Thishomestandbygeneratingsetisinherentlyprotectedby

designagainstdamagetothegenerator,transferswitchandfeeder

conductors(ifproperlysized).Ifa shortcircuitorlargeoverload

occurs,generatoroutputdropstozeroandnodamageresults.

GROUNDING

WARNING Failuretogroundthegeneratingsetcould

resultinseriouselectricalshock.

Connecta #8wireorlarger(followingapplicable

codes)between:

1.

A separategroundpipeorrodpenetratinginto

moistearth,and

2.

thesolderlessconnectorwhichislocatedontop

ofthegeneratorfortheremotestartmodelsand

onthestart-stopcontrolboxfortheelectricstart

models.

WARNING ^TheNationalElectricalCode(NEC)requires

thatallseparatelyderivedACsystemsbe

groundedperArticle250-26.Manufacturerhasaddeda bonding

jumperperarticle250-26(a)fromthenoncurrentcarryingmetal

partstotheconductortobegrounded.Manufacturerdoesnot

supplytherequiredgroundingconductororgroundingelectrode

becauseitwouldbeimpossibletocovereveryexceptionandall

localcoderequirements.SeeyourlocalcodesandtheNECman-

ualforthepropergroundingforyourapplication.

Asa generalrule,donotuseelectricalequipmentinwetordamp

areas.

Forconstructionsites,additionalrulesapplytoportable

alternatorswhenusedonconstructionsites,fromNEC,OSHAand

statecodes.Itistheresponsibilityoftheconsumertomeetthese

requirements.

GASOLINE

TANK,

HOLDER

AND

HOOD

Instructionsforinstallationandconnectionsforgaseousfuelare

includedwiththegaseousfuelpackage.

Theremotestartgas-gasolinemodelincludesagaso-

linetankbracketandtankhoodformountingthe

gasolinetankontherearofthecompartment.Usethe

followinginstructions.

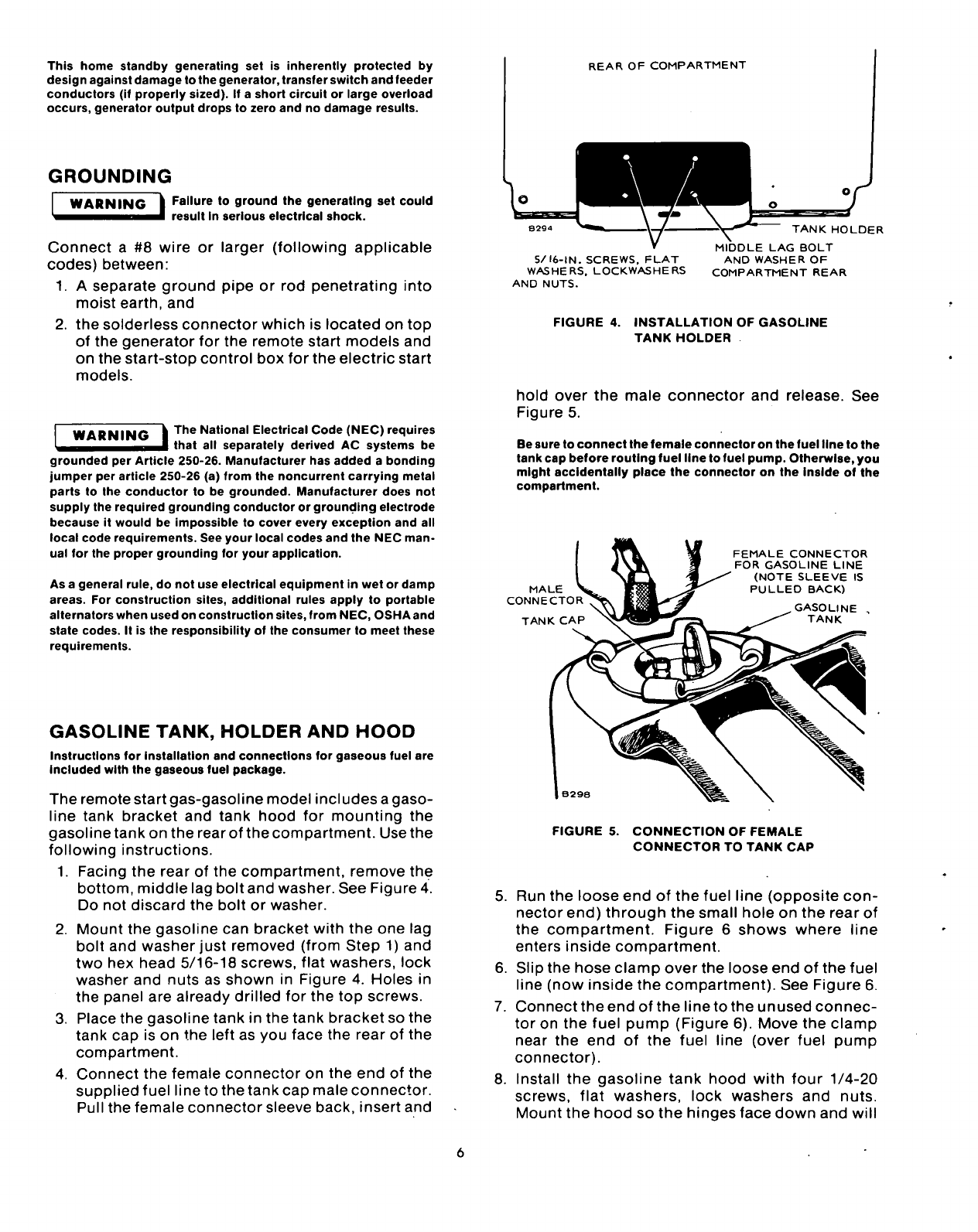

1.

Facingtherearofthecompartment,removethe

bottom,

middlelagboltandwasher.SeeFigure4.

Donotdiscardtheboltorwasher.

2.

Mountthegasolinecanbracketwiththeonelag

boltandwasherjustremoved(fromStep1)and

twohexhead5/16-18screws,flatwashers,lock

washerandnutsasshowninFigure4.Holesin

thepanelarealreadydrilledforthetopscrews.

3.Placethegasolinetankinthetankbracketsothe

tankcapisontheleftasyoufacetherearofthe

compartment.

4.

Connectthefemaleconnectorontheendofthe

suppliedfuellinetothetankcapmaleconnector.

Pullthefemaleconnectorsleeveback,insertand

TANKHOLDER

5/I6-IN.

SCREWS,FLAT

WASHERS.LOCKWASHERS

ANDNUTS.

MIDDLELAGBOLT

ANDWASHEROF

COMPARTMENTREAR

FIGURE4.INSTALLATIONOFGASOLINE

TANKHOLDER

holdoverthemaleconnectorandrelease.See

Figure5.

Besuretoconnectthefemaleconnectoronthefuellinetothe

tankcapbeforeroutingfuellinetofuelpump.Otherwise,you

mightaccidentallyplacetheconnectorontheinsideofthe

compartment.

FEMALECONNECTOR

FORGASOLINELINE

(NOTESLEEVEIS

MALESt.PULLEDBACK)

CONNECTOR

TANKCAP

5.

6.

7.

8.

FIGURE5. CONNECTIONOFFEMALE

CONNECTORTOTANKCAP

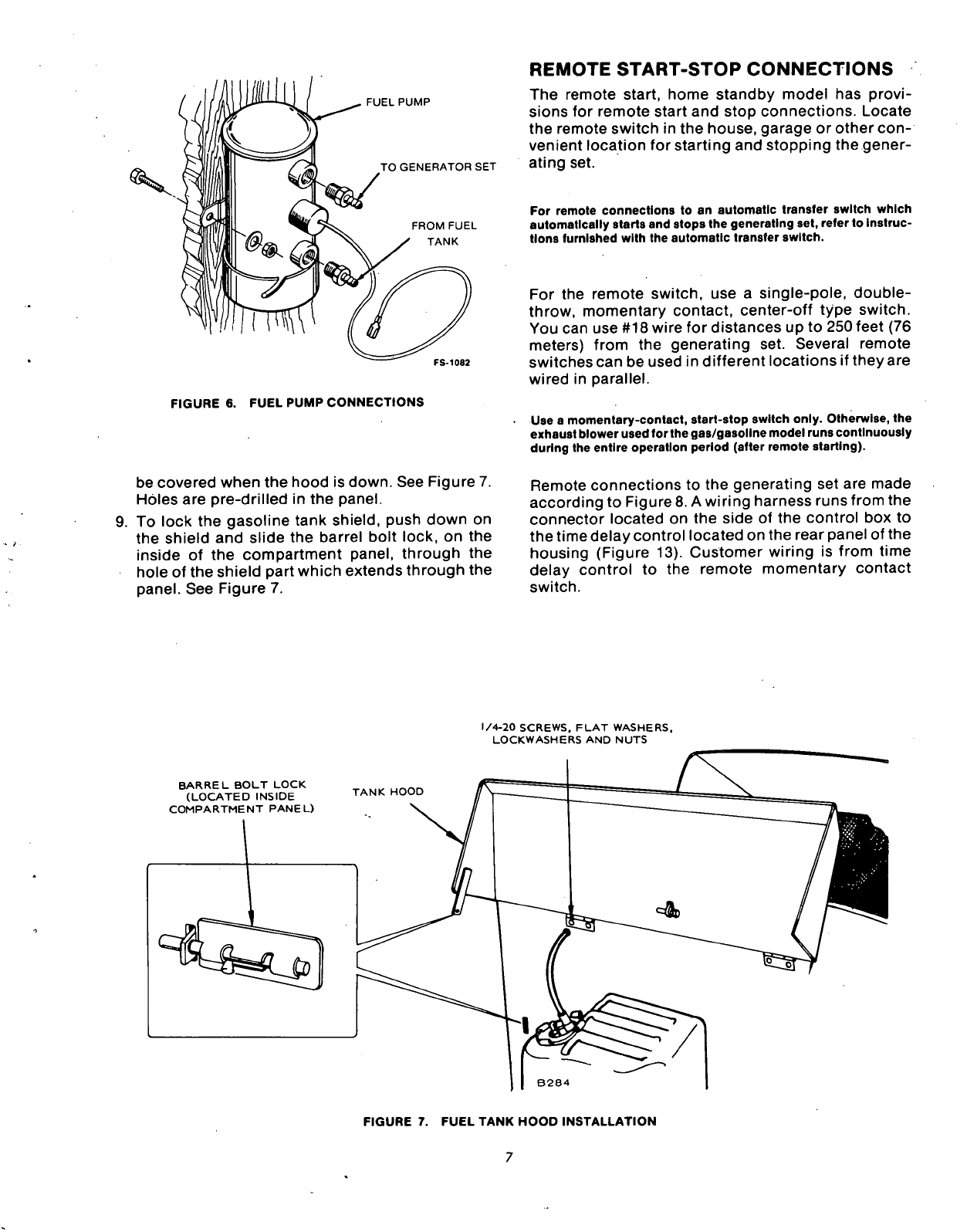

Runthelooseendofthefuelline(opposite

con-

nectorend)throughthesmallholeontherearof

thecompartment.Figure6 showswhereline

entersinsidecompartment.

Slipthehoseclampoverthelooseendofthefuel

line(nowinsidethecompartment).SeeFigure6.

Connecttheendofthelinetotheunusedconnec-

toronthefuelpump(Figure6).Movetheclamp

neartheendofthefuelline(overfuelpump

connector).

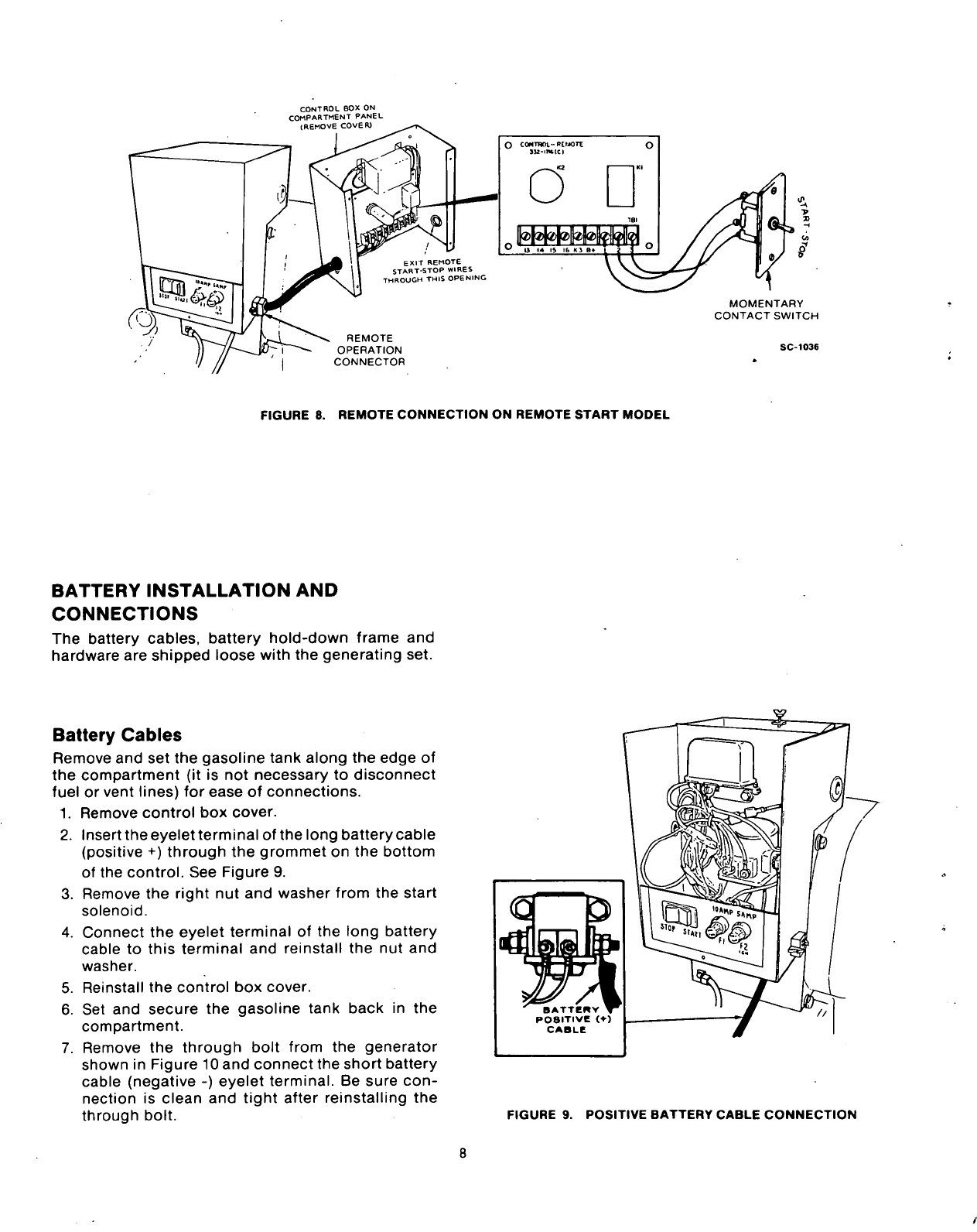

Installthegasolinetankhoodwithfour

1/4-20

screws,flatwashers,lockwashersandnuts.

Mountthehoodsothehingesfacedownandwill