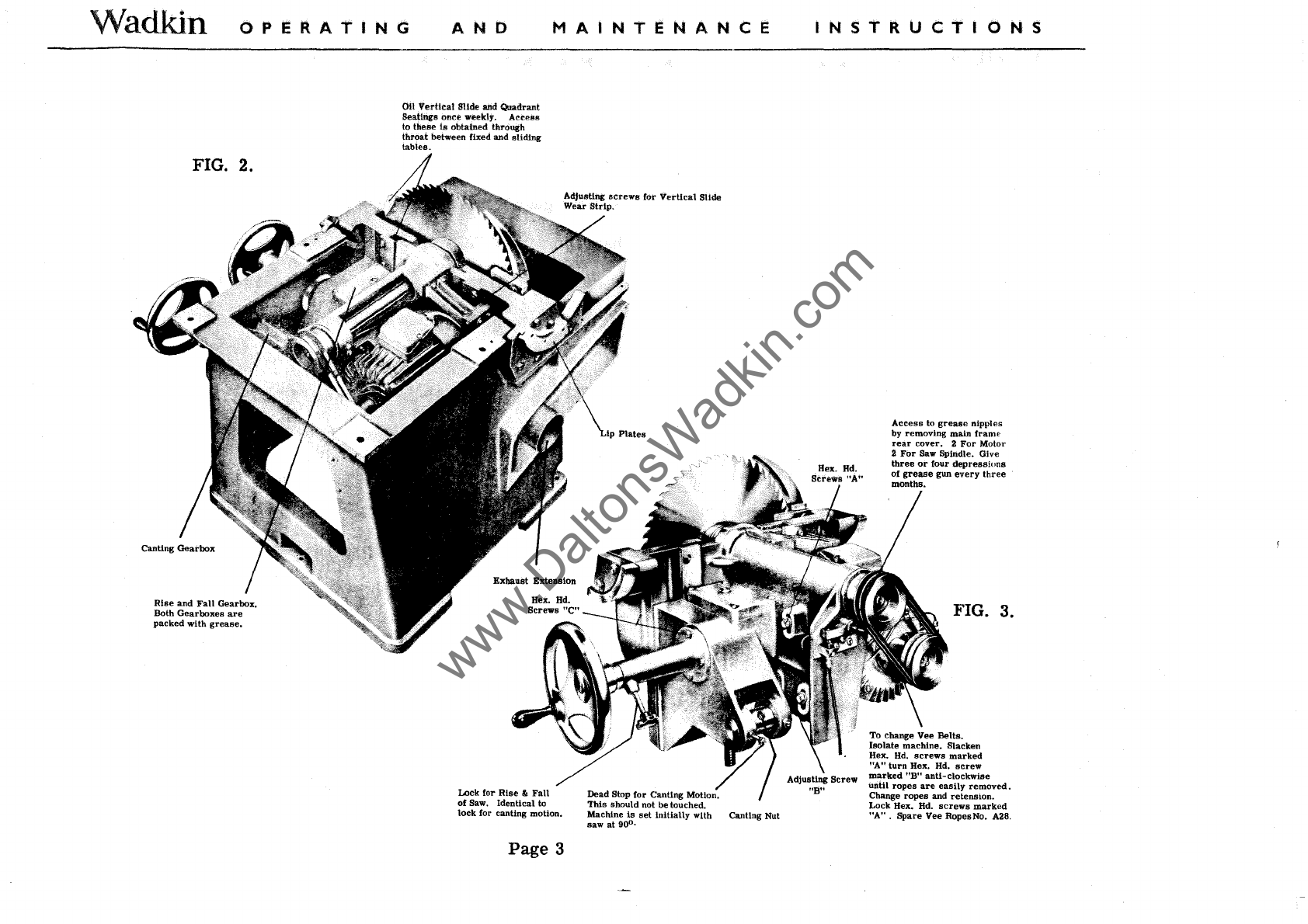

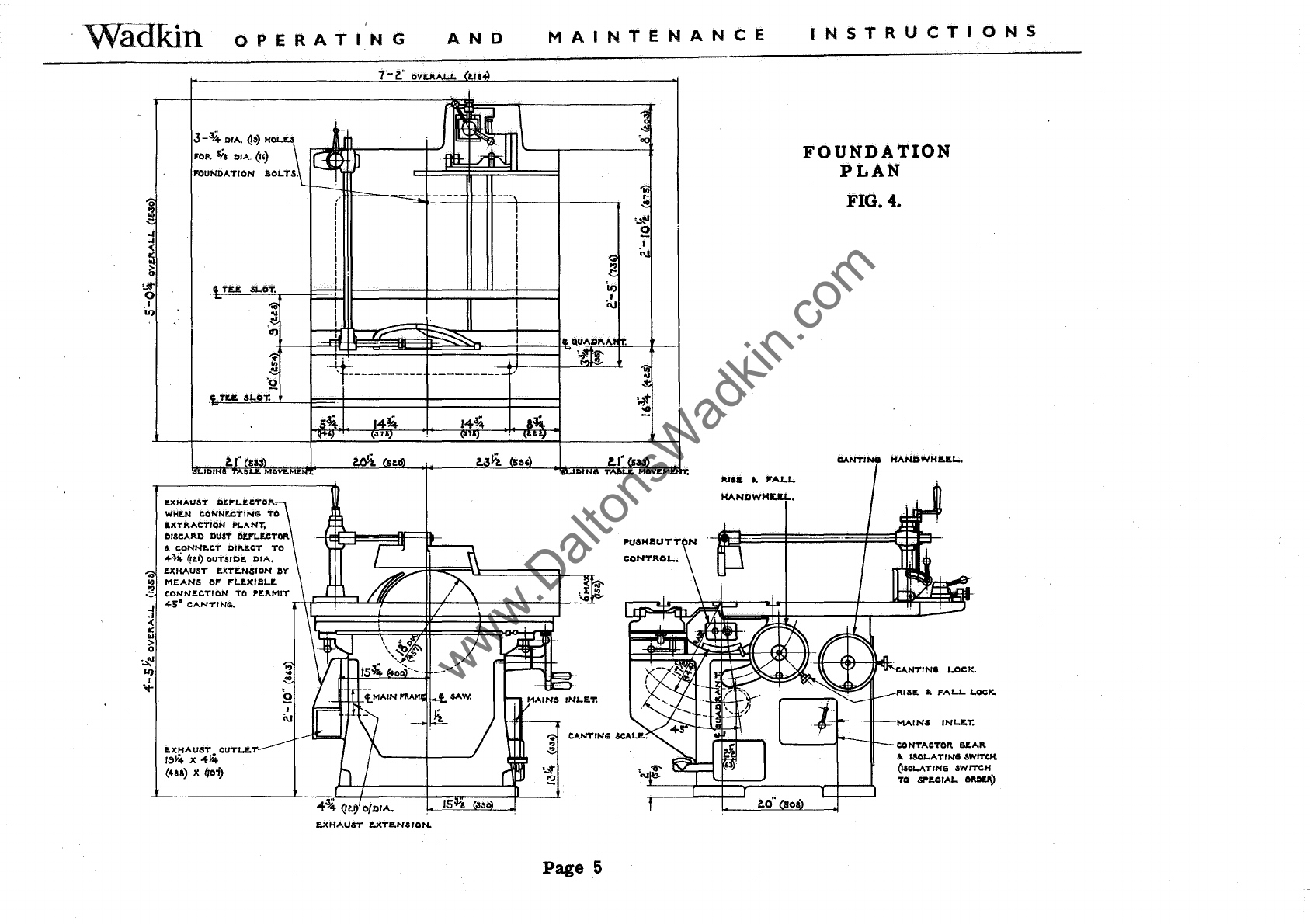

Wadkin

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

FOOT

OPERATED

BRAKE ADJUSTMENT

Grubscrew

marked

"A" Fig. 6

is

initially

set

to

depress

micro-switch

when foot pedal

is

operated

to

its

full extent.

Failure

of

brake

pedal to

return

will

prevent

machine being

started,

check

spring

for

fatigue and

replace

if

necessary.

To

replace

micro-switch;

isolate

machine,

remove

switch, disconnect

electrical

leads,

connect new

switch and

replace

switch on facing.

Start

machine

and

ensure

that when

brake

pedal

arm

is

depressed

to

its

full extent the

micro-switch

is

operated

by

the

grubscrew

marked

"A".

FENCES, TABLE AND GUARDS.

"A"

To

set

canting ripping fence

for

cutting. Move fence to

approximate

position

required.

Operate

first

lock by

rotating

clockwise, fine

adjust

to obtain

correct

dimension

required.

Operate

secondary

lock, this

also

squares

fence to dovetail groove. To unlock fence

operate

first

lock

in

anti-clockwise

direction

until dead stop

is

reached,

secondary lock need not be

operated.

CANTING RIPPING

FENCE

LOCKING ADJUSTMENT

Should the fence

secondary

lock not

operate

the two hexegon head

screws

(on the

right

hand

side

of the fence

base)

should be

slackened

off and

the

three

grubscrews

rotated

clock-

wise

each

by the

same

amount until

the

eccentric

secondary

lock holds

the fence

in

the

required

position

after

operating

the

first

lock.

Fig.

7.

Canting

lock.

Fence

pitching

screws

Secondary

lock.

Page

8

Fence

pOinter locking

grubscrew.

Fine

adjustment.

Eccentric

pivot

pin.

First

lock.