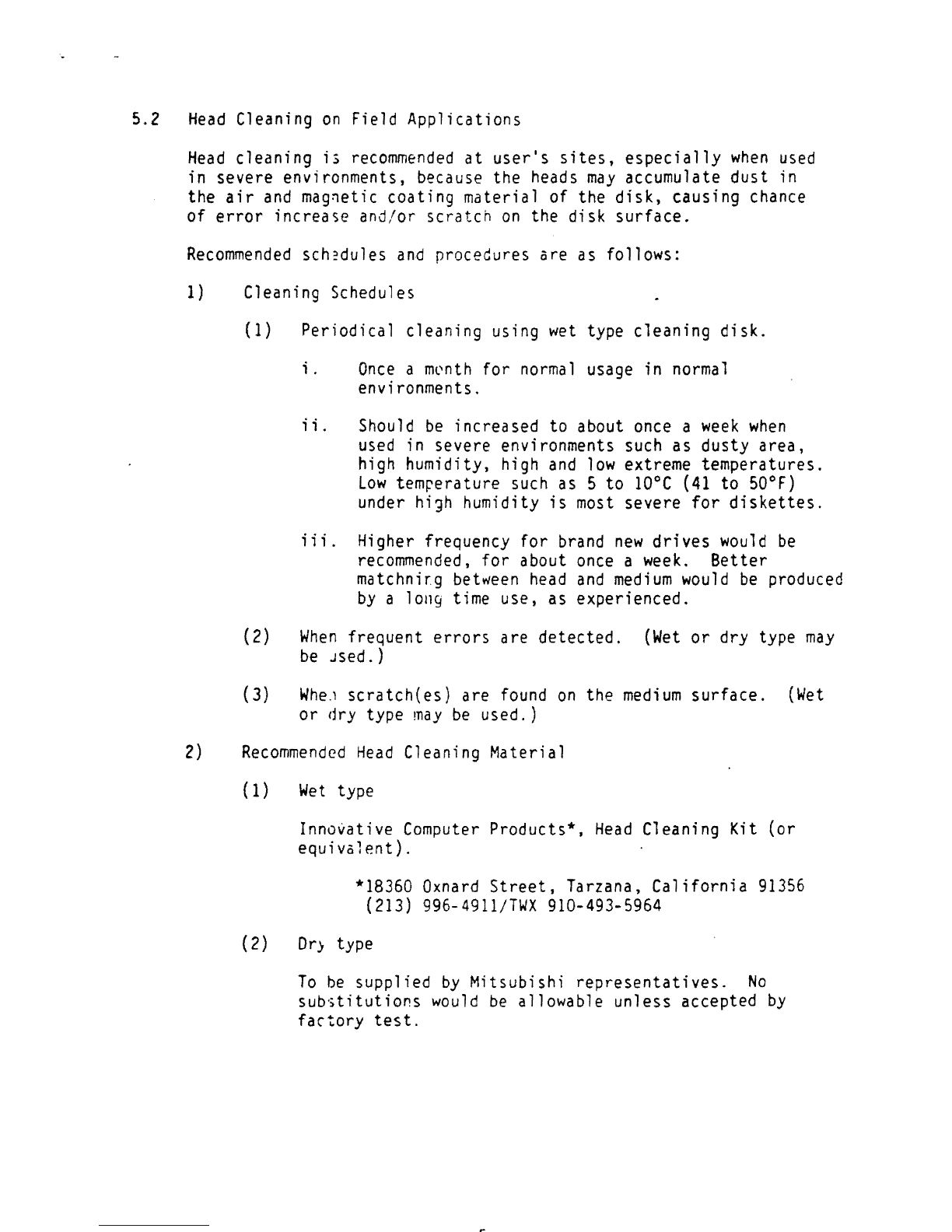

5.2

Head

Cleaning

on

Field Applications

Head

cleaning

is

recommended

at

user's

sites,

especially

when

used

in severe environments, because the heads

may

accumulate

dust

in

the

air

and

mag~etic

coating material of the

disk,

causing chance

of

error

increase and/or

scratch

on

the disk

surface.

Recommended

sch:?dules

and

procedures are as follows:

1)

Cleaning Schedules

(1) Periodical cleaning using

wet

type cleaning

disk.

i.

Once

a mrnth for

normal

usage in

normal

environments.

ii.

Should

be

increased to about once a

week

when

used in severe environments such as dusty

area,

high humidity, high

and

low

extreme temperatures.

Low

temperature such as 5

to

10°C

(41

to 50°F)

under

hi~h

humidity

is

most

severe

for

diskettes.

iii.

Higher frequency

for

brand

new

drives

would

be

recommended.

for

about once a

week.

Better

matchnirg between

head

and

medium

would

be

produced

by

a

10119

time use, as experienced.

(2)

When

frequent

errors

are

detected.

(Wet

or

dry type

may

be

Jsed.)

(3)

Whe.l

scratch(es)

are found

on

the

medium

surface.

(Wet

or

dry type

may

be

used.)

2)

Recommended

Head

Cleaning Material

(1)

Wet

type

Innovative

Computer

Products*,

Head

Cleaning Kit (or

equivalent).

*18360

Oxnard

Street,

Tarzana.

California

91356

(213)

996-4911/TWX

910-493-5964

(2)

Dr}

type

To

be

supplied

by

Mitsubishi

representatives.

No

substitutions

would

be

allowable unless accepted

by

fartory

test.