INSTRUCTION MANUAL·7

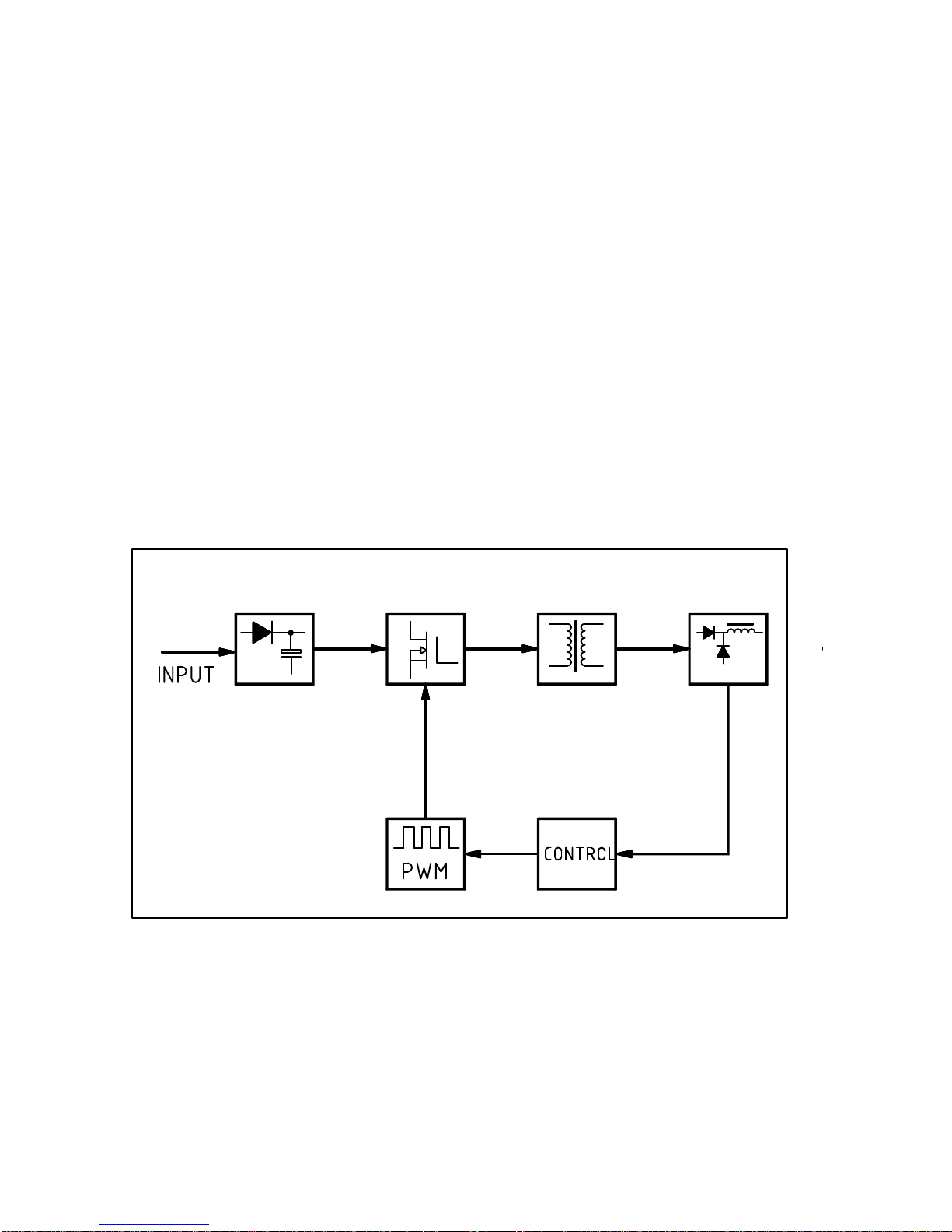

OOO PP P EE E RRR AAA T T T I I I OOO NNN

- - - OOO ppp ee e r r r aaa t t t i i i ooo nnn sss t t t eee ppp sss

-Turn on the air switch of the welding machine, open the gas cylinder valve, and adjust the flow

meter to the desired position.

-Choose contact tip’s aperture of the welding gun according to the diameter of the welding wire.

-Adjust the voltage adjustment knob and current adjustment knob to the desired position according

to the thickness and craftwork of the work piece.

-Adjust the inductance adjustment knob to the desired position to get the right rigidity.

-Press the switch on the welding gun, then welding can be carried out.

--- SSS eee ttt ttthhheee www ee e l l l ddd i i i nnn ggg ccc uuu r r r r r r eee nnn t t t

-The option of the welding current and welding voltage directly influences the welding stability,

welding quality and productivity. In order to obtain good weld, the welding current and welding

voltage should be set optimally. Generally, the setting of weld condition should be according to the

welding wire diameter, the melting form and the production requirement. Refer to the following

figure to set the welding current, while refer to the speed-read table on page 8to do the welding

operation according to different working condition.

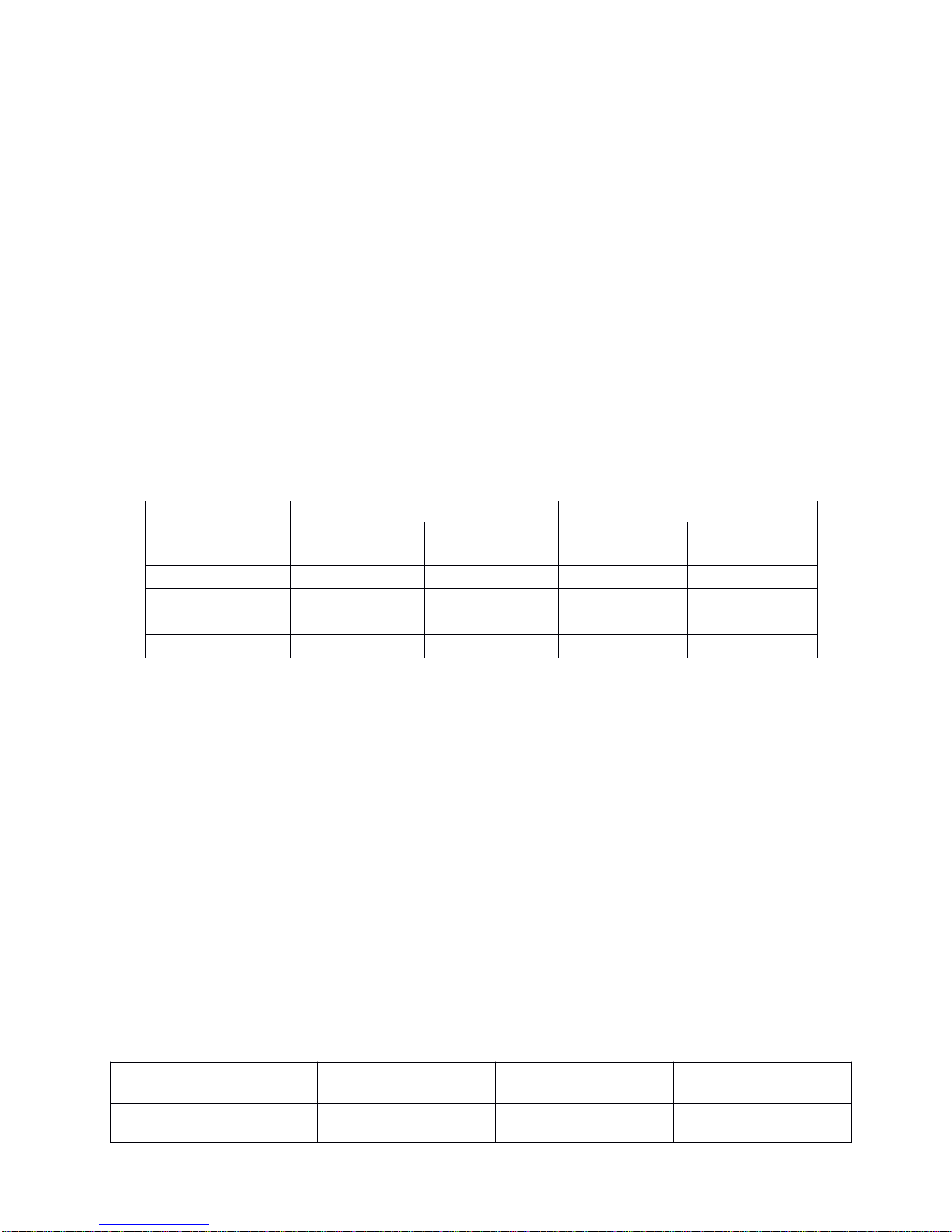

Range of welding current and voltage in short circuit transition and granular transaction.

- - - TTT hhh ee e ooo ppp t t t i i i ooo nnn ooofff ttthhheee www ee e l l l ddd i i i nnn ggg sss ppp eee eee ddd

The welding quality and productivity should be taken into consideration for the option of welding

speed. In case that the welding speed increases, it weakens the protection efficiency and quickens

the cooling. As aconsequence, it is not optimal for the seaming. In the event that the speed is too

slow, the work piece will be easily damaged, and the seaming is not ideal. In practical operation, the

welding speed should not exceed 30m/h.

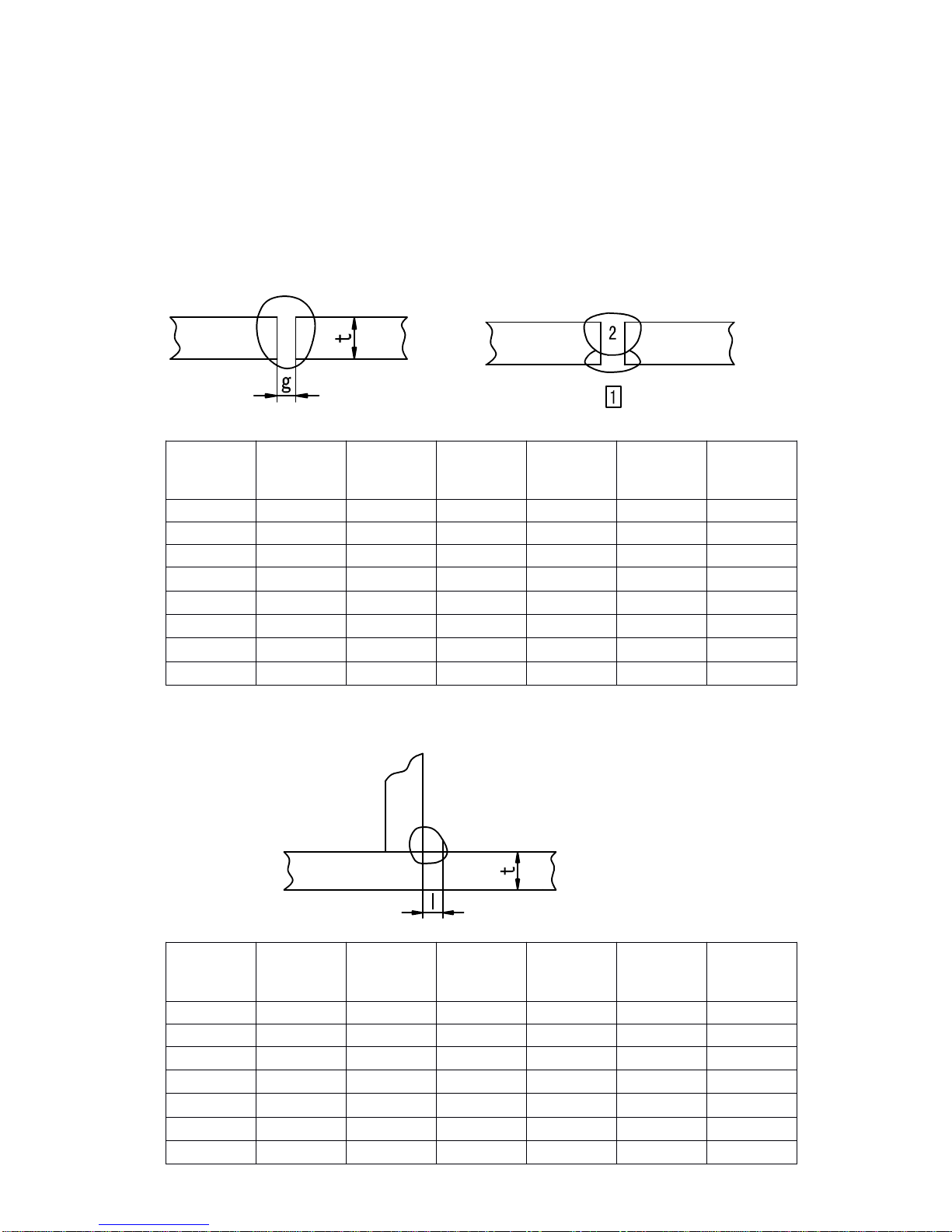

- - - TTT hhh eee l l l ee e nnn ggg t t t hhh ooofff wwwiiirrreee sss t t t r r r eee t t t ccc hhh i i i nnn ggg ooo uuu t t t

The length of wire stretching out the nozzle should be appropriate. The increase of the length of

wire stretching out of the nozzle can improve the productivity, but if it is too long, excessive spatter

presents in the welding process. Generally, the length of wire stretching out the nozzle should be 10

times as the welding wire diameter.

- - - TTT hhh ee e sss eee t t t t t t i i i nnn ggg ooofff ttthhheee CCC000222 ffflllooowww vvv ooo l l l uuu mmm eee

The protection efficiency is the primary consideration. Besides, inner-angle welding has better

protection efficiency than external-angel welding. For the main parameter, refer to the following

figure.

Option of C02flow volume

Wireφ(mm) Short circuit transition Granular transition

Current(A)Voltage (V) Current(A)Voltage (V)

0.6 40~70 17~19 160~400 25~38

0.8 60~100 18~19 200~500 26~40

1.0 80~120 18~21 200~600 27~40

1.2 100~150 19~23 300~700 28~42

1.6 140~200 20~24 500~800 32~44

Welding mode Thin wire C02

welding

Thick wire C02

welding

Thick wire, big

current C02welding

C02(L/min)5~15 15~25 25~50

MIG 250 i