Replace the motor assembly and deflector, as required. Disassembly is complete.

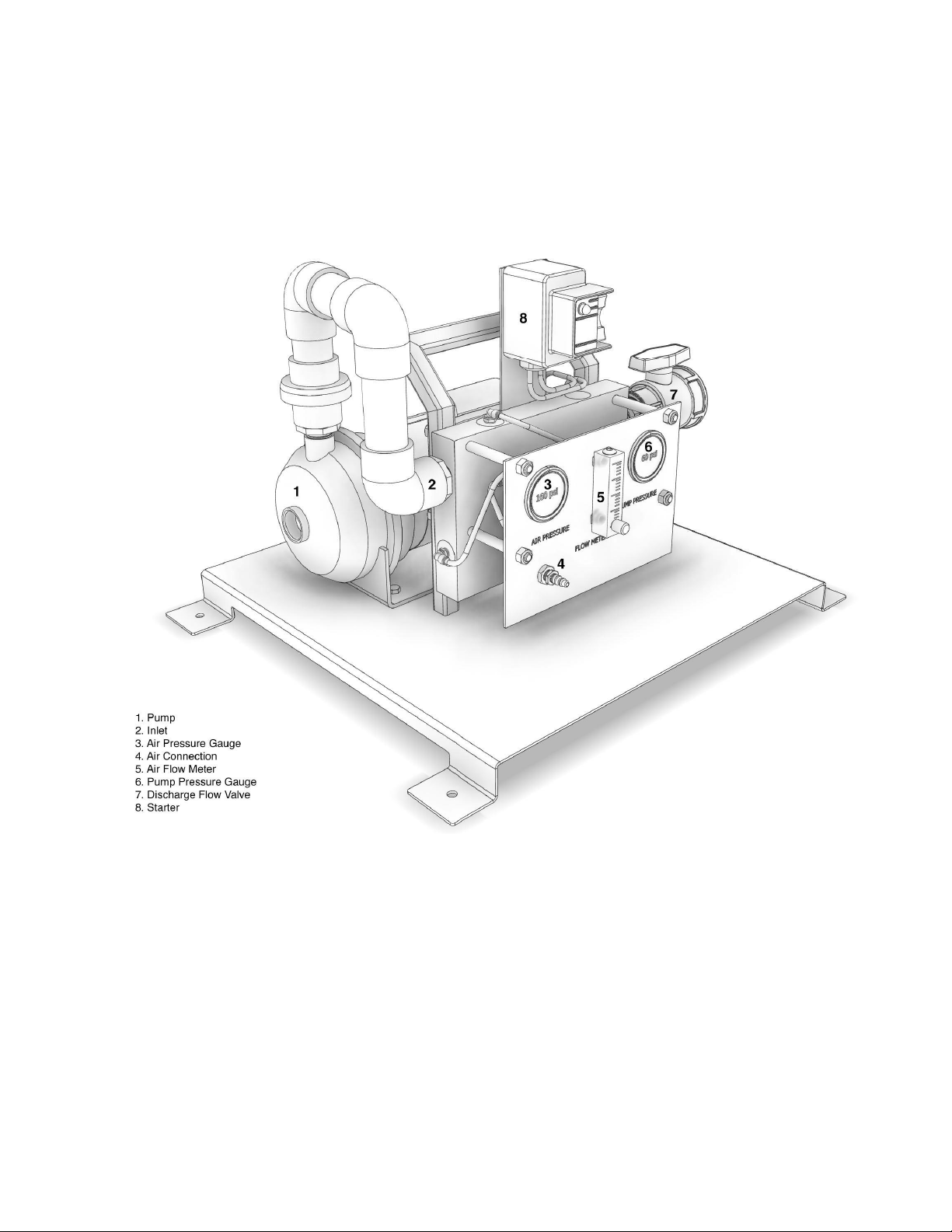

PUMP ASSEMBLY

If removed, replace the motor shaft deflector. Install the motor adapter, with the drain opening DOWN, using the four hex bolts.

Torque bolts to 168 lbs. in. (19 N m). Slide the seal housing assembly onto the motor shaft, seating it fully and squarely against

the motor adapter.

Using a quality grade O-ring lubricant, lubricate the outer elastomer of the mechanical seal stationary seat. Fully and squarely

install the stationary seat into the seal housing. With a clean, lint-free cloth, CAREFULLY wipe off excess lubricant or debris. DO

NOT damage the seat face.

Using a quality grade O-ring lubricant, lubricate the inner elastomer of the mechanical seal rotary assembly. Fully and squarely

install the rotary assembly against the stationary seat.

To install impeller, clean shaft and impeller thoroughly with denatured alcohol and a wire brush to remove cured Loctite from

threads. Wait for parts to dry and then apply Loctite 7649 primer to threads on shaft and impeller. Allow 3-5 minutes for primer

to dry. Apply 3 drops of Loctite 243 medium strength thread-locker to shaft threads and 2 drops on impeller threads. Tighten

impeller to a torque value of 144 lbs. in. (16 N m).

Using a quality grade O-ring lubricant, lubricate and install a new casing O-ring and internal O-ring (1SN only). Slide the back pull-

out assembly into the pump casing and secure using the eight casing cap screws. Torque the cap screws to 70 lbs. in. (8 N m),

using a cross pattern sequence to assure the casing is pulled down evenly. With new O-rings installed, install the casing vent and

drain plugs, tightening securely. Assembly is complete.

14 CLEANING & SANITIZING THE XTB NANOBUBBLE GENERATOR

In normal operation, the internal elements of the XTB generator can become fouled by mineral scale, biological matter, colloidal

particles and insoluble organic constituents. Deposits can build up on the surfaces during operation until they cause diminished

operation. Best practices include routine preventative cleaning with acid and alkali chemicals. In some instances, if large solids

are allowed to pass into the generator, blockages can occur.

15 GENERAL CHEMICAL CLEANING PROCEDURES

1. Prepare the cleaning solution

2. Introduce the cleaning solution

3. Recycle

4. Soak

5. Conduct high-flow pumping

6. Flush out

7. Restart

SAFETY PRECAUTIONS

•Maximum temperature 100o C or 212oF

•pH tolerance range 2-14

•Each cleaning situation is different; therefore, specific cleaning recommendations are dependent on the type of foulant.

Consult the general cleaning instructions for information that is common to all types of cleaning such as suggested

equipment, pH and temperature limits, and recommended flow rates; then apply the specific recommendation as

needed.