Table of Contents

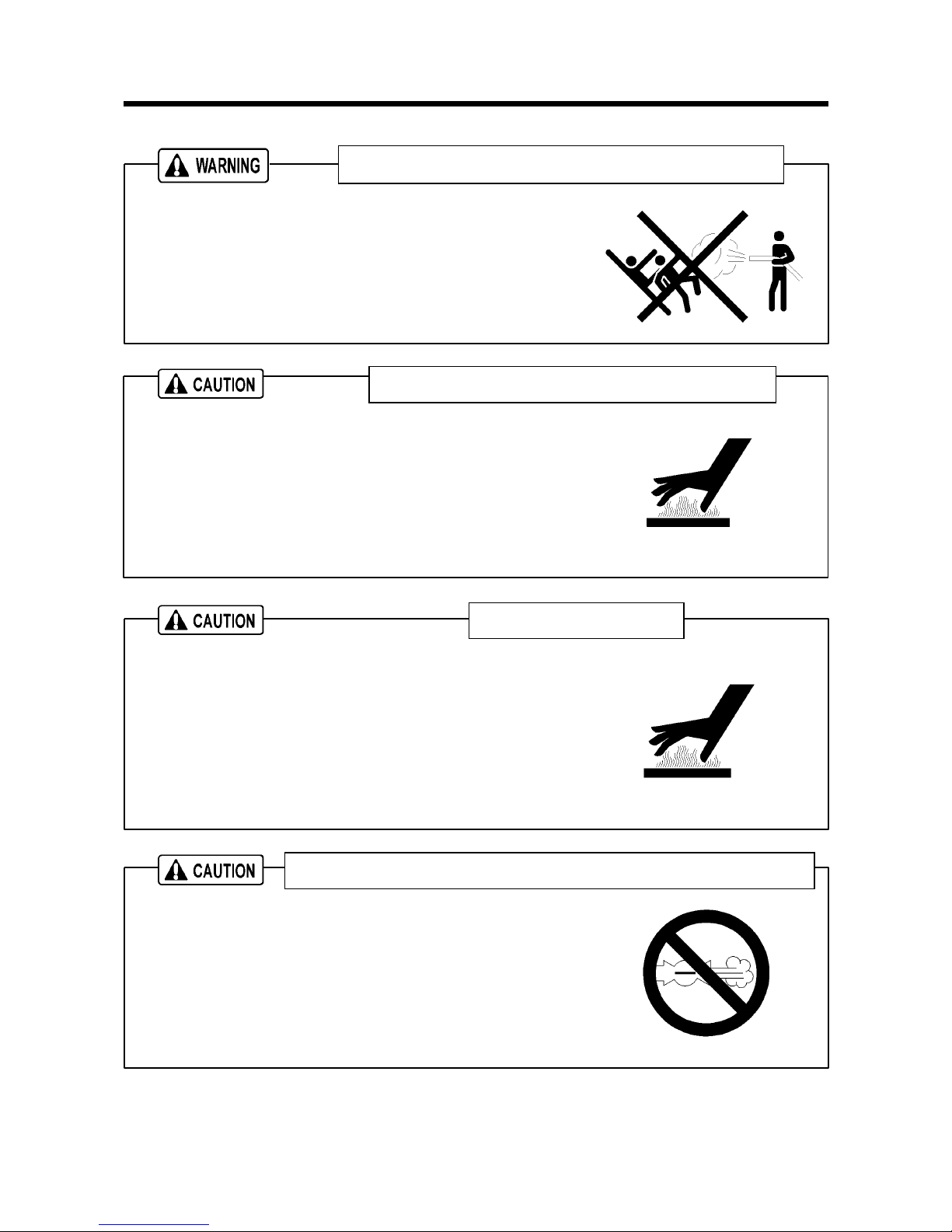

1. Safety .......................................................................................................................................................

1-1

1.1 Caution before Operation ................................................................................................................

1-2

1.2 Caution during Operation ................................................................................................................

1-6

1.3 Caution during Inspection and Maintenance ...................................................................................

1-8

1.4 Safety Warning Labels ....................................................................................................................

1-12

2. Operation .................................................................................................................................................

2-1

2.1 Unit Appearance and Part Names ...................................................................................................

2-1

2.2 Internal Components and Part Names ............................................................................................

2-2

2.3 Instrument Panel .............................................................................................................................

2-3

2.4 Compressed Air Service Valve .......................................................................................................

2-5

2.5 Door ................................................................................................................................................

2-5

2.6 Check before Starting Unit ..............................................................................................................

2-5

2.7 Unit Operation .................................................................................................................................

2-12

2.8 Stopping Procedures .......................................................................................................................

2-15

3. Transportation and Towing the Unit .....................................................................................................

3-1

3.1 Transportation .................................................................................................................................

3-1

3.2 Towing the Unit ...............................................................................................................................

3-2

4. Installation ...............................................................................................................................................

4-1

4.1 Location and Installation .................................................................................................................

4-1

5. Periodic Inspection/Maintenance ..........................................................................................................

5-1

5.1 Important Items as Periodic Inspection and Maintenance or after Maintenance .............................

5-1

5.2 Daily Inspection and Operation Log ................................................................................................

5-2

5.3 Periodic Inspection List ...................................................................................................................

5-3

5.4 Periodic Replacement of Parts ........................................................................................................

5-5

5.5 Items and Places of Inspection.........................................................................................................

5-6

5.6 Maintenance Items ..........................................................................................................................

5-7

6. Maintenance/Adjustment .......................................................................................................................

6-1

6.1 Adjustment of Regulator ..................................................................................................................

6-1

6.2 Maintenance of Battery ...................................................................................................................

6-2

6.3 Troubleshooting ..............................................................................................................................

6-4

7. Storage of the Unit .................................................................................................................................

7-1

7.1 Preparation for Long-term Storage .................................................................................................

7-1

8. Specifications .........................................................................................................................................

8-1

8.1 Compressor Specifications .............................................................................................................

8-1

9. Wiring Diagram .......................................................................................................................................

9-1

10. Piping Diagram .......................................................................................................................................

10-1