Morris Industries Ltd. 1

Maxim II

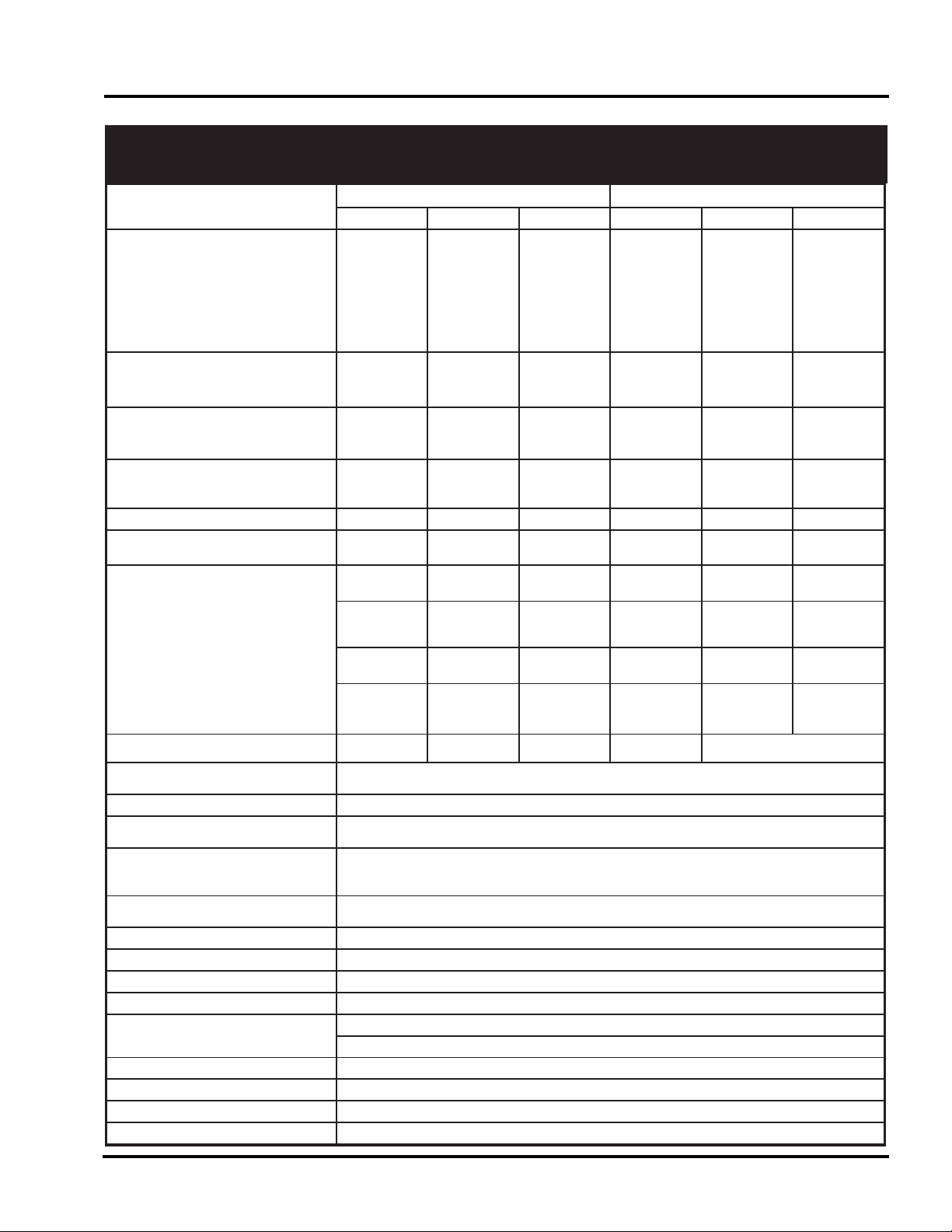

Specifications

2-2 October 2004 Maxim II Air Drill

eziSesaB sledoMemarF

ledoMemarF5

('92

)m48.8

('43

)m63.01

('93

)m98.11

('94

m49.41

)('55

)m77.61

('06

)m92.81

thgieW

)knahSnO-egdEhtiwsrekcaPleetS"2/13(

gnicapS"2/17- .sbl269,41.sbl930,71.sbl259,81.sbl752,52A/

/N

-gnicapSmc0.91 gk108,6gk547,7gk516,8gk084,11A/

/N

gnicapS"01- .sbl665,31.sbl520,51.sbl649,61.sbl055,2

sbl189,6

sbl108,82

-gnicapSmc4.52 gk661,6gk038,6gk307,7gk052,0

k462,2

k190,31

gnicapS"21- .sbl033,21.sbl151,41.sbl300,61.sbl909,0

sbl753,5

sbl492,72

-gnicapSmc5.03 gk506,5gk234,6gk472,7gk405,

k625,1

k604,21

htdiWgnikroW gnicapS)mc0.91("2/17-)m79.8("5'92)m94.01("5'43)m10.21("5'93)m60.51("5'94A/

/N

gnicapS)mc4.52("01-)m41.9('03)m76.01('53

)m91.21('04

)m42.51('0

m67.61('5

m92.81('06

gnicapS)mc5.03("21-)m48.8('92)m76.01('53

)m05.21('14

)m39.41('9

m67.61('5

m95.81('16

sknahSforebmuN )mc0.91("2/17-74553697A/

/N

)mc4.52("01-632484066

7

)mc5.03("21-925314945

6

htdiWemarF niaM-)m24.4("6'41)m24.4("6'41)m24.4("6'41)m24.4("6'4

m24.4("6'4

m24.4("6'41

gniWrennI-

gniWretuO-

)m92.2("6'7

A/N

)m50.3('01

A/N

)m18.3("6'21

A/N

)m50.3('01

)m92.2("6'7

)m18.3("6'21

)m92.2("6'7

)m18.3("6'21

)m50.3('01

htgneLllarevO)m28.7("8'52)m28.7("8'52)m28.7("8'52)m20.9("7'9

m20.9("7'9

m20.9("7'92

noitisoPtropsnarT htdiW-)m30.6("01'91)m30.6("01'91)m30.6("01'91)m68.6("6'2

m74.7("6'4

m74.7("6'42

thgieH-)m86.3("1'21)m92.4("1'41)m60.5("7'61)m33.5("6'7

m81.5('7

m81.5('71

seriT leehWrotsaCemarFniaM- IF51xL11)2(

DegnaRdaoL

IF51xL11)2(

DegnaRdaoL

IF51xL11)2(

DegnaRdaoL

IF51xL11)2(

DegnaRdaoL

IF51xL5.21)2(

FegnaRdaoL

IF51xL5.21)2(

FegnaRdaoL

leehWrotsaCemarFgniWrennI-

)gniwrep1(

51xL11)2(

gnitarylp6

)gniwrep1(

51xL11)2(

gnitarylp6

)gniwrep1(

51xL11)2(

gnitarylp6

)gniwrep1(

51xL11)2(

gnitarylp6

)gniwrep2(

51xL11)4(

gnitarylp6

)gniwrep2(

51xL11)4(

gnitarylp6

leehWrotsaCemarFgniWretuO-

)gniwrep1

(A/NA/NA/N 51xL11)2(

gnitarylp6

51xL11)2(

gnitarylp6

51xL11)2(

gnitarylp6

sleehWtropsnarTemarFniaM-

IF51xL11)4(

DegnaRdaoL

buHtloB6

IF51xL11)4(

DegnaRdaoL

buHtloB6

IF51xL11)4(

FegnaRdaoL

buHtloB8

IF51xL11)4(

FegnaRdaoL

buHtloB8

IF51xL5.21)4(

FegnaRdaoL

buHtloB8

IF51xL5.21)4(

FegnaRdaoL

buHtloB8

sgniWnosleehWrotsaClauDlanoitpOlanoitpOlanoitpOlanoitpO

gniWrennInodradnatS

gniWretuOroflanoitpO

sknaRforebmuN nrettaP"Z"wor4-gnicapS)mc0.91

("2/17

wor4-gnicapS)mc5.03("21&)mc4.52("01

msinahceMpirT knahs)mc1.5("2x)mc45.2(1htiwpirTnoihsuCgnirpS)gk081(bl004

snoitpOknahS nO-egdEdegroF

)slootegalliteergeD74()gnicapseloh)mc4.4("4/31(knahS'C'lanoitnevnoC

snoitpOleehWrekcaP

)gnicapS)mc4.52("01&)mc0.91("2/17(-rebbuRroleetS)mc1.5("2

)gnicapS)mc5.03("21&)mc4.52("01,)mc0.91("2/17(-rebbuRroleetS)mc9.8("2/13

gnicapS)mc5.03("21&)mc4.52("01(-rebbuRroleetS)mc4.

11("2/14 YLNO )

renepOotemarF ecnaraelClacitreV tnioPeoHralugeRhtiw"2/172-

srenepOefinK/toohSelbuoDhtiw"2/103-

gnicapSknaRotknaR )mc0.16("42

gnicapSknahSotknahS gnicaps)mc5.03("21no)mc4.19("63,gnicaps)mc4.52("01&)mc0.91("2/17no)mc2.67("03

htpeDemarF )sknar4()m39.1("67

sworraHraB-2 )YLNOgnicapS)mc4.52("01woR3(lanoitpO

sretluoC)nialProdelppiR(gnittuChsarT- )retemaid)mc8.05("02(-sertneC)mc2.67("03notnuoMwoRtnorF-lano

itpO

)nialP(rezilitreF- )tf06dna55noA/N()retemaid)mc8.05("02(-sertneC)mc8.05("02nognitnuoMmodnaR-lanoitpO

sreparcSduMrekcaP )srekcaPrebbuRdnaleetShtobroF(lanoitpO

srotcelfeDkcoR )gnicapS)mc5.03("21&)mc4.52("01,)mc0.91("2/17(lanoitpO

sthgiLytefaS dradnatS

niahCytefaS dradnatS

MAXIM II

Specifications and Options