Instruction Manual Optimix 10 Mixer Technology srl pag.2

GENERAL INDEX

CE MARKING .......................................................................................... 3

FINAL TESTING AND COMMISSIONING ...................................................... 3

RESERVED RIGHTS ................................................................................. 3

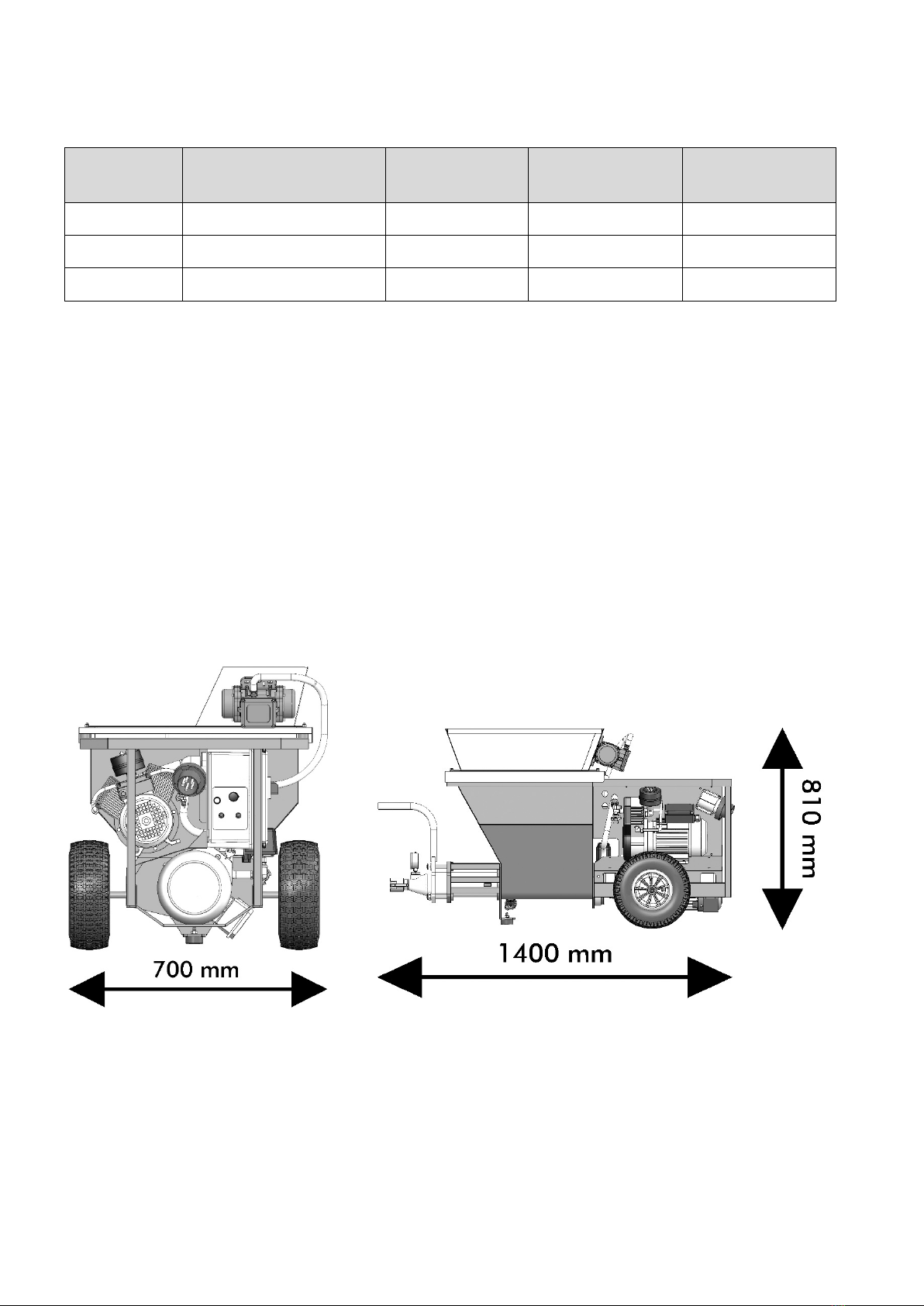

TECHNICAL DATA.................................................................................... 4

DIMENSIONS OF THE MACHINE ................................................................ 4

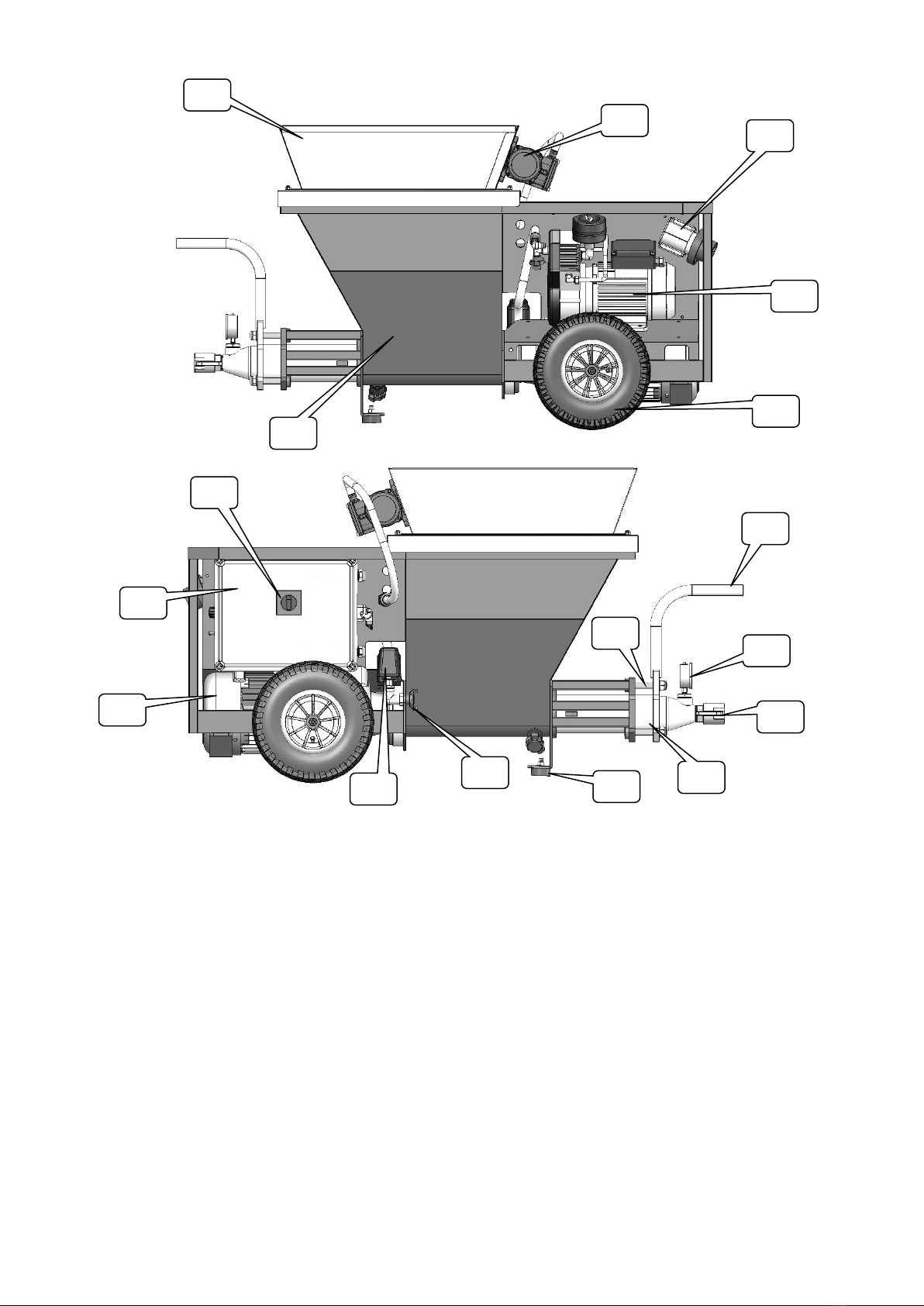

PARTS LIST ............................................................................................ 5

PACKAGING............................................................................................ 6

UNPACKING ........................................................................................... 6

USE DESTINATION .................................................................................. 7

DISPOSAL .............................................................................................. 7

MACHINE TRANSPORT ............................................................................. 7

SAFETY INSTRUCTIONS ........................................................................... 8

RESIDUAL RISKS .................................................................................... 9

FORESEEABLE INCORRECT USE ................................................................ 9

DIASSEMBLING OF ROTOR AND MIXER.....................................................10

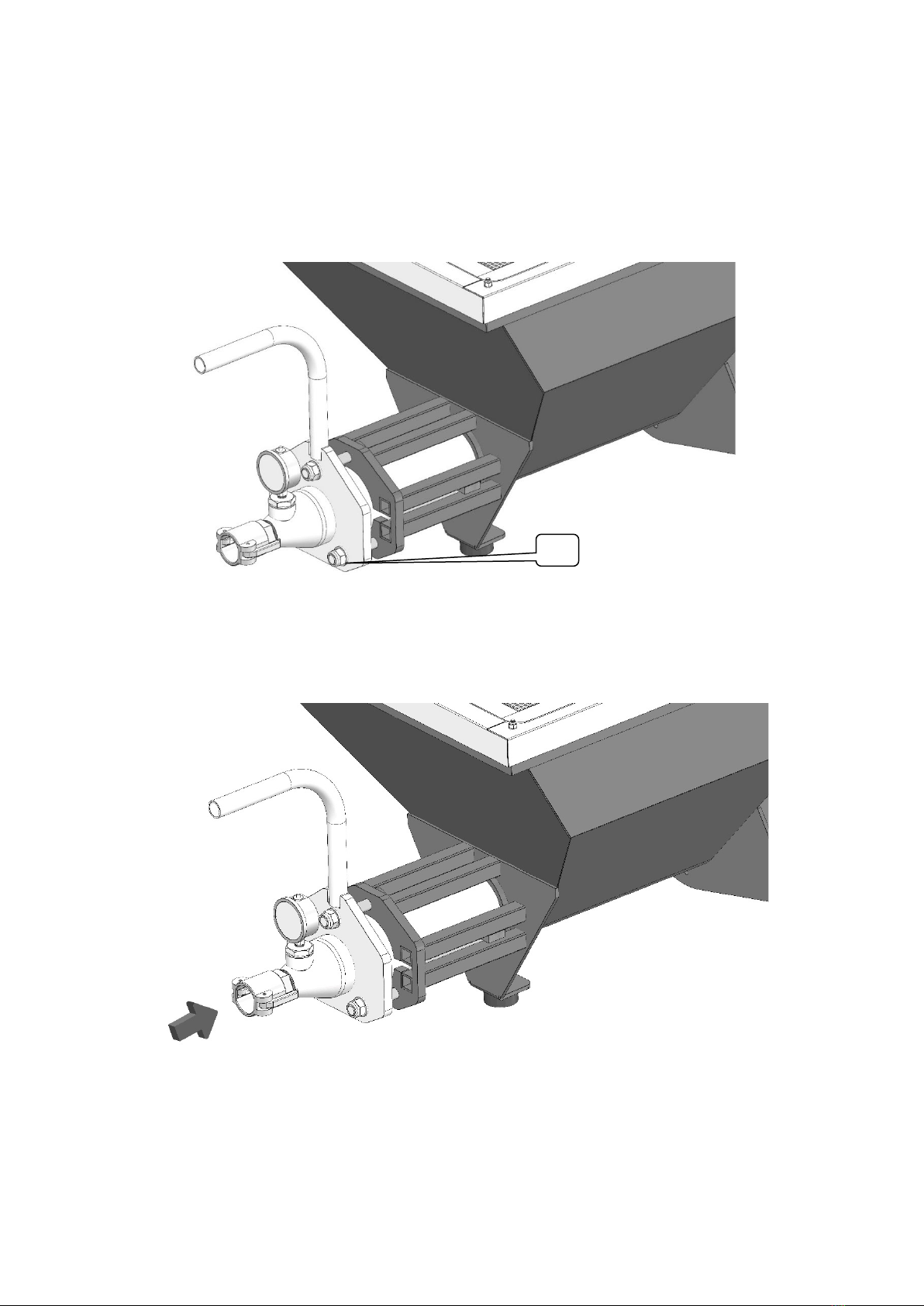

CONNECTION OF THE MATERIAL CONVEYING TUBE ...................................10

CONNECTION OF THE AIR TUBE TO THE MACHINE .....................................11

CONNECTION OF THE MATERIAL CONVEYING AND AIR TUBES TO THE

SPRAYING NOZZLE.................................................................................11

ELECTRICAL CONNECTIONS ....................................................................12

CONTROL PANEL ....................................................................................13

CHECKS BEFORE SWITCHING ON.............................................................14

MACHINE PREPARATION .........................................................................14

LOADING MATERIAL IN THE HOPPER ........................................................14

SPRAYING OF THE MATERIAL ..................................................................15

MACHINE SWITCHING OFF ......................................................................15

RESEARCH OF MALFUNCTIONS ................................................................16

ROUTINE MAINTENANCE.........................................................................17

WARRANTY ...........................................................................................18