Blitzer Assembly Manual

Page 6of 21

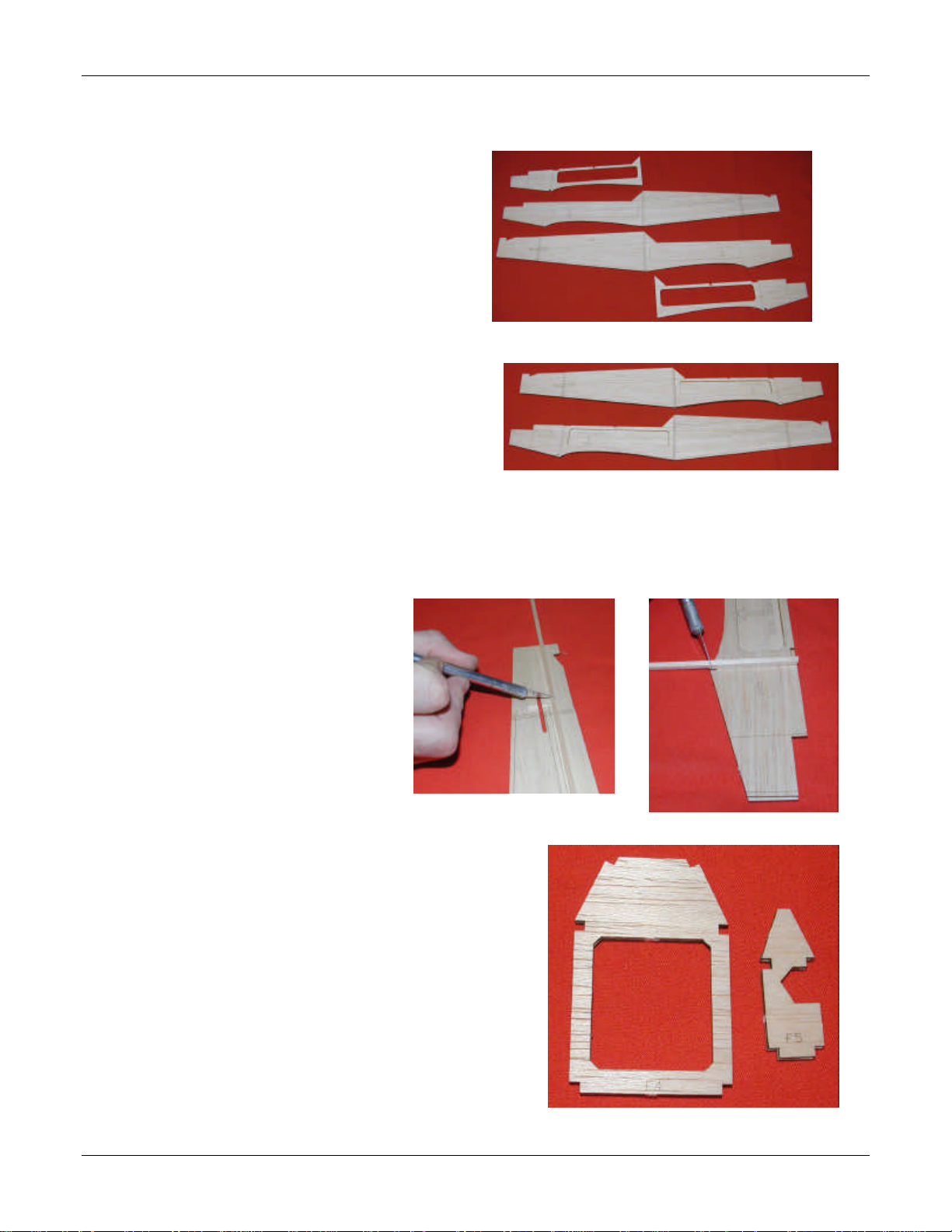

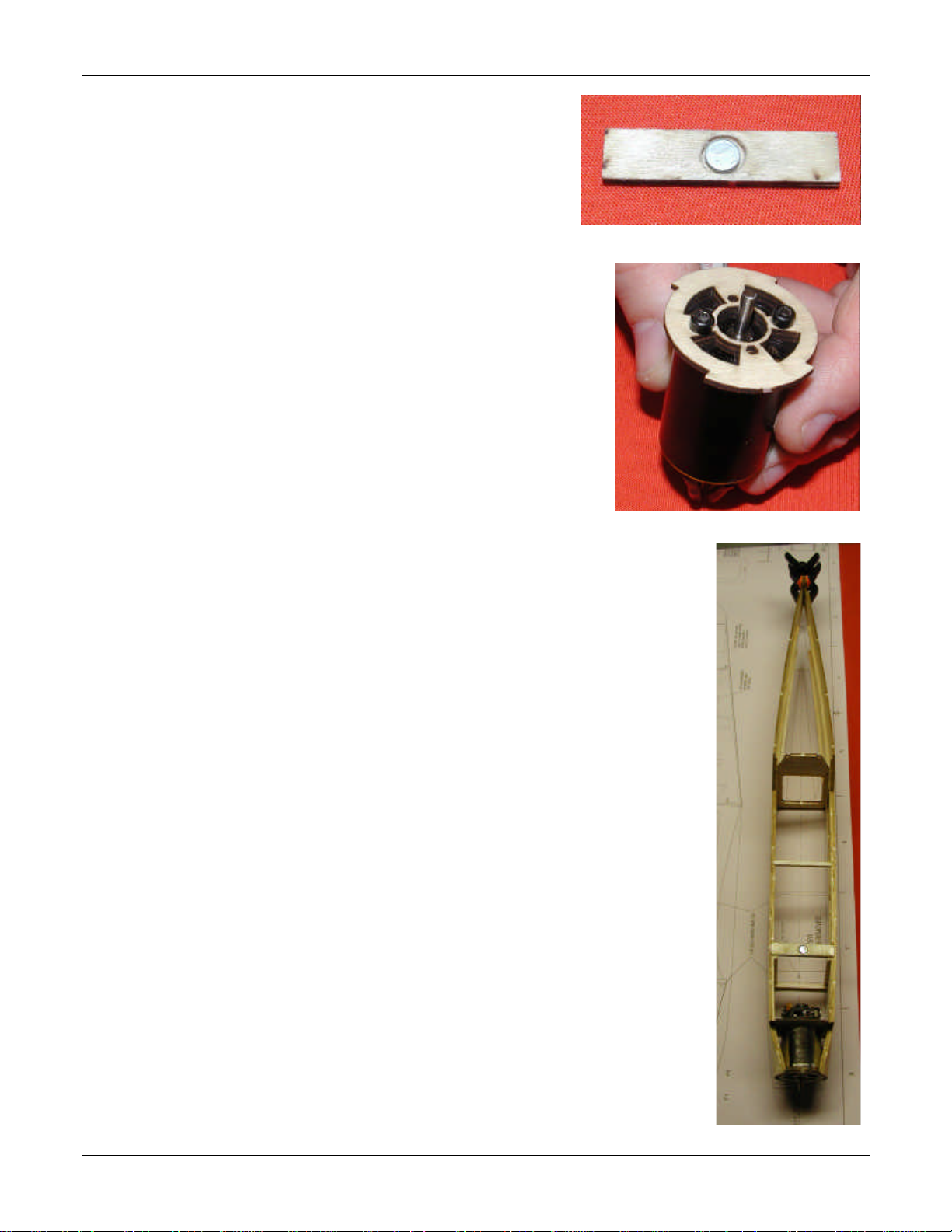

Photo 9

Photo 13

Photo 14

12)Several plywood parts get laminated together during the

course of building the model. Now is as good a time as any

to laminate them all. You may use either epoxy or medium

CA to glue them together. If you use CA, you may need to

use accelerator to cure it as it doesn’t always bond well in

plywood.

Laminate the ply hatch hold downs together, using the edges

to provide proper alignment. Glue in one of the magnets.

The last item to laminate is the firewall. Before you begin, trial

fit these two parts. They are made so that they fit the motor very

tightly, and the differences from cut-to-cut with the laser may

make for slight differences in size.

You can ensure proper alignment by using the motor to line up

the screw and bearing holes. Take care that you don’t glue the

motor in – it’s not easy to get it unglued.

Place the circular firewall doubler (ply, with small “ears”) on the

motor. Apply a thin coat of medium CA. Place the larger main

firewall in place, and screw it down to the motor. This will

ensure perfect alignment. Refer to Photo 13.

Remove the motor from the firewall after the glue has cured.

13) Glue the hatch hold down assembly into the fuselage. This will help to solidify

the fuselage somewhat.

14) Pull the fuselage tail together. Verify that you do not introduce a twist to the

fuselage as you do this, and glue in place with thin CA. Use a clamp as shown

in Photo 14, using the top view on the plans to verify straightness.

15) Insert former F5 at the place noted on the fuselage sides. Make sure that you

have the notch in the side of the former on the left side so as to provide an area

for the elevator pushrod to exit later. When you are sure of alignment, use thin

CA to glue it in place.

If you are building your Blitzer for rudder and elevator, the former will be

opened in a later step to make clearance for the rudder pushrod.

16) Use some 1/16” scrap balsa across the front and rear of the servo tray to

beef it up a little. Install the servo tray immediately behind F4 on the

top of the rails extending to the back. BE CAREFUL NOT TO GLUE

THE SERVO TRAY TO THE SIDES, ONLY TO THE RAILS!

17) The firewall will now be mounted in place. If you were careful in

earlier steps, the correct right thrust angle will be automatic. It should

be about 2 degrees. F3 will set the angle properly for you.

It helps a lot to have an extra set of hands at this point. One person should

hold the balsa around the firewall while the other glues it in.