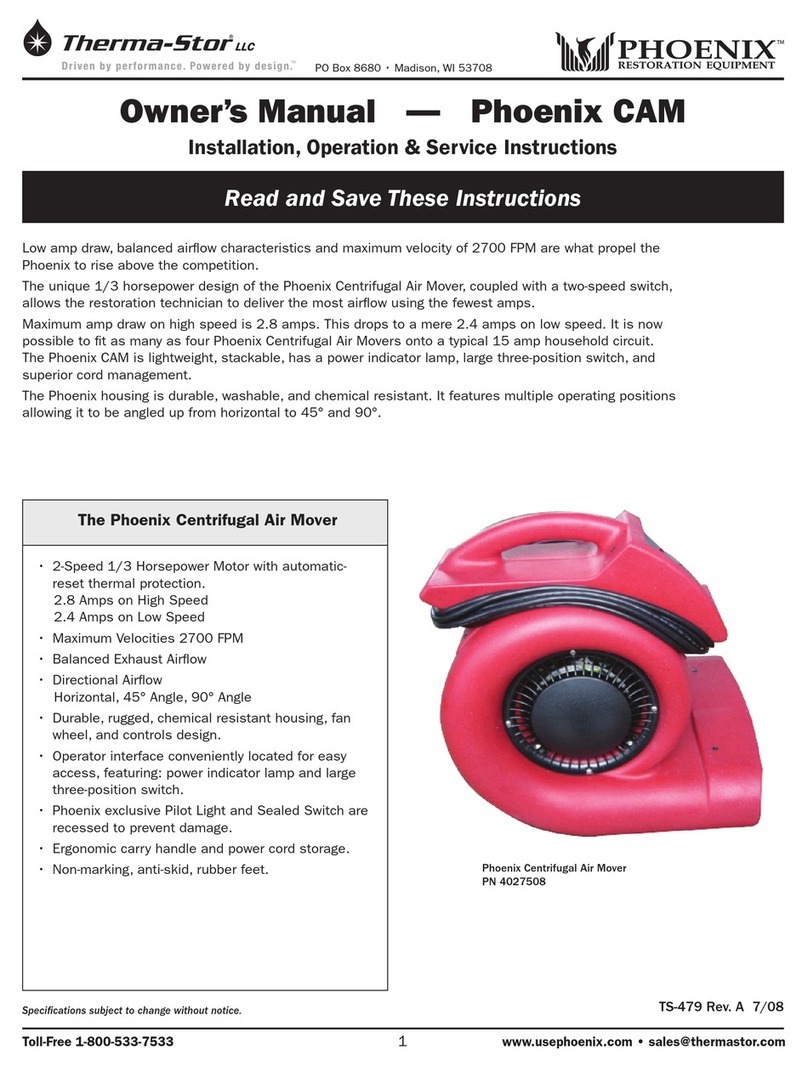

Cleanburn 14336 User guide

CLEAN BURN MODEL: DOUBLE-PISTON AIR COMPRESSOR #14336

OptionalAccessoriesforCleanBurnFurnaces/Boilers

INSTALLER'S MANUAL

PUBLICATION DATE: 1/4/10, Rev. 5 CLEAN BURN PART # 43142

IMPORTANTFORU.S.INSTALLATIONS: Allinstallationsmustbemadeinaccordancewithstateandlocalcodeswhich

maydifferfromtheinformationprovidedinthismanual. Savetheseinstructionsforreference.

IMPORTANTFORCANADIANINSTALLATIONS: Theinstallationofthisequipmentistobeaccomplishedbyqualified

personnelandinaccordancewiththeregulationofauthoritieshavingjurisdictionandCSAStandardB139,Installation

CodeforOilBurningEquipment.

I89056

WARRANTY INFORMATION

CleanBurn,Inc.,MANUFACTURER,herebywarrantsthatMANUFACTURER'sproductsshallbefreefromdefectinmaterial

and workmanship under normal use according to the provisions and limitations herein set forth.

MANUFACTURERwarrantstheheatexchanger/combustionchamberforaperiodoften(10)years(or15,000hours,

whichever comes first), from the date of purchase by the purchaser, as follows:

If the defect occurs in the first five (5) years (or 7500 hours, whichever comes first) , Clean Burn pays 100% of parts,

replacement or repair (the customer pays 0%), and pro rata thereafter according to the following schedule:

(a) If the defect occurs during the sixth year (or 7500-9000 hours, whichever comes first), customer pays 70% of

parts,replacementor repair.

(b) If the defect occurs during the seventh year (or 9000-10,500 hours, whichever comes first), customer pays 75%

of parts, replacement or repair.

(c) If the defect occurs during the eighth year (or 10,500-12,000 hours, whichever comes first), customer pays 80%

of parts, replacement or repair.

(d) If the defect occurs during the ninth year (or 12,000-13,500 hours, whichever comes first), customer pays 85% of

parts,replacementor repair.

(e) If the defect occurs during the tenth year (or 13,500-15,000 hours, whichever comes first), customer pays 90% of

parts,replacementor repair.

MANUFACTURERwarrantsallotherCleanBurncomponentparts,includingtheenergyretentiondisk,foraperiodofone

(1) year from the date of purchase by the purchaser.

LIMITATIONS:

The obligation of MANUFACTURER for breach of warranty shall be limited to products manufactured by MANUFACTURER (1) that

are installed, operated and maintained according to MANUFACTURER's instructions furnished and/or available to the purchaser upon

request; (2) that are installed according to all other applicable Federal, State and local codes or regulations; and (3) that the purchaser

substantiates were defective in material and workmanship notwithstanding that they were properly installed and correctly maintained as set

forth above and were not abused or misused.

The obligation of MANUFACTURER shall be limited to replacing or repairing the defective product, at the option of the

MANUFACTURER. MANUFACTURER shall not be responsible for any labor or costs of removal or reinstallation of its products and

shall not be liable for transportation costs to and from its plant at Leola, Pennsylvania.

Use of parts for modification or repair of the product or any component part thereof not authorized or manufactured by

MANUFACTURER specifically for such product shall void this warranty.

This warranty shall not apply to any damage to or defect in any of MANUFACTURER's products that is directly or indirectly caused by

(1) force majeure, Act of God or other accident not related to an inherent product defect; or (2) abuse, misuse or neglect of such product,

including any damage caused by improper assembly, installation, adjustment, service, maintenance or faulty instruction of the purchaser.

Other than as expressly set forth hereinabove, MANUFACTURER makes no other warranty, express or implied, with respect to any of

MANUFACTURER's products, including but not limited to any warranty of merchantability or fitness for a particular purpose.

And in no event shall MANUFACTURER be responsible for any incidental or consequential damages of any nature suffered by purchaser

or any other person or entity caused in whole or in part by any defect in any of MANUFACTURER's products. Any person or entity to

whom this warranty extends and who claims breach of warranty against MANUFACTURER must bring suit thereon within one year from

the date of occurrence of such breach of warranty or be forever barred from any and all legal or other remedies for such breach of warranty.

MANUFACTURER is not responsible for and hereby disclaims any undertaking, representation or warranty made by any dealer,

distributor or other person that is inconsistent with or in any way more expansive than the provisions of this limited warranty.

This warranty grants specific legal rights and shall be read in conformity with applicable state law. In some jurisdictions, the applicable law

mandates warranty provisions that provide greater legal rights than those provided for herein. In such case, this limited warranty shall be

read to include such mandated provisions; and any provision herein that is prohibited or unenforceable in any such jurisdiction shall, as to

such jurisdiction, be ineffective to the extent of such prohibition or unenforceability without invalidating the remaining provisions and

without affecting the validity or enforceability of such provision in any other jurisdiction(s).

TRADEMARKS

The Clean Burn logo is a trademark of Clean Burn, Inc. All other brand or product names mentioned are the registered

trademarks or trademarks of their respective owners.

COPYRIGHT

Copyright © 2010 Clean Burn, Inc. All rights reserved. No part of this publication may be reproduced, or distributed without

thepriorwrittenpermissionofCleanBurn,Inc. 34ZimmermanRoad,Leola,PA 17540. Subjecttochangewithoutnotice.

TABLE OF CONTENTS

NOTE: A Special Bulletin (which appears just after the Table of Contents) has been

added to your manual to highlight important information about the installation,

adjustment and operation of your air compressor. Be sure to read this sheet before

beginning any procedures in this manual.

SECTION 1: INTRODUCTION ................................................................................... 1-1

GuidetothisManual ..........................................................................................................1-1

ForYourSafety... ..............................................................................................................1-2

SECTION 2: UNPACKING ......................................................................................... 2-1

UnpackingandInspectingAllComponents .........................................................................2-1

SECTION 3: INSTALLING THE AIR COMPRESSOR ............................................... 3-1

AirCompressorExplodedViewwithPartsList ..................................................................3-2

InstallingtheAirCompressorComponents .........................................................................3-3

PreparingtheFurnaceCabinet(Saturn140/Saturn240)....................................................3-5

MountingtheAirCompressor(Saturn140/Saturn240) ....................................................3-5

PreparingtheFurnaceCabinet(CB-1750/CB-2500/CB-3250) ......................................3-7

MountingtheAirCompressor(CB-1750/CB-2500/CB-3250).......................................3-7

PreparingtheFurnaceCabinet(CB-3500/CB-5000)........................................................3-9

MountingtheAirCompressor(CB-3500/CB-5000) ........................................................3-9

MountingtheAirCompressor(CB-200-CTB/CB-350-CTB/CB-500-CTB)..................3-9

PreparingtheCB-500SeriesBurnerforusewiththeAirCompressor ...............................3-10

ConnectingtheAirCompressortotheCB-500SeriesBurner ...........................................3-12

WiringtheAirCompressortotheCB-500SeriesBurner ..................................................3-12

PreparingtheSaturnBurnerforusewiththeAirCompressor ............................................3-13

ConnectingtheAirCompressortotheSaturnBurner ........................................................3-14

WiringtheAirCompressortotheSaturnBurner ...............................................................3-14

SECTION 4: OPERATING & MAINTAINING THE AIR COMPRESSOR ...................4-1

AdjustingtheAirCompressorduringOperation ..................................................................4-1

MaintainingtheAirCompressor .........................................................................................4-2

APPENDIX A

TechnicalReferenceMaterials ........................................................................................... A-1

CB-500SeriesBurnerWiringDiagram ....................................................................... A-1

SaturnBurnerWiringDiagram .................................................................................... A-2

AirCompressorWiring .............................................................................................. A-3

SPECIAL BULLETIN

CleanBurnModel#14336isadouble-pistonaircompressorwhichcanbeinstalledonALLClean

Burnfurnaceandboilermodels.

IMPORTANT INFORMATION CONCERNING THE SERVICE RATING

OF THE AIR COMPRESSOR

Aircompressormodel#14336hasaserviceratingofapproximately75%. Thismeansthattheaircompressor

canoperatecontinuouslyforapproximately45minutes(75%ofonehour),andthenitmustnotoperatefor

approximately15minutes(25%ofonehour)toallowtheaircompressorto"cooldown." Thisworkswellfor

mostfurnace/boilerinstallationswheretheunitwillcycleonandoffafewtimesduringanhour.

CAUTION: If the furnace/boiler will run continuously (without cycling on and off a few times

during an hour), you must use an air compressor with a tank. (Refer to the air compressor specifications

foryourfurnace/boilerwhenpurchasinganaircompressorwithatank.) DONOTuseaircompressormodel

#14336 if your furnace/boiler will run continuously for periods which exceed the 75% service rating.

Thiswilloverheattheaircompressorandseverelydamagetheteflonringsandteflonskirtintheaircompressor,

resultinginpoorairpressureoutputfromthecompressor.

IMPORTANT INFORMATION CONCERNING ADJUSTMENT

OF THE AIR COMPRESSOR

Itisveryimportanttofollowtheinstructions"AdjustingtheAirCompressorDuringOperation"inthis

manual. Thisprocedureinvolvestheadjustmentofthepressurereliefontheaircompressorsothattheprecise

airpressure(12to18psi)requiredforproperburneroperationisprovidedtotheburner. Excessairpressure

isbledoffthroughthepressurerelief.

CAUTION: DONOTruntheaircompressorwithoutproperlyadjustingthepressurerelief. Thiswilloverheat

theaircompressorandseverelydamagetheteflonringsandteflonskirtintheaircompressor,resultinginpoor

airpressureoutputfromthecompressor.

IMPORTANT INFORMATION CONCERNING YOUR

AIR COMPRESSOR MODEL

Installer's Manual: Clean Burn Air Compressors

1-1

SECTION 1: INTRODUCTION

Guide to this Manual

IMPORTANT! This manual provides all the instructions necessary to install the Clean Burn

air compressor on your Clean Burn furnace or boiler. Refer to your equipment Operator's Manual

for instructions on assembling, installing, operating, and maintaining your furnace or boiler.

Consult the Table of Contents for a detailed list of topics covered in this manual. You'll find the step-

by-step procedures easy to follow and understand. Should questions arise, please contact your Clean

Burn dealer before starting any of the procedures in this manual.

Following is an outline of the air compressor installation process:

•UNPACKING

• INSTALLINGTHEAIRCOMPRESSOR

• InstallingtheAirCompressorComponents

• PreparingtheFurnaceCabinet

• MountingtheAirCompressor(Furnaces)

• MountingtheAirCompressor(Boilers)

• PreparingtheBurnerforusewiththeAirCompressor

• ConnectingtheAirCompressortotheBurner

• WiringtheAirCompressor

Proceduresarealsoprovidedforadjustingtheaircompressorduringfurnace/boileroperationandfor

maintainingtheaircompressor.

Please read all sections carefully--including the following safety information--before beginning any

installation procedures; doing so ensures your safety and the optimal performance of your Clean

Burn air compressor.

Installer's Manual: Clean Burn Air Compressors

1-2

For Your Safety...

IMPORTANT! Review the list of general safety

precautionsprovidedinSection1ofyourFurnace/

BoilerOperator'sManual. Theseprecautionsmust

be heeded toensureproper,safe air compressorand

furnace/boileroperation.

WARNING!

STOP

YOUR SAFETY IS AT STAKE!

DO NOT INSTALL, OPERATE, OR

MAINTAIN THIS EQUIPMENT

WITHOUT FIRST READING

AND UNDERSTANDING

THIS MANUAL!

Please read all sections in this manual carefully--including the following safety information--before

beginning any installation procedures; doing so ensures your safety and the optimal performance of

your Clean Burn air compressor and furnace/boiler.

For your safety, Clean Burn documentation contains the

following types of safety statements (listed here in order

of increasing intensity):

•NOTE: A clarification of previous

information or additional pertinent

information.

•ATTENTION: A safety statement

indicating that potential equipment damage

may occur if instructions are not followed.

CAUTION: A safety statement

that reminds of safety practices or directs

attention to unsafe practices which could

result in personal injury if proper

precautions are not taken.

WARNING: A strong safety

statement indicating that a hazard exists

which can result in injury or death if proper

precautions are not taken.

DANGER! The utmost levels of

safety must be observed; an extreme hazard

exists which would result in high probability

of death or irreparable serious personal

injury if proper precautions are not taken.

Installer's Manual: Clean Burn Air Compressors

2-1

SECTION 2: UNPACKING

Beforeinstallingtheaircompressoronyourfurnace/boiler,youshouldtakesometimetocarefullyunpackyour

shipment from Clean Burn.

Carefully open all shipping containers and inspect all components. Immediately notify the freight

company and your Clean Burn dealer in case of shipping damage or shortage(s). Keep all components

together so you will have them as needed for assembly and installation.

For your convenience, air compressor components are listed in Section 3 (in related groupings)

throughout the installation process. Detailed illustrations with labelled components should enable

easy assembly/installation.

Unpacking and Inspecting All Components

Installer's Manual: Clean Burn Air Compressors

2-2

Installer's Manual: Clean Burn Air Compressors

3-1

SECTION 3: INSTALLING THE AIR COMPRESSOR

IMPORTANT! If you are installing your furnace/boiler and air compressor at the same time, Clean

Burnrecommendsthefollowingsequenceofactivities:

1. AssemblyofFurnace/Boiler(forfurnace-throughtheinstallationofmounting/stabilizerbrackets).

2. InstallationofAirCompressoronFurnace/Boiler

3. InstallationofFurnace/Boiler(includingoilpump,wiring,oil/airlines,stack,thermostat)

KeeptheFurnace/BoilerOperator'sManualhandyforquickreferenceasspecifiedthroughouttheinstallationof

theaircompressor.

WARNING: If you have already installed your furnace/boiler and power has been connected

totheunit,ensurethatthepoweristurnedOFFbeforeproceedingwiththeinstallationoftheair

compressortoavoidelectricalshockhazards.

Installer's Manual: Clean Burn Air Compressors

3-2

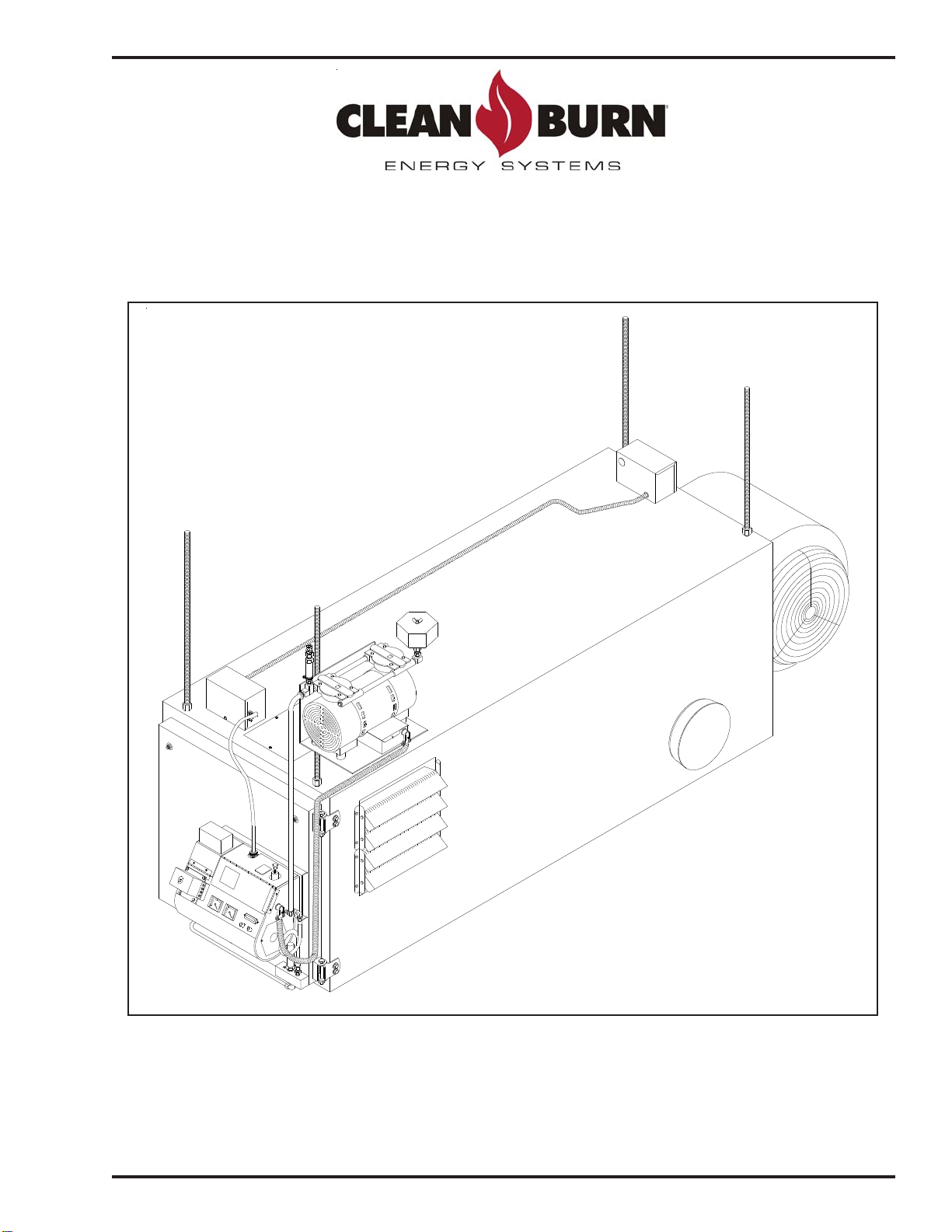

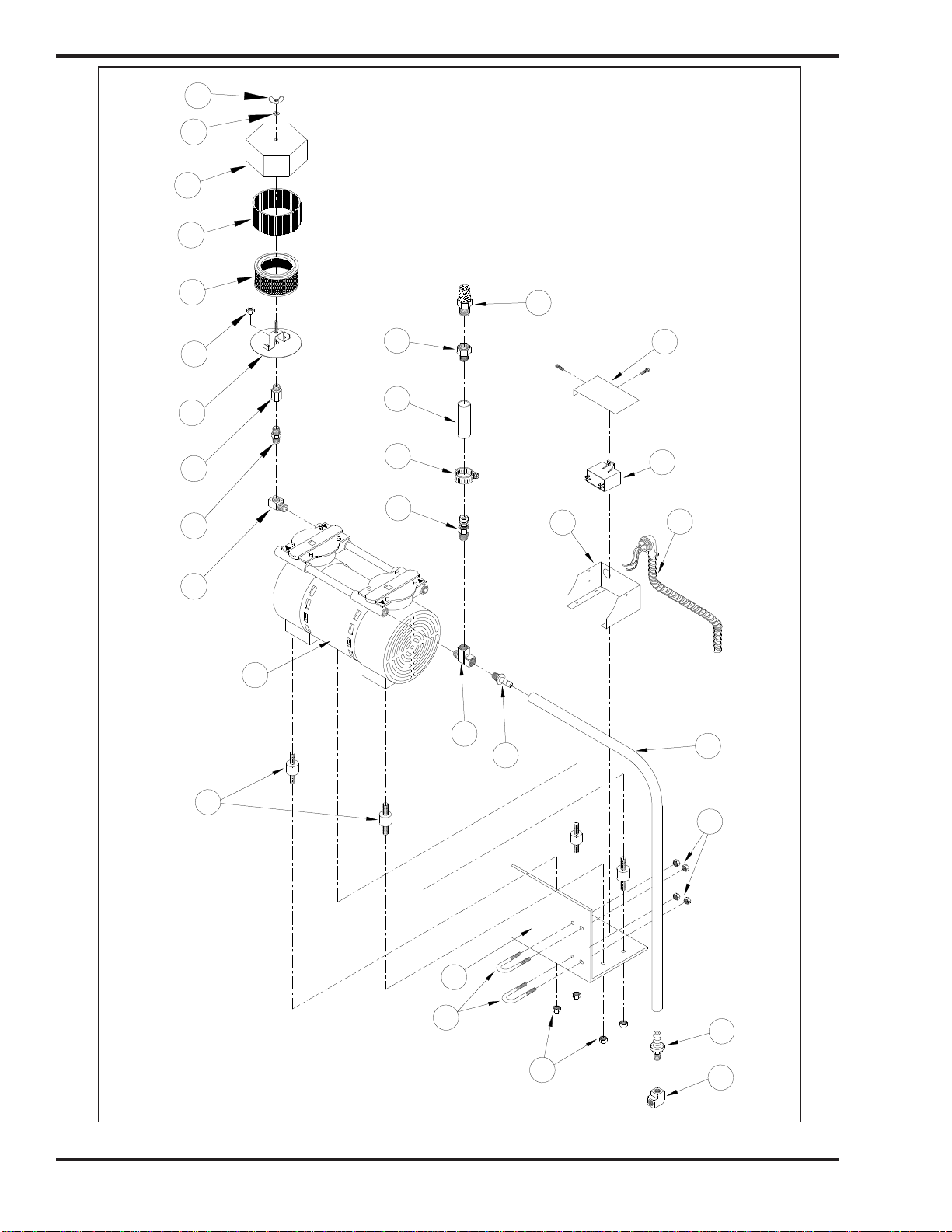

Figure3A-AirCompressorExplodedView

I89055

30

1

4

10

25

12

6

8

7

9

2

3

11

24

26

28

27

29

17

14

16

15

22

18

19

20

21

23

13

5

Installer's Manual: Clean Burn Air Compressors

3-3

ITEM QTY PART# DESCRIPTION

1 1 32280 1/8" ELBOW 90°

2 1 32234 HOSE BARB (3/8" H x 1/8"NPT)

3 1 54063 AIR HOSE (3/8",42" LONG)

4 1 32236 HOSE BARB(3/8"H x 1/4" NPT)

5 1 32233 BRASS STREET TEE (1/4" NPT)

6 1 32146 RELIEF VALVE

7 1 32091 HOSE CLAMP

8 1 13063 AIR HOSE (3/8" ID, 3" LONG)

9 1 32147 PIPE ADAPTER (1/2" x 3/8")

10 32157 MUFFLER

11 4 34092 1/4−20 NUT

12 1 12177 POWER CABLE

13 1 32518 AIR COMPRESSOR− DUAL PISTON (75R)

14 1 32210 1/4 BRASS STREET ELBOW

15 1 32150 1/4 BRASS NIPPLE

16 1 32411 1/4NPT F TO 3/8NPS BULKHEAD FITTING

17 1 70341 BASE PLATE

18 1 32412 3/8 NPS BULKHEAD NUT

19 1 32409 FILTER ELEMENT

20 1 N/A PART OF 32409

21 1 21130 FILTER HOUSING

22 1 34182 1/4" VINYL WASHER

23 1 34181 1/4" WING NUT

24 4 31104 VIBRATION INSULATOR

25 2 21075 "U" BOLT

26 1 25120 MOUNTING PLATE

1

29 1 21180 ELECTRICAL BOX COVER

28 1 33383 CAPACITOR

27 1 21179 ELECTRICAL BOX

30 4 34009 3/8−16 NUT

1. RefertoFigure3A.

2. Installtheairintakefilterintheinletportonthecompressorhead(noticethedirectionalarrow).

3. Installthe1/4"streetteeintheoutletportofthecompressorhead(noticethedirectionalarrow).

4. Install the relief valve on the street tee.

5. Install the hose clamp and 3/8" x 3" air hose. Then install the 3/8" x 1/2" bushing and muffler on

the relief valve.

6. Leavethehoseclamploosetoallowforinitialadjustmentofthereliefvalve(Section4).

7. Install the 3/8" H x 1/4" NPT hose barb on the street tee.

Installing the Air Compressor Components

Installer's Manual: Clean Burn Air Compressors

3-4

Figure3B-AirCompressorInstalledontheSaturn140/Saturn240

I89060

Installer's Manual: Clean Burn Air Compressors

3-5

Preparing the Furnace Cabinet (Furnace Models Saturn 140 / 240)

1. RefertoFigures3Aand3B.

2. Installall-threadrodsthroughthemountingholesinthebaseandtopofthefurnacecabinet. Usedouble

nutstosecurelylocktheall-threadrodsinposition.

Mounting the Air Compressor (Furnace Models Saturn 140 / 240)

CAUTION: Thecompressormustbesecurelymountedasdescribedinthissection. Ensurethat

all nuts and bolts are firmly tightened.

1. RefertoFigure3Aand3B.

2. Whilefacingtheburnersideofthefurnace,installtheaircompressoronthefrontrightall-threadrod

usingthetwoU-boltsandnutsprovided. Positionthemountingbracketapproximatelytwoinches

abovethetopofthefurnacecabinet.

Installer's Manual: Clean Burn Air Compressors

3-6

Figure3C-AirCompressorInstalled on the CB-1750 / CB-2500/CB-3250

I89056

Installer's Manual: Clean Burn Air Compressors

3-7

Preparing the Furnace Cabinet (Furnace Models CB-1750/2500/3250)

1. RefertoFigures3Aand3C.

2. Installall-threadrodsinthemountinglugsontopofthefurnacecabinet. Usedoublenutsto

securely lock the all-thread rods in position.

Mounting the Air Compressor (Furnace Models CB-1750/2500/3250)

CAUTION: Thecompressormustbesecurelymountedasdescribedinthissection. Ensurethat

all nuts and bolts are firmly tightened.

1. RefertoFigure3Aand3C.

2. Whilefacingtheburnersideofthefurnace,installtheaircompressoronthefrontrightall-threadrod

usingthetwoU-boltsandnutsprovided. Positionthemountingbracketapproximatelytwoinches

abovethetopofthefurnacecabinet.

Installer's Manual: Clean Burn Air Compressors

3-8

Figure3D-AirCompressorInstalledontheCB-3500/CB-5000

I89058

Table of contents

Popular Air Compressor manuals by other brands

Bend-Pak

Bend-Pak RS7580H603 Installation and operation manual

Central Pneumatic

Central Pneumatic CENTRAL PNEUMATIC 95499 Assembly and operation instructions

Champion

Champion 30000 Owner's and operator's manual

Vmac

Vmac UNDERHOOD 40 Series installation manual

Schulz

Schulz 20120HWV80X owner's manual

Craftsman

Craftsman 919.727580 owner's manual

Gardner Denver

Gardner Denver ELECTRA-SCREW 60 HP Service manual

Panasonic

Panasonic SD51C10JAU6 Specification sheet

DeWalt

DeWalt XR FLEXVOLT LI-ION DCC1054 Original instructions

MY PROJECT

MY PROJECT MPKT 60 B2 Operation and safety notes translation of the original instructions

VITO

VITO PRO-POWER VICO50A instruction manual

Sealey

Sealey SAC20030B quick start guide