INSTALLATION INSTRUCTIONS

FOR VSP D2

INTRODUCTION

Thank you for selecting & purchasing

MINILEC make phase failure relay VSP D2.The

following installation instructions would guide

you in installing your VSP D2 and making best

use of it.

VSP D2 is a phase failure relay operating on

negative sequence voltage sensing principle. It

offers protection against

* Unbalanced voltage condition.

* Phase failure condition.

* Phase sequence reversal condition.

Your VSP D2 is an auxiliary relay and it should be

used along with the motor starter only. The

effective working of VSP D2 will depend on

efficient working of the electromagnetic motor

starter. Before installing your VSP D2 check

whether the motor starter is operating perfectly by

starting the Motor with the “START” push button

and switching it off by “OFF” push button. If the

motor does not “START” or “STOP” on respective

operations, the starter needs to be serviced. Do

not install your VSP D2 with faulty motor starter.

TRIP SETTING, TRIP DELAY AND

. RESETTING

You can set your VSP D2 relay to trip the starter for

any unbalance voltage between 30V to 70V K6V

between any two phases.

The trip time delay is between 2 to 5 secs. The

VSP D2 relay can be set in Auto reset mode or

manual reset and remote reset mode by removing

or putting a short link between terminals 11&12.

VSP D2 will reset when the unbalance voltage is

reduced to less than 20V between all three

phases.

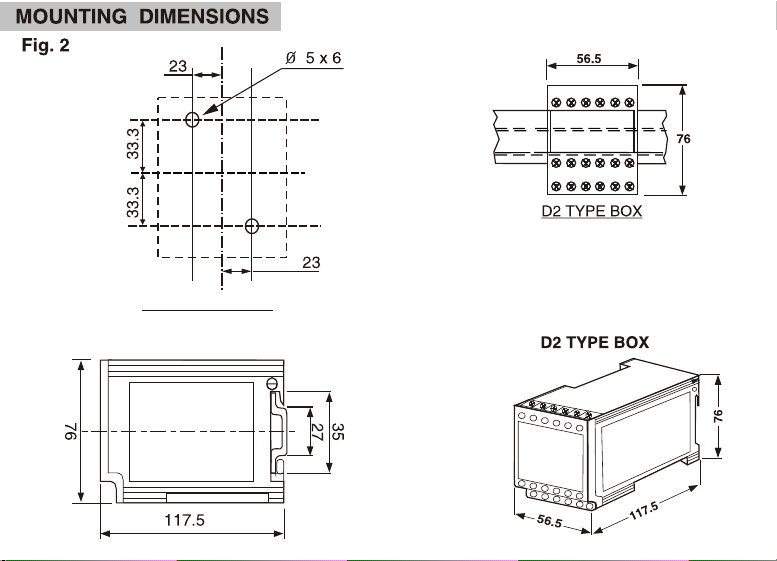

MOUNTING

Your VSP D2 can be Rail Mounted or Panel

Mounted.(See fig. 4A & 4B for mounting it on RAIL

and releasing it from RAIL respectively). It is

suitable for 35mm RAIL ( for panel mounting and

drilling details see fig.2 ).

CAUTION

1) Ensure that your VSP D2 is -

* Not installed near any heat sources like

burner, sunlight, electric arc etc.

*Not subjected to abnormal vibrations.

*Installed as near to the starter as possible.

2) 3 0

/

sensing (L1,L2,L3) is normaly taken from

outgoing terminals of motor starter. But in

.following conditions, sensing should be

. taken from incoming of motor starter, when

. VSP D2 is used in Automatic reset mode.

* Fully automatic starter.

* Multi speed motor starter.

* Reversible starters.

* When any other auto resetting type control

.switch is used in series with no volt coil of the

.starter.

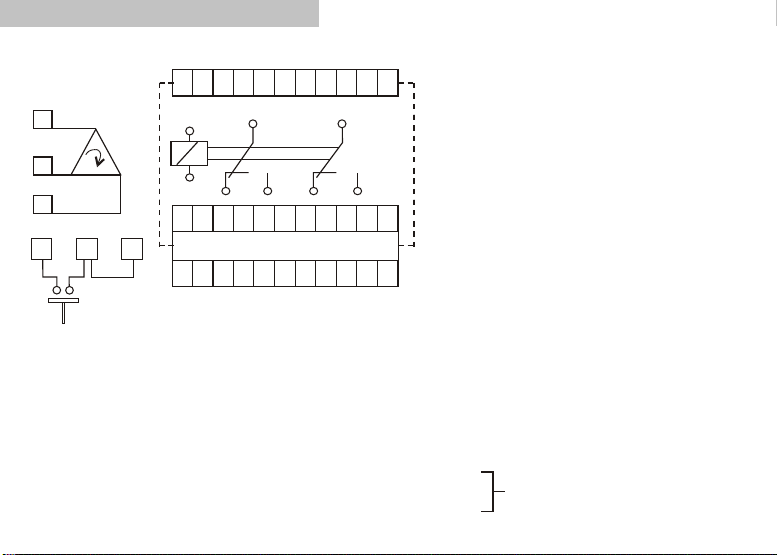

ELECTRICAL CONNECTIONS OF VSP D2:

See Fig.1 for Electrical connection

details of VSP D2.

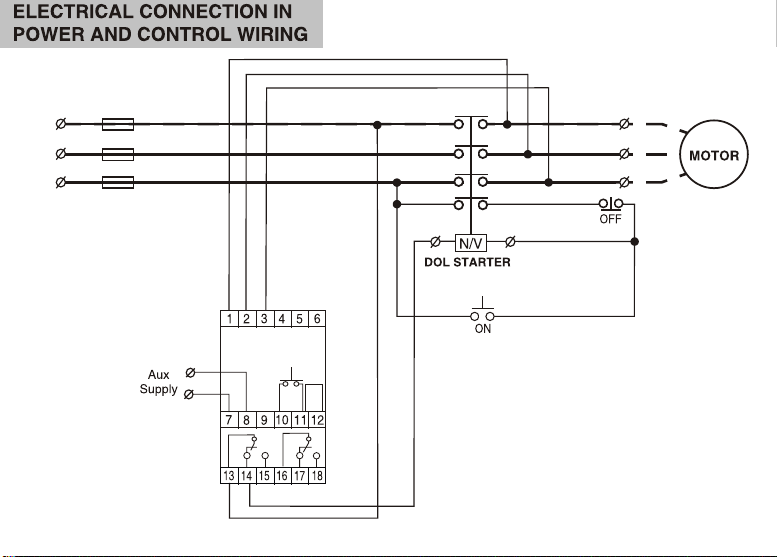

See Fig.3 for installation of VSP D2 in the

power and control wiring.

Auxiliary supply voltage should be as marked

on the front cover plate of VSP D2.

Connect the auxiliary supply wires at 7 & 8.

Connect R,Y,B phases at 1,2 and 3 respectively.

The R,Y, B sensing should be taken from outgoing

points of motor starter in case of Direct Online

Starter. In case of star delta starters, it should be

taken from outgoing terminals of main contactor.

The output relay contacts 13 and 14 is to be

connected in series with no-volt coil of the

contactor. The potential free output relay contact

16 & 18 can be connected to annunciator or used for

trip indication.

TECHNICAL SPECIFICATIONS

OF VSP D2

1. SYSTEM SUPPLY VOLTAGE :

220 / 230 / 240 / 380 / 415 VAC K20 %

2. AUX. SUPPLY :

110 / 220 / 230 / 240 / 380 / 415 VAC K 20%

3. FREQUENCY : 50 / (60) Hz, K3%

4. POWER CONSUMPTION : 3 VA ( max.)

5. OUTPUT RELAY CONTACT : 2 Changeover

6. OUTPUT CONTACT RATING [ RESISTIVE ] :

5Amp., 240 VAC

7. LIFE EXPECTANCY :

6

0.5 x 10 operations at 100% rating

8. UNBALANCE TRIP SETTING :

30 to 70V K6V

9. SET ACCURACY : K10% of set value

10. TRIP TIME DELAY :

3.5 Sec. K 1.5 Sec.

11. TEST PUSH BUTTON DELAY :

3.5 Sec. K1.5 Sec

12. RESETTING : Auto, Manual, Remote Reset

13. RESET GAP : 10 - 18V

14. INDICATION :

L1 : Green - Power ON

L2 : Red - Trip

15. ENCLOSURE : ABS.

16. DIMENSIONS [mm] :

Overall :76 x 56.5 x 117.5 [ LXWXD ]

Mounting : 67 x 46 [ LXW ]

17. MOUNTING :

35 mm Rail Mounting & Panel Mounting

18. WEIGHT [gms] : 400 (approx.)

19. OPERATING CONDITIONS :

00

TEMPERETURE : -5 C to + 60 C

HUMIDITY : Upto 95% R.H.

TESTING :

.

If you need to test the functioning of VSP D2 without connecting it in the control circuit of the motor

starter, follow the following procedure. Connect required auxiliary supply to VSP D2. Check the output

relay contacts at (13) & (14). Indication L1 should be ON. Press TEST push button on the front of the

VSP D2. Reset your VSP D2 by either pressing RESET push button on the front plate of VSP D2 or by

shorting terminals (10) & (11) of VSP D2 . If these operations are perfect, connect your VSP D2 in the

motor circuit. Consult Minilec if you find any irregularities in the above mentioned operation.

TESTING PROCEDURE

Wait till

supply

voltage

normalizes

Is it

within the

specified

tolerance

limits?

Check Aux.

supply voltage

at 7 & 8 of

VSP D2

Is

L1

ON ?

See Indication

Start

R,Y,B phase sequence

connected to VSP D2

is correct.

Start motor

Does

starter

hold

Now remove any one

fuse link in power

circuit for all the 3

phases one at a time

Does

VSP D2 trip

within 2-5 secs

& L2 get ON ?

Reset the relay and restart

VSP D2 operation is perfect.

Install it for permanent use

R,Y,B phase

sequence is incorrect

interchange wires

of 1 & 3 of VSP D2 .

Tighten all terminals

in power & control

wiring & at 1,2&3

of VSP D2

Check phase to phase voltage

across 1,2& 3 of VSP D2 after

removing fuse link.

NO

CONSULT

MINILEC

YES

Is

phase to phase

unbalance voltage

less than unbalanced

setting of

VSP D2

Set the unbalance voltage

setting at 30 V (minimum) &

reset the relay as per above steps.

YES

NO

NO

NO

NO

YES

END

VSP D2 will not trip Load

the motor & retest as per

above procedure.

YES

YES

D - dt.25/8/04