Moog G122-829A001 Supplement

1 Scope

These Application Notes are a guide to applying the

G122-829A001 P-IServoamplifier. These Application Notes

can be used to:

Determine the closed loop structure for your application.

Select the G122-829A001 for your application. Refer also

to data sheet G122-829.

Use these Application Notes to determine your system

configuration.

Draw your wiring diagram.

Install and commission your system.

Aspects, such as hydraulic design, actuator selection, feedback

transducer selection, performance estimation, etc. are not

covered by these Application Notes. The G122-202 Application

Notes (part no C31015) cover some of these aspects. Moog

Application Engineers can provide more detailed assistance,

if required.

2 Description

The G122-829A001 is a general purpose, user configurable,

P-Iservoamplifier. Selector switches inside the amplifier enable

either proportional control, integral control, or both to be

selected. Many aspects of the amplifier’s characteristics can

be adjusted with front panel pots or selected with internal

switches. This enables one amplifier to be used in many

different applications. Refer also to data sheet G122-829.

3 Installation

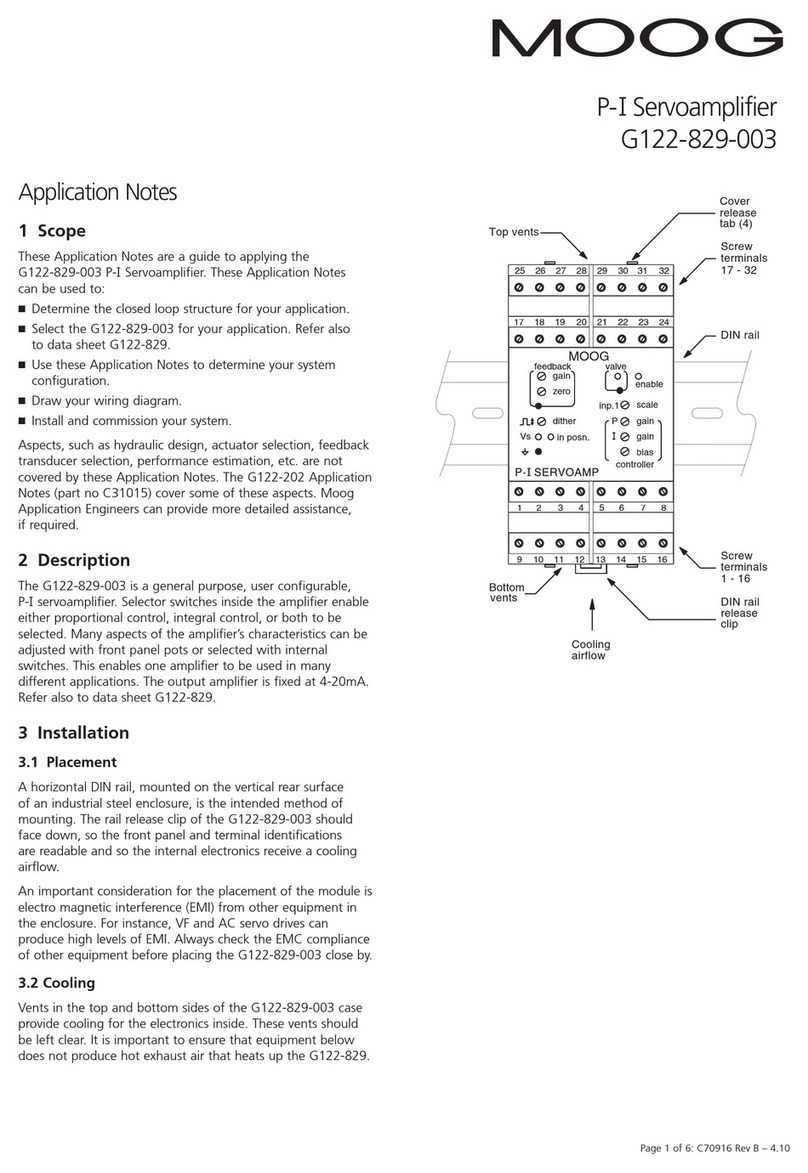

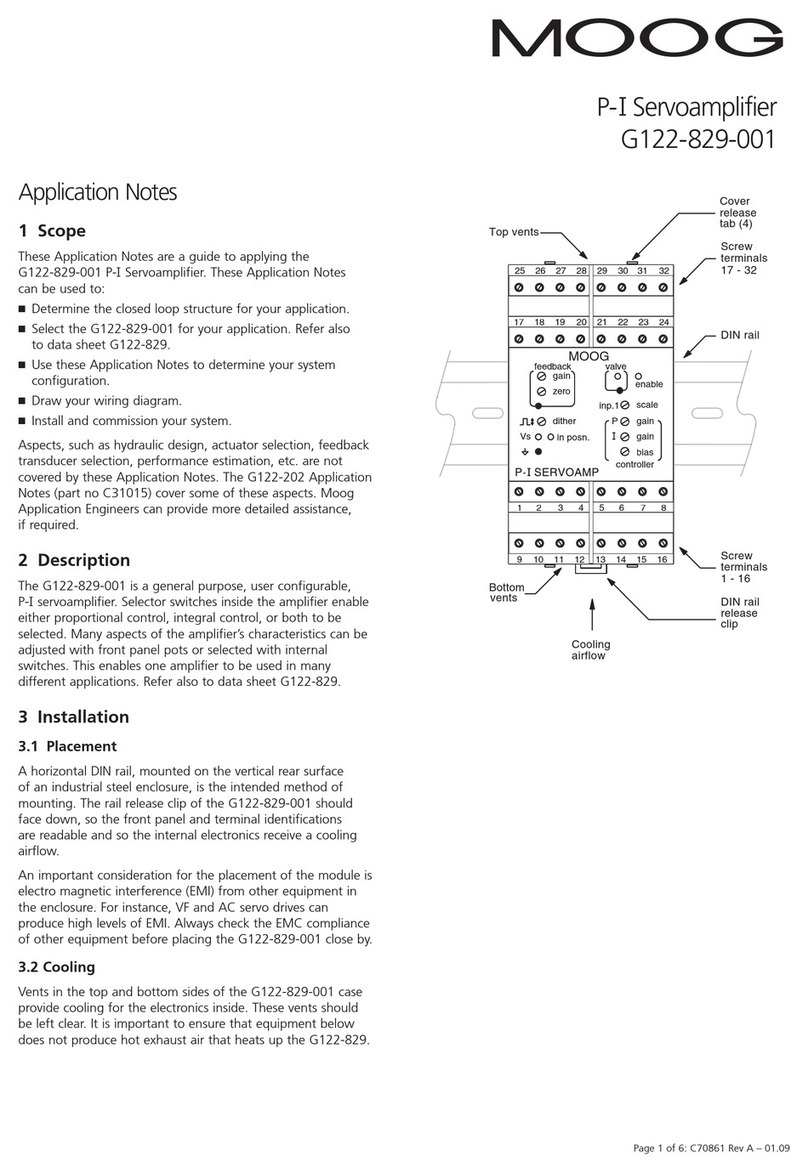

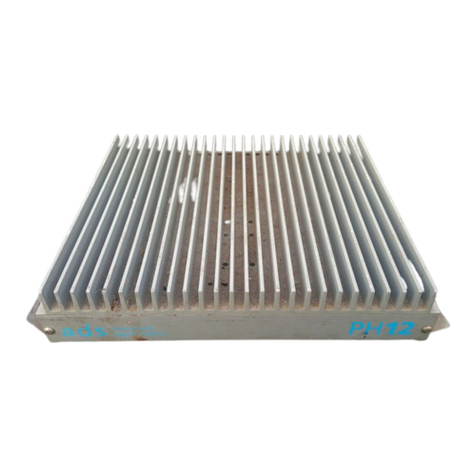

3.1 Placement

A horizontal DIN rail, mounted on the vertical rear surface

of an industrial steel enclosure, is the intended method of

mounting. The rail release clip of the G122-829A001 should

face down, so the front panel and terminal identifications

are readable and so the internal electronics receive a cooling

airflow.

An important consideration for the placement of the module

is electro magnetic interference (EMI) from other equipment

in the enclosure. For instance, VF and AC servo drives

can produce high levels of EMI. Always check the

EMC compliance of other equipment before placing

the G122-829A001 close by.

3.2 Cooling

Vents in the top and bottom sides of the G122-829A001 case

provide cooling for the electronics inside. These vents should

be left clear. It is important to ensure that equipment below

does not produce hot exhaust air that heats up the G122-829.

P-IServoamplifier

G122-829A001

MOOG

1

2

34

9101112

56

7

8

13 14 15 16

32313029

24

2

3

2221

28272625

20191

8

17

f

eedback

valve

e

n

ab

l

e

dither

V

s

in posn.

P

I

inp.1

sca

l

e

g

ai

n

g

ai

n

b

i

as

c

ontroll

er

gain

zero

Bottom

vents

Cooling

airflow

release

Screw

terminals

Top vents

Screw

terminals

DIN r

a

i

l

17 - 32

1 - 16

clip

Cover

release

tab (4)

DIN rail

Application Notes

Page 1 of 6: C70861 Rev E – 07.14

3.3 Wiring

The use of crimp “boot lace ferrules” is recommended for the

screw terminals. Allow sufficient cable length so the circuit

card can be withdrawn from its case with the wires still

connected. This enables switch changes on the circuit card

to be made while the card is still connected and operating.

An extra 100mm, for cables going outside the enclosure,

as well as wires connecting to adjacent DIN rail units,

is adequate.

The screw terminals will accommodate wire sizes from

0.2mm2to 2.5mm2(24AWG to 12AWG). One Amp rated,

0.2mm2should be adequate for all applications.

cablegland

100mmLoop

WiresEnclosure

Radial screen

termination

Cable

Grounded EMI

Preferred Wiring

Page 2 of 6: C70861 Rev E – 07.14

Cablegland

100mmLoop

CableEnclosure

Cable

Wire soldered

to screen

Drainwire.

or

(Heat shrink to

coverthe screen)

Alternative Wiring

3.4 EMC

The G122-829A001 emits radiation well below the level called

for in its CE mark test. Therefore, no special precautions are

required for suppression of emissions. However, immunity from

external interfering radiation is dependent on careful wiring

techniques. The accepted method is to use screened cables for

all connections and to radially terminate the cable screens, in

an appropriate grounded cable gland, at the point of entry into

the industrial steel enclosure. If this is not possible, chassis

ground screw terminals are provided on the G122-829A001.

Exposed wires should be kept to a minimum length. Connect

the screens at both ends of the cable to chassis ground.

4 Power supply

24V DC nominal, 22 to 28V

75mA @ 24V without a load, 200mA @ 100mA load.

If an unregulated supply is used the bottom of the ripple

waveform is not to fall below 22V.

It is recommended that an M205, 250mA T (slow blow) fuse,

compliant with IEC127-2 sheet 3, be placed in series with the

+24V input to protect the electronic circuit. If terminal 23 is

used to power a proportional valve, the fuse should be

increased to cater for the extra current.

To access the circuit card switches, the circuit card must be

withdrawn from the case. See paragraph 17.

5 Set-up adjustments

Trimpots are all 15 turns.

Plug-in resistors are all “quarter watt” 1% metal film. Two

suitable types are Beyschlag MBB0207 and Roderstein

MK20207.

The amplifier is shipped in the following default state.

top board switches

SW1 1 5mA off

2 10mA off

3 20mA off

4 30mA off

5 50mA on

SW2 OUT I

SW3 STEP not applicable

SW4 1 P-E E

2 CMD LAG off

SW5 1-4 IN 2 V

SW6 1 Pin 8 on

2 PR on

3 ILim off

4 INT off

SW7 1-2 4-20mA out off

bottom board switch, shown as [ ]

[SW1] 1 spare off

2 ENABLE on

3 DITHER off

4 4-20mA (fdbk) on

R27: 10k (summing amp gain = 1)

R17: 100k (P gain range 1 to 20)

R34: 100k (input 2 to error amp)

R33: not fitted (input 3 to output amp)

R16: not fitted (feedback derivative)

Feedback gain and zero pots: configured for 4-20mA input

Dither level pot: fully counter clockwise (FCCW)

Scale pot: FCCW

P gain pot: FCCW

I gain pot: FCCW

Bias pot: 0V

ON

shown in on position

shown in off position

SW1 and 6 switch positions

6.2 Input 1

An input to the error amplifier: This input is ±10V

non-inverting and has two important features:

It has a scale pot on its input that enables large inputs to be

scaled down to match smaller signals on other inputs. Scale

range is 10 to 100%. Set fully clockwise (FCW), an input of

100V can match a 10V signal on the other inputs. Note that

the maximum permissable input voltage is ±95V.

It has a switch selectable (SW4:2) lag of 55mS that can be

used to remove transients from the input signal that could

cause unwanted rapid movement in the output.

Input 1 is well suited to be a command because of these two

features. If input 1 is used for feedback, be sure the lag is

switched off. Input resistance after the scale pot is 94k Ohms.

6.3 Input 2

An input to the error amplifier: This input is differential, with

non-inverting and inverting inputs. It is switch selectable (SW5)

between 4-20mA and ±10V. The 4-20mA converter produces

0 to +10V for 4 to 20mA input to terminal 7. R34 connects

from the output of the amplifier to the input of the error amp.

It is a plug-in resistor with a default value of 100k Ohms,

giving a nominal ±10V input signal range when V is selected.

Input 2 is suitable for command or feedback. R34 can be

increased to give a larger input range.

Terminal 8, the inverting input, can be connected to ground

with SW6:1.

6.4 Input 3

An input to the output summing and limiting amplifier via a

plug-in resistor, R33. A typical use for this input is command

feed forward or closing the outer loop of a three stage valve.

With R33 at 10k Ohm, a ±10V input will produce ±100% valve

drive. Increasing R33 reduces the valve drive.

The summing amp gain can be changed with plug-in resistor

R27. This is useful if input 3 is being used to close the outer

loop of a three stage valve.

7 Output configuration

Select the output to match the input requirements of the valve

(SW2).

When voltage (V) is selected, ±10V is available into a

minimum load of 200 Ohm.

When current (I) is selected, the current level switches

(SW1:X) enable ±5 to ±100mA to be selected. The switch

selections sum, so, if for instance 45mA is required, select

30,10 and 5. The output can drive all known Moog valves

up to ±100mA. The maximum load at I(Amp) output is:

RL max = 11V – 39 Ohm

I(Amp)

eg. at 50mA RL max is 181 Ohm

When 4-20mA is selected, the output V/I switches must be

in I and the output current SW1 must have switch 3 selected

for 20mA. Maximum load for 4-20mA output is 500 Ohm.

The output amplifier is limited to approximately 105% of the

selected full scale output. If both the proportional and

integrator stages are saturated, the output will not be twice

the selected full scale but still only 105% of full scale.

8 Step push button

The step push button (SW3) injects -50% valve drive

disturbance into the output. When released, the valve drive

reverts to its original level. This feature is useful for closed loop

gain optimisation.

Page 3 of 6: C70861 Rev E – 07.14

Caution

If you intend to use the feedback amplifier adjusted for

4-20mA, don’t change the feedback gain or zero.

They are already adjusted for 4-20mA

To re-adjust for 4-20mA takes a little time, needs test

equipment and is tedious to do in the field.

6 Input configuration

Inputs 1, 2 and feedback go to the error amplifier and can be

used for feedback or command. Care needs to be taken in

selecting signal polarity to achieve negative feedback for

the overall closed loop. Since the input error amplifier sums

the signals, the transducer feedback signal needs to be the

opposite polarity of the command. This can be achieved in

two ways:

Arrange for an opposite polarity feedback transducer signal

and connect it to input 1, input 2 or the positive feedback

amplifier input.

If the feedback transducer signal is the same polarity as the

command, you only have one option: Connect it to the

negative input of the feedback amplifier.

6.1 Feedback input

An input to the error amplifier: The feedback amplifier is the

best choice for the feedback signal, for six reasons:

It leaves input 1 available for command. See 6.2 below.

It has inverting (negative) and non-inverting (positive) inputs.

It has zero and gain adjustment pots. This enables a signal

that does not go to zero volts and has less span than the

command, to be scaled up to the command. While this is

not essential, it helps when setting up and trouble-shooting.

There is a front panel test point for the zeroed and amplified

signal. This is very convenient (essential) for setting up and

trouble-shooting.

There is the option of a plug-in resistor, R16, to give a

feedback

derivative (lead or D) in the output of the feedback

amplifier.

It can be set up for a current input by connecting a 240 Ohm

resistor between terminals 17 and 18 with the 4-20mA

switch ([SW1:4])

.

Default

The feedback amplifier default set-up is 4-20mA flowing into

terminal 18 and out of terminal 17, producing an output of

0 to -10V. Reversing the terminals, and hence the current flow,

will not result in a 0 to +10V output. The feedback zero must

be adjusted for this arrangement.

Adjusting feedback amp for 4-20mA input and

0 to -10V output

Set the feedback gain to minimum (fully counter clockwise).

The trimpot has 15 turns and will click when minimum is

reached.

Connect terminal 17 to terminal 26 (ground).

Connect the positive of a variable DC power supply to

terminal 18 and the negative to terminal 26.

Connect a digital multimeter (DMM), on DC Volts, between

the front panel feedback amp and ground test points.

Set the variable supply to 0.96V.

Adjust the feedback amp zero trimpot until the DMM reads

0.00V.

Set the variable supply to 4.80V.

Adjust the feedback gain trimpot until the DMM reads

-10.00V.

Set the variable supply to 0.96V again and check the

feedback test point is still 0.00V. Trim if necessary and check

the 4.80V setting again.

( )

9 P-Iselection

For position closed loops, initially select only P (SW6:2). For

pressure or velocity loops select I(SW6:4) initially and then P.

See paragraph 12 below for more detail. For a complete

discussion of P and Icontrol, see the G122-202 servoamplifier

Application Notes (part no C31015).

10 Integrator input

The servoamplifier has a unity gain input error amplifier

followed by two parallel stages, one a proportional amplifier

and the other an integrator. The outputs of these two stages

can be switched to the output power amplifier (see paragraph

7 above) which then drives the valve.

The input to the integrator stage can be switch selected

(SW4:1) from either the output of the error amplifier, Iin = E,

or the output of the proportional stage, Iin = P. The latter

arrangement is used in the G122-202. It is beyond the scope

of these Application Notes to detail the benefits of each

arrangement. If you have experience with the G122-202,

Iin = P would seem to be an easy choice.

11 P only gain

For position loops select only P control (SW6:2). Input a step

disturbance of 50% valve current with the step push button

(SW3). Adjust the P gain for the required stability, while

monitoring the front panel valve test point, or the feedback

signal. The gain range of the proportional amplifier can be

moved by changing the plug-in resistor R17. The value loaded

when shipped is 100k Ohms, which gives a 1 to 20 range.

Selecting 200k Ohms will give 2 to 40. The circuit will function

correctly with the value of R17 between 100k Ohms and

10M Ohms.

Note that as P gain is increased, the movement due to the step

push button decreases.

12 P and Igains together

If you are inexperienced with integral control the following

set-up method is a good starting point.

Iin = E: Initially select only I (SW6:4). Press the step push

button (SW3). Increase Igain until one overshoot in the

feedback signal is observed.

Next select P (SW6:2) and I(SW6:4) together and increase the

P gain to reduce the overshoot.

For the Iin = E arrangement the P and Isequence could be

reversed. i.e.: adjust P first, followed by I.

Iin = P: For an Iin = P arrangement, only the “P followed

by I” sequence of adjustment can be used.

For a more thorough discussion see G122-202 Application

Notes (part no C31015).

13 Ilimit

The contribution from the integrator to the output amplifier

can be reduced by selecting Ilimit on (SW6:3). When this

switch is on the integrator contribution is reduced to

approximately 15% of the level when it is off. This feature is

useful in a position loop that may require integral control to

achieve the required steady state accuracy. The limited integral

control removes valve null error when the final position is

reached. It is also useful in a pressure loop to limit overshoot,

if the valve drive saturates.

14 Dither

The dither frequency is fixed at 200Hz and the level is

adjustable with the front panel pot to ±10% of valve drive,

regardless of the type and level of valve drive selected. It can

be turned on or off with ([SW1:3]). Dither is seldom needed in

a position loop but can be beneficial in pressure or velocity

loops. Increase dither until it can just be detected in the

controlled variable, such as pressure or velocity. Dither can

compromise valve life, so it should be kept to a minimum.

15 Enable

A relay on the circuit card needs to be energised to connect

the output stage to its screw terminal and to un-clamp the

integrator. The clamp prevents integrator wind-up when the

loop is not operating. Supply 24V to the appropriate terminal

to energise the relay. The enable switch ([SW1:2]) on the circuit

card can be set to permanently energise the relay and provide

a permanent enable.

16 In position

When the valve drive signal falls below ±10% of the selected

full scale signal, the “in position” signal goes true and provides

an opto-isolated current path between the + and – terminals.

This can be connected to a PLC to initiate the next step in a

control sequence. Do not apply more than 40V to the +

terminal and ensure the load on the – terminal is less than

20mA.

The “in position” signal is not relevant for a velocity loop.

17 Withdrawing the circuit card

from its case

The circuit card needs to be withdrawn from its case to set the

selector switches, change the plug-in resistors and operate the

step push button.

To do this, push one cover release tab with a pen or

screwdriver, while gently pulling on the top cover on that side.

The cover will release approximately one mm. Repeat on the

second tab on that side. Repeat on the other side and then

withdraw the cover and circuit card until the required switches

are exposed. The rigidity of the connecting wires will hold the

circuit card in position while changes are made.

Page 4 of 6: C70861 Rev E – 07.14

Page 5 of 6: C70861 Rev E – 07.14

18 Specifications

Function: P, I, or P & I, switch selectable.

Input 1: Connects to error amp via 94k.

Scaled to 95V max with switch

selectable lag of 55mS.

Input 2: Differential 4-20mA or ±10V,

switch selectable.

Connects to error amp via R34.

±15V max.

R in = 390k – ±10V.

R in = 240R – 4-20mA.

R34 is plug-in, 100K (default).

Input 3: Connects to summing amp via R33.

R33 plug-in. ±10V gives ±100% valve

drive when R33 = 10k Ohm, ±10% when

R33 = 100k Ohm.

Feedback input: Differential 4-20mA or ±10V,

switch selectable.

±15V max.

R in 100k – ±10V.

R in 240R – 4-20mA.

Feedback amp: Zero, ±10V.

Gain, 1 to 10.

Derivative (velocity) feedback via

plug-in resistor R16 and fixed capacitor.

Transducer excitation: +10V @ 10mA max.

Error amp: Unity gain.

Bias ±1.5V.

Proportional amp gain: 1 to 20 with R17 = 100k (default).

Max gain 2000 with R17 = 10M.

Integrator gain: 1 to 45 per second.

Integrator input: Switch selectable from output of unity

gain error amp or proportional gain amp.

Enable: Relay, +24V @ 8mA, 17 to 32V.

Output amp: Switch selectable voltage, current or

4-20mA, single ended output, return

to ground.

V. ±10V, minimum load = 200 Ohm.

I. ±5, 10, 20, 30, 50mA to a maximum

of ±100mA.

max load = 11V – 39 Ohm

I(Amp)

4-20mA. Max load 500R.

Step push button: -50% valve drive disturbance.

Valve supply: Terminal 23, 300mA max.

In position: ±10% of valve drive. 20mA and 40V max

output to PLC.

Front panel Vs, internal supply – green

indicators: Valve drive positive – red

negative – green

Enable – yellow

In position – green

Front panel Valve ±10V (regardless of output

test points: signal selection)

Feedback amplifier output

signal 0V

Front panel Input 1 scale

trimpots: Error amp bias

(15 turns) P gain

Igain

Dither level

Feedback amp gain

Feedback amp zero

( )

Dither: 200 Hz fixed frequency.

±10% valve drive. Switch selectable

on/off.

Supply: Terminal 1,

24V nominal, 22 to 28V

75mA @ 24V, no valve current,

200mA @ 100mA valve current.

±15V output: Terminals 14 and 15,

± (110mA – max valve current).

Wire size range: 0.2mm2to 2.5mm2

(24AWG to 12AWG).

Recommended M205, 250mA T (slow blow) fuse

supply protection: compliant to IEC127-2 sheet 3.

If terminal 23 is used to power a

proportional valve, the fuse should be

increased to cater for the extra current.

Mounting: DIN rail

IP 20

Temperature: 0 to +40ºC

Dimensions: 100W x 108H x 45D

Weight: 180g

CE mark: EN50081.1 emission

EN61000-6-2 immunity

C tick: AS4251.1 emission

19 Internet

www.moog.com/dinmodules

+15V

-15V

TP

Power Supply

1

2

Output Amp

TP

valve

11

LED

valve

L E DV s

bias

7

8

100K

6

5

10K

47K 47K

26

17

18

4-20mA

100K

feedback lead

Feedback Amp

TP

feedback

gain

zero

20

19

Transducer

Excitation

+

dither

Dither

Oscillator

dither

Error Amp

Av=1

Pgain

LED

enable

EP

gain

P Gain Amp

Integrator

INT

PR

In Position

Comparator

12

3

4

31

32

22

23

24

499R

scale

Integrator input

select

cmd lag

N.F.

R16

N.F.

R17

100K

R34

9

+24V

0V

Supply

16

signal +

signal -

Input 2

13

signal

0Vref

Input 1

27

+10V

0V

Typical

Feedback Input

see note 1

see note 1

see note 1

see note 1

+

see note 1

PLC

+24V

Enable

+24V

In position

see note 1

13

10

B

D

E

F

A

efb Valve

Typical D66X

Prop. valve

spool

see note 2

mfb Valve

Connect to

Note: 1. Connect cable screen to enclosure cable gland

or chassis ground terminal on G122-829

+24V

25

0Vref

1K

+24V

+24V

14

+15V

15

-15V

28

lim

2.2uF

+10V

+

Note: 2. Connect spool (pin F) to terminal 22,

only if the spool signal is a current.

pins 31 & 32.

+

+

-50%

Step P.B.

R33 5mA

10mA

20mA

30mA

50mA

+24V enable

240R

100K

100K

100K 100K

200R

100R

51R

33R

20R

V

V

V

V= 1V

39R

Note: 3. Switches shown in default shipping mode.

Av=10

390K

linear pot

feedback

21

V

V

Input 3

Sum &

Limit Amp

signal

250mA

Tfuse

+

-

+

SW6:1

SW5:1 to 4

SW4:1

SW6:3

SW6:4

SW6:2

SW4:2

[SW1:4]

[SW1:3]

[SW1:2]

SW3

SW1-X

SW2

SW2

SW2

Note: 4. [ ] indicates bottom board.

10K

10K

100K

R27

10K

-

4-20mA

SW7:1&2

-V

240R

390K

-Vr

390K

Pin 8 390K

Industrial Controls Division. Moog Inc., East Aurora, NY 14052-0018. Telephone: 716/652-3000. Fax: 716/655-1803. Toll Free 1-800-272-MOOG.

Moog GmbH. Germany. Telephone: 07031-622-0. Fax: 07031-622-100.

Moog Sarl. France. Telephone: 01 45 60 70 00. Fax: 01 45 60 70 01.

Moog Australia Pty. Ltd. Telephone: 03 9561 6044. Fax: 03 9562 0246.

Moog pursues a policy of continuous development and reserves the right to alter designs and specifications without prior notice. Information contained herein is for guidance only and does not form part of a contract.

Australia: Melbourne, Sydney, Brisbane Austria: Vienna Brazil: S~

ao Paulo Denmark: Birkerød England: Tewkesbury Finland: Espoo France: Rungis Germany: Böblingen, Dusseldorf Hong Kong: Shatin India: Bangalore

Ireland: Ringaskiddy Italy: Malnate (VA) Japan: Hiratsuka Korea: Kwangju-Kun Philippines: Baguio City Singapore: Singapore Sweden: Askim USA: East Aurora (NY)

20 Block-wiring diagram

Page 6 of 6: C70861 Rev E – 07.14

Table of contents

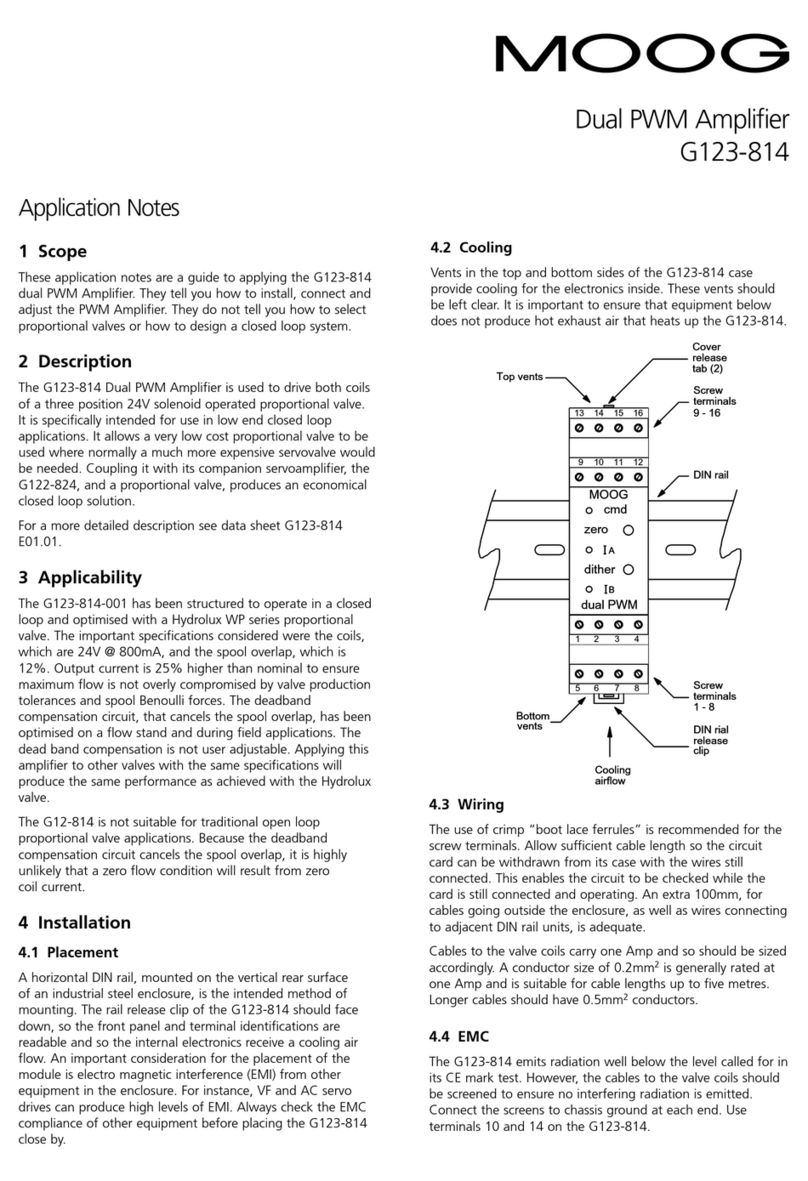

Other Moog Amplifier manuals