Table of Contents

Filling Tank ...................................................................................................................5-16

Unloading Tanks ..........................................................................................................5-18

Rate Calibration ...........................................................................................................5-19

Seeding Fine Seeds (Canola, Mustard, etc.) ...............................................................5-22

Applying Inoculant .......................................................................................................5-22

Hydraulic Fan Drive .....................................................................................................5-23

Fan Speed Recommendations ....................................................................................5-24

Double Shoot Settings .................................................................................................5-25

Double and Triple Shoot Settings .................................................................................5-26

Collector Valve Settings ............................................................................................5-26

Flapper Valve Run Test .............................................................................................5-26

Opener Operation ........................................................................................................5-27

Accumulator System Operation and Pre-Charge Information ...................................5-27

Setting Maximum System Pressure (Trip Out Force) ................................................5-28

Relieve System Pressure .........................................................................................5-29

Normal Operation .....................................................................................................5-29

Pressure Adjustment (On the go) .............................................................................5-30

Depth Adjustment ........................................................................................................5-31

Work Switch .................................................................................................................5-33

Quick Tips ....................................................................................................................5-34

Shank Trip Force .......................................................................................................5-34

Packing Force ...........................................................................................................5-34

Hydraulic System .....................................................................................................5-34

Lifting and Lowering the Openers ............................................................................5-34

Setting the Seed Depth ............................................................................................5-35

Seeding Conditions ..................................................................................................5-35

Straw Management ..................................................................................................5-35

Air Drill Frame ..........................................................................................................5-36

Trouble Shooting Guide ............................................................................................5-36

Wing Lift Hydraulics .....................................................................................................5-37

Opener Hydraulics ......................................................................................................5-38

General Guidelines ......................................................................................................5-43

Monitor .....................................................................................................................5-44

General Field Operation ..............................................................................................5-44

Turning ......................................................................................................................5-45

Seed Rate Settings ..................................................................................................5-45

Fertilizer Application .................................................................................................5-45

Fan Setting ...............................................................................................................5-45

Product Application...................................................................................................5-45

Adjustments and Operational Checks ......................................................................5-46

Checking Seed Flow ................................................................................................5-46

Moisture Alert ...........................................................................................................5-46

Air Leaks ..................................................................................................................5-46

Tank Low in Product .................................................................................................5-46

Manual Override ..........................................................................................................5-47

Rate Setting..............................................................................................................5-47

Calculating Meter Shaft RPM ...................................................................................5-47

Operating in Manual Override .....................................................................................5-48

Section 6:

Maintenance .................................................................................................................6-1

General ..........................................................................................................................6-3

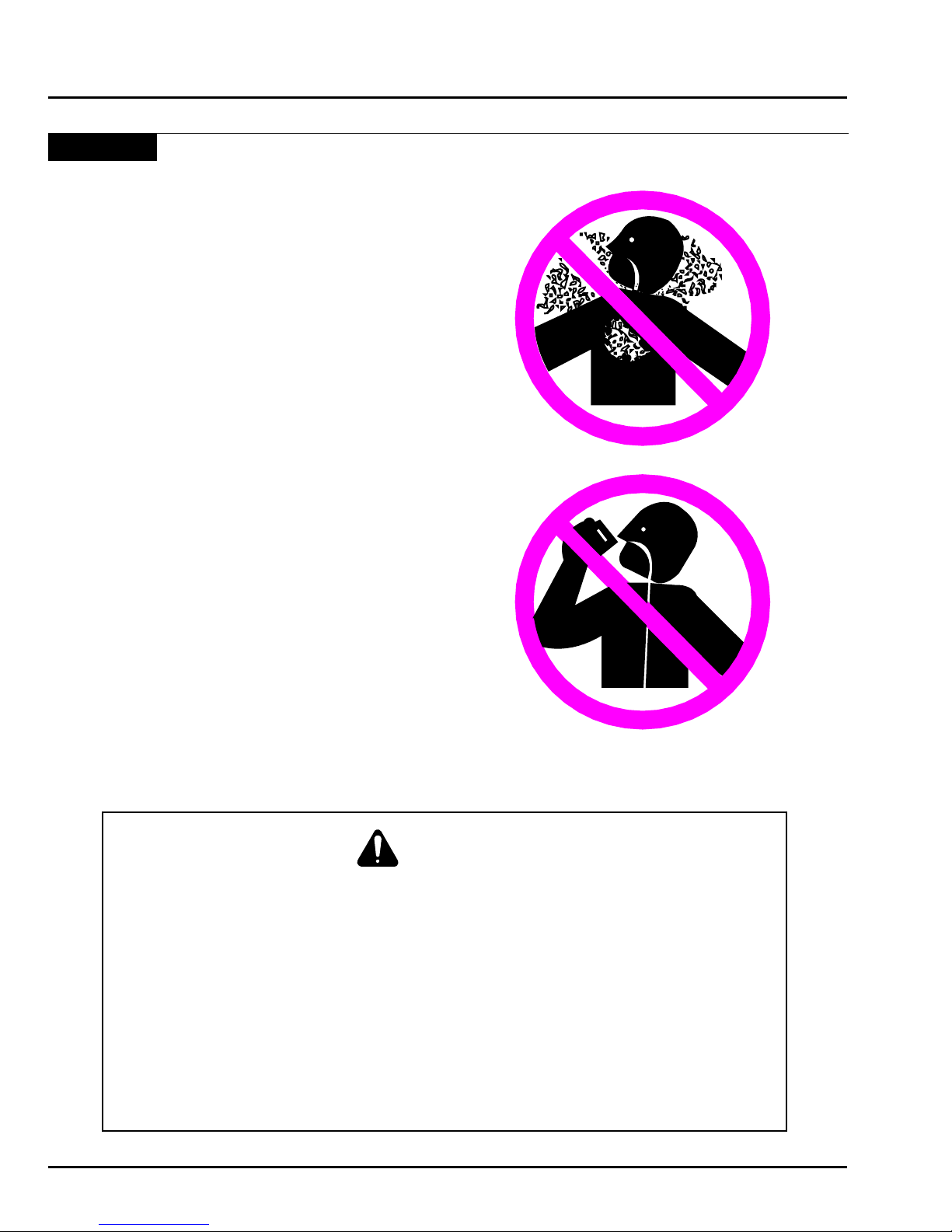

Safety ............................................................................................................................6-3

Tighten Bolts .................................................................................................................6-4

Tires ..............................................................................................................................6-4

ii November 2014 CX 8105