9WWW.MOJOTONE.COM

SECTION 6:

SOLDERING BASICS

Before you start slinging solder in your kit

or if you have never soldered before, take

a moment to read over this section about

soldering.

When assembling your amp kit, whether

it’s putting components on the eyelet board,

wiring up the tube sockets or connecting

wires to the potentiometers, the rst thing you

want is a good solid mechanical connection.

So for example if you are connecting a wire

to a pin on a tube socket or on the back of

a potentiometer, you do NOT want to set

the wire on the pin or let it oat loosely and

throw a bunch of solder on there. Solder is

not a great conductor, specially some of the

newer lead-free solder, think of it as more of

a semi-conductive glue. So what you want

is a solid physical connection between the

components that you are connecting together.

For example, when soldering to a tube

socket, you would want to create a hook with

the wire or component lead, hook it through

the pin, then use a pair of needle nose pliers

to pinch the hook together around the pin.

Now the wire has a solid connection to the

pin, so even if solder were to fail, in theory

you have the components connected together.

After you have created the mechanical

“bond”, then you can add a little solder to

help solidify the joint.

Working with eyelet boards

When installing components onto the

eyelet boards, you want the component to

lay or sit down onto the board, feeding the

leads into the eyelets and them bending

them underneath the board. Once all the

components are installed on the board and

the connecting wires are attached as well,

then start soldering the joints. After they have

been soldered, be sure to clip the excess leads

that are underneath the boards so that they do

not short against other components.

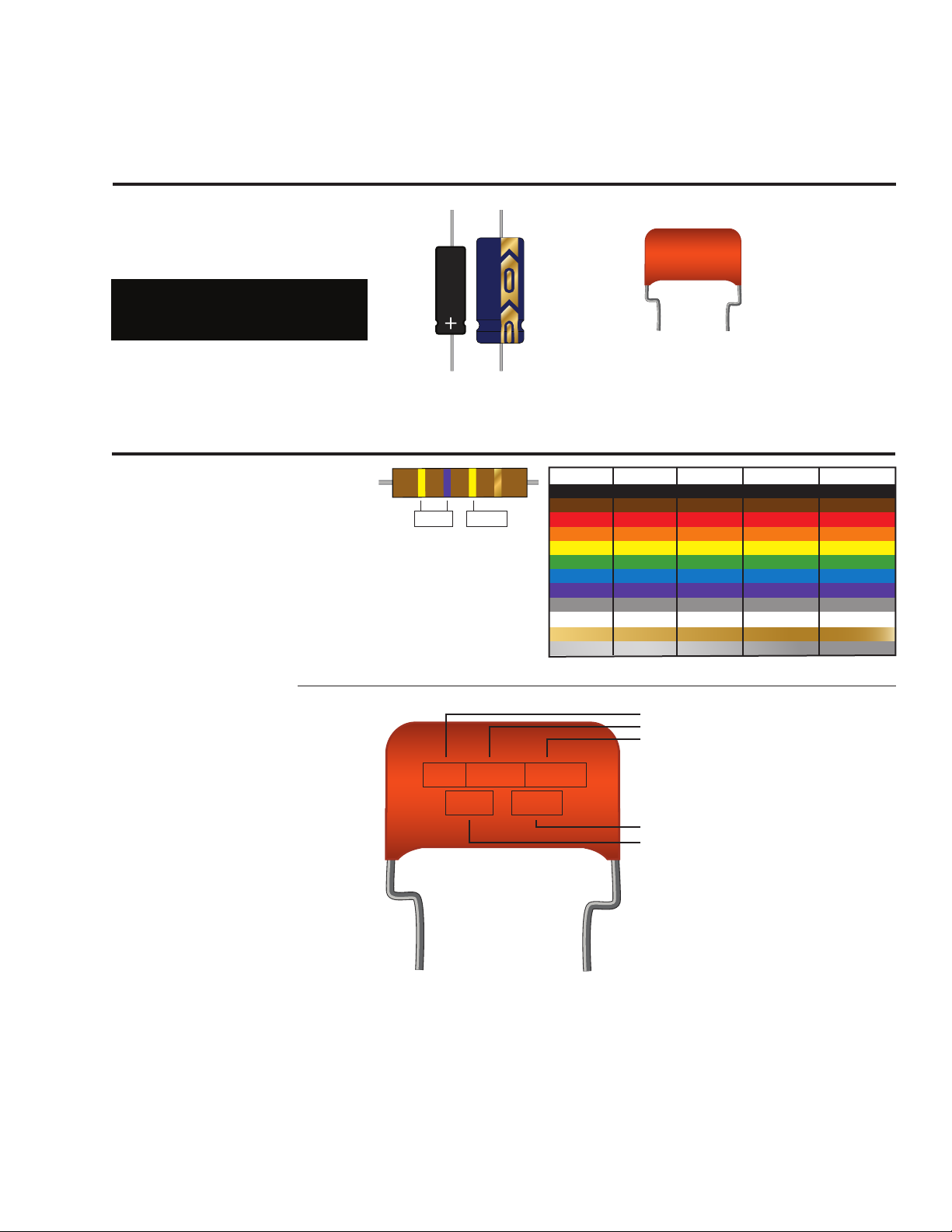

PRO TIP: There is an exception to laying a

component down on the eyelet board and

that would be when higher wattage resistors

are in the power supply OR if the amplier

is running the power tubes in a cathode

biased conguration. These components

are dropping voltages across them during

operation, which results in excess heat, and

needs to oat a little above the board to

dissipate the heat.

Soldering a Connection

{Connect the components together. Be

sure you have a solid mechanical connection

before you proceed.

{Make sure the tip of the iron is clean.

{Heat the components by touching the tip

of the iron to both components at the same

time. It should take about 2-3 seconds for the

connecting component leads to become hot

enough to ow solder.

{Slowly ow the solder into the connection.

The solder should liquefy and spread over the

connection. If the solder does not melt almost

instantly or if it beads up and falls off, double

check the temperature of your soldering iron

and make sure the tip of the iron is clean.

{Remove the solder from the connection.

{Remove the iron from the connection and

allow the joint to cool. Once it has cooled

you can gently pull the component to test the

connection.