MQT PT40024 User manual

2.5

HP

10"

TILE

SAW

INSTRUCTION

MANUAL

PT40024

Model

No.

TS250

WARNING:

Before

operating

tile

saw,

read

this

manual

and

follow

all its

safety

and

operating instructions,

and

keep

this manual

for

future

reference.

Specifications

Save

This

Manual

You

will need the manual for

the

safety

warnings

and precautions, assembly

instructions,

operating

and

maintenance

procedures,

parts

list

and

diagram.

Keep

your invoice with this

manual.

Write

the

invoice

number on the inside

of

the front cover.

Keep

the

manual

and

invoice

in

safe

and

dry

place

for

future reference.

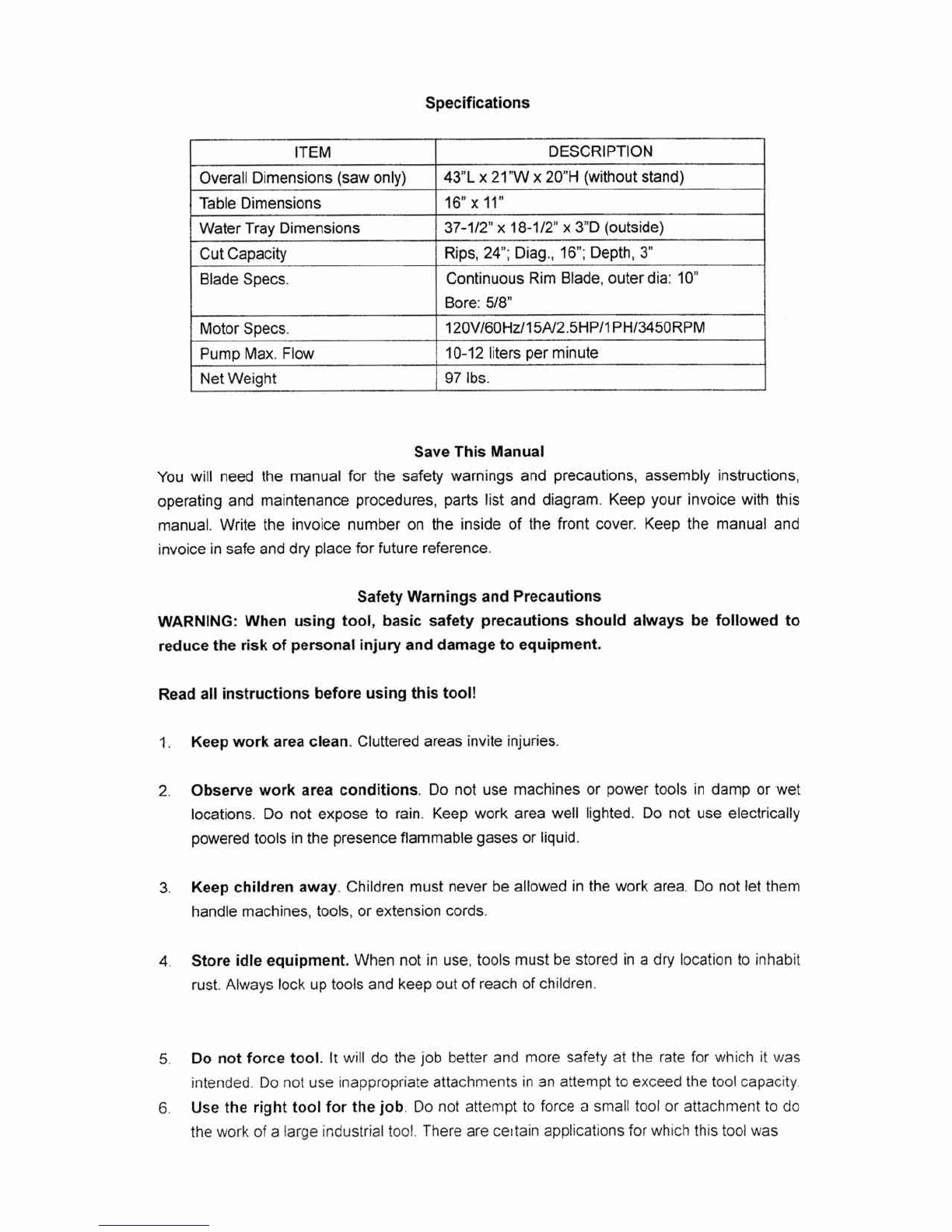

ITEM

Overall Dimensions

(saw

only)

Table

Dimensions

Water Tray

Dimensions

Cut

Capacity

Blade

Specs.

Motor

Specs.

Pump

Max.

Flow

Net

Weight

Safety

Warnings

and

Precautions

WARNING:

When

using

tool,

basic

safety

precautions

should

always

'be

folIowed

to

reduce

the

risk

of

personal injury

and

damage

to

equipment.

DESCRIPTION

43*L

x

21"W

x

20nH

(without

stand)

16"

x

11"

37-1/2"

x

18-112

x

3"D

(outside)

Rips,

24';

Diag.,

16";

Depth,

3"

Continuocrs

Rim

Blade,

outer

dia:

10"

Bore:

518"

120V160H~ll5A12.5HPll

PH13450RPM

10-12

liters per minute

97

Ibs.

Read

all

instructions

before

using

this

tool!

1.

Keepwork

area

clean.

Cluttered

areas

invite

injuries

2.

Observe

work

area

conditions.

Do

not

use

machines

or

power

tools in

damp

or

wet

locations. Do not

expose

to rain.

Keep

work area well lighted.

Do

not

use

electrically

powered

tools

in

the

presence

flammable

gases

or

liquid.

3.

Keep

children

away.

Children

must

never

be

allowed

in

the

work

area.

Do

not

let

them

handle

machines,

tools,

or

extension

cords.

4.

Store

idle

equipment.

When

not

in

use,

tools

must

be

stored

in

a

dry

location

to

inhabit

rust.

Always

lock

up

tools

and

keep

out

of

reach

of children.

5.

Do

not

force

tool.

It

will

do

the job

better

and

more

safety

at

the

rate

for

which

it

was

intended Do

not

use

tnappropriate

attachmentsin

an

attemptto

exceed

the

tool

capacity.

6

Use

the

right

tool

for

the

job

Do

not

attempt

to

force

a

small

tool

or

attachment

to

do

the work

of

a

large

industrial

too!.

There

ate

ce~

tain applications

for

which this tool

was

designed. Do not modify this

tool

and

do

not

use

this tool

for

a

purpose

for which it

was

not intended.

7.

Dress

properly.

Do

not

wear

loose

clothing

or

jewelry

as

they can be caught in

moving

parts.

Protective, electrically non-conductive clothes and non-skid

footwear

are

recommended

when

working.

Wear

restrictivehair

covering

to

contain

long

hair.

8. Use

eye

and

ear

protection.Always wear ANSI

approved

impact

safety

goggles.

9.

Do

not

overreach.

Keep

proper footing

and balance

at

all times. Do not

reach

over

or

across

runningmachines.

70.

Maintain

tools

with

care.

Keep

tools sharp and clean for better and safer

performance.

Follow instructions for lubricating

and

changing

accessories.

Inspect tool cords

periodically and

if

damaged,

have

them repaired

by

an

authorized technician. The

handles must

be

keptclean,

dry

and

free

from

oil and greaseat all

times.

11.

Disconnect

power.

Unplug tool when not

in

use.

12.

Remove

adjusting

keys

and

wrenches.

Check

that

keys

and

adjusting

wrenches

are

removedfrom the tool

or

machinework surface

before

plugging it

in.

13.

Avoid

unintentional

starting.

Be

sure

the switch is in the

Off

position

when

not in

use

andbefore pluggingin.

14.

Stay

alert. Watchwhat

you

are doing,

use

common sense.

Do

not operate

any

tool when

you

aretired.

15.

Check

for

damaged

parts.

Before using any

tool,

any

part

that

appears

damaged

should

be

carefully

checked

to determine that it will operate properly and perform its intended

function.

Check

for alignment

and

binding

of

moving

parts;

any broken

parts

or

mounting

fixture,

and

any other condition

that

may

affect

properoperation.

Any

part

that

is

damaged

should

be

properly repaired

or

replaced

by

a

qualified technician.

Do

not

use

the tool

if

any

switch

does not turn On

and

Off

property.

16.

Guard

against

electric

shock.

Prevent

body contact

with

grounded

surface

such

as

pipes,

radtators,

rangesand refrigeratorenclosures.

17.

Replacement

parts

and

accessories.

When

servicing,

use

only identical replacement

parts.

Use

of

any

other

parts

will

void

the

warranty.

Only

use accessories

~ntended

for

use

with

this

tool.

Approved

accessories

are

available

from

your

local

retaller

I

8

Po

not

operate

tool

if

underthe influence

of

alcohol

or

drugs.

Read

warning labels

on

prescriptions

to

determine

if

your

judgment or

reflexes

are impairedwhile taking

drugs.

If

there

is

any

doubt,

do

not

operate

the

tool.

9

Use

proper

size

and

type

extension cord. If

an

extensioncord

is

required, it must

be

of

the

proper

size

and

type

to

supply the

correct

current to

the

tool

without heating

up.

Otherwise, the extension

cord

could melt

and

catchfire,

or

cause

electrical damage

to

the

tool.

If

you

are

using

the

tool outdoors,

use

an

extension

cord

rated

for

outdoor

use

(signified

by

"WA"

on

the

jacket).

20.

Maintenance.

For

your

safety,

service and maintenance should be performed regularly

by

a

quafified

technician.

Note: Performance

of

this

tool

(if

powered

by

line

voltage)

may

vary

dependingon variations in

local

line

voltage. Extension

cord

usage

may also

affect

tool

performance.

Warning:

The

warnings,cautions and instructions

discussed

in

this

instruction

manual

cannot

cover

all

possible

conditions

and

situations

that

may

occur.

It

must

be

understood

by

the operator

that

common

sense

and

caution

are

factors which

cannot

be

built into

this

product,but

must

be

supplied

by

the

operator.

GroundingNoltageWarning

Warning:

Before

using

this

tool,

make

sure

that

the

power

cord

wit1

be

plugged

into

an

outlet

which

has

a

three-prong ground,

is

120V

AC,

is

protected

by

a

30

Amp. Circuit

breaker

and

has

a

Ground

Fault

Interrupter.

Common

household

current

is

110-7

20V.

As

long

as

the

outlet

used

with

the

Tile

Saw

is

rated

from

110-120V

there will be

no

complicationsusing it with householdreceptacles. Plug the tool

into

a

11

0-720V

properly grounded outlet protected

by

a

1

SAmp,

dual

element

time delay

or

circuit

breaker.

NEVER

try

to plug

a

110-120V

tool into

a

220-240V

circuit, or serious complications

and

possible

injury

to

the

operator

may

occur.

The

plugs

have

different

shapes

to

preventthis.

This

tool

has

a

three-prong

plug.

The

third round prong is the ground. Cutting

off

the

ground

will result in

a

safety

hazard

and

void warranty.

If

the

outlet

you

are

planning

to

use

is

the

two-prong

type,

do

not

remove

or alter

the

grounding

prong

in

any

way.

Use

an

adapter and

always

connect thegrounding

lug

to

a

known grounding

source, It is recommended that

you

have

a

qualified electrician

replace

the two-prong outlet

with

a

properlygrounded three-prong outlet.

Extension

Cords

Your

tool

has

a

three-prong plug, therefore

you

must

use a

three-prong

extension

cord

Only

use

rounded

jacket

extenscon cords l~stedby the

UL

Improper use

of

extens~oncords

may

cause

ineffiaent

operationof your tool

whrch

can

result in overheating.

Be

sure

your

extens~on

cord is

rated

to

allow

sufficient

current

flow

to

the

motor. Ifyou

are

using

the

tool

outdoors.

use

an

extension

cord

rated

for outdoor use

(signified

by

"WA"

on

the

jacket).

Unpacking

When

unpacking,

check

to

make

all

parts

listed on pages

8-10

is

included.

If

any

parts

are

missing

or

broken,

please

call

your

localretailer.

Notes:

Table Stand

is

specifically

designed

for

use

with

this

10"

Tile

Saw

and

is

not included.

Stand

is

available for

purchase

from your local retailer.

And

table stand

is

packed

in

an

individual

carton.

If

the

stand

is

no2

to

be

used

with

the

tile

saw,

the

saw

must

be

securely

mounted

onto

a

flat,

level

surface

capable of supporting the

weight

of

the

tile

saw

in

addition to

the

weight

of

all

work

pieces.

AssembIy

1.

Slide the

water

tank through

the

slot in

the

machine

frame

so

that

the

entire

tank

rests

inside

the

machine

frame.

2.

Mountthe motor to

the

machineframe

by

connecting

the

supporting

frame

to

the

machine

frame

at the

point

shown En

the

assembly

diagram on

page

10.

Secure

using

two

bolts,

elastic

washers

and big

flat

washers

as

shown.

3.

Next,

attach

the

blade

guard

to

the

motor

using

the locking

knob

and

flatwasher

provided.

Please note:

this

product does

not

include

a

blade.

Please

see

the following

section,

"Changinglinstallingthe Blade." for instructions

on

howto properlyinstall

a

now

blade.

4.

Plug

the pumpintothe

back

ifthe

back

of the

motor

andattachthe

pump

to

the water tank

using the four suction feet on the

bottom

of

the

pump.

5.

Slide

the

table

holder

through

the

middle of

the

rail

cover

and

fit the

two

inserts

aver the

ends

of

the cover

to

prevent

the

table holderfrom slipping out.

6.

Attach the rail

and

table

assembly you created in

step

5

to

the

frame

using

two

sets

of

the

bolts,flatwashers and

teeth

washers

as

shown

in

the

assembly

diagram.

7.

Before

operating

this

tool, mountthe

table

saw

to

the

table

stand

by following

the

steps

outlined

in

the

assembly

and

operating instructions

far

the table stand. If the stand

is

not

to

be

used

with

the

tile saw,

the

saw

must

be

securely

mounted

onto

a

Rat,

level

surface

capable of supporting

the

weight

of

the

tile

saw

inaddition

to

theweight

of

all

work

pieces.

Changinglinstalling

the

Blade

I.

Be

sure

to

power

cord

is

unpluggedfrom

its

power

source.

2. Loosen

the locking knob locatedon the

side

of

the blade

guard

and

raise

guard.

Tighten

the

knob

to lock

the

guard

in

an

"upnposition.

3.

Depress

the

brake

shaft

button

(see

Fig.

1

on

page

7)

whileturning the blade

(or

spindle if

you

have

not

yet

installed

a

blade)

with

your

hand

until

the

shaft

button depresses fully.

This will prevent the spindle from spinning

and

allow you

to

unscrew the

nut

and

outer

flange.

4

Slrde

the

new

blade

over

the

spindle,

and

refasten the

outer

flange

and

nut

Be

sure

to

t~ghten

the

nut

fully

before

use.

5.

Lower

the

blade

guard

and

tighten the lockingknob.

Installing

the

Water

Supply

To prevent excessivewear on

the

blade,

be

sure to maintain

a

continuous

flow

of water over

the blade

while

cutting.

Never

cut

anything

if

the

water flow

is

notcontinuous.

1

Attach

the

pump

as

described

in

step

4,

"Assembly."

Position the

pump

so

it

will

not

interfere

with

the

motion

of

thetable

while

cutting.

2.

Fill

the water

tank

with enough water so

that

the

pump

is

completely submerged,

but

not

so

muchwater

that

the

tank

overflows.

Note:When

using

thetile

saw,

extreme care

must

betaken

to

insurethat

the

saw's

power

cord

is

positioned to remain dry

and

free

from

water

at

all times. Severe personal

injury

or death

can

occur

if

the

power cord

or

the operator

of

this tool should

become

wet

at

any

time

while

this

tool

is

in

use.

Care

and

common

sense

must

be

usedin planning

a

safe

work area.

Operation

Preparingto

Cut:

1.

Placeyour markedtile you wish to

cut

and

place

it

aside

for

a

moment.

2.

Fill

the

tank with water

as

described

in "Installingthe

water

supply"

above.

3.

Plug the

pump's

power cord into power unit. Make sure

the

pump power cord

is

positioned

so

it

will

remain

in

a

dry

location

once

the

machine

is

in

use.

4

When

it is

safe

to

do so, plug the power unit cord into an appropriateoutlet.

5

Put

on

your

ANSI

approved

eye

protection.

6.

Flipthe power switch locatedon the front of the motorto the

"on"

position.

7.

Before

operatingthe tile

saw,

tet

the motor

run

for

approximately one minute.

Make

sure

the

bSade is

rotating

at full

speed

and

there

are

no

unusual noises.

If

you

feel

the

units is

no2

operating

properly,

do

not

use

this tool.

CuttingTile:

I

Placeyour

marked

tile on

the

table

and

brace

it

against

the

upturned

edge

(fence)

on

the

back

of

the table. Align the

cut

markwith the blade.

2.

Once

the

ti!e

saw

has

been

turned

on,

allowthe bladeto

spin

up

to fult

speed.Watch

to

be

sure

that

the

pump

is supplying

a

continuousflow

of

water to the blade.

3.

Keepingyour

hands

clear

of

the

blade, movethe table and

the

tile

underneaththe blade.

Feed

the tile underneath

the

bladevery

slowly.

Do

notforce

it.

If the rotationaj

feed

of

the

bhde

slows

down

significantly,

then you

are

forcing the tile.

No

spectators

should

be

allowed

in

the

working

area.

4.

While

cutting,

watch

to

be sure that

the

blade

remains

wet. If

it

runs

dry,

check

the

action

of the pump

and

the

water levelof the tub.

5.

If the motor

stops

suddenly,flip the power

switch

to the

"off'

position.

Walt

approximately

15

minutes, remove

the

circuit

breaker

cap

located directly

above

the power sw~tch,

and

push the reset button.

Using

the

parallel

guide:

If

you

have

to

cut

a

number

of

tile to the

same

dirnens~on,using

the

Parallel

Guide

may

save

you

a

srgnificantamount of time.

I.

Mark

the

firsttile

to

the

correctdimensions, allowing

space

for

grout

2.

Nth

the

motorturned off,

place

the

marked tile

on

the table against the

fence.

Align

the

cut

mark

with

the

blade.

3.

Loosen

the locking

knob

on

the parallel

guide.

Place

the

hooked portionof

the

guide over

the upturnededge

of

the table, on

the

side

of

the cutting

groove

where

you

have

placed

the

part

of

the

marked

tile that you intendto

keep

and use

after

cutting.

The

parallelguide

will be parallel

to

the

tile

and

perpendicular

to

the

fence.

4.

Slidethe

parallelguide

along

the

fence

until it

abuts

the

tile,

keeping

surethat the mark

on

your tile remains in linewith the blade.

5.

Tighten

the

locking

knob on the parallelguide

6.

When

you

are

satisfied

that

the

tile is aligned

with

the

blade,

and

the guide

Is

in

place,

and

it

is

safe

to do so, turn on the power

switch.

Cut

the

tile

as

described in previous

instructions.

7.

Check

to

be

sure

that

the tile

has

been

cut to proper dimensions beforeusing the parallel

guide to cut your other tiles. Periodically

test

the

fit of

each

tile

as

you

continue cutting, to

be sure the parallelguide

has

not moved

Usingthe Angle Guide:

Use

the angle guide for cutting

angjed

edges

on your tiles.

1.

Attach

the

angle

guide to the

fence

as

you

did

the

paralle!

guide,

using

the

two

locking

knobs

ta

holdthe

guide

in

place.

2.

Use

the

cutting groove in

the

middle

of

thetableto

brace

the

edge

of

your tile

as

you slide

thetile

and

the table underneaththe blade.

Maintenance

Always unplugthe

power

cord

before

servicingand before performing

any

maintenance

General

Maintenance:

1.

Regularly

inspect

the diamond

saw

blade.

Using

a

dull

blade

will

cause

excessive

wear

on

the

motor, and will not produce

a

satisfactory cut. Replace with

a

new

one

when

needed.

2.

Inspect the mounting

screw

on

all

safety

coven,

and

the arbor

nut

on

the

cutting wheel

shaft.

T~ghtenany that appear loose.

3.

Protect the motor and electr~calcomponents from

prolonged

or

excessive exposure to

water

or wet conditions. Wipe

the

unit

dry

as

needed.

4.

Periodically

apply

a

light lubricantto

the

rat1 cover.

Note.

The

pump

is non-serviceable. If

~'r

should

fail,

first

try clearingthe

intake

of

debris

and

be

sure

the bole

is

not

plugged.

If

the pumpstilt

does

not

work,

it

must

be replaced.

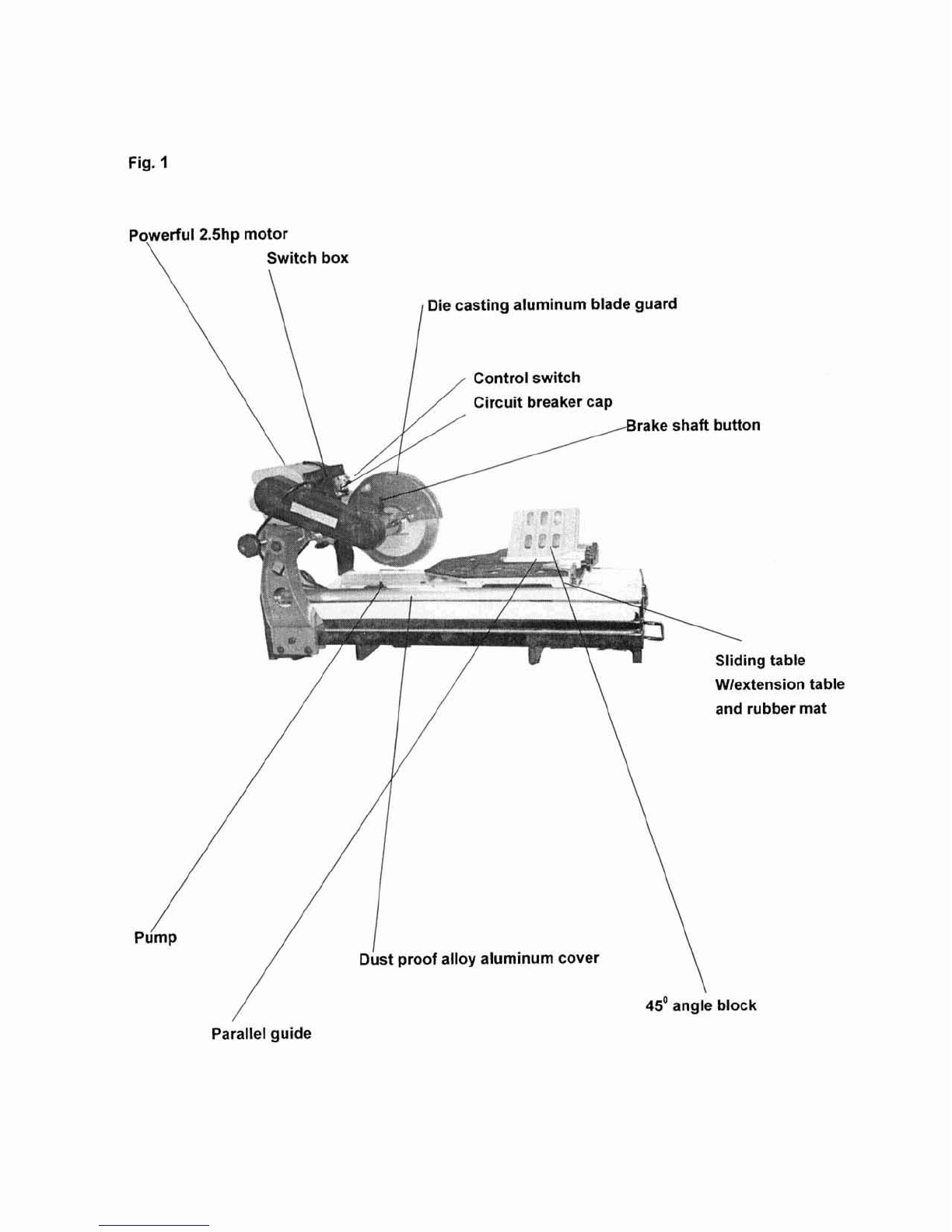

Fig.

1

Powerful

2.5hp

motor

\

Switch

box

Die

casting

aluminum

blade

guard

Control

switch

Circuit

breaker cap

button

\

Sliding

table

Wlextension

table

and

rubber

mat

45'

angle block

Parallel

guide

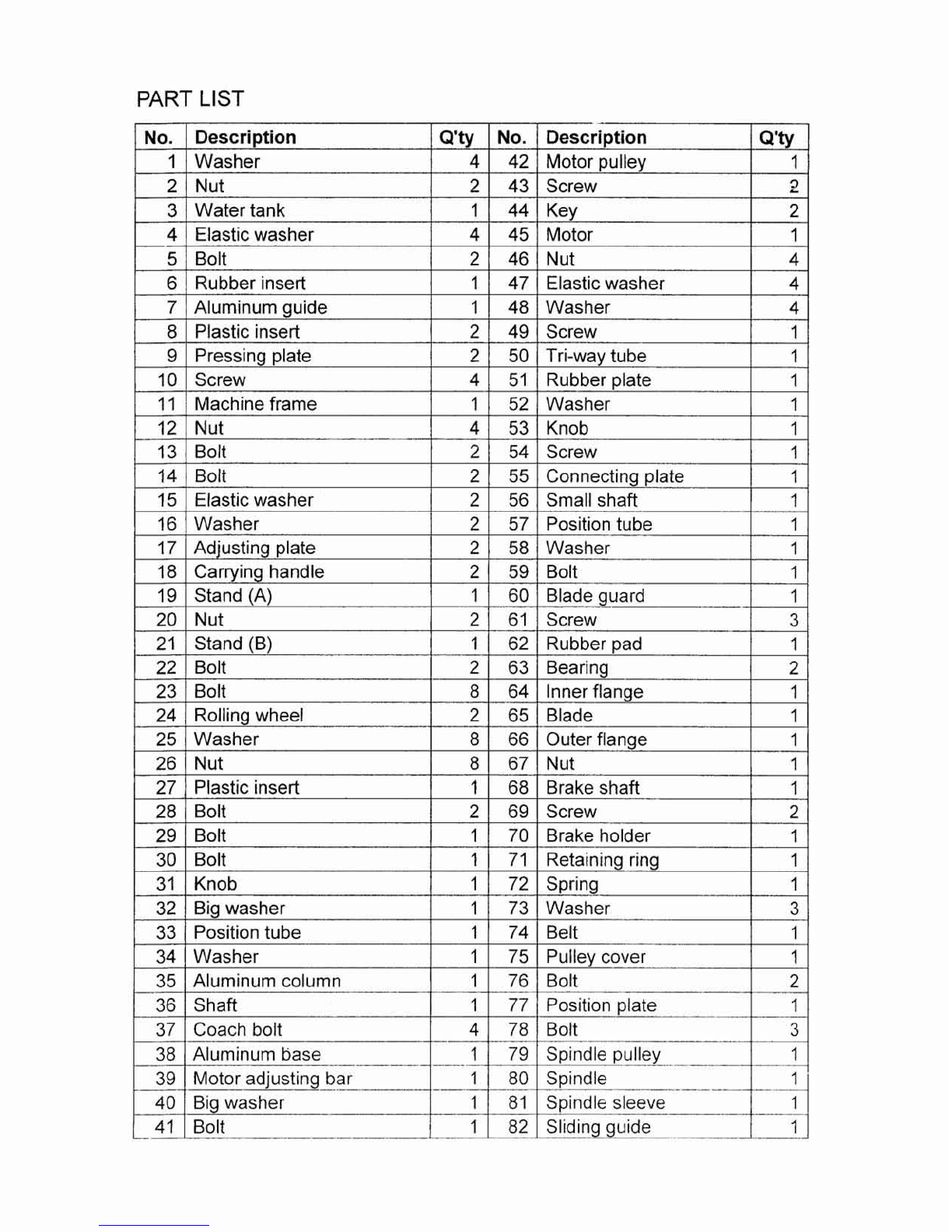

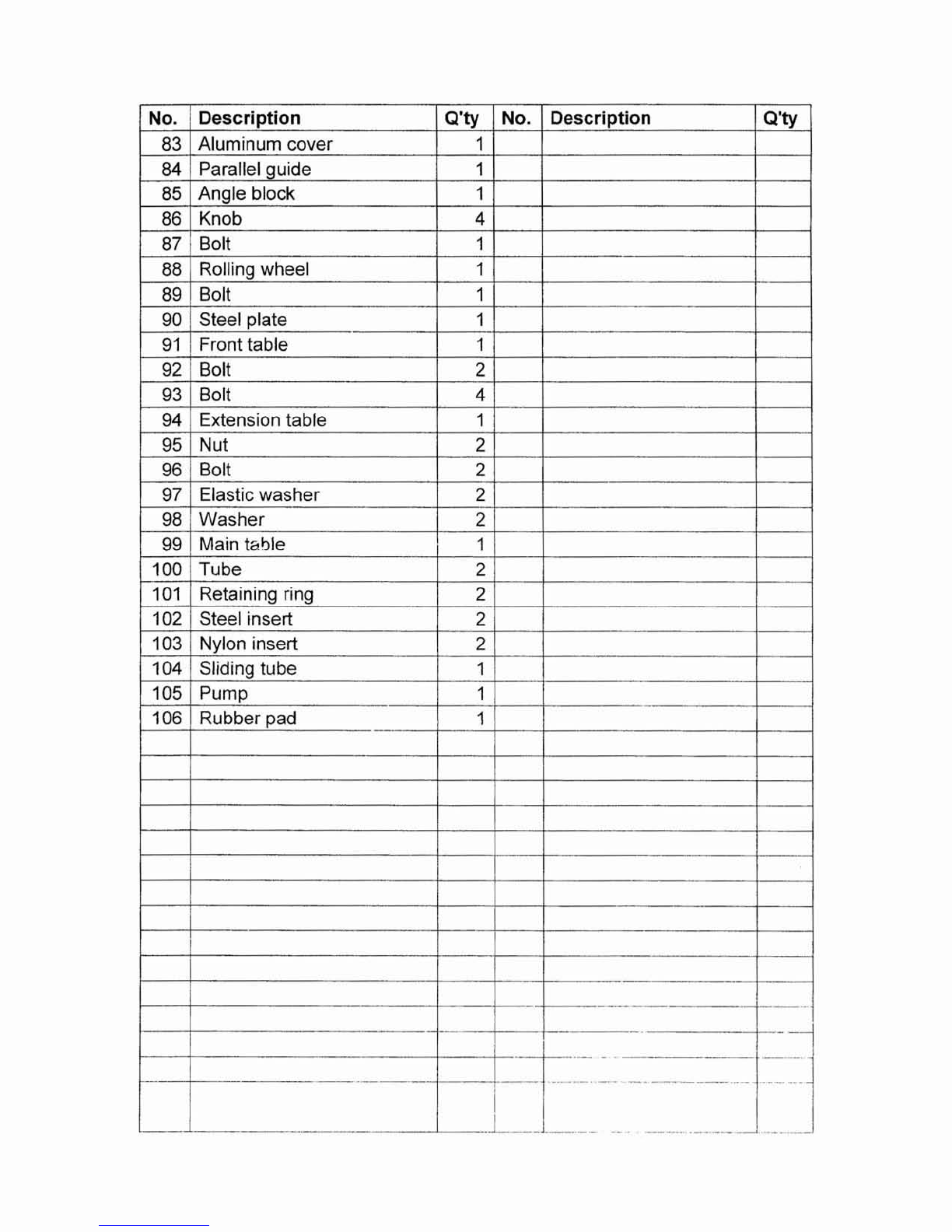

PART

LIST

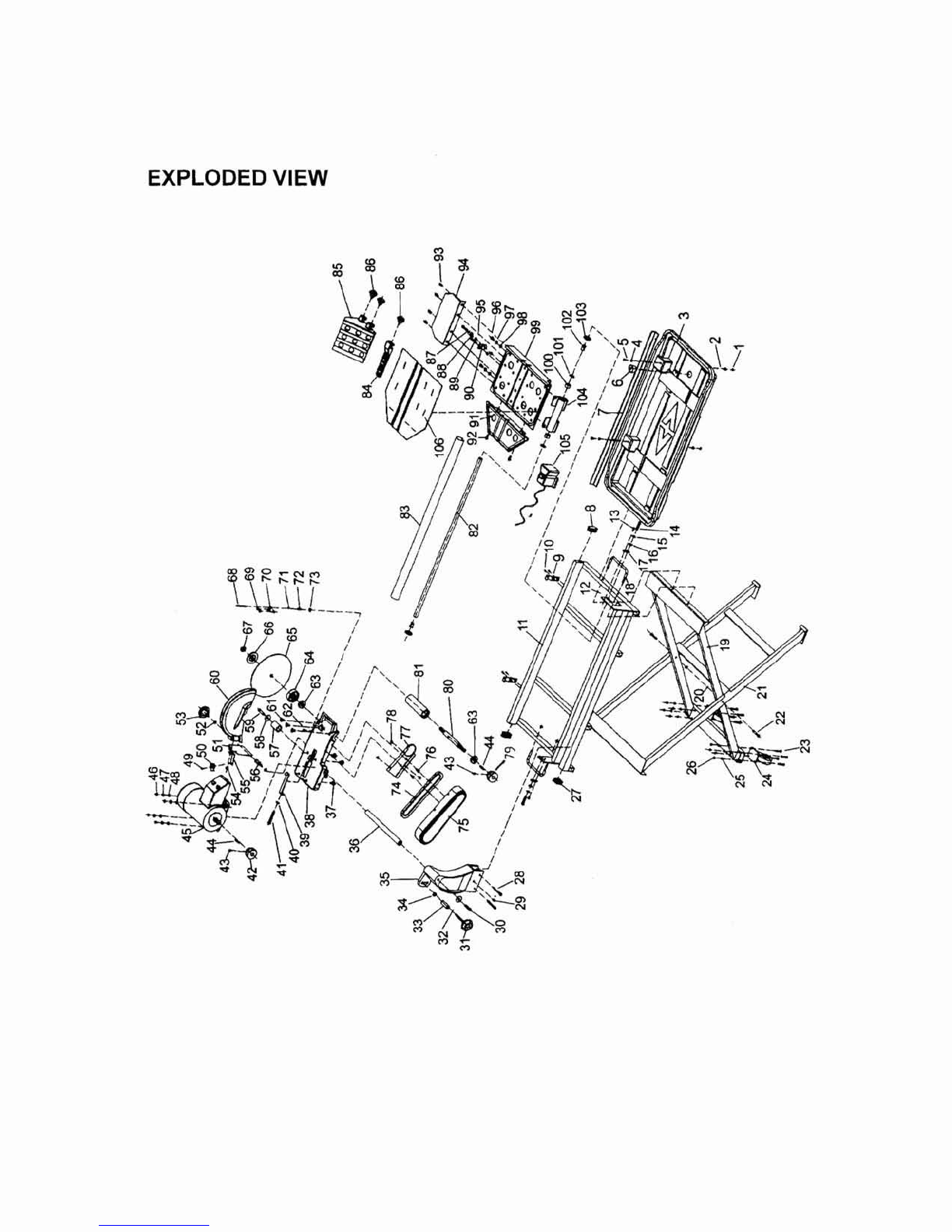

EXPLODED

VIEW

Table of contents

Popular Saw manuals by other brands

Jet

Jet J-7020 Operating instructions and parts manual

Parkside

Parkside PHKS 1350 C2 Translation of the original instructions

Craftsman

Craftsman 315.271030 owner's manual

Axminster Craft

Axminster Craft AC216TS Original instructions

Brobo

Brobo FA 3000K Product and maintenance manual

Craftsman

Craftsman 113.241680 owner's manual