Temposonics® G-Series

Handheld Programmer

MTS SensorsI 3I

To adjust your programmer settings, perform the following steps:

1. Connect the programmer to the sensor’s 6 wires (using an integral cable or

extension cable). The 4 connections at the bottom of the programmer are for

the 24 Vdc power supply and a multimeter. Switch on the power supply. The

sensor will enter serial programming mode, then the sensor’s LEDs will

display Green Flashing, Red OFF. The LEDs on the handheld programmer

must display Green ON, Red OFF to continue programming successfully.

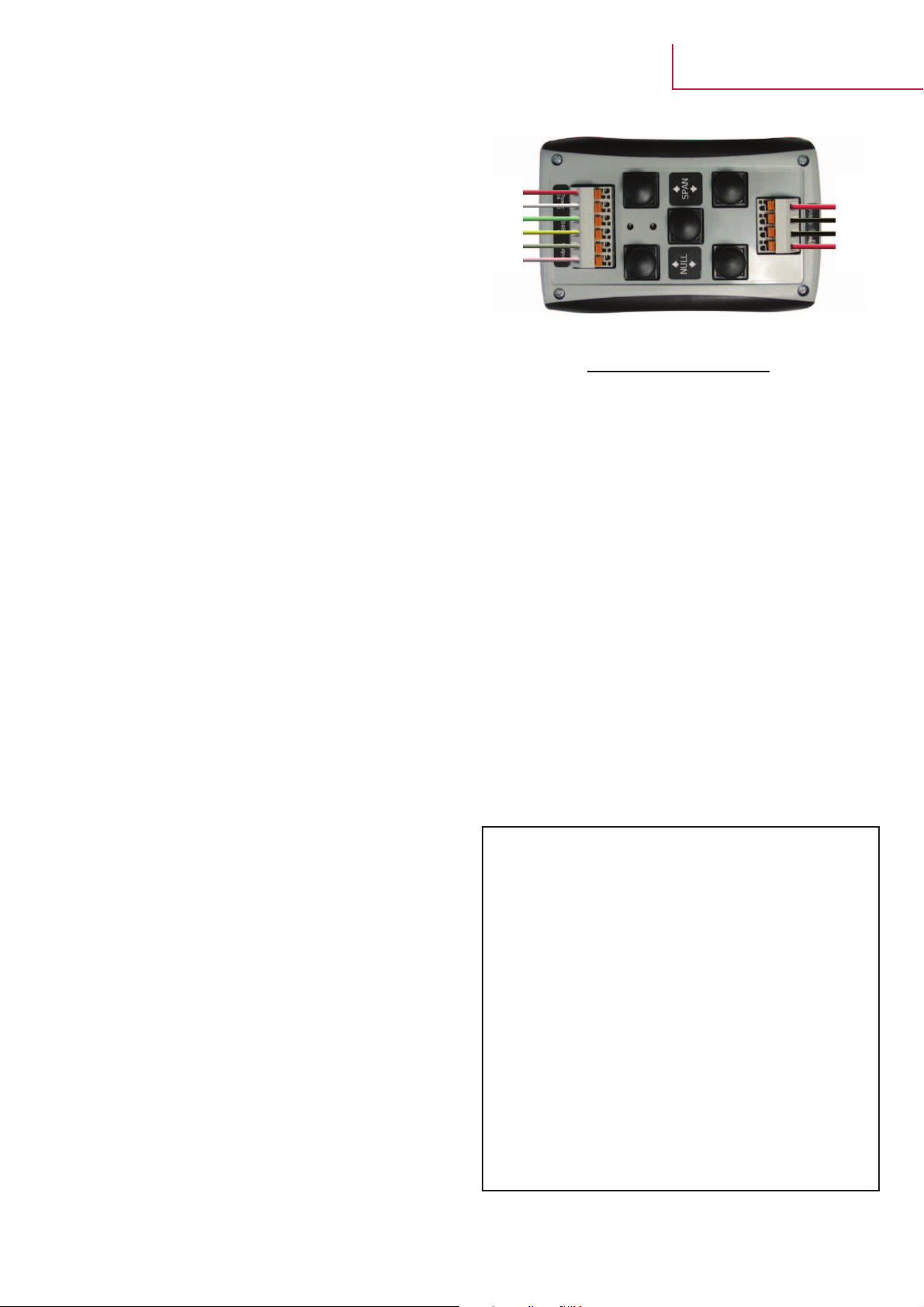

2. Move the position magnet to the appropriate ‘Setpoint 1’ position.

Do not allow the magnet to move until step 4. Use ‘Null’ up or ‘Null’ down

buttons to increase or decrease the output shown on the multimeter, (press

and hold the button for at least a half second).

3. The increments by which the value is adjusted can be changed from coarse

to fine by pressing the programmers’ center button. Coarse mode adjust

yields output changes equivalent to 3 - 5 mm steps. Fine mode adjust yields

output changes equivalent to 0.35 mm steps for ‘Null’ adjustments

and 0.7 mm steps for ‘Span’ adjustments.

4. Move the position magnet to the Setpoint 2 position. Do not allow the

magnet to move until step 5, Use ‘Span’ Up or ‘Span’ Down buttons to

increase or decrease the output shown on the multimeter.

To fine-tune the adjustment, repeat steps 2 and 4. Use the fine mode adjus-

ment feature if necessary. When both ‘Setpoint 1’ and ‘Setpoint 2’ have the

appropriate output values, continue to step 5.

5. After all changes are made, press and hold the programmer’s center button

for 3 seconds. The programmer will confirm that new settings have been

saved by briefly flashing both the Green and Red LEDs. The programmer’s

LEDs will then change to indicate normal sensor functionality (Green ON,

Red OFF).

Notes

- G-Series Analogue sensor outputs are adjustable over the entire active

stroke length. The minimum adjustment increment is 0.35 mm, and the

minimum spacing between Setpoint 1 and Setpoint 2 is 50 mm.

- Changing the output polarity for switching between forward-acting and

reverse-acting outputs should not be attempted with the Handheld

Programmer. Instead, use the G-Series PC Setup Software to program the

sensor for a different output range. Due to the G-Series method of proce-

sing, (unlike the R-Series Analogue sensor), changing the output polarity

by only adjusting the setpoint values will limit the output range or add

unnecessary cycle time.

- If the sensor had been previously re-programmed to significantly reduce

the distance between setpoints, then it may be necessary to make only

small changes when re-programming the sensor again. Since the output

values are limited in range, it may be necessary to increase the stroke

distance by performing multiple programming cycles. To increase the

distance between the setpoints again, use small changes for the new loca-

tions of Setpoint 1 and/or Setpoint 2. Perform the steps 2 through 5 to

save the new settings. Repeat the whole procedure, as needed, to get

additional distance between setpoints.