4 D

ESK

T

OP

S

ERIES

–

AUTOMATIC OPERATION

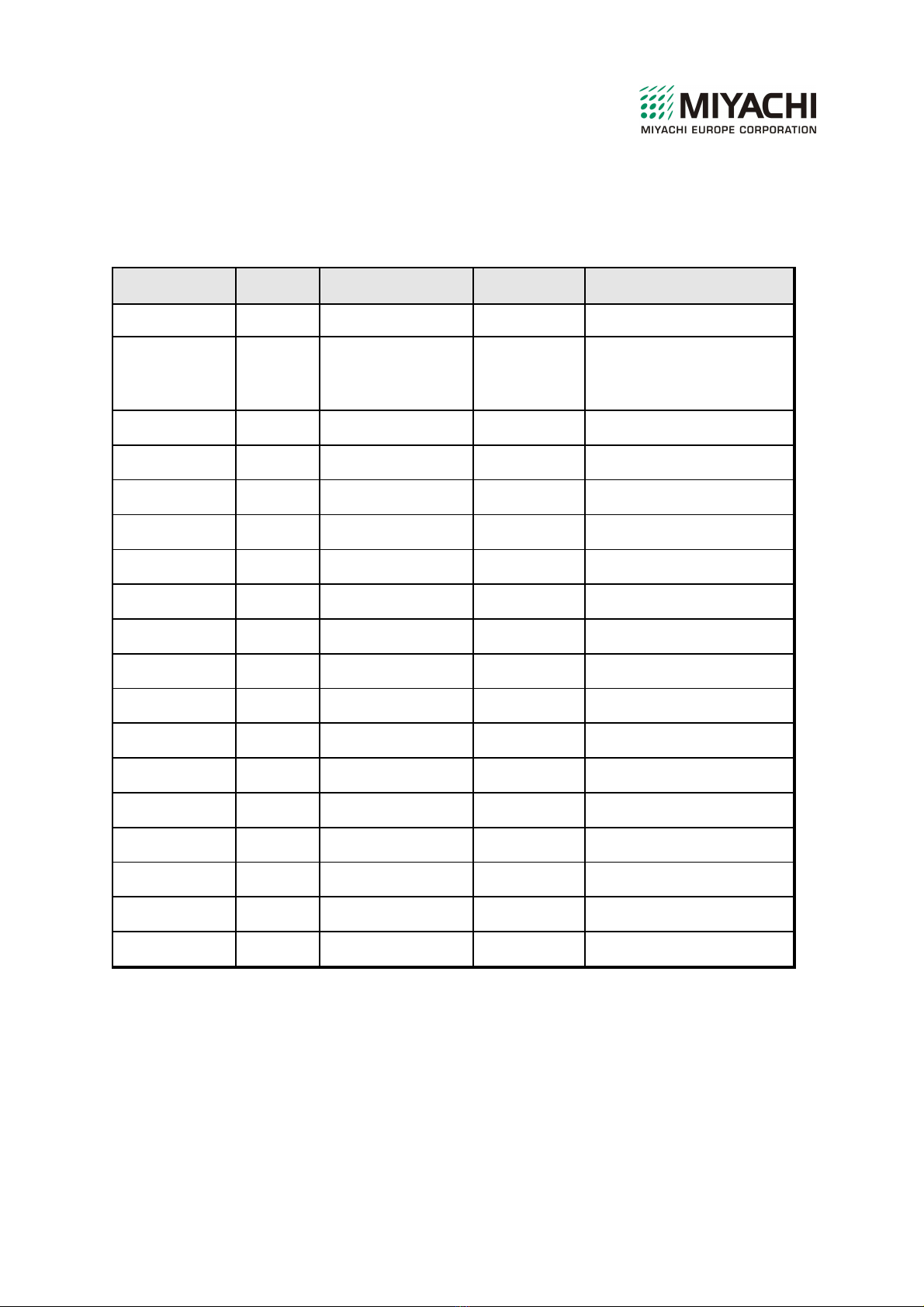

Contents

1 SAFETY PRECAUTIONS........................................................................................................6

1.1 GENERAL SAFETY PRECAUTIONS..............................................................................6

1.2 WARNINGS ON THE DESKTOP SYSTEM:....................................................................6

2 INTRODUCTION....................................................................................................................8

2.1 GENERAL ........................................................................................................................8

2.2 INTENDED USE..............................................................................................................9

2.3 PRINCIPLE OF OPERATION.......................................................................................10

2.4 SOUND LEVEL..............................................................................................................10

2.5 SYSTEM REQUIREMENTS...........................................................................................10

2.6 SPECIFICATIONS – AIR AND ELECTRICAL SUPPLIES...........................................11

3 CONSTRUCTION .................................................................................................................12

3.1 GENERAL CONSTRUCTION........................................................................................12

3.2 TAPE INTERPOSER MODULE ....................................................................................16

3.3 ACF MODULE...............................................................................................................16

3.4 SAFETY MEASURES AND DEVICES...........................................................................16

3.4.1 Protection guards....................................................................................................16

3.4.2 Hot parts..................................................................................................................16

3.4.3 Electrical safety.......................................................................................................16

3.4.4 Emergency stop .......................................................................................................16

3.5 CERTIFICATION...........................................................................................................17

3.6 DT-350 SYSTEM DESCRIPTION..................................................................................18

3.7 DT-360 SYSTEM DESCRIPTION..................................................................................19

3.8 DT-370 SYSTEM DESCRIPTION..................................................................................20

3.9 DT-450 SYSTEM DESCRIPTION..................................................................................21

4 INSTALLATION....................................................................................................................22

4.1 TRANSPORTATION.......................................................................................................22

4.2 INSTALLATION.............................................................................................................22

4.3 POST INSTALLATION ADJUSTMENT INSTRUCTIONS ............................................26

4.3.1 DT-350 and 260 systems.........................................................................................26

4.3.2 DT-370 systems.......................................................................................................30

4.3.3 DT-450 systems.......................................................................................................32

5 THE CONTROL PANELS.....................................................................................................37

5.1 MAIN CONTROL PANEL..............................................................................................37

5.2 MAIN CONTROL PANEL (TD200 HEAT CONTROL).................................................38

5.3 CONSTANT HEAT CONTROL PANEL.........................................................................38

5.4 UNIFLOW CONTROL PANEL......................................................................................39

5.5 TD200 CONTROL PANEL.............................................................................................39

5.5.1 TD200 keys..............................................................................................................39

5.5.2 TD200 screens DT-350, DT-360, DT-370 ..............................................................40

5.5.3 Failure messages DT-350, DT-360, DT-370 ..........................................................44

5.5.4 TD200 screens DT-450 (General)...........................................................................46