee

Milwaukee 2603-20 User manual

Milwaukee

Milwaukee C12 RAD User manual

Milwaukee

Milwaukee 2602-20 User manual

Milwaukee

Milwaukee 5374-20 User manual

Milwaukee

Milwaukee BS18C2 User manual

Milwaukee

Milwaukee M4 D User manual

Milwaukee

Milwaukee M12 BDD User manual

Milwaukee

Milwaukee 1001-1 User manual

Milwaukee

Milwaukee PDD 12 X User manual

Milwaukee

Milwaukee 1610-1 User manual

Milwaukee

Milwaukee PES 7.2 T User manual

Milwaukee

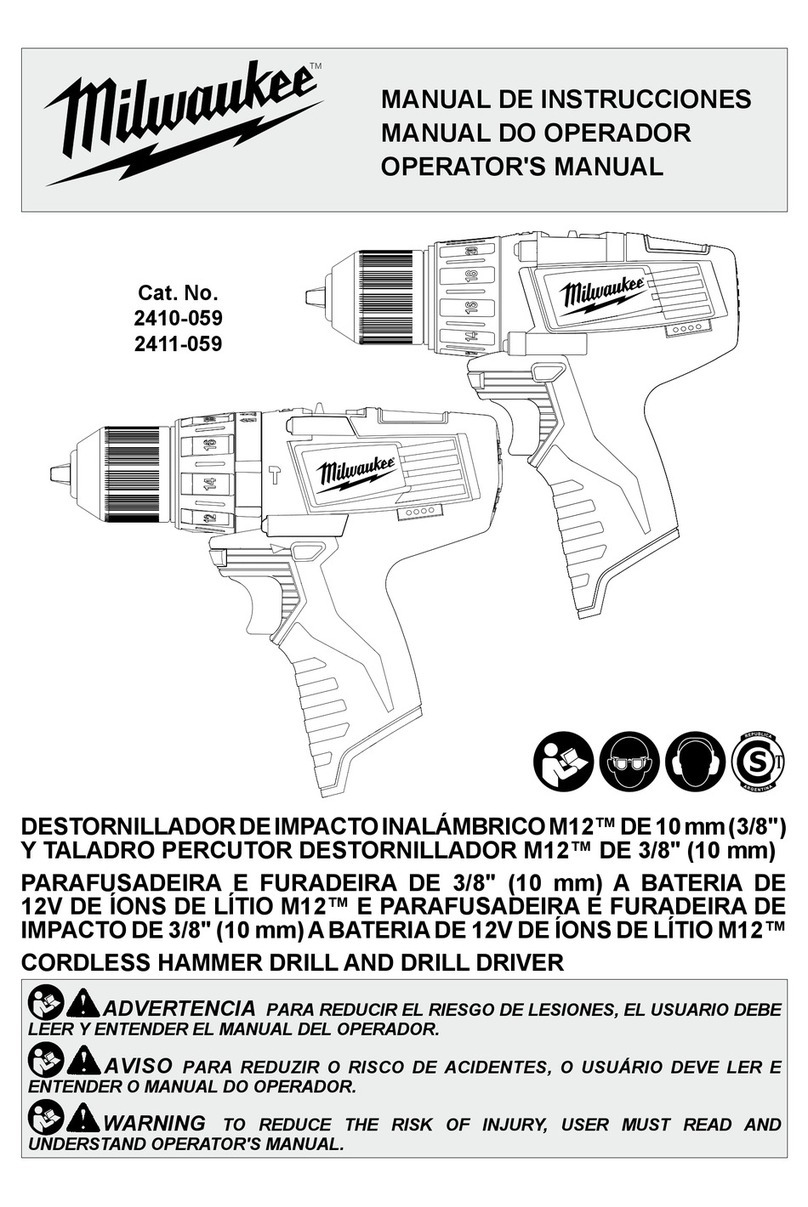

Milwaukee 2410-059 User manual

Milwaukee

Milwaukee 2604 -22 User manual