QUICK START GUIDE EPC9147C Motor Drive Controller Interface Board

EPC – POWER CONVERSION TECHNOLOGY LEADER | EPC-CO.COM | ©2021 | | 7

EXTRA FUNCTION PORT

The EPC9147C is provided with an extra function port (J2) that can be

used to expand functionality to the board. Table 6 provides the pin

allocation map for the expansion port. The usage of the expansion port

depends on ocial ST rmware. In the demo provided by EPC, these

functions are not used.

QUICK START PROCEDURE

Please check EPC’s EPC9147C product page for updates on compatible

eGaN FET/IC inverters with reference settings for specic motors:

https://epc-co.com/epc/Products/DemoBoards/EPC9147c.aspx

The demo program is set to drive a specic motor: Teknic M-3411P-LN-08D.

If a dierent motor needs to be used, please follow these steps:

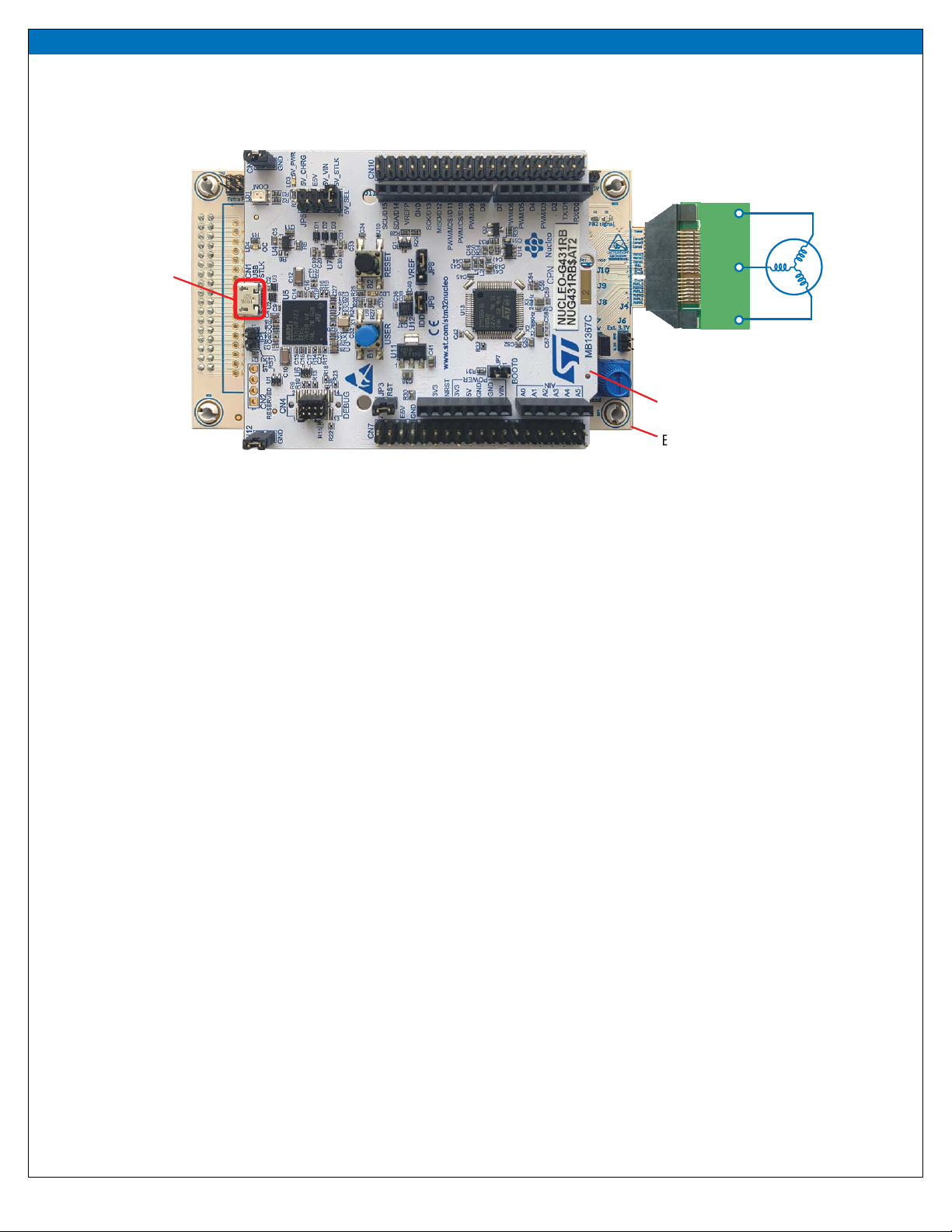

1. Verify that the ST Nucleo G431RB is properly mounted on the EPC9147C

as shown in Figure 2.

2. Verify that on ST Nucleo board, CN11, CN12, JP6, and JP3 jumpers are

mounted. JP8 must be in position 2-3, 5V_SEL must be in 5V_STLK

position, and JP1 and JP7 are not mounted.

3. Connect the motor Teknic M-3411P-LN-08D to the power board. Only

the three phase wires of the motor are needed, because the rmware

is sensor-less.

4. Connect 48 V 3.0 A power supply to the power board connected to the

EPC9147C.

5. Power up the 48 V power supply.

6. Press the black button once.

7. Press the blue button once. Motor start spinning at a xed speed.

8. Press the blue button once again. Motor Stops.

Warning: The human interface controls and knob, as well as the

entire EPC9147C, and the ST Nucleo board are not isolated. The

EPC9147C is referenced to Power Ground and extreme caution must

be observed when operating the board at high voltage.

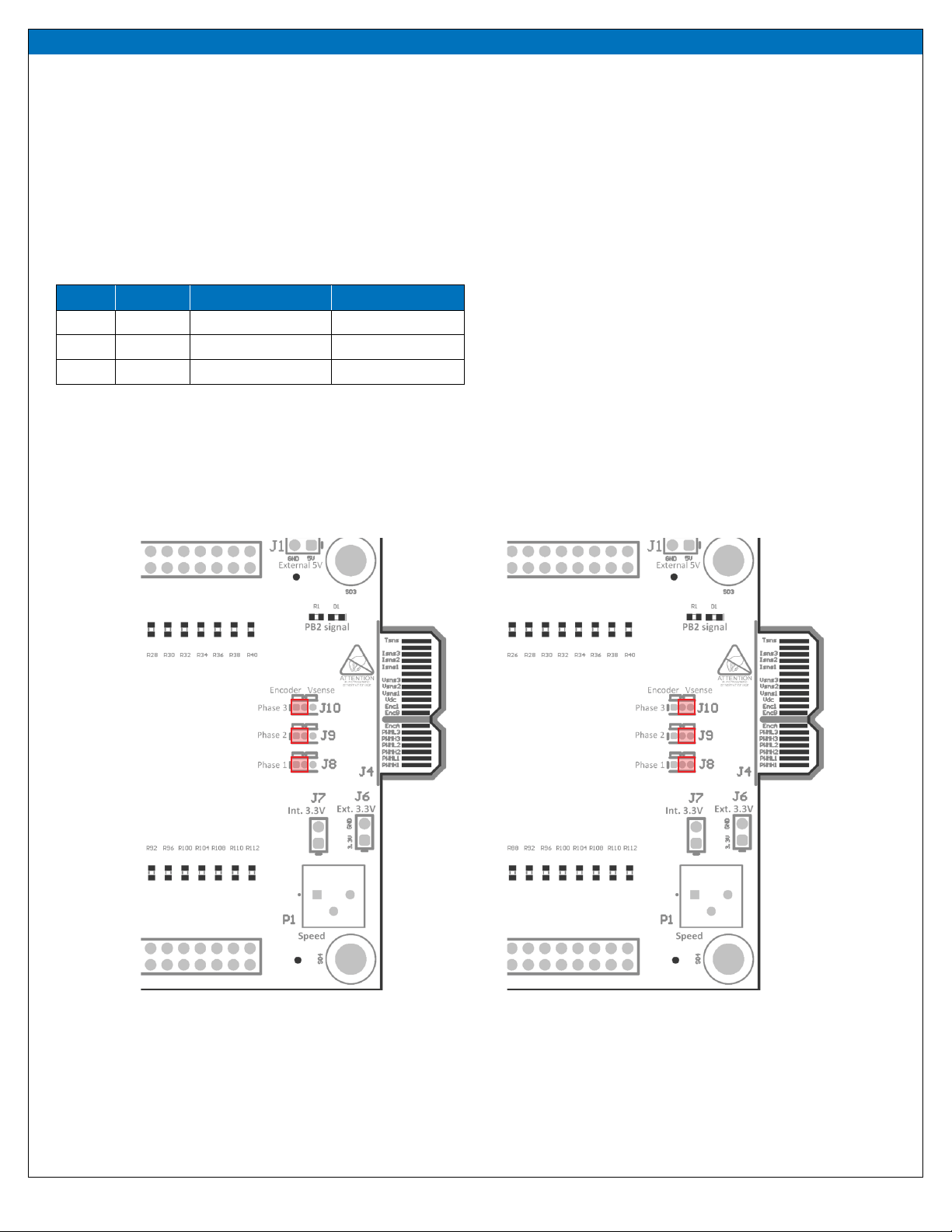

Table 6: Extra Function port (J2) pin allocation map

Pin # Connector

15 V

2 GND

3 PFC shutdown

4 PFC iL

5 ICL shutout

6 PFC PWM

7PFC Vac

8 PFC Synce

MOTOR COMMISSIONING PROCEDURE

To commission a new motor, the user must install the entire development

suite from ST website after registration.

Download and install the following programs:

ST Motor Control Workbench:

https://www.st.com/content/st_com/en/products/embedded-

software/mcu-mpu-embedded-software/stm32-embedded-software/

stm32cube-expansion-packages/x-cube-mcsdk.html

STM32CubeMX

https://www.st.com/en/development-tools/stm32cubemx.html

STM32CubeIDE

https://www.st.com/en/development-tools/stm32cubeide.html

For your reference, the page about the ST Nucleo G431RB is at this link:

https://www.st.com/en/evaluation-tools/nucleo-g431rb.html#tools-

software

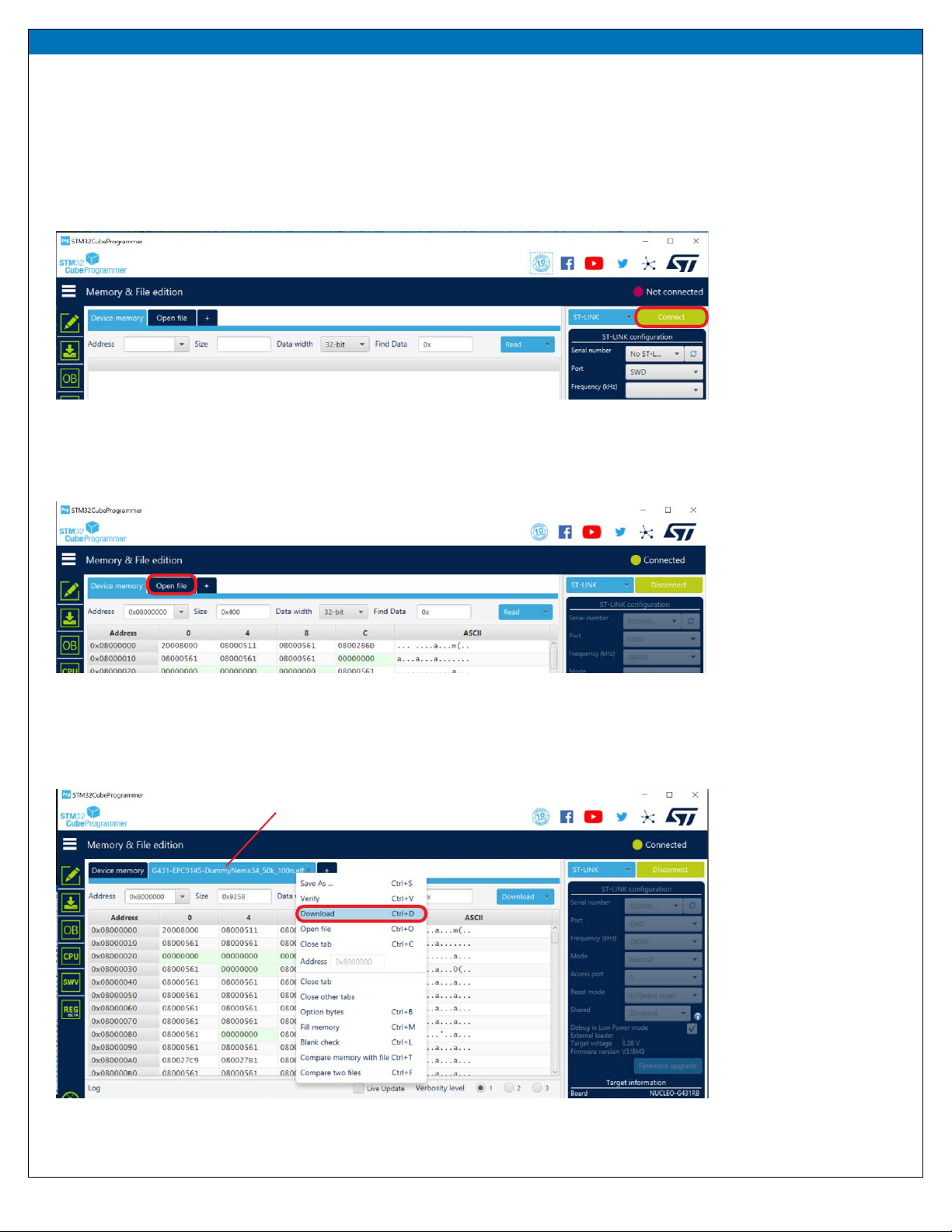

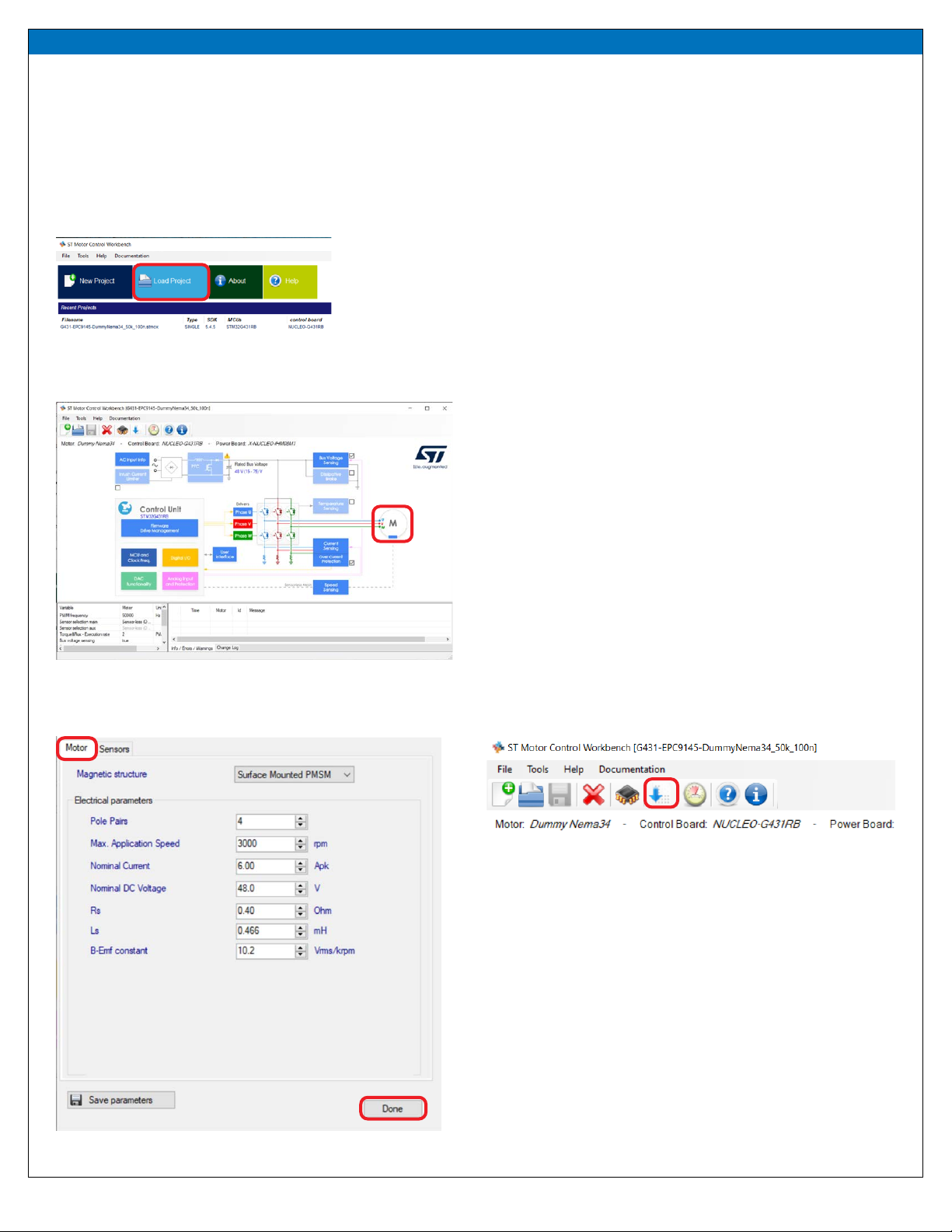

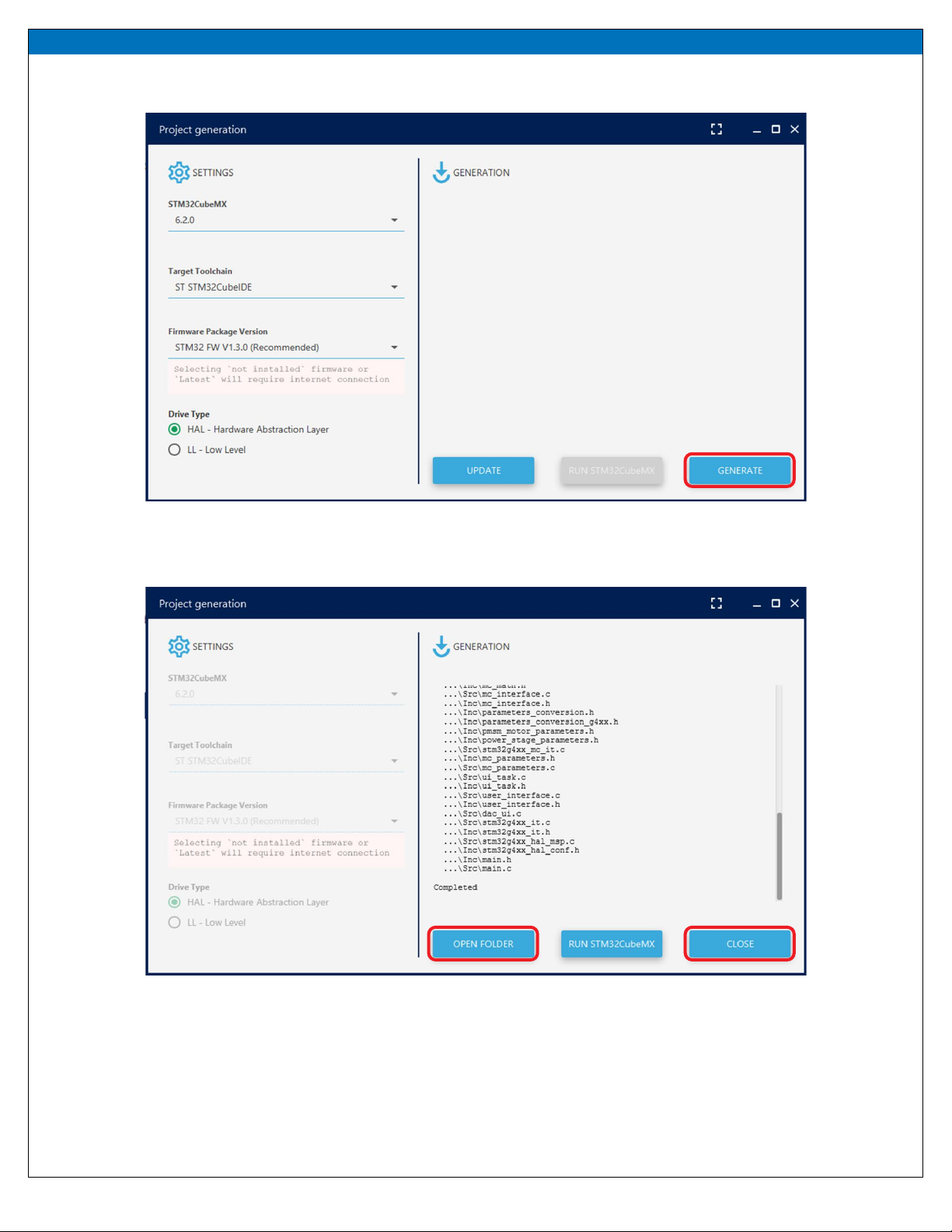

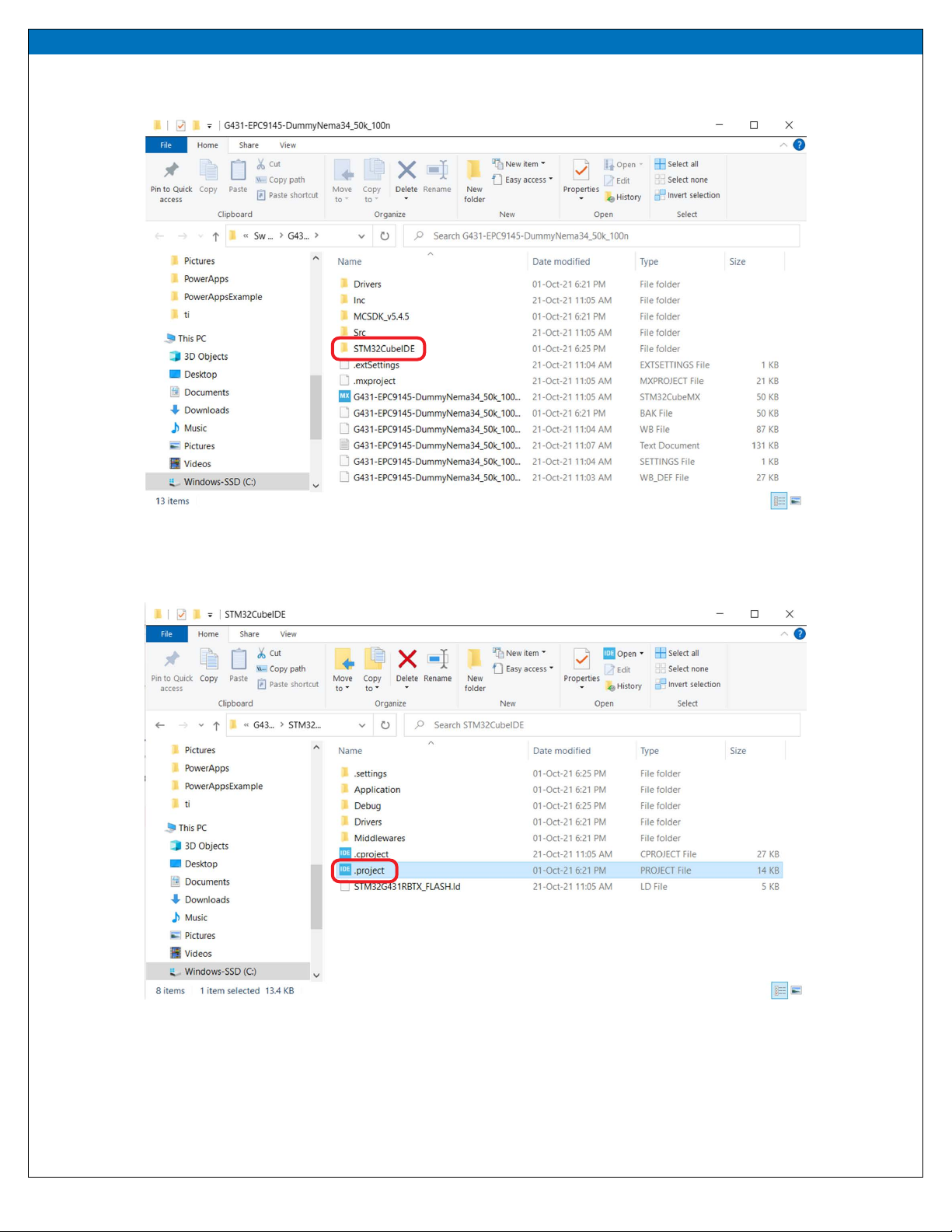

Once the software is properly installed, the user must follow this procedure:

1. Use the Motor Control Workbench with specic EPC project relevant to

the specic EPC power board being used

2. Modify the motor parameters to adapt the system to the desired motor

3. Generate the code

4. Use STM32CubeIDE to compile, link, and ash the generated .elf le to

the ST Nucleo board