Page 2 Part No. XG0512

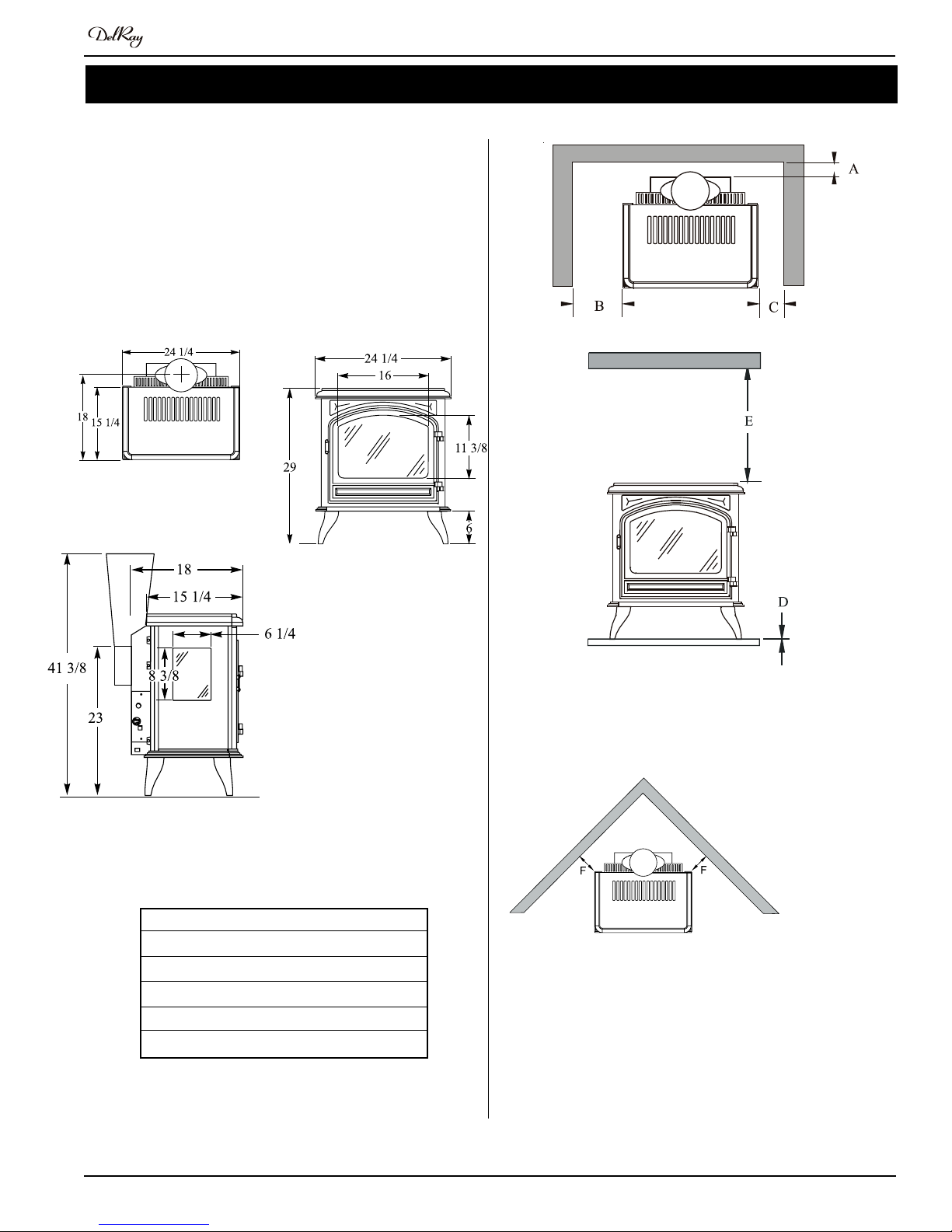

Rio DX Cast Stove

Introduction

About this Stove:

Thank you for purchasing the Rio DX Cast Stove, and choosing a

Delray Gas Product. This Rio Stove features a 28,000 BTU double

burner with embers, and a hi-lo adjustable control. .

This Stove is certified for use with Montigo Direct Vent Components.

The Rio DX Stove is certified as a heating appliance by CGA and

AGA tothe Vented Gas Fireplace Heater standard (ANSI Z21.88-

2005 · CGA 2.33-2005) and is rated for:

Natural Gas 28,000 BTU/H Maximum Input

20,500 BTU/H Minimum Input

Propane 28,000 BTU/H Maximum Input

20,500 BTU/H Minimum Input

How to use this manual:

This manual covers installation, operation and maintenance. Light-

ing, operation and care of this fireplace can be easily performed by

the homeowner. However, all installation and service work should be

performed by a qualified or licensed installer, plumber, or gasfitter

who is qualified or licensed by the state, province, region, or govern-

ing body in which the appliance is being installed.

This manual covers all versions. Sections which are specific to a

particular version are marked with a symbol, plus the appropriate

model number.

Warranty and Installation Information:

The Montigo warranty will be voided by, and Montigo disclaims any

responsibility for, the following actions:

Modification of the fireplace and/or components including Direct-

Vent assembly or glass doors.

Use of any component part not manufactured or approved by

Montigo in combination with this Montigo fireplace system.

Installation other than as instructed in this manual.

Consult your local Gas Inspection Branch on installation require-

ments for factory-built gas fireplaces. Installation & repairs should be

done by a qualified contractor.

Installations in Canada must conform to the current CAN/CGA

B-149.1 and .2 Gas Installation Code and local regulations. If the

optional air-circulating fan kit is installed, it must be electrically

grounded in accordance with CSA C22.1 Canadian Electrical Code

Part 1 and/or Local Codes.

Installations in the USA must conform to local codes, or in the

absense of local codes to the National Fuel Gas Code, ANSI

Z223.1-1988. If the optional air-circulating fan is installed, it must be

grounded in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70-1987. See

Appendix A for replace installations within the State of Mas-

sachusetts.

Table Of Contents

Introduction............................................................................... 2

Installation

Choosing a Location ...................................................... 3

Installing the Gasline...................................................... 4

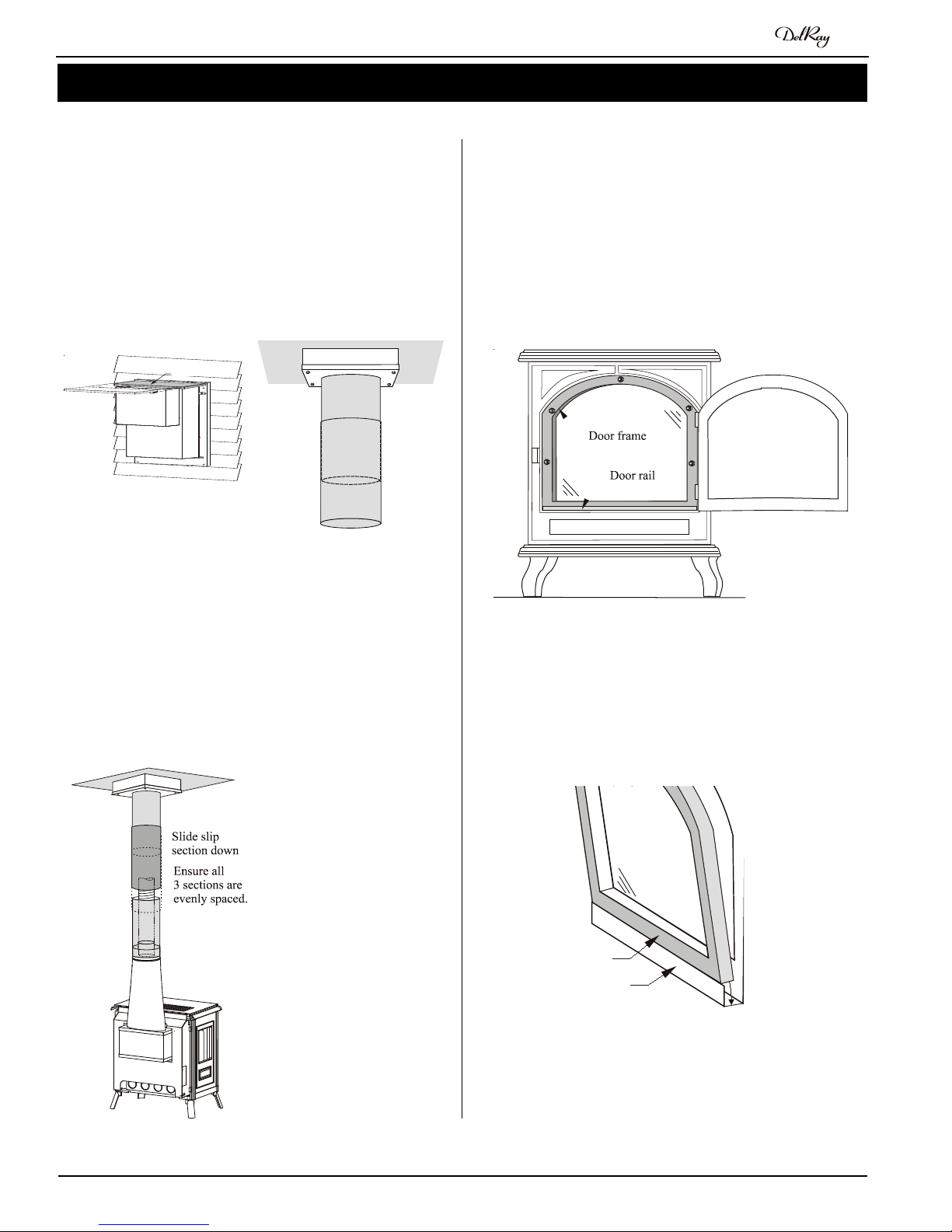

Direct Vent Installation ................................................... 4

General Requirements ...................................... 4

Terminations ...................................................... 4

Horizontal(Top Vent Through-the-Wall) Installations6

Vertical (Top Vent Through-the-Roof) Installations. 7

Removing and Installing the Door.................................. 8

Installing the Logset ....................................................... 9

Wiring ........................................................................... 9

Operation..........................................................................10 - 12

Maintenance.....................................................................12 - 13

Warranty.................................................................................. 14

Appendix

A. Termination Locations.............................................. 15

B. Accessories and Vent Components..................16 - 17

CAUTIONS

Due to its high operating temperatures, the appliance

should be located out of traffic & away from furniture and

draperies.

Children and adults should be alerted to the hazards

of the high surface temperature, which could cause

burns or clothing ignition.

Young children should be carefully supervised when

they are in the same room as the appliance.

Clothing or other flammable materials should not be

placed on or near the appliance.