2. INSTALLATION OF THE MACHINE

2.1 Unpacking and Handling the Machine

FA 3000K consists of the following major components (Figure 2.1):

Brobo S350D cold saw with automatic actuation

F3000 automatic material feeder

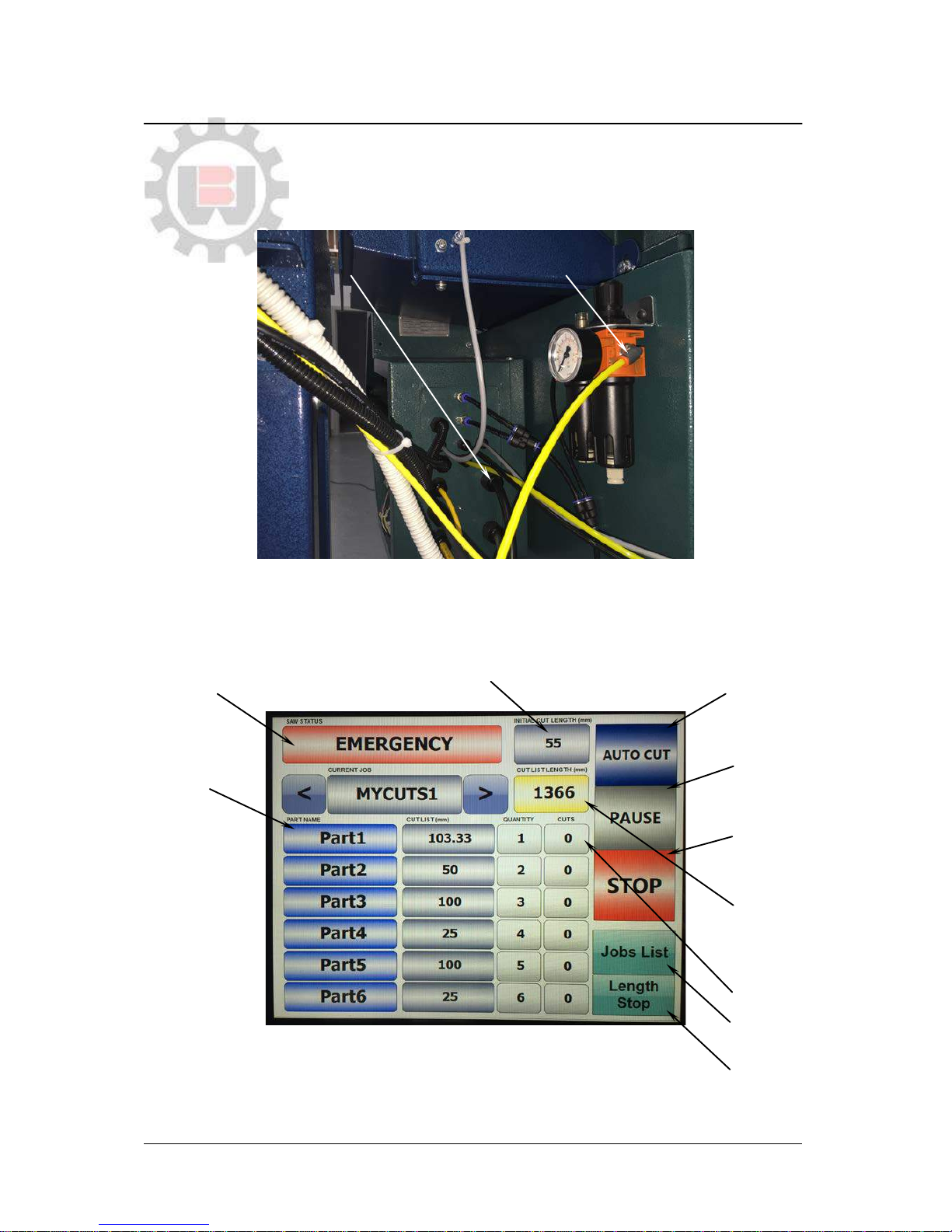

Electrical control box with 10 inch HMI touch screen

Figure 2.1 – FA 3000K Major Components

FA 3000K will arrive at your workshop in three packages:

FA Cold saw unit with electrical box.

Material feeder unit.

Spare table with the control tablet.

Cold saw unit is the heaviest of the components, hence needs to be placed in position first with the rest of the

machine to be built around it. When selecting suitable space keep in mind the space requirements of the feeder

unit which is 3+ m long.

When happy with unit position, unpack the material feeder and proceed first to attach the feeder legs to the main

body (using four M8 bolts), and then to attach the material feeder itself to the cold saw unit (two M10 bolts). Refer

to Section 5 for machine assembly drawings.

Place the electrical box as illustrated in Figure 2.1, leaving the Operator in optimum position, accessible to

controls and the main cutting area, but out of the way of the machine cutting and feeding zone.

When determining location for the machine, ensure that floor is as level as possible and that the requirements

from Section 2 (below) and safety precautions in Section 6 are adequately met. Additionally for best performance

ensure that the feeder working table is leveled, adjusting the two standing feet if necessary.

When sourcing the power supply cable, check that they are within the acceptable standards (Section 6). Install the

power cable as per electrical schematics in Figures 5.5 and 5.6 (Section 5). The installation of the Earthing

system must comply with the IEC Standards Part 195: Earthing and Protection Against Electric Shocks 1998.

Insufficient lighting during the unit operation would constitute a safety hazard according to the ISO 8995 – 2002

‘Lighting of Indoor Workplaces’. For this reason, the user must provide adequate lighting in the working area

(500 LUX), while also preventing dazzling illumination sources.