- 2 -

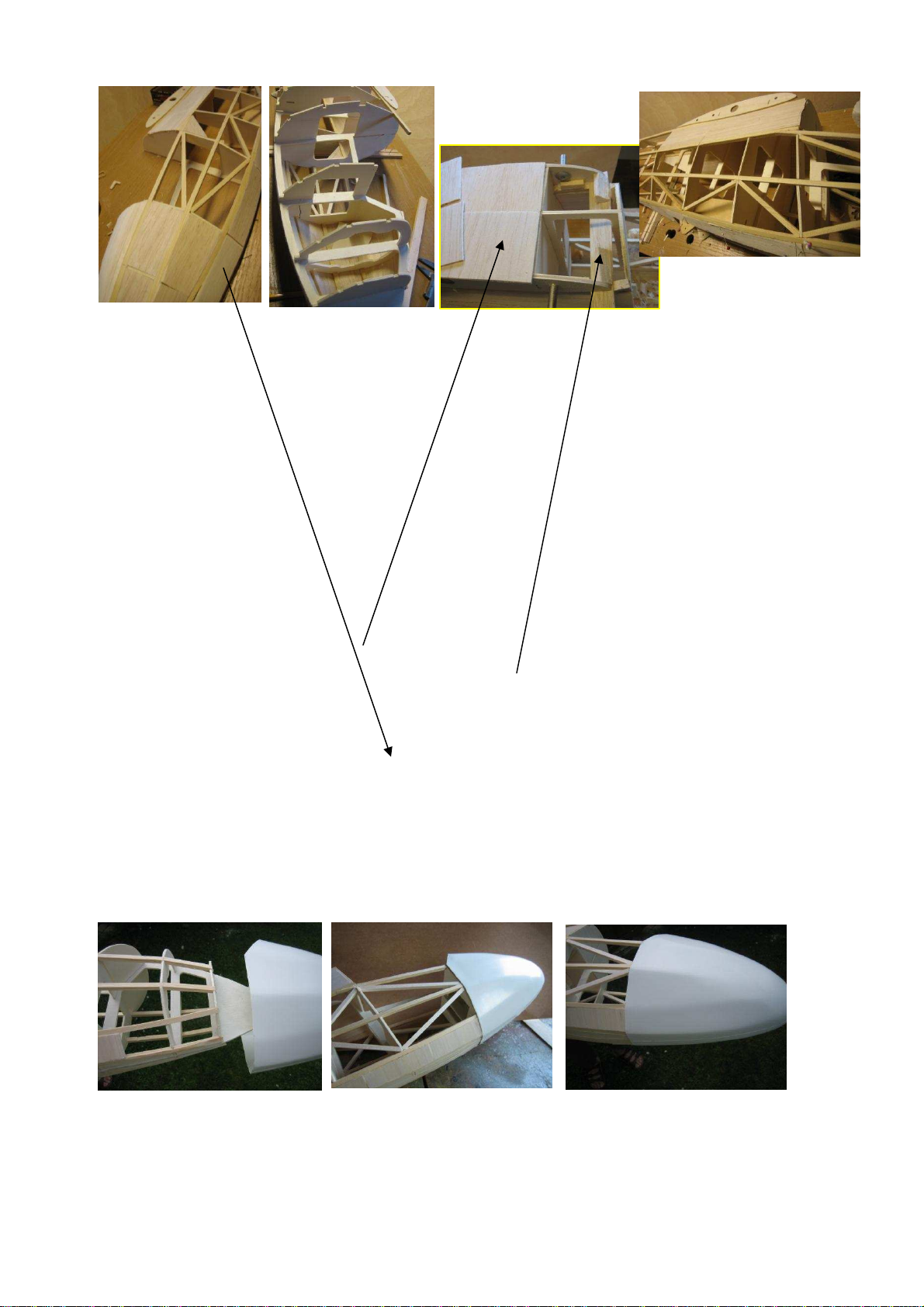

Match and glue all those diagonals between the frames 8-12

After this, match and glue the diagonals D2 between frame 3 and 4 and D3 between frame 3 and 9

Match and glue the fillings F1 between frames 6 to 9 above the stringer G4 back to the stringer G5

Match and glue the lower fillings F2 between stringer G3 and the fuselage bottom.

Take the fuselage halve from your building jig, turn it round.

Cut some pinewood rails to a length of about 25cm and squeeze them with a clamp to your

building jig that about 20cm are riding out over the edge.

Then push the fuselage over these rails and you will now be able to build the 2

nd

halve of the

fuselage the same way.

Check that the fuselage stays straight!

The wheel housing will be lined out by 0,4mm plywood.

Glue the elevator saddle 24 in place.

Push the 4 mushroom-shaped aluminium dowels from the inside out through rib 5 and glue in

place using Epoxy resin!

The wing joining tube must be sanded before gluing it with Epoxy resin into the fuselage.

Match and glue in place the covering F2, balsawood 1,5mm, above rib 5.

Match and glue the covering F3 between stringer G5 and fuselage top and make it fit to the leading

edge as well as the trailing edge! It is roof top like at the trailing edge and radiuses to the leading

edge. (See picture of the Original Ka8 at the end of this instruction, above on the right side and

below the big picture in the middle)

Match and glue in place the bottom planking of the fuselage made from 4mm plywood underneath

the cockpit region.

Match and glue the tail skid 13b.

The main Skid is made of ash wood and already cut to length.

The only thing left to do is to sand it down on the front end like shown on the plan!

Triangle strips of balsawood are used as the bearing for the rubber suspension. Glue them to the

fuselage bottom as shown in the plan.

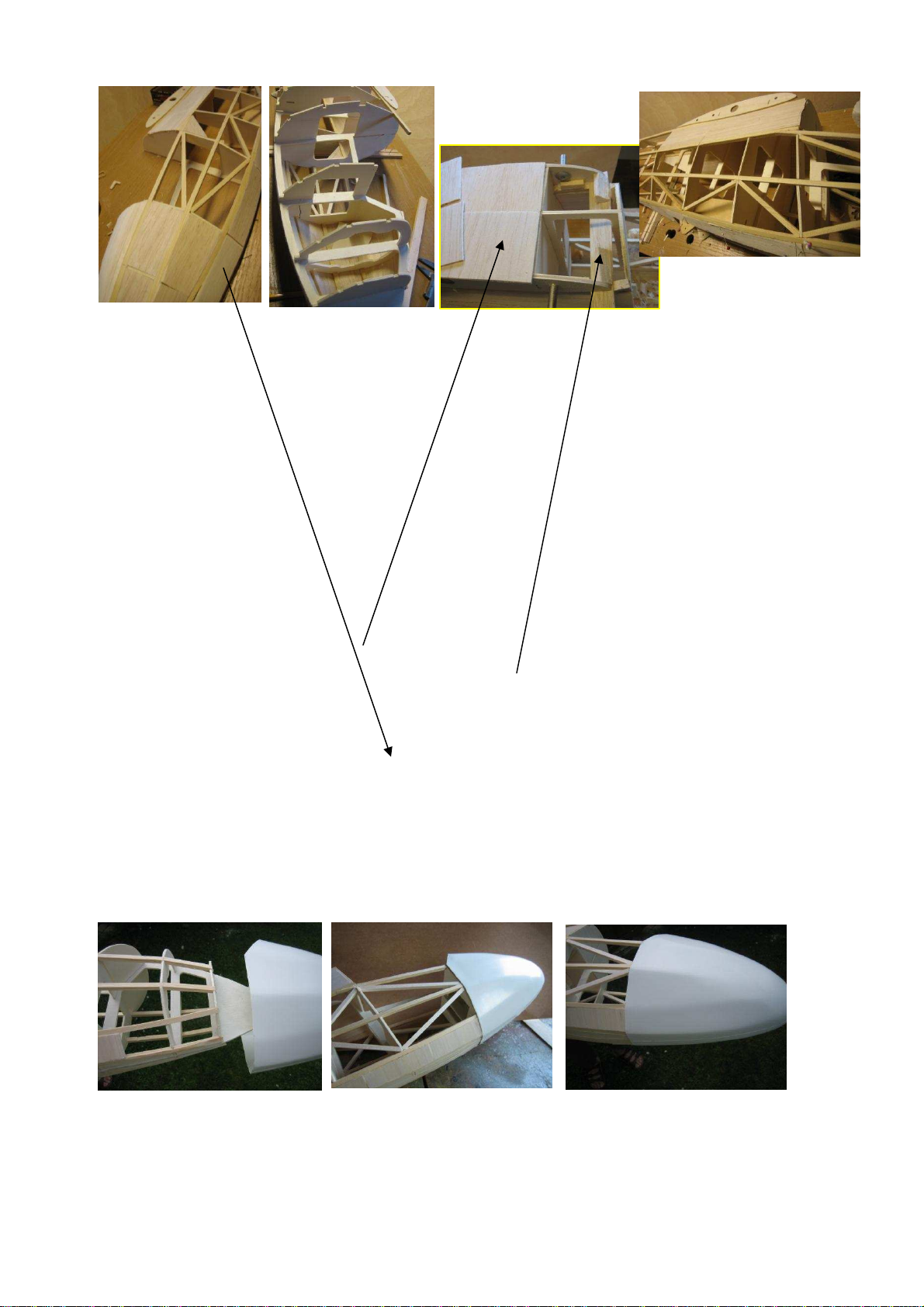

Match the nose cone and glue it in place by using Epoxy resin.

Fix the main skid to the fuselage bottom on both ends using a self-tapping screw.

Now the canopy frame will be glued together using parts 3b, 6a, and the pined wood stringer 6b.

Put a sheet of clear plastic between the canopy frame and the fuselage. This prevents the canopy

frame from sticking to the fuselage frame while gluing!