SERVICE

REFRIGERATION - MEDIUM TEMP

“REFRIGERATION DIFFERENTIAL” MODE

1. Hold down the “set” button (#2) for at least

five seconds until flashing “ PS” is shown.

Press the “ up arrow” button (#1) to reach the

flashing “rd” and press the “set” button (#2)

once. Make sure that this is set to “5.0”, this

your refrigeration differential.

2. If an adjustment needs to be made to the set

temperature, use the “up arrow” button (#1)

or the “down arrow” button (#3) to adjust the

temperature. Press the “set” button (#2) to

save your adjustment. Doing this will send

you back to the menu showing a flashing

“rd”.

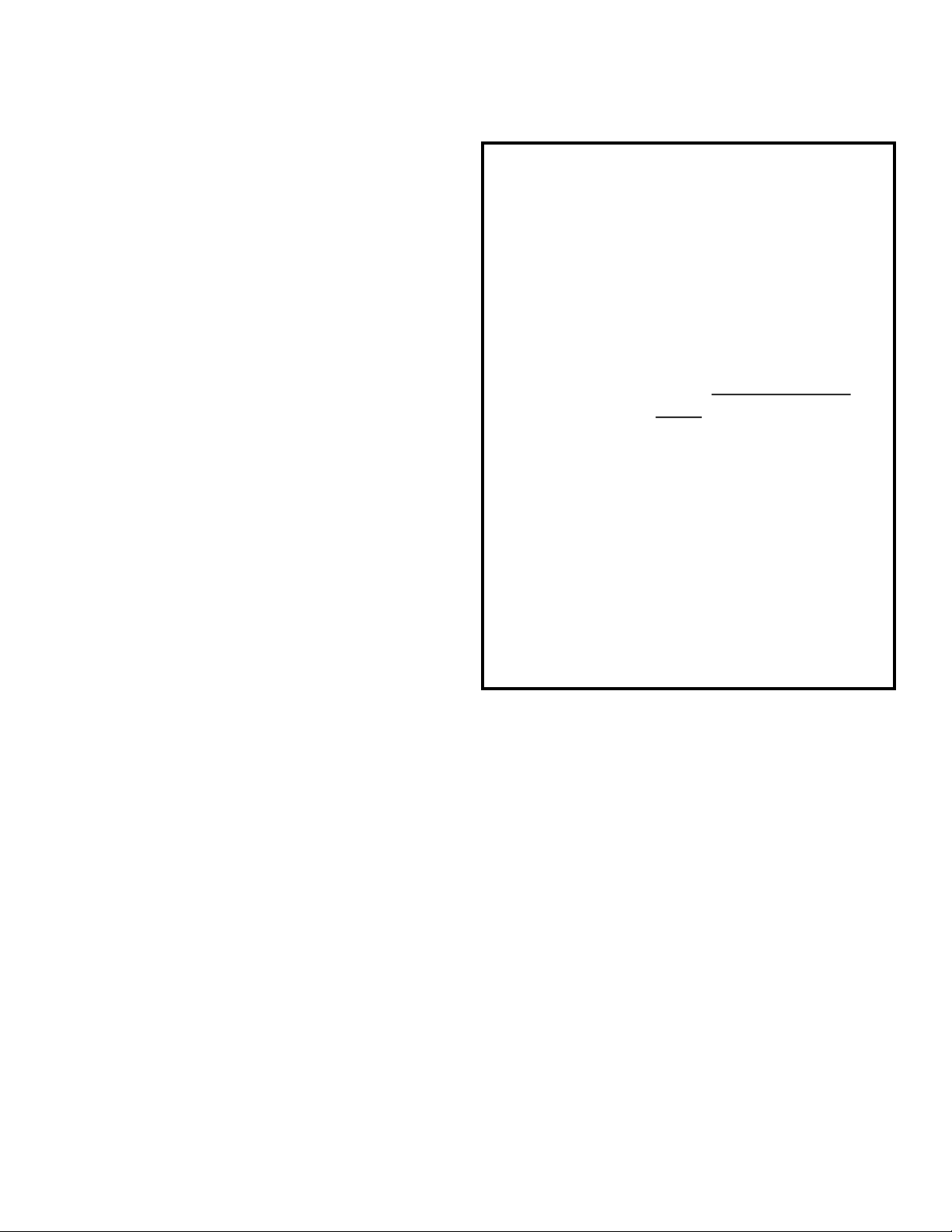

“DEFROST INTERVAL” MODE

1. Press the “up arrow” button (#1) to display

the “dI” parameter as shown and press the

“set” button (#2) once. Make sure that

this is set to “2” , this is equivalent to how

often the unit will begin defrost mode (every

2 hours).

2. If an adjustment needs to be made use the

“up arrow” button (#1) or the “down arrow”

button (#3) to adjust the hour. Press the “set”

button (#2) to save your adjustment. Doing this

will send you back to the hidden menu showing

a flashing “dI”.

“DEFROST PERIOD” MODE

1. Press the “up arrow” button (#1) to display

the “dp” parameter as shown and press the

“set” button (#2) once. Make sure that

this is set to “10”, this is equivalent to how

long the unit will be in defrost mode (10

minutes).

2. If an adjustment needs to be made use the

“up arrow” button (#1) or the “down

arrow” button (#3) to adjust the hour.

Press and hold the “set” button (#2) to save

your adjustment. Doing this will send you

back to operational mode.

“OFF” MODE

1. If for any reason your digital thermostat is

displaying a flashing “Temperature/Off” your

digital thermostat is in “Off” mode. To return

to the “On” mode, press and hold the

5