Milwaukee M12 FIWF12 User manual

Other Milwaukee Impact Driver manuals

Milwaukee

Milwaukee M18 2663-20 User manual

Milwaukee

Milwaukee M18 FUEL FID3 User manual

Milwaukee

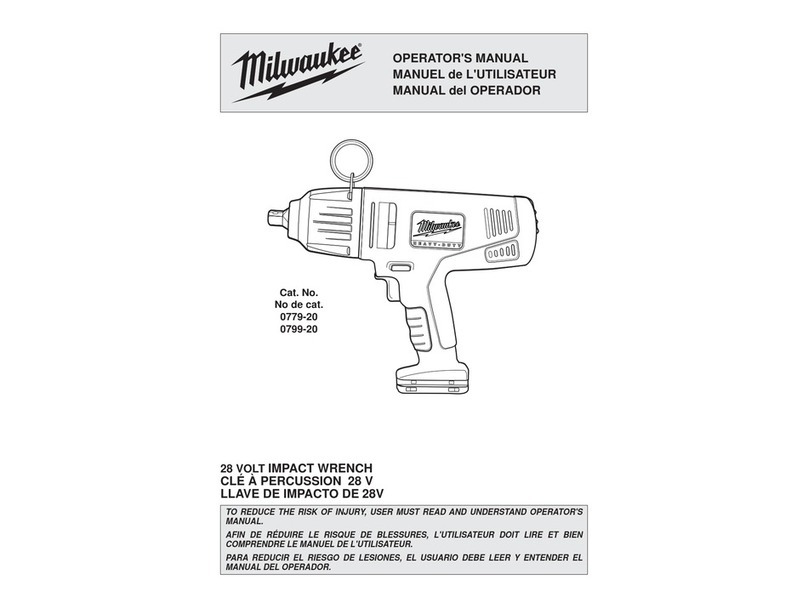

Milwaukee 0779-20 User manual

Milwaukee

Milwaukee HEAVY DUTY M12 BRAID User manual

Milwaukee

Milwaukee 2401-20 User manual

Milwaukee

Milwaukee M18 FUEL 2960-20 User manual

Milwaukee

Milwaukee 2650-20 User manual

Milwaukee

Milwaukee M18 FUEL SURGE 2760-20 User manual

Milwaukee

Milwaukee M12 FUEL CID User manual

Milwaukee

Milwaukee M18 2656-20 User manual

Milwaukee

Milwaukee 9070-20 User manual

Milwaukee

Milwaukee M18 ONEFHIWF12 User manual

Milwaukee

Milwaukee M12 FUEL 2552-20 User manual

Milwaukee

Milwaukee 2662-20 User manual

Milwaukee

Milwaukee M18 FUEL 2759-20 User manual

Milwaukee

Milwaukee M18 FUEL 2769-22 User manual

Milwaukee

Milwaukee M12 FID-0 User manual

Milwaukee

Milwaukee M18 FUEL 2869-20 User manual

Milwaukee

Milwaukee M12 BIW12 User manual

Milwaukee

Milwaukee 2953-20 User manual